This guide explains CNC machining for the energy sector and how buyers choose suppliers, materials, and quality control for reliable parts. If you want a fast engineering review and a clean quote, you can request a quote for energy CNC machining parts .

Energy parts fail expensively. A minor leak, a worn journal, or a misaligned flange can trigger shutdowns, safety reviews, and rushed reorders. Meanwhile, quotes swing because drawings miss CTQs, material specs lack traceability, or inspection plans do not match real duty.

I will show you a fast decision framework, the CTQ rules that control risk, and the QC evidence you should demand. You will also get an RFQ checklist to compare CNC machining, die casting, and forging routes with confidence.

Quick Decision Guide for Energy CNC Machining

If you buy parts for oil & gas, renewables, or power generation, you should pick the process that protects CTQ features and controls risk at the lowest total cost. In practice, energy CNC machining wins when you need tight interfaces, fast iteration, and clean inspection evidence, while die casting or forging plus CNC machining wins when you need near-net shape economics at stable volume.

-

Choose CNC machining when the part’s function depends on precision bores, sealing faces, alignment datums, or high-mix demand.

-

Choose die casting or forging plus CNC machining when you want near-net shape, then machine only the CTQs.

-

Lock CTQs first, then let everything else stay as tolerant as function allows.

Process choice matrix for energy parts

| Decision factor | CNC machining | Die casting + CNC machining | Forging + CNC machining |

|---|---|---|---|

| Best fit volume | Prototype to medium volume | Medium to high volume | Medium volume to high reliability |

| Geometry | Prismatic and rotational, easy access | Complex ribs, thin walls, near-net housings | Strong load paths, critical mechanical parts |

| Change frequency | High, frequent ECOs | Low, stable design | Medium, stable interfaces |

| CTQ control | Excellent on machined datums | Machine CTQs after casting | Machine CTQs after forging |

| Typical energy use | Manifolds, shafts, brackets, housings | Housings, covers, brackets, enclosures | Shafts, hubs, couplings, structural interfaces |

When CNC machining is the best choice for energy parts?

CNC machining is the best choice when precision drives function and you cannot hide variation. You should start with CNC machining if you expect design changes, if you need fast first articles, or if your energy component includes sealing, rotating, or alignment interfaces.

You typically win with CNC machining when you need:

-

Tight tolerance energy parts such as bores, journals, and matched datums

-

Low to medium volume, mixed SKUs, or uncertain demand

-

Fast prototyping and quick engineering changes without tooling rework

-

Hard-to-source materials or performance alloys that need controlled machining

-

A clear inspection package, including FAI and CMM evidence, for buyer approval

You can also use CNC machining as a risk reducer in early programs. You can validate fit, sealing, and assembly stack-up before you invest in casting or forging tooling.

Buyer checkpoint: If a supplier cannot explain how they will hold your datums in one setup and how they will measure them, you should treat that quote as high risk.

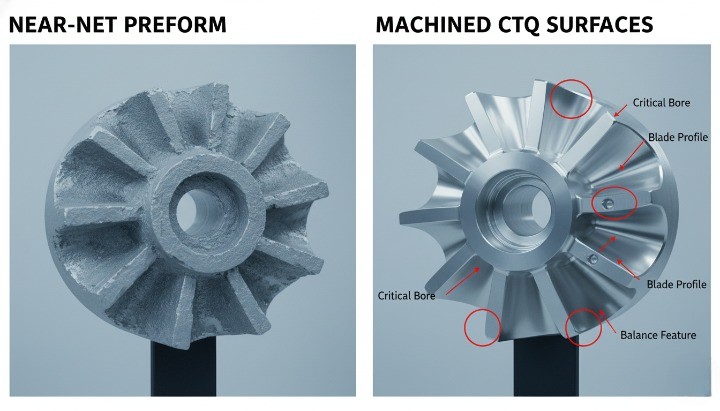

When die casting or forging plus CNC machining lowers total cost?

Die casting or forging plus CNC machining lowers total cost when you can form the shape cheaply, then machine only the CTQs. This route often beats full CNC machining when your volume is stable and your geometry drives heavy material removal from billet. If you plan to use a near-net preform, you can start from custom die casting parts and then CNC machine sealing faces, datums, and bores to lock CTQ performance.

You should consider die casting + CNC machining when:

-

The part has complex external geometry, ribs, bosses, and weight targets

-

You want near-net housings, covers, brackets, and enclosures

-

You can accept as-cast surfaces on non-critical areas

-

You plan to machine sealing faces, bearing seats, and datum pads afterward

You should consider forging + CNC machining when:

-

The part carries high mechanical load, fatigue risk, or shock loading

-

You want a strong preform, then machine precision interfaces

-

You buy shafts, hubs, couplings, and structural connectors that need high reliability

A simple cost-control workflow works well in energy sourcing:

-

Form near-net shape with die casting or forging

-

Machine only the CTQs that drive sealing, rotation, and alignment

-

Define inspection evidence that matches CTQ risk

-

Stabilize the route before you scale volume

This strategy also helps you control inspection cost. You avoid measuring everything to tight limits, and you focus metrology on what truly drives uptime.

The CTQ rule for energy components: seal, rotate, align, resist corrosion

CTQ means “critical to quality,” and it describes the few characteristics that directly control real-world performance. If you do CTQ work well, you reduce downtime risk and supplier disputes.

For energy components, CTQs usually fall into four buckets:

-

Seal: gasket faces, O-ring grooves, valve seats, leak paths

-

Rotate: journals, bearing fits, concentricity, runout, balance features

-

Align: datum faces, hole true position, flatness, perpendicularity

-

Resist corrosion: correct alloy, correct material condition, traceability, and surface protection

Corrosion control deserves special attention in energy projects. The global cost of corrosion is widely cited at about US$2.5 trillion, roughly 3.4% of global GDP (2013), which shows why buyers treat corrosion-related CTQs as commercial risk, not cosmetic preference.

If you source oil & gas pressure-control components, you will also see industry standards referenced in RFQs and contracts. For example, API Specification 6A covers wellhead and tree equipment and provides consistent industry practices for that equipment class.

CTQ-to-process and CTQ-to-inspection map

| CTQ focus | Common feature on energy parts | CNC machining approach | Inspection evidence buyers trust | Risk if missed |

|---|---|---|---|---|

| Seal | Gasket face, O-ring groove, valve seat | Face milling/turning, controlled finish | Surface finish check + CMM for form/position | Leaks, rework, shutdown |

| Rotate | Journal, bearing bore, shaft shoulder | Turning + finish pass, possible grind | Runout/roundness checks + CMM report | Vibration, wear, seizure |

| Align | Hole pattern, datum pads, mating faces | Single-setup machining, datum control | CMM true position/profile report | Assembly issues, misalignment |

| Resist corrosion | Material spec, heat/lot traceability | Correct material control + handling | Material certs, heat numbers, traceability | Premature corrosion, claims |

Why CNC Machining Matters in the Energy Industry?

CNC machining matters in the energy industry because it delivers controllable tolerances, repeatable datums, and inspection evidence on parts that operate under pressure, heat, corrosion, and vibration. When you source energy components, you do not just buy geometry. You buy uptime, safety margin, and traceability.

Energy projects also carry large corrosion exposure. Industry research estimates the global cost of corrosion at about US$2.5 trillion, around 3.4% of global GDP (2013). That is why buyers treat corrosion-related requirements as commercial risk, not a “nice to have.”

Energy industry requirements for CNC machined parts

Energy parts face duty cycles that punish variation. You should expect requirements that combine mechanical performance with documentation and repeatability. You also need a process that holds CTQ features without inflating every dimension.

Most energy RFQs repeatedly emphasize five requirement buckets:

-

Pressure and leak integrity on sealing faces, grooves, and threads

-

Dimensional stability on bores, journals, and datum interfaces

-

Corrosion resistance through correct alloy, condition, and surface protection

-

Traceability from material heat number to finished lot

-

Inspection evidence that matches the CTQ risk

Use this checklist to translate energy requirements into CNC machining deliverables.

| Energy requirement | What you should specify on the drawing/RFQ | What CNC machining must control | What you should ask to see |

|---|---|---|---|

| Leak integrity | Seal land finish, groove geometry, mating face flatness | Setup strategy for datums, finish process | Surface finish results, CTQ measurements |

| Rotation reliability | Fits, runout, concentricity targets | Turning strategy, stable datums | Runout data, bore/journal measurements |

| Corrosion resistance | Alloy, condition, coating, handling notes | Material ID, contamination control | Material certs + lot traceability |

| Repeatability | CTQ list, sampling plan, acceptance rules | In-process control points | FAI and consistent report format |

| Fast quoting | Clear CAD + 2D + CTQ callouts | DFM feedback and route plan | A quote that states assumptions |

If you want a practical tolerance baseline before you tighten anything, you can align your team using your tolerance reference page and keep CTQs focused.

Energy component failure modes and how CNC machining prevents them

Energy failures usually start small. A slight mismatch on a datum face becomes a leak path. A rough journal accelerates wear. A thread form issue loosens under vibration. You can prevent most of these failures when you design and machine around CTQs.

These are common failure modes and the CNC machining controls that reduce risk:

-

Leaks at seals You prevent leaks when you control flatness, surface finish, and groove geometry on sealing features. You also protect sealing faces during handling and packing.

-

Vibration and premature wear You reduce vibration when you control concentricity and runout on rotating interfaces. You also stabilize the route so the same datum strategy repeats across batches.

-

Assembly misalignment You avoid misalignment when you machine critical faces in fewer setups and verify true position on hole patterns with datum-based inspection.

-

Corrosion-driven field claims You reduce corrosion risk when you enforce correct material traceability and specify the surface treatment that matches service conditions. The economic impact of corrosion is large enough that many organizations treat corrosion control as a measurable cost lever.

If you want a simple sourcing rule, use this: match inspection to failure mode. A leak risk needs seal-face verification. A vibration risk needs runout evidence. A corrosion risk needs traceability and surface protection records.

For buyers who want a structured QC path, your quality-control workflow page can help set expectations early and reduce supplier interpretation.

What procurement teams evaluate in energy CNC machining suppliers?

Procurement teams evaluate more than price. They evaluate the supplier’s ability to repeat a stable process and defend CTQ compliance with evidence. A practical way to verify this is to review the supplier’s CNC machining quality control workflow, including how they plan inspections, manage nonconforming parts, and document results.

In oil and gas supply chains, you will often see API standards referenced. API Specification Q1 defines quality management system requirements for organizations providing products for the petroleum and natural gas industry. For wellhead and tree equipment, API Specification 6A provides consistent practices for that equipment class. In nuclear supply chains, many buyers reference ISO 19443 as a nuclear-specific quality management system standard for organizations supplying products and services important to nuclear safety.

Here is a practical supplier scorecard procurement teams can use in energy CNC machining.

| What buyers check | What “good” looks like | Proof you can request |

|---|---|---|

| CTQ understanding | Supplier repeats your CTQ list back accurately | CTQ plan, setup plan, measurement method |

| Metrology capability | CMM use with datum strategy, calibrated gauges | Sample CMM report, calibration records |

| Traceability | Heat numbers link to lots and inspection packs | Material certs, lot traveler, labeling photos |

| Process stability | Controls tool wear and key operations | In-process checks, control plan summary |

| Documentation | Clear FAI format and revision control | FAI sample pack, revision log |

| Export readiness | Parts arrive protected and labeled | Packaging spec, corrosion prevention plan |

If you want faster, cleaner quotes, you can standardize your RFQ package and reduce back-and-forth. Your RFQ preparation guide is a strong internal reference for that workflow.

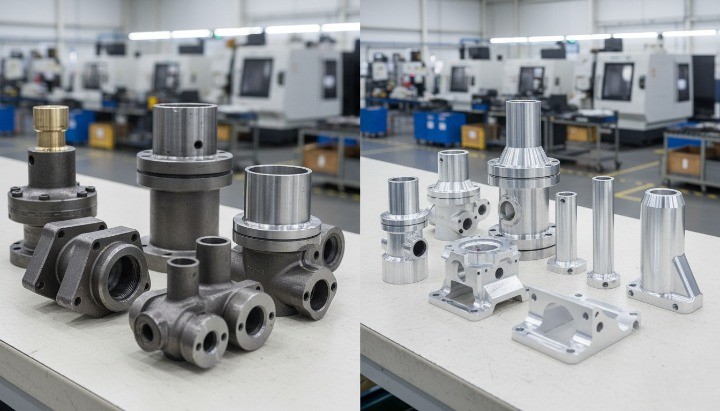

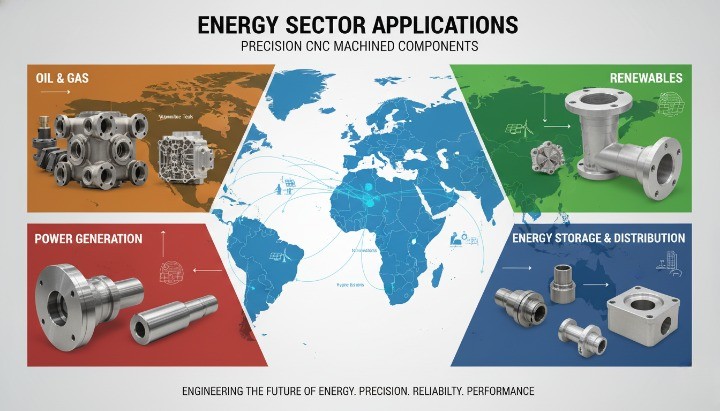

Energy CNC Machining by Sector and Application

Energy CNC machining supports oil and gas, power generation, renewables, hydrogen systems, and grid storage. The best suppliers map each application to CTQ features, then match the machining route and inspection plan to that risk. That approach protects uptime and reduces disputes during incoming inspection.

Energy sector application snapshot

| Energy sector | Common CNC machined parts | CTQ features buyers should call out | Standards buyers often reference |

|---|---|---|---|

| Oil and gas | Valve bodies, manifolds, connectors, pressure control parts | Sealing faces, bores, threads, true position, erosion zones | API 6A, API Spec Q1 |

| Power generation | Shafts, couplings, rotating interfaces, mounts, housings | Runout, concentricity, fits, flatness, balance features | ISO 19443 for nuclear supply chains |

| Renewables | Wind drivetrain interfaces, solar mounts, hydro flow parts | Alignment datums, corrosion control, sealing interfaces | Project and customer specs |

| Hydrogen and fuel cells | Plates, manifolds, fittings, sealing interfaces | Flatness, surface finish, leak paths, cleanliness | Project and customer specs |

| Energy storage and grid | Cooling plates, enclosures, brackets, inverter hardware | Thermal contact, sealing, electrical isolation zones | UL 9540 for ESS safety |

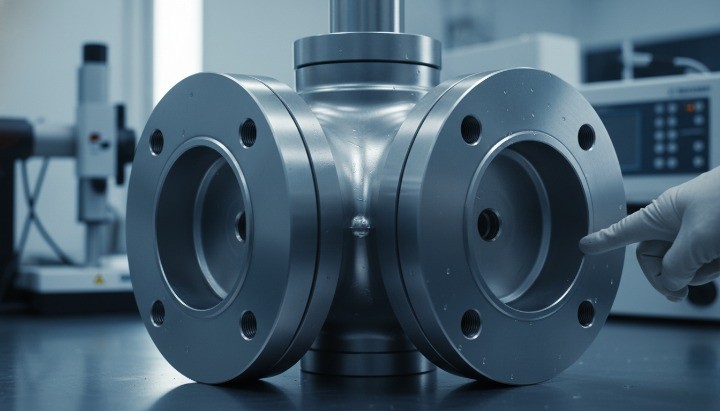

CNC machining for oil and gas parts and pressure control components

Oil and gas equipment puts heavy stress on sealing, threads, and pressure-containing geometry. You should prioritize machining routes that protect sealing faces and control bore geometry in stable setups. Buyers often source CNC machined aluminum manifolds for fluid routing and pressure control, so you should treat manifold CTQs—sealing faces, port true position, bores, and threads—as first-priority features.

Common oil and gas CNC machined parts include:

-

Valve bodies and valve trim interfaces

-

Manifolds and flow blocks

-

Connectors, adapters, and flanged interfaces

-

Pump components and wear parts for abrasive duty

CTQ features that drive field performance:

-

Sealing faces and gasket lands

-

Bore size, roundness, and concentricity

-

Thread form and thread engagement strength

-

Hole true position for bolted patterns

-

Local erosion zones that need controlled finish

Many RFQs reference API Specification 6A for wellhead and tree equipment practices. Many buyers also reference API Specification Q1 for quality management system expectations in petroleum and natural gas supply chains. (source:api.org)

CNC machining for power generation parts and rotating equipment

Power generation components punish imbalance and misalignment. You should focus on runout control, concentricity, and a stable datum strategy for rotating interfaces. Buyers often source precision machined steel shafts for these assemblies, so you should define journal fits, sealing lands, and runout CTQs clearly and require inspection proof that ties results to functional datums.

Common power generation CNC machined parts include:

Common power generation CNC machined parts include:

-

Shafts, couplings, and sleeves

-

Bearing seats and housings

-

Mounts, brackets, and instrumentation housings

-

Precision interfaces for rotating equipment assemblies

CTQ features that prevent vibration and wear:

-

Runout and concentricity on journals and bores

-

Fits that control bearing preload and alignment

-

Flatness on mounting faces

-

Surface finish on wear and seal interfaces

If you source into nuclear supply chains, buyers may reference ISO 19443 for quality management system requirements in organizations that supply products and services important to nuclear safety.

Renewable energy CNC machining for wind, solar, hydro, and geothermal

Renewable energy programs often scale fast, and they operate outdoors. You should plan for corrosion control, stable alignment, and repeatable hole patterns across production lots. You also need a packaging plan that protects machined datums in global shipping.

Common renewable energy CNC machined parts include:

Common renewable energy CNC machined parts include:

-

Wind drivetrain interfaces, sensor mounts, structural connectors

-

Solar mounting hardware, inverter-related housings, thermal parts

-

Hydro and geothermal flow hardware with sealing interfaces

CTQ features that drive reliability:

-

Hole position and flatness on structural interfaces

-

Sealing surfaces on flow components

-

Surface protection compatibility with service environment

-

Thread integrity for vibration and field assembly

You can reduce supplier variation when you define two things early. You should define cosmetic zones and contact surfaces. You should also state the service environment such as offshore salt exposure or wet duty.

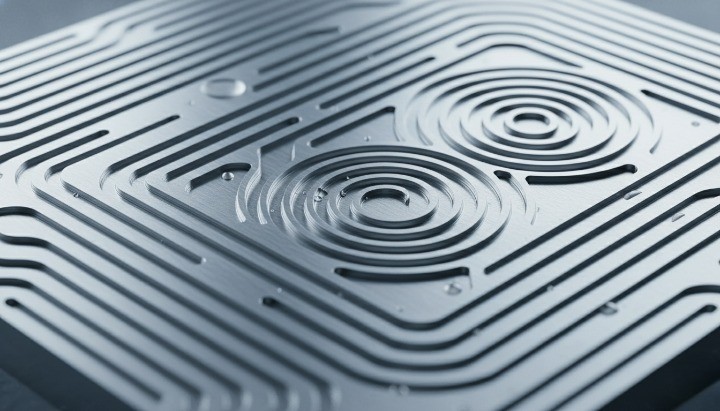

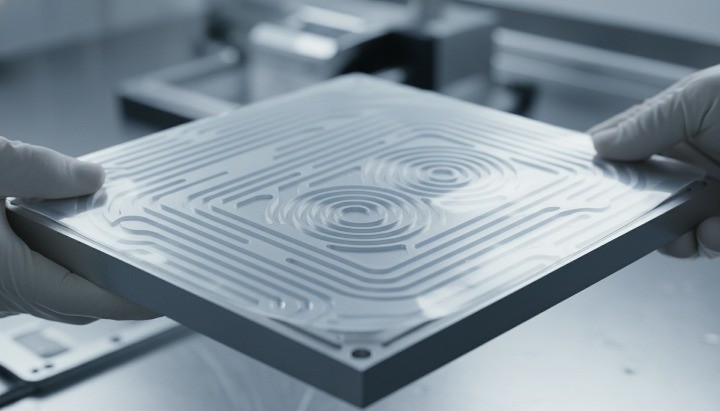

CNC machining for hydrogen and fuel cell components

Hydrogen and fuel cell systems amplify small leaks and flatness errors. You should focus on flatness, surface finish, and controlled leak paths. You also need cleanliness discipline because contamination can damage sealing and flow performance.

Common hydrogen and fuel cell CNC machined parts include:

-

Plates and manifolds

-

Precision fittings and connectors

-

Sealing interfaces and flow channels

-

Lightweight housings for subsystems

CTQ features that buyers should call out:

-

Flatness on mating surfaces

-

Surface finish on sealing lands and grooves

-

True position on port features and patterns

-

Cleanliness requirements for assembly

You can make RFQs easier when you state what “leak tight” means in your acceptance plan. You can specify the test method, test pressure, and acceptable leakage criteria if your program requires it.

CNC machining for energy storage and grid infrastructure parts

Energy storage and grid equipment mixes mechanical, electrical, and thermal requirements. You should prioritize thermal contact, electrical isolation zones, and enclosure integrity. Your machining plan should also support safe assembly and field servicing.

Common energy storage and grid CNC machined parts include:

Common energy storage and grid CNC machined parts include:

-

Cooling plates and thermal spreaders

-

Enclosures, brackets, and structural frames

-

Power electronics housings and mounting hardware

-

Busbar-related fixtures and mechanical supports

CTQ features that drive safety and performance:

-

Flatness for thermal contact surfaces

-

Sealing for enclosures and cooling circuits

-

Isolation zones that must stay free of burrs and damage

-

Hole position for repeatable assembly and wiring routing

Many storage projects reference UL 9540 at the system safety level for energy storage systems and equipment. Buyers often align their documentation and compliance pathway around that standard and related component standards.

Common Energy CNC Machined Parts and CTQ Features

Energy CNC machined parts fail at interfaces, not in CAD. You should treat sealing faces, rotating fits, and datum alignment as your CTQ core. Then you should machine and inspect those features with a clear plan.

Most buyer disputes come from unclear CTQs. You can prevent that risk when you attach a CTQ list to your RFQ and match each CTQ to a measurement method.

CTQ checklist by part family

| Part family | Where failure starts | CTQ features to call out | Inspection evidence to request |

|---|---|---|---|

| Valve bodies and manifolds | Leak paths and misaligned ports | Sealing faces, bores, threads, true position | CMM report, surface finish results, thread gauge record |

| Pump housings and impellers | Vibration, wear, efficiency loss | Runout, balance features, wear surfaces | Runout data, balance record, critical diameters report |

| Shafts and couplings | Bearing wear and vibration | Concentricity, journals, fits, surface finish | Runout and concentricity data, diameter chart, finish check |

| Brackets and connectors | Assembly stress and fatigue | Flatness, hole position, edge condition | CMM true position, flatness report, deburr verification |

| Enclosures and thermal parts | Leaks and thermal gaps | Flatness, thermal contact, leak paths | Flatness map, leak test plan, cosmetic protection plan |

Valve bodies and manifolds: sealing faces, bores, threads, true position

Valve bodies and manifolds rely on sealing faces, bore geometry, and port alignment. If you hold those CTQs, you prevent most leaks and assembly conflicts.

Oil and gas buyers often reference API standards for wellhead and tree equipment. API Specification 6A provides consistent industry practices for wellhead and tree equipment.

Oil and gas buyers often reference API standards for wellhead and tree equipment. API Specification 6A provides consistent industry practices for wellhead and tree equipment.

Use this CTQ set for energy valve bodies and manifolds:

-

Sealing faces: flatness, finish, damage control in handling

-

Bores: size, roundness, concentricity to datum

-

Threads: correct form and gauging plan

-

True position: port patterns and bolt circles to datums

You should also align gasket contact finish with the gasket type your system uses. ASME PCC-1 includes guidance on gasket contact surface finish by gasket category.

Pump housings and impellers: runout, balance features, wear surfaces

Pump housings and impellers fail when runout, balance, and wear surfaces drift. Those issues show up as vibration, seal wear, noise, and efficiency loss. For rotating equipment support, buyers often source aluminum bearing housings and similar interfaces, so you should treat housing datums and bore geometry as CTQs from day one.

You should control these CTQs early:

You should control these CTQs early:

-

Runout at critical diameters and mounting interfaces

-

Balance features that let you correct unbalance

-

Wear surfaces and clearances that govern performance

-

Smooth transitions that reduce erosion and cavitation damage

Balance is not guesswork. ISO 1940-1 specifies balance tolerances and verification methods for rigid rotors.

Procurement tip for pump parts:

-

Ask the supplier to state where they will measure runout

-

Ask how they will mark datums for repeatable inspection

-

Ask whether they can support balancing verification when required

Shafts and couplings: concentricity, journals, fits, surface finish

Shafts and couplings live or die on concentricity, fit, and surface finish. If the supplier loses datum control, you get vibration, heat, and premature bearing failure.

You should call out these CTQs on rotating parts:

-

Concentricity between journals, shoulders, and bores

-

Journal size and fit class for bearings and seals

-

Surface finish on journals and seal lands

-

Runout at assembly references and functional diameters

A practical sourcing rule helps here. You should keep all rotating CTQs in one setup when possible. That approach reduces stack-up error and improves repeatability.

Structural brackets and connectors: flatness, hole position, fatigue risk

Brackets and connectors look simple, but hole position and flatness control real assembly stress. A small shift can create forced alignment during installation, then fatigue cracks over time.

You should focus on:

-

Flatness on mating faces that clamp or locate assemblies

-

Hole true position to primary datums

-

Edge condition in contact and harness routing zones

-

Consistent deburring where cracks initiate

Many flange systems reference ASME B16.5 for flanges and flanged fittings scope and requirements. You should confirm the flange standard your customer uses before you lock the drawing notes.

Use a simple fatigue risk filter for brackets:

-

You should treat sharp internal corners as high risk

-

You should specify radius or chamfer intent where loads reverse

-

You should avoid forcing misalignment during assembly

Enclosures and thermal parts: flatness, thermal contact, leak paths

Enclosures and thermal parts fail when flatness drifts or leak paths open. In energy storage and power electronics, thermal contact also drives performance and service life.

You should treat these as core CTQs:

-

Flatness on thermal contact faces

-

Surface condition that supports consistent thermal interface materials

-

Seal land geometry for ingress protection or coolant sealing

-

Burr control near isolation zones and harness interfaces

If your enclosure uses bolted flanges, you should align tightening and surface preparation practices with recognized flange assembly guidance. ASME PCC-1 focuses on bolted flange joint assembly practices.

Procurement tip for thermal parts:

-

Ask for a flatness map on the thermal contact face

-

Ask how the supplier protects the face in shipping

-

Ask whether they can run a leak test when the design needs it

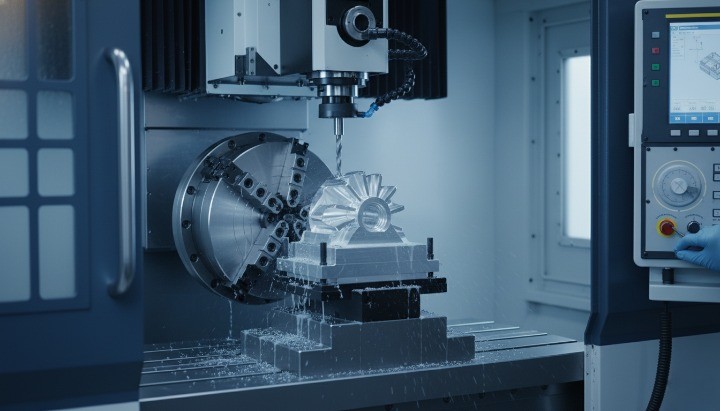

CNC Machining Processes Used in the Energy Industry

Energy CNC machining uses turning, milling, multi-axis machining, grinding or honing, EDM, and Swiss machining to control CTQ features like sealing, rotation, alignment, and corrosion-critical interfaces. You should choose the process based on which CTQ you must protect, not based on what sounds advanced.

Process selection cheat sheet for energy parts

| CTQ you need to control | Best-fit process | Why it works in energy CNC machining | What you should verify |

|---|---|---|---|

| Concentric journals and bores | CNC turning | Holds rotation features to one axis and one datum | Runout and diameter chart |

| Port patterns and datum faces | CNC milling | Controls prismatic datums and hole true position | CMM position report |

| Multi-face datum consistency | 4-axis or 5-axis CNC machining | Reduces setups and re-clamping variation | Setup plan and datum strategy |

| Tight form and high finish on bores | Grinding or honing | Improves geometry and surface finish on critical fits | Roundness and surface finish |

| Hard materials and sharp internal forms | EDM machining | Uses electrical discharges to shape conductive materials | Feature accuracy and recast control |

| Small precision fittings | Swiss machining | Guide bushing support improves stability on small parts | Size capability and in-process gauging |

CNC turning for shafts, bores, journals, and sealing lands

CNC turning is the fastest way to control rotational CTQs in energy components. You should use turning when the function depends on coaxial features, stable fits, and repeatable diameters.

Turning works well for:

-

Shafts, sleeves, and couplings

-

Bearing journals and seal lands

-

Precision bores and shoulders that reference one axis

You should ask the supplier how they will hold the main datums in one setup. You should also ask where they will measure runout. That one answer often predicts field vibration risk.

CNC milling for housings, pockets, patterns, and manifolds

CNC milling controls prismatic CTQs that drive sealing and assembly alignment. You should use milling for housings, flow blocks, patterns, and bolt interfaces that depend on flatness and true position.

Milling fits energy parts such as:

-

Valve bodies and manifolds

-

Pump housings and equipment mounts

-

Hole patterns for flanges and structural interfaces

You should make datums explicit on the drawing. Then you should require a datum-based measurement approach. That step keeps CMM results aligned with functional intent.

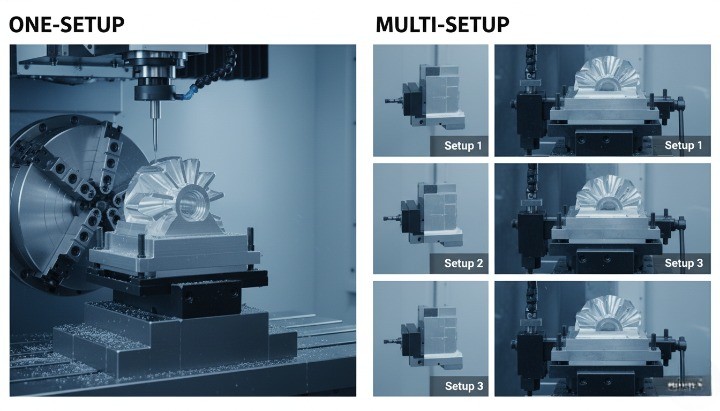

4-axis and 5-axis CNC machining to reduce setups and improve datums

4-axis and 5-axis CNC machining reduce setups, improve datum consistency, and help you machine multiple faces in one clamping. This matters in energy parts because every re-clamp can shift alignment and create inspection disputes.

Machine builders and CAD/CAM vendors commonly highlight the same advantage. Fewer setups reduce repositioning error and help maintain accuracy across multiple faces.

Machine builders and CAD/CAM vendors commonly highlight the same advantage. Fewer setups reduce repositioning error and help maintain accuracy across multiple faces.

You should consider multi-axis machining when:

-

Your part has multiple critical faces with shared datums

-

Your part needs angled ports, intersecting holes, or compound features

-

Your quote shows high setup cost or high fixture complexity

Procurement tip: ask for a setup count in the quote. If you see many setups, you should expect higher variation and higher lead time risk.

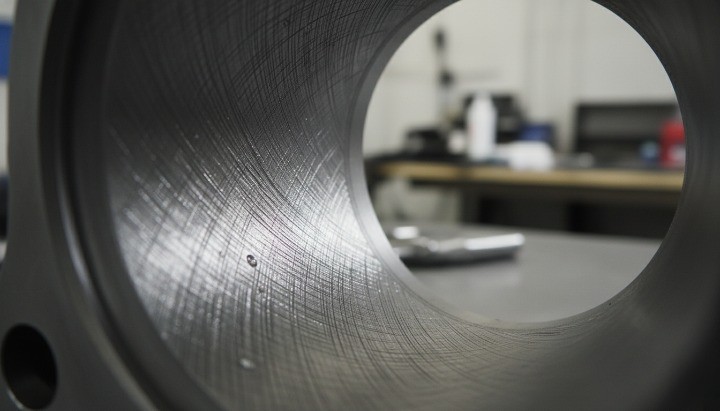

Precision grinding and honing for tight tolerance energy parts

Grinding and honing help when you must hit tight form and functional surface finish on critical fits. You should use these finishing processes when turning or milling cannot reliably deliver the required geometry or texture.

Honing is an abrasive process that improves geometric form and can improve surface finish, especially inside bores. (source:wikipedia.org)

Honing is an abrasive process that improves geometric form and can improve surface finish, especially inside bores. (source:wikipedia.org)

You should consider grinding or honing for:

-

Bearing bores that require stable size and form

-

Seal interfaces where surface finish controls leakage

-

Wear surfaces that need consistent texture and low friction

You should ask the supplier to state the target surface finish method. You should also confirm how they will measure form, not only size.

EDM machining for hard materials and complex internal features

EDM machining removes material using electrical discharges, not cutting force, so it can shape hard conductive materials and intricate features. EDM fits energy applications when you need sharp internal corners, deep narrow features, or hardened alloys that challenge conventional tools.

You should use EDM when you face:

-

Hardened steels and difficult-to-cut conductive alloys

-

Fine slots, small radii, and complex cavities

-

Wire EDM profiles that need clean edge definition

EDM still needs process discipline. You should ask about surface integrity and any post-process steps if your part has fatigue-sensitive surfaces.

Swiss machining for small precision fittings and connectors

Swiss machining uses a guide bushing and sliding headstock to support small diameter work close to the cutting zone. That support improves stability and helps hold tight tolerances on small, high-volume precision parts.

You should consider Swiss machining for:

-

Small fittings, connectors, and precision pins

-

Slender parts that deflect on conventional lathes

-

Complex turned parts that need short cycle times at volume

Procurement tip: ask for the supplier’s bar size range and typical tolerances for Swiss machining. Then ask how they control burrs on small ports and cross-holes.

Materials for CNC Machining in the Energy Industry

Material choice drives corrosion risk, temperature margin, and machining cost in energy CNC machining. You should pick materials that match the service environment first, then optimize the machining route and inspection plan around CTQ features.

Corrosion also has real economic impact. A widely cited industry study estimates the global cost of corrosion at about US$2.5 trillion, roughly 3.4% of global GDP (2013).

Material selection snapshot for energy CNC machined parts

| Service condition | Common material family | Why buyers choose it | RFQ notes you should add |

|---|---|---|---|

| General corrosion resistance | Stainless steel | Passive film protection and broad availability | Grade, heat treatment condition, surface finish on CTQs |

| Offshore and chloride exposure | Duplex and super duplex | Stronger and more resistant to chloride SCC than many austenitic grades | Grade, corrosion duty, welding needs, PMI expectations |

| High temperature and aggressive media | Inconel and nickel alloys | Oxidation and corrosion resistance at elevated temperature | Alloy grade, condition, heat lot traceability, machining plan |

| High strength and cost control | Carbon and alloy steels | Strong and economical for many structural duties | Heat treat spec, hardness range, coating or plating plan |

| Lightweight structures and housings | Aluminum alloys | Low density and protective oxide layer | Grade, anodize or coating, galvanic corrosion controls |

| Electrical and thermal performance | Copper and brass | High conductivity for electrical and heat transfer | Alloy, cleanliness, burr control, surface protection |

Stainless steel CNC machining for corrosion resistance

Stainless steel CNC machining fits energy parts when you need reliable corrosion resistance with stable sourcing. Stainless steel resists corrosion because chromium forms a passive surface film. Many references cite about 10.5% chromium as the threshold for that protective behavior.

You should use stainless steel CNC machining for:

-

Valve bodies, manifolds, fittings, and housings

-

Instrumentation enclosures and brackets in wet duty

-

Parts that need clean surface behavior after finishing

Procurement tip: you should call out the grade and condition, not just “stainless.” That single line reduces quote variation and material mismatch.

Duplex and super duplex machining for offshore and chloride service

Duplex and super duplex machining supports offshore and chloride environments where stress corrosion cracking risk increases. Duplex stainless steels use a dual austenitic and ferritic microstructure, and industry guides note strong chloride SCC resistance compared with common austenitic stainless families.

You should consider duplex machining when:

You should consider duplex machining when:

-

You face seawater splash zones or chloride contamination

-

You need higher strength with corrosion resistance

-

You want improved SCC margin without switching to nickel alloys

Machining note: duplex grades can raise cutting forces and tool wear. You should ask the supplier for a tool and coolant plan, plus a clear inspection method on bores and sealing lands.

Inconel and nickel alloy machining for high temperature environments

Inconel and nickel alloy machining fits energy components that must keep strength and resist oxidation and corrosion at high temperature. Technical bulletins for INCONEL alloy 625 describe good resistance to oxidation and scaling at elevated temperature. Nickel Institute publications also explain that many nickel alloys resist corrosion through passivation behavior, similar in concept to stainless systems.

You typically see Inconel machining in:

-

Hot gas paths and thermal hardware

-

Corrosive chemical exposure components

-

High duty rotating or sealing interfaces that need temperature margin

Buyer tip: you should specify the exact alloy grade and the material condition. Nickel alloys vary widely, and “Inconel” alone is not a purchase specification.

Carbon steel and alloy steel machining for high strength energy parts

Carbon steel and alloy steel machining fits energy parts that prioritize strength and cost control, while you manage corrosion with coatings and packaging. These steels work well for structural connectors, frames, shafts, and load-bearing interfaces.

You should choose alloy steel machining when:

-

The part sees cyclic load, impact, or high clamp force

-

You need heat treatment to reach a hardness window

-

You can protect the surface with plating, paint, or controlled packing

Procurement tip: you should define the heat treat condition and hardness range. Then you should align inspection to that requirement.

Aluminum CNC machining for lightweight energy components

Aluminum CNC machining fits energy housings, mounts, and thermal structures when weight and machinability matter. Aluminum has low density and forms a protective oxide layer in air.

You will often use aluminum CNC machining for:

-

Enclosures and brackets in renewable energy systems

-

Power electronics housings and mounting hardware

-

Lightweight structures that need fast cycle times

You should manage two common risks:

-

Galvanic corrosion when aluminum contacts dissimilar metals in an electrolyte

-

Surface damage that affects sealing and cosmetic zones

Copper and brass machining for electrical and thermal applications

Copper and brass machining fits energy components that need high electrical conductivity or strong thermal transfer. References note copper’s very high thermal conductivity, second only to silver among pure metals. ()

You will often see copper or brass machining in:

-

Electrical contacts, busbar-related hardware, and terminals

-

Thermal spreaders, cooling interfaces, and heat transfer parts

-

Grounding components and conductive fixtures

Buyer tip: copper burrs can create assembly and safety issues. You should specify burr control zones and require a deburr inspection step for edges near insulation and wiring routes.

Tolerances, GD&T, and Surface Finish for Energy CNC Machining

Energy CNC machining succeeds when you control a small set of CTQ features with the right tolerances, GD&T, and surface finish, then verify them with a repeatable inspection method. You should define sealing, rotating fits, alignment datums, and critical threads first. Then you can relax everything else to reduce cost.

| CTQ interface | What you should call out on the drawing | What you should require in inspection |

|---|---|---|

| Sealing face | Flatness, surface finish, controlled contact area | Flatness result, finish measurement, damage check photos |

| Rotating fit | Fit class, runout or concentricity strategy, finish | Runout data, diameter chart, surface finish |

| Alignment | Datums, true position or profile, functional stack | CMM report using the same datums |

| Threads | Thread standard, size, class, engagement notes | Go/No-Go gauging record, thread gage method |

Tight tolerance CNC machining for sealing surfaces and leak prevention

Sealing surfaces drive leak risk, so you should place your tightest tolerances on the seal land, groove geometry, and the datums that locate the seal. If you spread tight tolerances across non-functional faces, you will pay more and gain little reliability.

You should define sealing CTQs like this:

-

Seal land flatness and contact width

-

Groove geometry for O-rings or seals

-

Port alignment to datums that control assembly stack-up

-

Surface finish that matches gasket or seal type

ASME PCC-1 includes recommended gasket contact surface finishes by gasket type. For example, it lists 3.2–6.4 μm Ra (125–250 μin) for spiral-wound gaskets and for soft-faced metal core gaskets with facing layers.

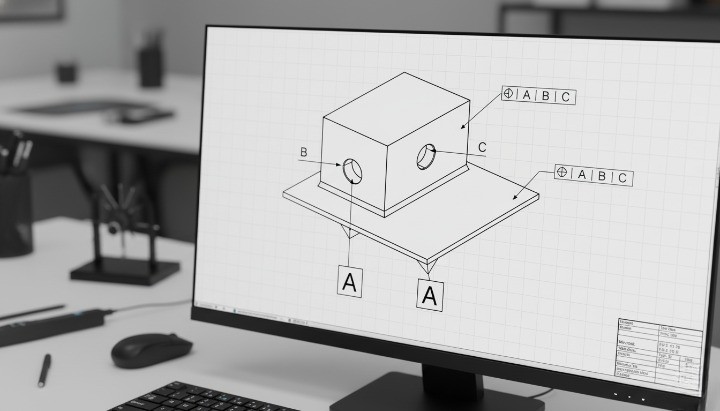

GD&T for energy parts: datum strategy for repeatability and assembly

GD&T helps you communicate functional intent, and datums make inspection match assembly reality. You should use GD&T to control form, orientation, location, and runout on the features that create uptime risk.

ISO 1101 defines the symbol language and interpretation rules for geometrical tolerancing, including tolerances of form, orientation, location, and runout.

ISO 1101 defines the symbol language and interpretation rules for geometrical tolerancing, including tolerances of form, orientation, location, and runout.

You should apply a simple datum strategy:

-

Pick datum A as the primary mounting or sealing face

-

Pick datum B as the locating feature that controls lateral shift

-

Pick datum C as the feature that locks rotation or clocking

-

Put true position or profile on hole patterns tied to A|B|C

You should not accept CMM reports that ignore your datum scheme. You want the report to reference the same datums your assembly uses.

Surface roughness requirements for sealing faces and wear surfaces

Surface roughness affects sealing, wear, and corrosion behavior, so you should specify it on the few surfaces that touch, seal, or slide. Then you should keep the rest as standard shop finish to control cost.

ISO 1302 specifies rules for indicating surface texture on technical product documentation using symbols and textual indications.

You should separate surface finish into zones:

-

Sealing faces and gasket lands

-

Wear surfaces and bearing journals

-

Cosmetic faces and non-contact faces

-

Coated or anodized faces where finish affects coating behavior

ASME PCC-1 provides practical finish guidance for flange gasket contact surfaces by gasket type, which helps you avoid “too smooth” or “too rough” surfaces that cause leakage or embedment issues.

Thread quality for vibration and pressure service in energy equipment

Threads fail in energy service when the thread form, functional diameter, or engagement control drifts. You should specify the thread standard, class, and inspection method so suppliers do not guess.

For Unified inch screw threads, ASME B1.2 provides specifications and dimensions for the gages used to verify UN and UNR thread forms, and it describes the purpose and use of each gage.

You should include these thread notes in your RFQ:

-

Thread type and class, plus any plating allowance

-

Engagement length or minimum full-thread engagement rule

-

Go/No-Go gauging requirement and sampling plan

-

Burr control zones on thread starts and cross-holes

You should treat threads as CTQs when they carry pressure boundaries, sealing, or vibration loads. Then you can require thread gauging evidence in the FAI pack.

Critical Quality Control for Energy CNC Machined Parts

Critical quality control keeps energy CNC machined parts reliable because it proves CTQ compliance with repeatable measurement, traceable materials, and risk-based testing. You should require a QC package that matches the failure mode, not a generic checklist. You should also insist on clear datums, consistent reporting, and documented process stability.

QC deliverables buyers should request

| QC deliverable | What it proves | When you should require it |

|---|---|---|

| First article inspection report | The first build meets drawing requirements | New part, new supplier, or drawing revision |

| CMM report with datums | Location, profile, and assembly alignment | Hole patterns, manifolds, complex geometry |

| Material certificates with heat number | Traceability to the mill heat and test results | Pressure parts, corrosive service, regulated projects |

| Process control evidence | Repeatability across batches | Medium to high volume or recurring orders |

| Leak or pressure test record | Leak integrity under defined conditions | Seal-critical parts and pressure boundaries |

| NDT results and personnel qualification | Defect detection for cracking or weld issues | Fatigue risk, weldments, critical duty |

First article inspection for energy CNC machining and what to review

First article inspection proves that the supplier’s process can make a compliant part before you scale volume. Many manufacturers use structured FAI documentation models such as AS9102 to capture requirements, verify features, and document materials and special processes, even outside aerospace when customers want strict traceability.

You should review these items in every energy FAI pack:

-

Ballooned drawing that links every requirement to a measured result

-

CTQ list with measurement method for each CTQ

-

Material certs and heat number traceability

-

Surface finish results on sealing and wear surfaces

-

Thread verification records for pressure or vibration threads

-

Clear revision control and deviation handling

Buyer tip: If the supplier cannot link each CTQ to a gage method and a result, you should treat the FAI as incomplete.

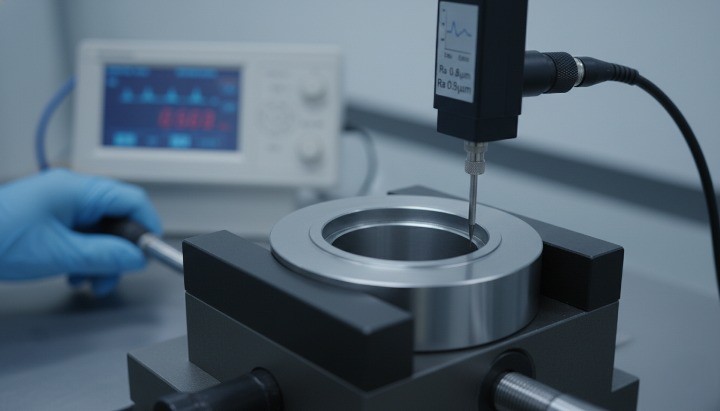

CMM inspection for energy components: datums, position, profile

CMM inspection matters when assembly depends on datum alignment, true position, and profile control. You should require datum-based CMM programs that match your drawing datums, because the report must reflect real assembly intent.

The ISO 10360 series defines acceptance and reverification tests for coordinate measuring machines and helps users verify CMM performance over time.

You should ask for these CMM report essentials:

-

Datum setup description and alignment strategy

-

True position results for hole patterns and ports

-

Profile results for complex surfaces when required

-

Measurement uncertainty or equipment verification evidence

-

A stable report template so you can compare lots

Buyer tip: You should reject “floating” measurements that ignore your datum scheme. They create pass-fail confusion and hide alignment risk.

Material certificates and heat number traceability for energy projects

Material traceability protects you when corrosion, pressure duty, or compliance requirements drive risk. You should link each finished part lot back to the mill heat and its test results through an MTR and consistent marking.

Industry guidance explains that mills test each heat for chemistry and mechanical properties, record results on an MTR, and then mark material so fabricators can relate pieces back to the MTR.

You should require these traceability controls:

-

Heat number on material and on the MTR

-

Lot and part marking method that survives finishing

-

Traveler or router that links operations to the lot

-

Clear segregation rules for mixed materials

-

Record retention expectation for your project

Buyer tip: If the heat number on the part does not match the certificate pack, you should stop the lot and quarantine it.

Process control and repeatability in CNC machining production

Repeatability comes from process control, not from a tight inspection at the end. You should ask the supplier to show how they control the machining route for each CTQ, especially when tool wear, heat, or re-clamping can shift results.

You should expect these controls on stable energy CNC machining:

-

Defined setup count and datum strategy for CTQ faces

-

In-process gauging for bores, journals, and sealing lands

-

Tool life rules or wear offsets for CTQ features

-

Consistent deburring and cleaning for contamination-sensitive parts

-

A sampling plan that focuses on CTQs, not every dimension

Buyer tip: You should require the supplier to state the “control point” for each CTQ, meaning where they measure it and how they react when it trends.

Leak testing, pressure testing, and NDT triggers for critical components

You should add leak testing, pressure testing, or NDT when a dimensional report cannot prove functional safety. The trigger is simple: if failure causes shutdown, safety exposure, or expensive field service, you need functional testing evidence.

For valves, API 598 specifies inspection and testing types such as shell tests and closure tests. For piping systems, common code guidance references hydrostatic testing at not less than 1.5 times design pressure in ASME B31 systems, with limits based on component ratings and stress.

For NDT, ISO 9712 defines qualification and certification requirements for personnel performing industrial NDT methods such as penetrant and radiographic testing. ASTM E1417 establishes minimum requirements for liquid penetrant examination of nonporous components.

Practical test trigger matrix for buyers

| Risk trigger | What you should require | Why it fits the risk |

|---|---|---|

| Pressure boundary or seat leakage risk | Hydrostatic or pneumatic test record | Proves leak integrity under defined conditions |

| Hidden cracking risk or fatigue-critical area | NDT report with qualified personnel | Finds defects that dimensions cannot reveal |

| Surface-breaking defect risk on machined or welded surfaces | Liquid penetrant testing | Detects surface-breaking defects reliably |

| Complex internal geometry where visual checks miss defects | Radiographic testing where applicable | Reveals internal flaws in welded joints |

Buyer tip: You should define the test method, acceptance criteria, and documentation format in the RFQ. That step prevents “we tested it” claims without usable evidence.

Design for Manufacturability for Energy CNC Machining

Design for manufacturability keeps energy CNC machining stable because it reduces setups, avoids long-reach tooling, and protects CTQ features like sealing, rotation, and alignment. You should design around datums and inspection first. Then you should simplify geometry so the shop can hold tolerance without heroic fixturing.

When you apply DFM early, you cut lead time risk and quote spread. You also reduce field failures because you keep the process repeatable.

DFM outcomes you should target

| DFM target | What you change in the design | What you gain in production |

|---|---|---|

| Fewer setups | Consolidate datums and accessible faces | Better repeatability and shorter lead time |

| Shorter tools | Reduce deep pockets and thin walls | Less chatter and fewer scrap parts |

| Clear CTQs | Tighten only seal, rotate, align features | Lower total cost and fewer disputes |

| Easier inspection | Add datum scheme and measurable notes | Faster FAI and cleaner CMM reports |

CNC machining design rules for manifolds, valve bodies, and housings

You should design manifolds and housings so the shop can machine critical faces in fewer clamps. You also want straight tool access to ports and sealing lands. That combination improves true position and surface finish.

Use these rules for better energy CNC machining:

-

Keep CTQ faces on the same side when possible.

-

Add datum pads that a fixture can locate repeatably.

-

Avoid deep, narrow pockets that force long tools.

-

Use consistent wall thickness to reduce distortion in machining.

You should also plan intersection geometry. Cross-holes and intersecting ports often create burr traps. You can reduce rework when you add small reliefs and specify deburr zones on the drawing.

Sealing groove design and surface finish planning for energy parts

You should treat sealing grooves as CTQs. A small geometry drift can create leak paths even when the rest of the part looks perfect. You should also match groove style to your seal type and duty cycle.

If you use O-rings, you should reference established groove guidance. Parker’s O-Ring Handbook provides groove design recommendations and dimensions for many common sealing cases.

If you use straight-thread O-ring ports in hydraulic service, you should reference ISO 6149. ISO describes metric port dimensions and also states that ports can be used at working pressures up to 63 MPa for non-adjustable stud ends, with limits depending on size and conditions.

Sealing DFM rules that reduce leaks:

-

Specify the sealing face finish only on the contact band.

-

Avoid sharp edges at groove entry. You should add a lead-in.

-

Keep the groove away from a nearby step that can tilt the gasket.

-

Protect sealing faces in shipping. You should define a no-contact zone.

Deep hole drilling and boring strategy for energy components

Deep holes drive cost and risk because chips pack, tools deflect, and bores drift. You should design holes so the shop can evacuate chips and measure the result reliably.

Deep hole drilling methods depend on coolant delivery and chip evacuation. Technical references on deep hole drilling describe gundrilling and BTA drilling and emphasize high-pressure coolant and chip evacuation for higher depth-to-diameter holes.

Design rules you should apply:

-

Avoid extreme L/D holes when you can split the feature.

-

Add a pilot and provide a stable entrance surface.

-

Keep intersecting cross-holes away from the deepest zone.

-

Specify straightness or position only when function needs it.

Procurement tip: you should ask the supplier what method they will use. You should ask how they will verify straightness and bore size. Those answers predict scrap risk.

Thread design: tap vs thread mill vs inserts for heavy duty use

Threads cause expensive failures in energy service when burrs, form error, or engagement problems slip through. You should specify thread type, class, engagement, and inspection method in the RFQ.

Unified inch screw threads use fit classes such as 1A/1B, 2A/2B, and 3A/3B. Industry references summarize that higher class numbers mean tighter fits, with “A” for external and “B” for internal threads.

Use a practical selection rule:

-

Choose tapping for common threads in softer materials and lower risk zones.

-

Choose thread milling for larger threads, tougher alloys, and better control.

-

Choose inserts when you expect frequent assembly cycles or soft base metal.

Thread DFM rules you should apply:

-

Add a lead-in chamfer on thread starts.

-

Avoid blind holes with no chip room. You should add relief.

-

Define plating allowance if you coat the part.

-

Require Go/No-Go gauging for CTQ threads.

Reduce setups and control datums for stable CNC machining quality

You should treat setup count as a quality variable. Every re-clamp can shift datums and inflate inspection effort. You can cut risk when you design parts that machine most CTQs in one or two controlled setups.

Use this setup reduction checklist:

-

Put primary sealing and mounting faces on accessible planes.

-

Use one datum scheme across all CTQ callouts.

-

Avoid features that require flipping for a single hole or face.

-

Add fixture-friendly locating features on non-cosmetic areas.

-

Group tight tolerances on features that share a setup.

If your design forces many setups, you should consider 4-axis or 5-axis machining. You can also consider near-net preforms, then machine only CTQs.

Cost and Lead Time in CNC Machining for the Energy Sector

Energy CNC machining cost and lead time depend on how many times you clamp the part, how tightly you control CTQs, and how much inspection evidence you must deliver. You should treat setup count, material readiness, and QC scope as the three levers that move quotes the most.

Quality also changes total cost. ASQ notes that many organizations see quality-related costs as high as 15–20% of sales, and a common “rule of thumb” puts poor-quality costs around 10–15% of operations.

Cost and lead time levers at a glance

| Lever | What increases cost and lead time | What lowers cost and lead time |

|---|---|---|

| Setups | Many re-clamps, complex fixturing, long reach tools | Fewer setups, multi-axis access, stable datums |

| CTQ scope | Tight tolerances everywhere, unclear CTQs | CTQ-first tolerances, relaxed non-critical features |

| Inspection | Full-dimension reporting, unclear datums | CTQ-focused plan, datum-based CMM, consistent templates |

| Material | Long-lead alloys, unclear condition, reorders | Clear grade/condition, traceability ready, approved sources |

| Finishing | Late decisions, masking complexity, rework | Defined finish zones, handling plan, predictable routing |

CNC machining cost drivers for energy components

The biggest CNC machining cost driver is setup complexity. Every extra setup adds fixturing time, probing time, risk of datum shift, and extra inspection. You should also expect cost jumps when you demand tight form and finish on many surfaces.

The most common cost drivers in energy parts are:

-

Setup count and re-fixturing

-

Tight tolerances on non-CTQ surfaces

-

Deep bores, long reach tools, and chatter control

-

Hard-to-machine alloys and tool wear

-

High inspection burden and special testing requirements

You can reduce quote spread when you standardize your RFQ inputs. NIST has also highlighted that inadequate modeling and design data creates measurable losses in discrete manufacturing, which is why clean CAD and clear requirements matter for lead time.

Prototype CNC machining and low volume production for energy projects

Prototype CNC machining wins when you expect design change and you need parts fast without tooling risk. You should use CNC in early stages to validate sealing, alignment, and assembly stack-up. Then you can decide if a near-net route makes sense.

Prototype and low volume planning works best when you:

-

Define CTQs clearly on the drawing

-

Ask for a simple DFM review before the first cut

-

Request FAI evidence on CTQs, not a 100% tight inspection of every feature

-

Lock a repeatable datum scheme so rev changes do not reset the process

You should also plan lead time around material readiness. A supplier can machine quickly, but they cannot beat a long alloy lead time if the RFQ does not specify grade and condition upfront.

High volume energy parts: when die casting or forging reduces cost

Die casting or forging plus CNC machining reduces cost when you can form the bulk shape near net, then machine only CTQs. That strategy reduces material removal, cycle time, and setup burden on non-critical geometry.

NADCA guidance describes machining savings from designing castings closer to near-net shape to eliminate machining operations, and from designing the tooling so required machining stays on one plane to enable a single setup.

You should consider die casting or forging when:

-

Volume stays stable and revision frequency drops

-

The part wastes a lot of billet in full CNC machining

-

You can keep as-cast or as-forged surfaces on non-CTQ areas

-

You can machine sealing faces, bores, and datums after forming

You should still keep CNC machining for the CTQs. That hybrid route protects sealing, rotation, and alignment while controlling unit cost.

Total cost of ownership: machining time, inspection time, scrap risk

Total cost of ownership in energy CNC machining includes inspection time, scrap risk, and field-failure exposure, not just the unit price. You should price the full chain: machining, QC, packaging, shipping, incoming inspection, and rework.

ASQ reports that quality-related costs can reach 15–20% of sales, which is why improving process stability and CTQ clarity often beats negotiating cents off a unit price. NIST also notes that some estimates put machinery maintenance between 15% and 70% of the cost of goods produced, which shows how downtime and reliability can dominate operating cost in real factories.

Use this buyer-side TCO checklist:

-

Machining time and setup time per batch

-

Inspection time, reporting format, and re-measure cost

-

Scrap and rework rate risk on CTQ features

-

Packaging and corrosion prevention for long shipping lanes

-

Functional testing cost when leaks or safety risk matters

How to Choose a CNC Machining Supplier for Energy Industry Parts?

You should choose an energy CNC machining supplier based on evidence of capability, measurement competence, and repeatability on CTQ features. Price matters, but CTQ control matters more when leaks, vibration, corrosion, and downtime drive real cost.

Start with a checklist. Then ask the supplier to prove each item with a sample pack from a similar job.

Supplier qualification scorecard for energy CNC machining

| Category | What “good” looks like | What you should request |

|---|---|---|

| Capability | Stable routing for seal, rotate, align CTQs | Machine list, part size limits, sample part photos |

| Inspection | Datum-based CMM reporting and calibrated gauges | Sample CMM report, gauge list, calibration evidence |

| Documentation | Clear FAI, traceability, revision control | Sample FAI pack, traveler, lot labeling photos |

| Packaging | Corrosion prevention that survives your shipping lane | Packaging spec, VCI method, photos of packed parts |

| Communication | Fast DFM feedback and quote assumptions stated | DFM notes, setup count, CTQ inspection plan |

Energy CNC machining capability checklist: machines, size, materials, finishing

You should confirm that the supplier can machine your largest envelope, hold your tightest CTQs, and finish parts without damaging sealing faces. You also want proof that they run your target materials with stable tool life.

Use this capability checklist in your RFQ:

-

Machine type and axis capability for your geometry

-

Work envelope limits and fixture approach for your part size

-

Material experience for stainless, duplex, nickel alloys, and aluminum

-

Surface finishing capability and masking discipline for CTQ zones

-

Assembly support if you need inserts, press fits, or sub-assemblies

If you buy oil and gas components, you often see buyers reference a sector-specific QMS like API Specification Q1. It defines quality management system requirements for organizations providing products for the petroleum and natural gas industry.

Inspection capability checklist: CMM, gauges, calibration, reporting

You should treat inspection as a core manufacturing capability. Energy parts fail at interfaces, so you need measurement that matches functional datums and produces repeatable reports.

Use this inspection checklist:

-

CMM capability for true position, profile, and datum alignment

-

Thread gauges and plug/ring gauges for CTQ threads

-

Surface finish measurement for sealing and wear surfaces

-

Calibration system that keeps gauges valid and traceable

-

Report format that stays consistent across lots and revisions

ISO explains that ISO/IEC 17025 helps testing and calibration laboratories demonstrate competence and generate valid results. That standard supports confidence in calibration work. You can use it as a practical procurement filter. If a supplier outsources calibration, you can ask if the lab follows ISO/IEC 17025.

Buyer rule: You should not accept “pass” statements without measurement evidence on sealing faces, runout, and true position.

Documentation checklist: FAI, traceability, revision control, lot control

Documentation reduces supplier disputes because it makes the process auditable. You should ask for a documentation pack that connects material, machining, inspection, and shipping to the exact revision you ordered. You can also verify the supplier’s baseline credibility by reviewing their certificates and quality documentation, including certifications tied to inspection, process control, and traceability.

Use this documentation checklist:

-

Ballooned drawing with measured results for each requirement

-

CTQ list and the measurement method for each CTQ

-

Material certificate pack and heat number linkage to the lot

-

Revision control rules for ECO changes and re-FAI triggers

-

Lot control and part marking plan that survives finishing

ISO 9001 specifies requirements for establishing and maintaining a quality management system, including process control and continual improvement. Many buyers use it as a baseline QMS expectation. For oil and gas supply chains, API Specification Q1 provides sector-specific QMS requirements.

Buyer rule: You should require traceability on any part where corrosion, pressure duty, or safety exposure drives risk.

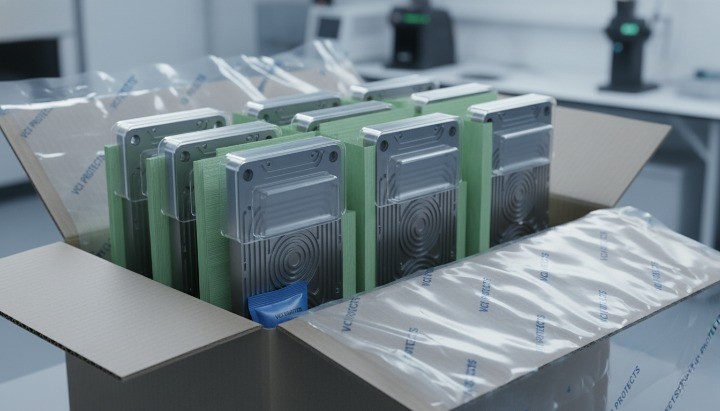

Export packaging and corrosion prevention for global energy projects

Export shipping creates hidden failures. A perfect sealing face can arrive scratched. A clean bore can arrive rusted. You should qualify packaging as part of the manufacturing process, especially for long sea freight and storage windows.

Use this packaging checklist for energy CNC machined parts:

-

Protect sealing faces and datum pads with rigid guards

-

Use VCI or equivalent corrosion prevention for ferrous parts

-

Separate parts to prevent metal-to-metal contact and fretting

-

Label lots clearly and keep the certificate pack aligned to the lot

-

Define storage duration and humidity exposure assumptions

ASTM D3951 establishes minimum requirements for commercial packaging of supplies and equipment and is widely used as a structured packaging reference. If you need stricter long-term storage protection, many organizations reference military packaging practices such as MIL-STD-2073 for items entering military distribution systems.

RFQ communication and DFM feedback for faster, cleaner launches

You should judge a supplier by how they communicate before they cut metal. A good supplier asks CTQ questions early, proposes a stable datum scheme, and states quote assumptions clearly.

Use this RFQ communication checklist:

-

Supplier repeats CTQs back in their own words

-

Supplier lists setup count and key datums per setup

-

Supplier flags high-risk features and offers DFM changes

-

Supplier states inspection scope and report format in the quote

-

Supplier confirms finishing, masking, and handling for CTQ zones

Buyer rule: You should treat vague quotes as risk. If the supplier cannot state how they will hold and measure CTQs, you should expect variance, rework, and schedule slips.

Energy CNC Machining RFQ Checklist

A strong energy CNC machining RFQ removes guesswork. You should define CTQs, materials, finishes, inspection evidence, and shipping assumptions in writing. Then you get stable quotes, faster DFM, and fewer first-article surprises.

CAD files, drawings, and CTQ callouts for accurate CNC machining quotes

You should send the right files in the first email. Quotes swing when suppliers must assume datums, tolerances, or surface finish intent.

Include these RFQ files:

-

3D CAD (STEP preferred) and 2D drawing (PDF) with the same revision ID

-

Ballooned drawing or a CTQ list that highlights seal, rotate, and align features

-

Datum scheme that matches assembly and inspection

-

Assembly context or mating part references for critical interfaces

-

Any special notes for deburring, cleaning, or cosmetic zones

Use this CTQ header line in your RFQ:

-

CTQs: sealing faces and grooves, rotating fits and runout, alignment datums and true position, corrosion-critical surfaces

If you want FAI-style reporting, you can reference widely used documentation expectations like AS9102 for structured first article inspection documentation.

Material specification and surface finish requirements for energy parts

You should specify grade, condition, and finish zones. Suppliers can machine “stainless” ten different ways. You want one clear target.

Material fields you should fill:

-

Material grade and standard (example: 316L, 2205 duplex, 4140, 6061-T6)

-

Condition and heat treatment window, if applicable

-

Corrosion environment (offshore chloride, sour service, wet duty, indoor)

-

Surface finish zones: seal land, wear land, cosmetic, non-critical

Finish fields you should fill:

-

Surface roughness callouts on sealing and wear surfaces

-

Coating or anodizing type, thickness range if you control it, and masking zones

-

Handling rules for sealing faces and datum pads

If your project relies on formal surface texture notation, ISO 1302 defines how to indicate surface texture on technical product documentation. If you use GD&T to control assembly repeatability, ISO 1101 defines the symbol language and interpretation rules.

Inspection requirements and documentation package for energy components

You should ask for evidence that matches the failure mode. A pressure boundary part needs traceability and tests. A bracket needs flatness and position proof.

Choose what you need from this list:

-

First article inspection report with ballooned drawing mapping

-

CMM report for datums, true position, and profile

-

Surface roughness results for sealing and wear surfaces

-

Thread gauge records for CTQ threads

-

Material certificates with heat number traceability

-

Leak or pressure test records when sealing integrity drives risk

-

NDT reports when cracking risk matters

If you want a baseline QMS expectation, ISO 9001 specifies requirements for establishing and maintaining a quality management system. If you buy oil and gas supply chain parts, API Specification Q1 provides QMS requirements for organizations providing products to the petroleum and natural gas industry.

Quantity, lead time, packaging, and shipping inputs for stable planning

You should define logistics as part of quality. Corrosion, dents, and seal-face damage often happen after final inspection.

Planning inputs you should provide:

-

Annual volume estimate and order cadence

-

Target lead time and any hard dates for FAT or site commissioning

-

Packaging rules: face protection, separators, rust prevention, labeling

-

Shipping lane: air vs sea, destination country, and customs documentation needs

-

Storage duration after arrival and humidity exposure expectations

If you want a recognized packaging baseline, ASTM D3951 establishes minimum requirements for commercial packaging of supplies and equipment (excluding hazardous materials).

If you source energy storage system components that must support safety compliance, UL 9540 provides a basis for system-level safety of energy storage systems and equipment.

FAQ

What energy parts are best made with CNC machining?

CNC machining is the best choice when function depends on sealing, rotation, or precise alignment. You should use CNC machining for parts that need tight datums and repeatable inspection.

Typical examples:

-

Valve bodies, manifolds, sealing blocks, and port interfaces

-

Shafts, couplings, bearing fits, and rotating equipment features

-

Pump housings, wear components, and precision bores

-

Instrument housings, sensor mounts, and alignment-critical brackets

-

Prototype and low-volume parts that will change after testing

You should consider hybrid routes when volume rises and geometry stays stable.

How to reduce cost for CNC machining energy components?

You reduce cost when you tighten tolerances only on CTQs, reduce setups, and simplify inspection. You should treat setup count as a cost variable you can design down.

Use these cost controls:

-

Mark CTQs and relax non-functional surfaces

-

Combine faces so the shop can machine CTQs in fewer clamps

-

Avoid extreme deep pockets and long-reach tools

-

Standardize threads and avoid unnecessary custom forms

-

Define inspection scope on CTQs instead of demanding “measure everything”

You should also request a quote that states setup count and inspection deliverables.

What tolerances are realistic for energy CNC machined parts?

Realistic tolerances depend on feature type, material, part size, and inspection method. You should define tolerance by function, not by habit.

Use this practical approach:

-

Put your tightest requirements on sealing faces, rotating fits, and alignment datums

-

Use GD&T to control the assembly stack, not just individual dimensions

-

Keep free surfaces and cosmetic faces at standard shop tolerance

-

Ask the supplier to propose the lowest-risk tolerance plan during DFM

If you rely on GD&T for this, ISO 1101 provides the rule set for specifying and interpreting geometrical tolerances.

What inspection reports should I request for energy CNC machining?

You should request inspection reports that prove CTQs with datums and traceability. A “pass” statement is not enough for seal and alignment interfaces.

A strong pack usually includes:

-

FAI-style report with ballooned drawing mapping

-

CMM report for true position, profile, and datum alignment

-

Surface roughness results on sealing and wear surfaces

-

Thread gauge records for CTQ threads

-

Material certificates with heat number traceability

-

Leak or pressure test records when sealing drives risk

If you want a structured FAI documentation model, AS9102 establishes documentation requirements for first article inspection.

How to qualify a CNC machining supplier for oil and gas parts?

You qualify an oil and gas machining supplier by process control, traceability, and standards alignment, not by promises. You should verify that the supplier can repeat a stable route and measure CTQs with the right evidence.

Use this oil and gas qualification checklist:

-

Evidence of a controlled QMS aligned with API Spec Q1 expectations

-

Experience with pressure control parts and standard practices in API Spec 6A contexts

-

Traceability from material heat to finished lot and inspection record

-

Leak or pressure testing capability when pressure boundaries apply

-

Clear packing and corrosion prevention suited to long shipping lanes

You should request one sample documentation pack from a similar job before you award production.

Conclusion

Energy CNC machining works best when you protect CTQs—seal, rotate, align, and resist corrosion—then prove compliance with CMM inspection, FAI reporting, and material traceability. You can cut lead time and reduce scrap when you reduce setups, control datums, and apply tight tolerance CNC machining only on sealing surfaces, rotating fits, and alignment features. A clear energy CNC machining RFQ checklist also helps you compare CNC machining vs die casting vs forging with total cost in mind.

If you want an engineering-led DFM review for energy parts and a clean quote, share your drawings, CTQ list, material and surface finish requirements, and your inspection package expectations here.