Before the advancement of technology in the recent world, many manufacturing operations in industries were carried out using manual processes and there were lots of limitations and inconsistency in the products produced. The defense industry isn’t left out on these shortcomings.

But with the evolution and adoption of CNC machining in the defense industry, there have been rapid and notable improvements. Many of the benefits and usefulness of this advanced technology in the military defense has been captured in this article.

Background of CNC Machining in the Defense Industry

CNC in the defence industry became a thing in the twentieth century. It was first introduced as an improvement on the existing traditional defense machining. With computerized systems and some level of automation, it promised to make up for the downsides of manual machining.

These lapses include production time-consumption, inconsistency in products formed, limitation to making only simple component designs, excessive waste material, and many more.

But this innovation has by far taken a huge turn on the manufacturing industries, making the processes a lot easier and efficient. Since its evolution, there has been a wide adoption of the defense machining automated technique by many industries, and the defense sector is not left out.

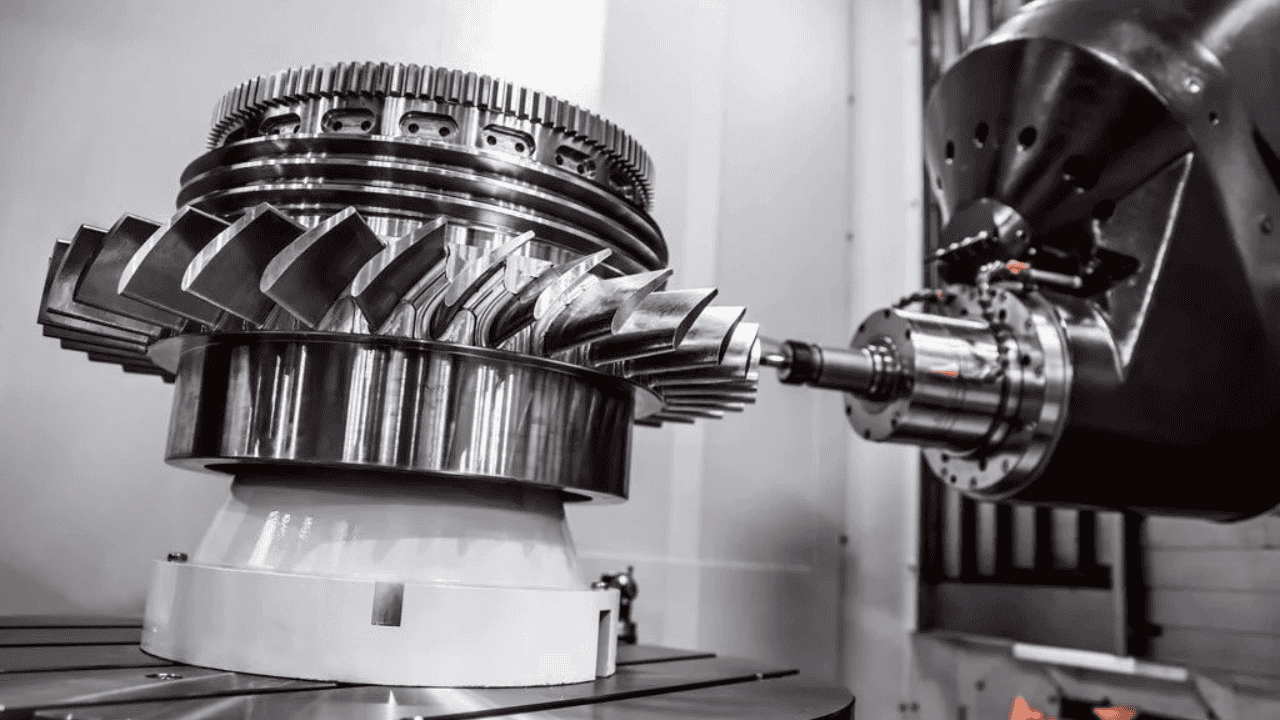

The defense sector is known to rely heavily on CNC machining for the production of major aircraft components, weapons, armored vehicles, and surveillance systems because it is a reliable process for creating parts with exceptional precision.

Benefits of CNC Machining in the Defense Sector

Cost-Effectiveness

A major benefit of computer numerical control machining in various industries is the automation of manual and repetitive tasks, reduction of labour cost, and material waste. Although the cost of initial setup may be expensive, it provides long-term operating stability for an industry.

Also, over a period of time, the investment put into CNC in defense machining pays off because it can be used for bulk production of components.

Consistency and Precision

Many of the machineries used in the defense machining industry require different parts with tight tolerance and a greater level of accuracy and precision. This is very important when manufacturing mission-critical components such as weaponry, radar, armored vehicles, and spacecraft components.

CNC machining process can reproduce the same component either with simple or complex geometry over and over again with high accuracy and precision

Efficiency and Speed

CNC machining in the defense industry is a very efficient method of machining. With the aid of its computer technology and an automatic system of operation it enhances production by reducing manual processes.

Also, the defense machinist creates a set of instructions and commands by which the CNC machine functions, that is, the CAM software containing the G-code of readable instructions is imputed into the system and it then produces precise components with excellent dimensional stability based on the commands given.

For military projects that require quick deployment, the different parts of a CNC machine work hand in hand to ensure a high-quality component is produced.

Customization

Another benefit of machining in the military industry is the ability to design specialized components tailored to the needs of a specific defense project. It allows rapid customization and prototyping. That way engineers, defense machinists, and military equipment manufacturers can design and manufacture parts with specific features.

Quality Control

CNC machining in the defense industry employs quality control in order to ensure that components meet the highest standards of precision, durability, and reliability.

The process facilitates stringent quality assurance protocols, including automated inspections, real-time monitoring, and adherence to industry regulations such as ISO and MIL-SPEC standards. All of these automated inspections help the defense machinist to detect faults and errors of components in time thereby reducing material waste and saving cost of production during machining in the military sector..

Common Materials Used for CNC Machining in the Defense Industry

Aluminum

Aluminum alloy is a versatile material that is widely used in the manufacture of many structural components where lightweight, strength, and malleability properties are required. It is used in making aircrafts and vehicles in the defense industry. Aluminum offers excellent corrosion resistance and is easy to machine, making it a preferred material for CNC in defense machining applications.

Titanium

Titanium is widely known for its exceptional strength-to-weight ratio and corrosion resistance. It is a top choice material for manufacturing aircraft parts such as airframes, missile components, engine parts in the CNC machining industry.

Nickel Alloys

Nickel alloys such as Monel, Invar, Inconel, Hastelloy are materials suitable for CNC machining parts in the defense industry. They are applied in the manufacture of aerospace parts and military machines where optimal functionality is demanded under stress and hostile situations. These alloys are often found in jet engines, turbines, and armor plating.

Plastics

Plastics offer high chemical resistance, low thermal conductivity, and durability. They are used for lightweight components, such as insulators, electric enclosures and are highly cost-effective. Examples of plastics used for CNC machining in the defense industry include; PVC, PEEK, UHMW, and Acetal which is the most commonly used plastic.

Stainless Steel

Stainless steel is a non-magnetic material used to manufacture firearm components, naval structures, and high-strength fasteners in the defense industry. The grade 304 stainless steel is used in the manufacture of defense machines like the submarine due to its high corrosion resistance to seawater.

Applications of CNC Machining in the Defense Industry

Weapons System

CNC machining is not actually a recent trend. It has been in use since the mid-20th century playing a critical role in the evolution of modern weaponry. The 4-axis CNC machining process was used to manufacture the Tomahawk missile system that was used during the Gulf War in the 1990s.

CNC machines are used also to manufacture critical parts of the very popular AK47 firearm. Due to the stringent tolerance, precision, and accuracy that this machining process offers, it is highly used in the production of firearms, missile parts, smart munitions, and guided weapon systems.

Aircraft and Spaceship component

CNC machining can be used in the defense industry for manufacturing landing gears, drones, turbine blades, aircraft fuselage, and many other aircraft structural components which cannot be fabricated by other manufacturing methods. Also, many aerospace manufacturers in the defense industry tend to rely on CNC machining because of its many advantages like tight tolerance, excellent precision, and formation of intricate designs.

For instance, Lockheed Martin used the 5-axis CNC machining process to manufacture and achieve high precision and tight tolerance on the skin component of the F-35 fighter jet that was used by the U.S. Air Force. This bodily feature helped the fighter jet remain undetectable by the radar during the wars.

Radar and Electronic Systems

Radar is a very important technological equipment used in the defense industry to track, monitor, detect, and identify potential threats such as ballistic missiles within a country’s border. It is quite essential that this system is accurately manufactured in order to avoid false signals which could lead to an imminent counter-attack that might start a war.

The application of CNC machining in the radar and electronic systems of the defense industry helps maintain signal integrity and operational costs by providing accurate precision. It is used in defense electronic equipment such as sensor housings, communicating devices, and radar antennas.

Vehicles and Armored Vehicles

One of the many benefits of CNC machining that makes it a top choice in manufacturing industries is the ability to produce parts with high precision.This is one feature that is very exceptional when creating parts and components of a system or machine..

CNC machining is used to achieve precise intricate components of armoured vehicles in the defense industry. Components such as armor plating, tank hulls, engine parts, and vehicle suspension systems are created with CNC machines to ensure structural integrity and durability.

Limitations of CNC Machining in the Defense Industry

Security Issues

CNC machining is a digital technology that makes use of cloud-based data storage. This storage model increases the risk of cyberattacks and data breaches. It is very important to get a trusted and qualified manufacturer to carry out your CNC machining project in the defense industry.

Compliance Standards

Due to the different laws and regulatory standards guiding the manufacturing processes in the defense industry, it might be difficult to adhere to all laws and increase the cost of CNC machining operations. Such compliance regulatory bodies include MIL-SPEC standards , Defence Contract Management Agency (DCAA), and the International Traffic in Arms Regulations (ITAR)

Future Trends of CNC Machining

Use of Artificial Intelligence and Machine Learning

With the many technological advancements that artificial intelligence has brought to the CNC machining industry, it has without a doubt come to stay and isn’t fading anytime soon. These technologies improve predictive maintenance, enhance quality control and are predicted to drive a higher efficiency and operation optimization in the defense industry.

Integration of Advanced Robotics

Robotics and humanoids are already becoming a focal point with more tech giants diving into it. In the future, we expect lots of defence machining innovations pointed towards that direction. This advanced robotics will help enhance productivity and reduce manual intervention in high-precision defense applications.

Conclusion

CNC in defense machining has actively contributed to the level of developments we have in the military industrial complex today. Its numerous applications are testament to the expertise and resourcefulness of military equipment manufacturers.

At HM, we go the extra mile to ensure we use state-of-the-art CNC machines in fabricating intricate parts needed for the defence industry. We boast of a robust factory and well-trained and experienced manpower to deliver orders in a timely manner. You can contact us today to fabricate components for you or to help me integrate CNC into your defence manufacturing process.