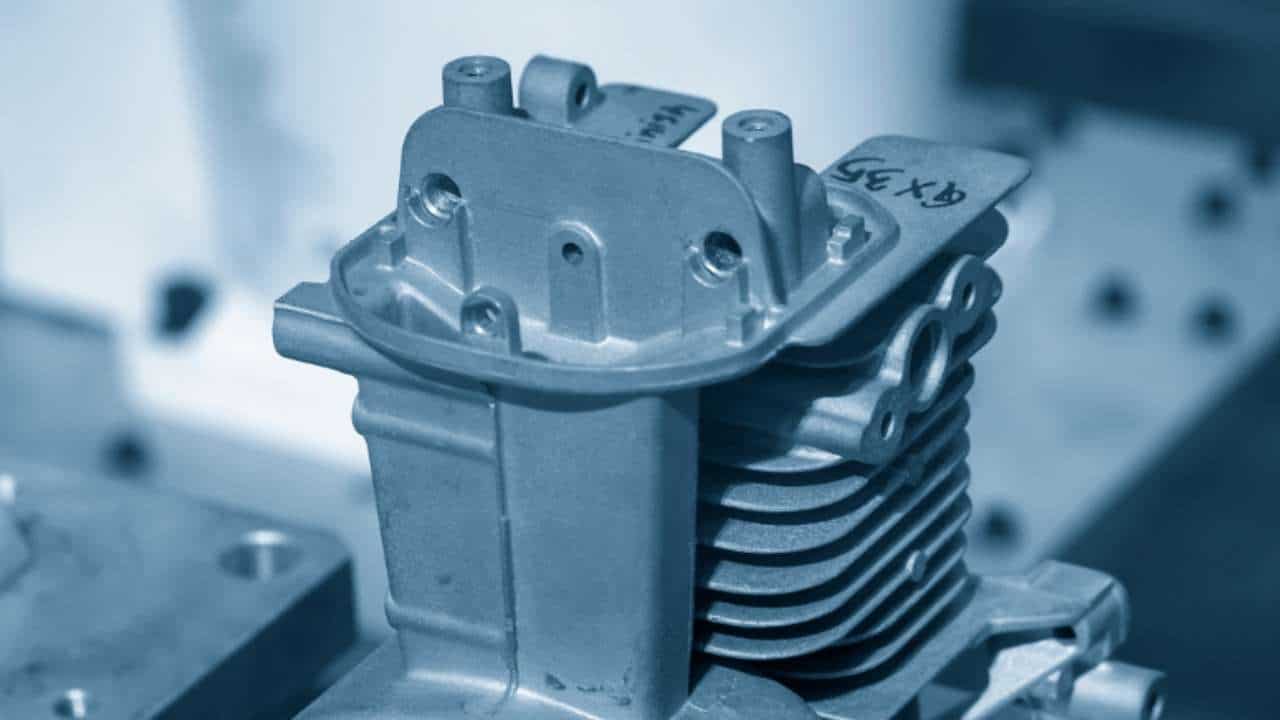

Die casting is an industrial process that relies on the power and intensity of high pressure to reshape and remake molten metal into unique metal parts.

With titanium die casting, you can manufacture cast titanium-based components and parts, relevant for different industries. In this article, we will explore the different types of titanium die casting and their applications.

What Is Titanium Casting?

Titanium casting process is one in which titanium components are formed by first creating a wax copy of the design by means of injection molding. After which a ceramic coated shell is made around the wax leaving a cavity opening upon removal of the wax.

The ceramic shell having the structural shape of the component is filled with molten titanium and allowed to cool. Upon cooling, the shell is destroyed leaving behind the cast titanium component.

Titanium casting is employed in automobile industries, aerospace, medical industries, because it is more suitable for producing structural components and equipment that has high strength-to weight and is highly resistant to corrosion.

Types of Titanium Alloys for Die Casting

Titanium alloys are widely used for die casting because of the qualities they possess. They have the highest strength-to-weight ratio compared to other ferrous and non-ferrous metals, are light-weight, resistant to corrosion and are heat-resistant. Below are the types of titanium alloys used for titanium casting processes:

Ti 6AI-4V

Also referred to as titanium grade 5, an alpha-beta Ti alloy is the most commonly used alloy in the world for titanium die casting in the aerospace for airframes, fasteners, hydraulic systems. You can also use it in sports for bicycle frames, tennis rackets, hockey sticks, and in the marine industry for propellers, and pipelines.

It consists of 4% vanadium, 0.2% (max) oxygen, 0.5% (max) iron, 6% aluminium and 90% titanium. Overall, these extra elements make it able to withstand extreme temperature, lightweight, and resistant to corrosions and acids.

Ti-5AI-2.5Sn

This type of titanium alloy is preferred for a lot of reasons and chief amongst them is its good frabicability, strength, and how weldable it is in different industrial processes. Ti-5AI-2.5Sn alloy also possesses great oxidation resistance, manages a service temperature mark of 480°C (896°F).

Aside from these useful properties, it is noteworthy that Ti-5AI-2.5Sn is not a heat-treatable alloy. They are also hard when it comes to machining but an experienced machinist could apply high feed rates, slow speed, and more coolant flow.

Ti 6AL 4V ELI

This alloy has a high melting point of over 1604°C, making it possible to withstand high degrees of the titanium casting furnace. As such, it is a high-in-demand alloy for several heat sensitive applications.

Also, manufacturers find it easy to work with because of its fair welding properties. With an incredibly high tensile strength, you can use it in aerospace fabrications and surgical implants.

Ti 3AI 2.5

If you need a Ti alloy with almost one and half the tensile strength of naturally occurring titanium, this is a top choice. It’s a grade 9 alloy with several great properties that makes it widely popular for construction and architectural needs.

Despite being more weldable than most grades of titanium, the Ti 3AI 2.5 is about 59% lower in density than steel. This is why it’s commonly used in aerospace and marine applications.

What Are The Advantages Of Titanium Die Casting

As one of the most widely used manufacturing techniques, titanium die casting has several advantages. Below are some of its most common benefits:

Efficient Mass Production: Because of the simple mechanism of die casting process, it allows you to produce many identical titanium die casting components that are dimensionally stable and durable with little or no machining.

Complex Thin-Walls: Titanium die casting process produces a cast with thinner walls compared to other techniques like the metal mold and sand castings. This helps in reducing the weight of a titanium part while increasing its surface area. It also is cost-effective.

Better Surface Finishing: Many surface texture and finish options can be achieved during Ti die casting.

Dimensional Stability and Accuracy: The final components obtained at the end of every titanium die-casting process are usually dimensionally stable, long-lasting, and maintain close tolerances which ensures that the product functions properly.

Steps For Titanium Die Casting

To create the perfect end product, you need to follow the right titanium die casting process. These are the steps for a solid Ti casting.

Processing of Raw Material

This initial stage involves the extraction of titanium from its ore through the kroll process or the hunter process. But in case it is a small production to be done, you can purchase the titanium alloy parts from a commercial store nearby.

Mold Design

The mold material which can be either sand, ceramic, or metal. Since it’s a titanium die casting process, a die mold is designed according to requirements. Also, specific lubricants can be applied inside the walls of the die mold to allow for easy removal of the casted titanium at the final process.

Melting and Pouring

At this stage, the titanium alloy is melted and injected into the die mold by pouring under high-pressure. It is also known as pressure die casting titanium. Production of large volume Ti casts with intricate shapes and close tolerance is achieved.

Cooling and Solidification

The molten titanium in the mold is allowed to cool and solidify for a while taking the shape of the die to form the desired titanium casting.

Mold Removal and Post Treatment

After solidification, the titanium cast is ejected from the die mold and undergoes post-treatment such as cleaning, polished, or deburred to get the final finished titanium die casting component.

Applications of Titanium Die Castings

There are several ways you can leverage Titanium die casting across industries. They include the following:

Aerospace Components

Due to their strength and ability to withstand corrosion and harsh conditions, titanium die castings are crucial in creating airplane parts, accessories, and even engine components.

Medical Component

Titanium die castings are considered highly biocompatible. This feature alone makes them the ideal choice for several medical components and tools. You can use titanium alloys in dental and surgical implants. And they can even serve as artificial joints for people who have mobility issues.

Automotive Component

Its low weight and high strength is a combination that makes titanium die casting one of the best materials you can use to produce parts for high-end luxury cars that look shiny but remain solid. They make great suspension systems and chassis.

Bicycle

Titanium die casting makes parts and components for different types of bicycles. Because of its durability, these parts last very long as frames and can withstand different riding conditions.

Sports Equipment

Sports equipment also needs to be durable and not susceptible to corrosion. Titanium die-casted parts make golf clubs and shop parts that last and remain in great condition whenever you use them.

Chemical Tools

You can use titanium die casting alloys to make reactors and heat exchangers that handle different kinds of chemicals and temperature levels.

Conclusion

This article has shown how important Titanium alloys are for industrial needs. Much more than that, we’ve also seen that subjecting them to titanium die casting processes can yield important titanium parts relevant for high-in-demand needs.

At HM, we take pride in being one of the best titanium cast parts manufacturers. We use state-of-the-art facilities under the highest industry standards to produce the best components for our clients. Contact us now for premium die casting services.