Since its discovery in 1913, the development and use of stainless steel has grown by leaps and bounds. With the high demand for complex, high-precision CNC steel parts that are strong, corrosion-resistant, and durable, your venture into stainless steel Computer Numerical Control (CNC) machining is a step in the right manufacturing direction!

This post takes you through the different categories and grades of SS to consider for your CNC machining. Further, it discusses the general benefits of SS CNC machining, tips on addressing the key challenges you are likely to face, and industry application areas.

Understanding Stainless Steel CNC Machining

Stainless steel CNC machining is a cutting-edge production technology that uses computerized machines to efficiently and accurately produce high-precision stainless steel parts.

Therefore, you require a Computer Numerical Control (CNC) machine with suitable machining tools.

So, stainless steel CNC machining requires that you have a digital design of the part you intend to produce.

Computer-aided manufacturing (CAM) software helps you translate the part’s digital design into a language or code that your machine can read and send machining instructions to the tools.

Because instructions can be saved, this technology allows you to automatically undertake repeated tasks efficiently with no risks of errors commonly witnessed in manual machining approaches.

The 3 Main Stainless Steel CNC Machining Processes

Stainless Steel Machining entails the following three processes:

- SS CNC Milling: This is the process of producing high-precision stainless steel CNC milling components using special CNC rotating cutters.

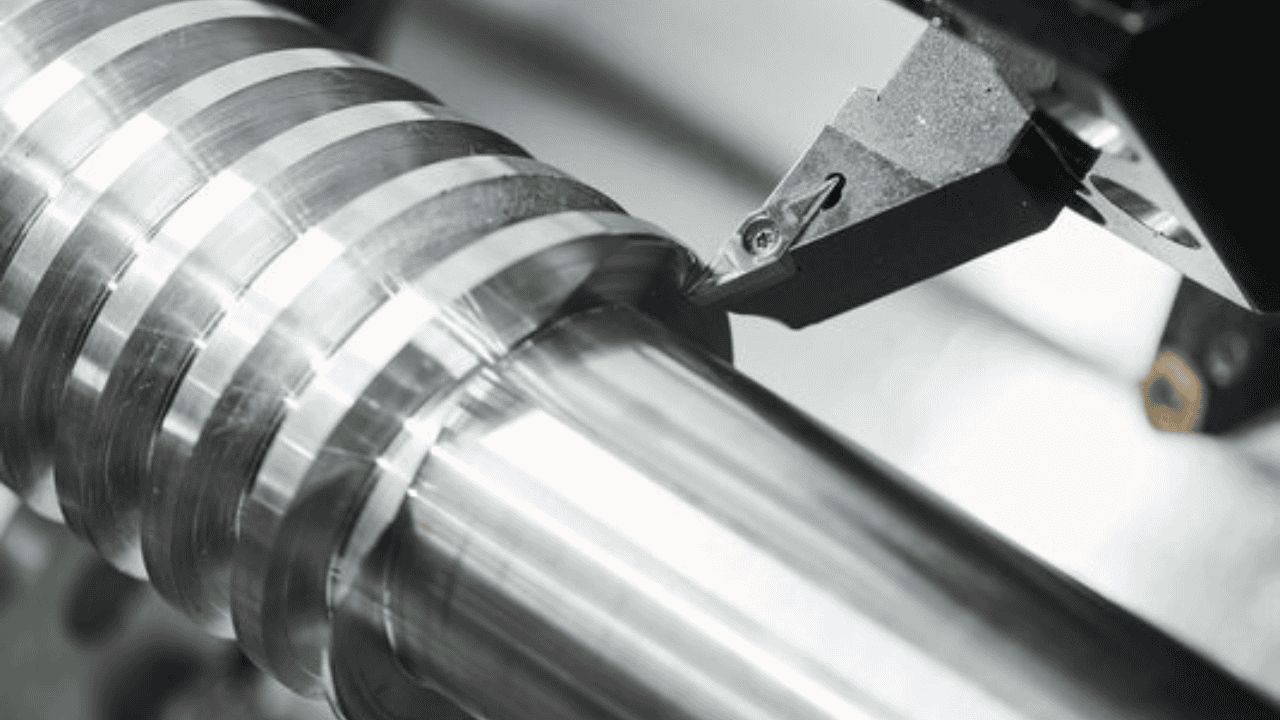

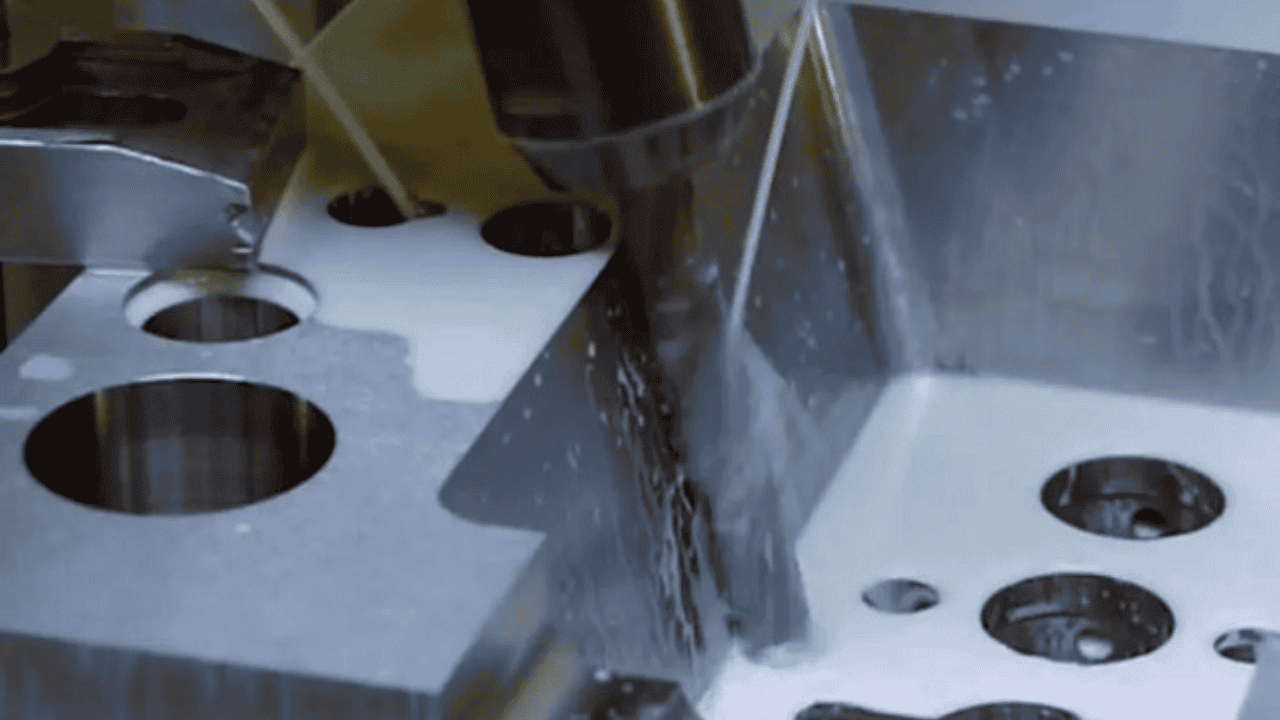

SS CNC Turning: This is a CNC machining process where the stainless steel workpiece rotates around a suitable cutting tool to form a desired SS part. A complete guide on CNC turning is here. - SS CNC Drilling: This refers to making holes or threads of specific sizes on stainless steel CNC drilling parts.

Types of Stainless Steels & Grades for CNC Machining

There are five types or categories or families of stainless steel. Under each category are SS grades you can choose from to suit your various CNC parts. Here are things you should consider when selecting SS grades for CNC machining

Below are the 5 SS categories and grades you should know about.

Austenitic Stainless Steel

As the name suggests, austenitic stainless steel has an austenitic structure. This Stainless steel grade is non-magnetic and is the most commonly used steel alloy in CNC machining. About 70% of stainless steel produced belongs to this family.

The material’s main alloy elements are nickel and chromium. Manganese, Nitrogen, and Molybdenum. Other elements may be added to achieve the desired properties.

Some of the properties that make Austenitic stainless steel ideal for your CNC machining parts are its:

- Weldability

- Formability

- Corrosion Resistance

Austenitic Stainless Steel Grades

Below are some of the most common austenitic stainless steel grades you can consider for your various CNC machining projects.:

301 Grade Stainless Steel

If your stainless CNC machining requires parts with high strength, resistance to corrosion, and good formability, this is the grade you can consider for CNC machining.

302 Grade Stainless Steel

Besides having chromium and nickel, this SS grade boasts a high carbon content. Its high strength and corrosion resistance make it suitable for CNC machining complex stainless steel parts.

303 Grade Stainless Steel | Free Machining Stainless Steel.

This is the easiest-to-machine stainless steel for CNC machining. Its sulfur composition makes it a free-machining stainless steel grade. However, the effect of this is the reduction in corrosion resistance and hardness properties.

304/304L/304H Grade Stainless Steel

304 is a versatile and balanced stainless steel grade of iron, chromium, nickel, carbon, and other enhancement elements.

304 alloy steel is also known as 18/8 stainless steel. This is because of its standard chromium and nickel compositions, which are 18% and 8%, respectively.

The SS grade boasts high strength and corrosion resistance. This makes it a versatile material for CNC-machined stainless steel parts.

316 Grade Stainless Steel

316-grade stainless steel is a top contender for steel alloy parts where toughness and corrosion resistance are critical.

The SS grade is enriched with molybdenum, making it more corrosion-resistant with excellent performance at high temperatures than 304 alloy steel. Manganese enhances its weldability and formability, making it ideal for various stainless steel CNC machining projects.

Alloy 20 Stainless Steel

Also known as Carpenter 20, this austenitic stainless steel grade is suitable for CNC machining of parts with high corrosion resistance, including resistance to sulfuric acid.

321H Stainless Steel Alloy

321H stainless steel is a high-carbon alloy with added titanium, which helps limit chromium carbide precipitation.

The precipitation occurs at temperatures ranging from 425 to 800 degrees Celsius (797 to 1472 degrees Fahrenheit) depending on alloy compositions.

Therefore, this grade is suitable for producing stainless steel CNC engine parts or components that perform under high-temperature conditions.

309S Alloy Steel Grade

Another austenitic grade for CNC machining that performs at high temperatures is 309S stainless steel. Its high chromium content makes it highly resistant to oxidation. The addition of nickel enhances its strength.

Ferritic Stainless Steel

Ferritic stainless steel belongs to the AISI 400 series of stainless steel.

They are magnetic steel alloys with superior thermal conductivity compared to austenitic types.

Its main composition is iron, carbon, and high chromium. It may have little or no nickel. Compared to austenitic stainless steel, Ferric SS is much easier to machine.

Because this SS cannot be heat-treated, it is not as tough as austenitic alloys. However, its good corrosion resistance makes it suitable for stainless steel CNC machining of marine or decorative parts.

Grades of Ferric Stainless Steel for CNC Machining

There are various grades of ferric stainless steel to consider for your CNC machining. Some common grades are 405 SS, 409 SS, 430 SS, and 442 SS.

Read more about Ferric stainless steel grades here.

Duplex Stainless Steel CNC Machining

This class of stainless steel grade contains both ferric and austenitic families of stainless steel. It is suitable if your CNC machining project demands high-strength stainless steel parts with excellent corrosion resistance.

This category is subdivided into:

- Standard duplex stainless steel grade

- Normal Duplex stainless steel grade

- Super Duplex Stainless steel grade

Common examples of duplex stainless steel you may need for your CNC machining include:

- Duplex 2205 Stainless Steel

- Duplex 2507 stainless steel

- Duplex 2304 stainless steel

Martensitic & Precipitation Hardening Stainless Steel (PH SS)

Martensitic stainless steel is composed of Chromium(11.50 to 18%), with carbon and nickel added. The category is divided into high-carbon and low-carbon martensitic stainless steel.

They are suitable for projects that demand parts with high strength, superior toughness, and corrosion resistance. Some of its popular grades are:

- 410 Stainless Steel

- 420 Stainless steel

- 440A Stainless steel

Read more on Martensitic stainless steel and its grades here.

Precipitation Hardening Stainless Steel (PH SS)

In addition to the standard Fe-Cr-Ni alloy composition, this SS family is enriched with small quantities of other elements to attain the desired properties.

The additive elements may include titanium, aluminum, copper, and Niobium.

PH SS can be placed into three categories namely:

- Martensitic PH SS

- Semi-austenitic PH SS

- Austenitic PH SS

Some common PH SS grades for stainless steel CNC machining are 17-4 PH, 17-7 PH, and A-286.

Further reading on PH SS is here.

General Advantages Stainless Steel CNC Machining

Here are their general benefits for choosing SS for CNC machining:

Good Corrosion Resistance

SS CNC parts have good corrosion resistance. This is because it is composed of chromium, which reacts with oxygen to create a protective outer layer.

Production Versatility

Various grades of stainless steel allow for the easy production of different CNC-machined parts to suit industry requirements.

High Tensile Strength CNC Parts

SS CNC machining ensures you produce high-performance parts with high tensile strength. This is possible because of its various alloy elements such as chromium, nickel, titanium, molybdenum, etc.

Captivating Surface Finish (Aesthetic Property)

Stainless steel CNC machining ensures you produce parts that exude a shine of beauty!

The more chromium your chosen stainless steel has, the more your machined parts will shine without getting tarnished with time.

Low-Temperature Tolerance | Cryogenic Resistance

Stainless steel grades such as 304 and 304L maintain their properties even at low temperatures with no risk of brittleness or cracking.

Stainless Steel CNC Machining Challenges and Solutions

SS Workpiece Deformation Due to Poor Setting or Overheating

Stainless steel has a lower thermal conductivity. This leads to heat accumulation that can affect your cutting tools, resulting in distorted parts. Improper setting of the SS workpiece can also lead to deformation..

Solution:

Ensure your CNC machine is configured to operate at a moderate speed and feed rate. Always ensure you use the right tool and in perfect condition.

If during the machining process, you notice overheating signs, stop the machine. Let it cool down as you check possible causes.

To contain heat accumulation, you must have an efficient cooling system. Oil-based coolant will serve you well.

Chip Formation

SS CNC machining produces long chips. If not removed, they are entangled around your tool causing overheating. This can cause damage to your machine, workpiece surface, and cutting tool.

Solutions:

- Use a high-pressure coolant system to remove the SS chip from your workpiece during CNC machining.

- Consult an expert machinist to advise on the most suitable chip breaker to purchase

- Use sharp cutting tools to limit the production of excess chips.

Machinability Challenge Due to Work-Hardening

Stainless steels are generally more difficult to machine than softer alloys such as aluminum. This is due to their high strength and work-hardening properties.

Solution:

- Select cutting tools that are resistant to wear and suitable for your machining.

- Embrace the climb-milling/down-milling technology.

- Configure your CNC machine settings to suit your SS material and size.

More tips on how to avoid work-hardening is here

High Cost of Cutting Tools

Because SS is harder than softer metals. Because of this, they require expensive premium cutting tools.

Solution

- Only use wear-resistant tools suitable for your stainless steel grade. Seek help from an expert machinist.

- Ensure your cutting tools are sharp because blunt tools cause overheating, resulting in tool damage.

- Optimize your cutting process by selecting the right stainless steel grade, setting suitable parameters, and having an efficient cooling system in place.

Industrial Applications of Stainless Steel CNC Machining

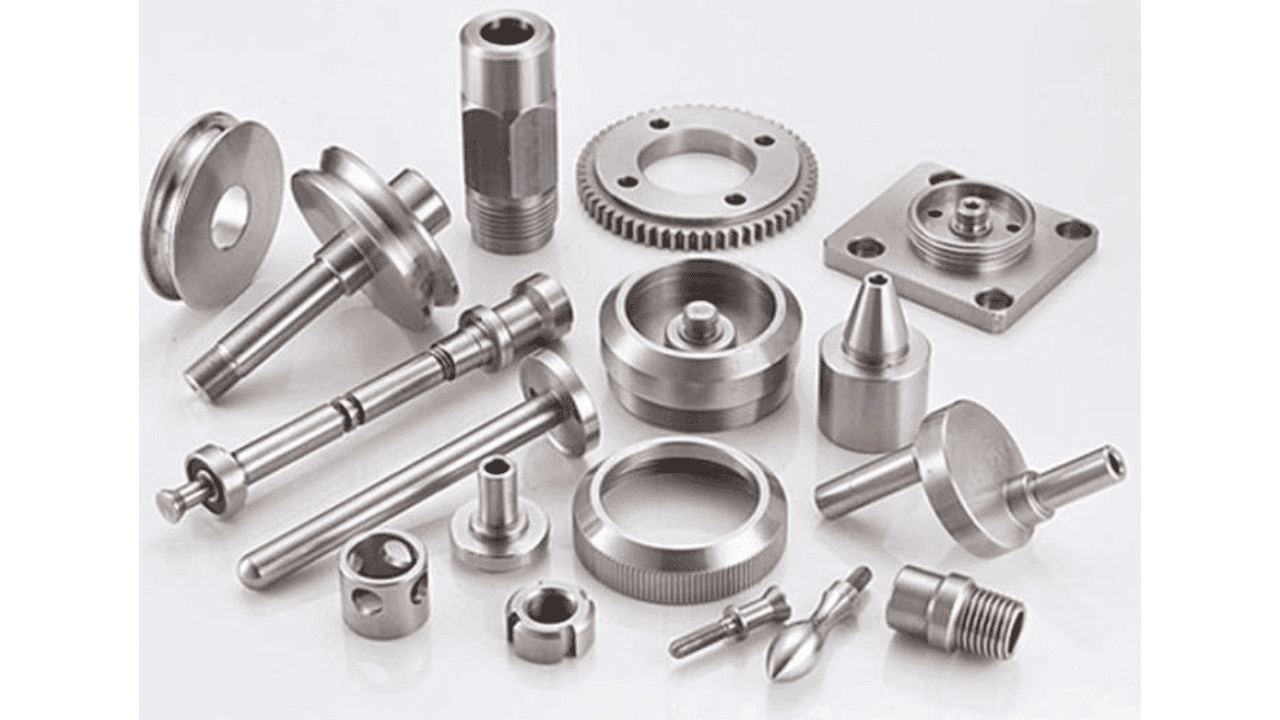

There are over 100 grades of stainless steel. Therefore, stainless steel CNC machining allows you to produce a wide range of parts for different industry applications.

Below are the main industries that use CNC-machined stainless steel parts.

Automotive Industry Applications

In the automotive industry, CNC machining with stainless steel helps produce high-precision auto parts such as axles, shafts, exhaust components, engine parts, and brake lines.

SS CNC Parts for the Hardware Industry

The hardware industry also depends on CNC machining for its SS CNC hardware parts. These include but are not limited to hinges, fasteners, stainless steel wheels, spacers, and many more!

SS CNC Parts for Aerospace

The aerospace industry depends on SS CNC machining for its supply of high-performance stainless steel CNC aerospace parts. These parts boast strength, excellent corrosion resistance, and high-temperature tolerance. Such parts include hinges, landing gears, bushings, clamps, etc.

Stainless Steel CNC Machining for Marine Industry

SS CNC machining provides the marine industry with corrosion-resistant stainless steel parts such as shafts, engine propellers, and marine-based hardware components.

SS CNC Machining for the Medical Sector

The medical sector relies on stainless steel machining for high-precision CNC medical parts for surgical instruments, ligation devices, forceps, catheters, etc.

Conclusion

SS CNC machining requires an in-depth knowledge of SS materials, the type of tools you need, and how to address possible challenges.

For smooth CNC machining, you must engage the services of a machining expert.

HM has the manufacturing capacity and capability to support your SS CNC machining requirements. If you require a manufacturing partner you can trust, contact us.