Does your manufacturing project require the use of copper or copper alloys to produce parts through die-casting process? This article explains how this cost-effective manufacturing process works, the common copper alloys you can choose from and why, available die-casting techniques you can use, and industry application areas.

The Meaning of Copper Die Casting.

This is a high-pressure die-casting process that involves the injection of molten copper or its alloy into a reusable mold or a die cavity to form components or parts for different applications and conditions.

It is a cost-effective process that allows you to produce large quantities of accurate parts much faster and can be integrated with other production processes.

Copper Alloy Die Casting Equipment/Tools

The high-pressure die-casting process requires high temperatures for heating copper or its alloy, and high pressure for injecting the molten material into the die cavity.

Therefore, apart from the furnace, you require a suitable die-casting machine equipped with a die set, melting furnace, cooling system, locking mechanism, ejection mechanism, trimming mechanism, etc.

Depending on your part application, you may also need other machining tools for post-production processes such as drilling, surface finishing, or polishing where necessary.

Pure Copper or Cu Alloys Die Casting?

Though you can use pure copper die casting in special circumstances for the production of some electrical parts, it is suitable for most manufacturing processes. Why?

Pure copper melts at high temperatures making the die-casting process more demanding and costly.

Again, molten copper readily attracts and reacts with oxygen present in the air to form copper oxide.

So, if you do not control air exposure, the quality of your parts will be affected by the oxidation process. Air dissolved in the molten copper will also result in creating porous parts. Further, the thermal stress during the cooling process results in shrinkage porosity, exposing your parts to cracks and high breakage risks.

So, because of the above challenges, Cu alloys are always the best choice for your die-casting projects.

The added elements ensure the process runs smoothly while ensuring that die-cast parts have properties that suit various applications and conditions.

Common Cu Alloys for Die-casting

Unlike some die-castable materials such as Zamak alloys that have limited grades, there are more than 400 variations of Cu alloys! Let’s explore some of the 4 most common ones:

Copper-Aluminum Alloy (Aluminum Bronze)

Aluminum-bronze is a Cu alloy composed of up to 12% aluminum with smaller percentages of other elements such as nickel, iron, or manganese to enrich its properties.

Its high strength and corrosion resistance make it ideal for high-stress die-cast auto parts or components for marine environments.

Copper-zinc alloy (Brass)

Brass is an alloy of copper and zinc with copper being the base metal.

Copper composition can be as low as 60% or as high as 90% depending on the desired properties.

There are various types of brass alloys you can choose from to suit your die-casting requirements.

Copper-zinc alloy boasts good machinability, corrosion resistance, and aesthetic outer shine.

It is your ideal material for the cost-effective production of large quantities of complex die-cast parts such as ornaments, musical instruments, or hardware fittings.

Copper-Tin Alloy (Bronze)

Some of your Cu-alloy die-casting projects may require bronze as your production material.

The alloy helps in producing die-cast parts that can withstand harsh working conditions.

They also have high tensile strength, are resistant to corrosion, and can withstand tear and wear.

Some of the parts you can die-cast from bronze are door locks, door handles, sink faucets, etc.

Copper-nickel alloy (Cupronickel)

The combination of nickel to copper makes the alloy, cupronickel, to be strong and more resistant to corrosion. The ratios of the two metals vary to suit different application and environmental requirements.

For instance, for copper-nickel die casting of auto parts, cupronickel with 90% copper and 10% nickel is your ideal material.

However, if your copper die-casting parts are for marine environments, cupronickel with 70% copper and 30% nickel will be ideal.

Note: Apart from the common copper alloys you can use for die-casting parts, there are other patented alloys for specific part requirements.

2 Main Copper Die Casting Methods

Below are the two techniques or methods you can use to die-cast parts from copper alloy materials.

Copper Cold Chamber Die Casting

Cold chamber copper die casting requires that you melt your copper or copper alloy material in a special furnace. Having a separate heating place is necessary because copper has a high melting point.

Note: If the heating system is within your die-casting machine like in hot chamber die casting, the extremely high temperature that copper requires to melt will surely damage it.

So, when the right high temperature is attained, the molten material is transferred into a cold machine chamber from where it is injected into the die cavity at high pressure. The cooling process immediately follows to form a die-cast part.

Benefits:

- Suitable for copper die casting because of the metal’s high melting temperature.

- It allows you to produce intricate copper die-casting parts with high precision.

- It forms parts with desirable mechanical properties and a high-quality outer finish.

Limitations:

- You require more energy for the heating process.

- The melting process takes longer, which lowers the production rate.

- Since copper cools very fast, defects such as shrinkage porosity are common.

Vacuum Cu Die Casting

Copper vacuum die casting involves the use of a vacuuming system that removes gases and air from your die-cavity before high-pressure injection of the molten Cu.

Benefits:

- The method produces high-quality pasts free from porosity or other casting defects

- It allows for the die-casting of complex Cu alloy parts with superior surface finishes

Limitations:

- The vacuum system makes your copper die-casting process more complex

- The initial investment cost is high because the machine is expensive

Industry Applications of Copper Die Casting

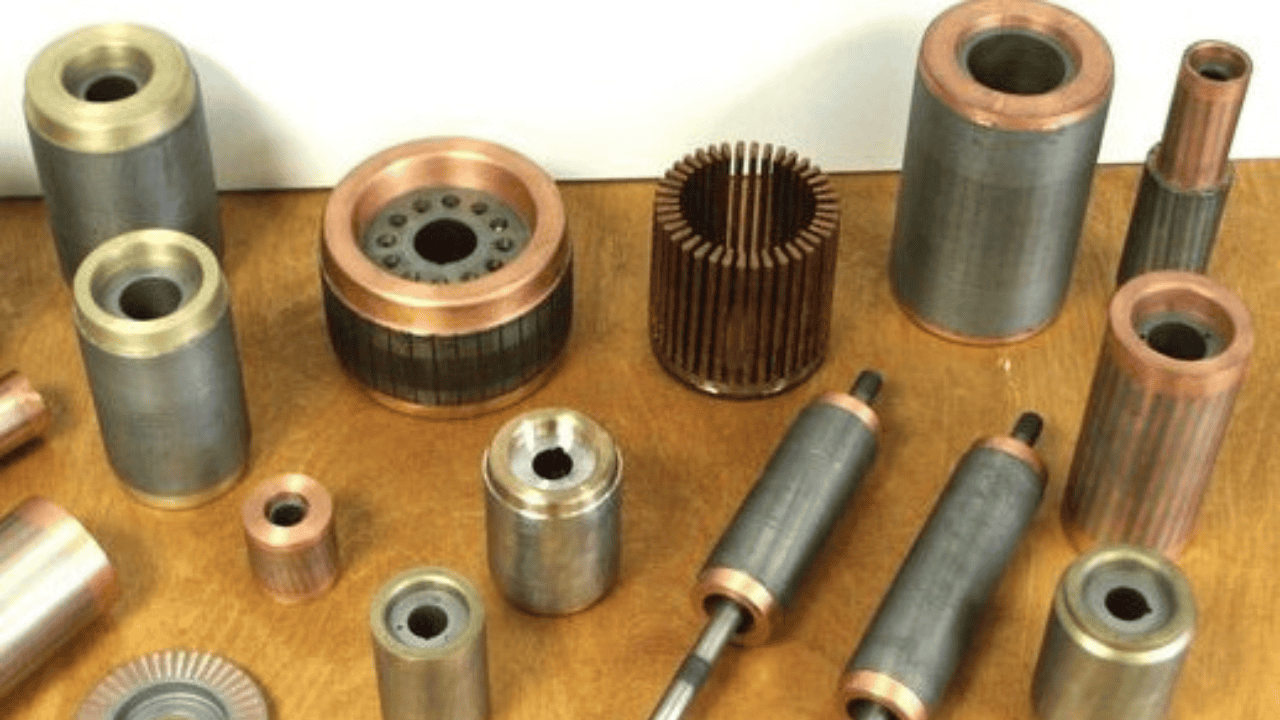

With copper alloy die-casting manufacturing, you can produce a wide range of parts targeting different industries. Let’s appreciate how various industries make use of this manufacturing process.

Automotive Industry

The strength and high thermal conductivity of copper make it suitable for producing certain die-cast auto parts.

Some automobile manufacturers rely on Cu-alloy die casting to produce heat exchanger parts such as radiators.

Electric vehicles (EVs) use motors, battery connectors, and busbars made through Cu die-casting.

Copper Die Casting for the Aerospace Industry

In the aerospace industry, Cu-alloy die casting is adopted in the production of some high-performance parts that can withstand high temperatures such as bushings and brackets.

On parts where high electrical conductivity is desirable such as the aerospace’ electric grid or engine control systems, die-cast copper connectors are used.

Electrical and Electronics Industry

The high electrical conductivity of copper makes it ideal for the manufacturing of certain electrical parts.

These can be in the form of electrical dust bars, sockets, connectors, circuit breaker parts, heat sinks, and heavy-duty battery terminal lugs.

Other electrical parts you can produce through Cu alloy die-casting are switchgear components such as enclosures and contact holders.

In equipment where heat management is necessary, copper alloy die-cast housings or casings are used.

Plumbing Industry

In the plumbing industry, copper alloys such as brass and cupronickel find their use in die-cast parts such as water valves, couplings, and water pipe fittings.

Marine Applications

Copper alloy die-cast parts also find application in marine conditions where corrosion resistance, wear resistance, and durability are desirable. Some of the copper die-cast parts that find use in such harsh environments include hinges, pumps, valves, and rail fittings.

Consumer Appliances and Furniture Hardware

Consumer electrical appliances such as refrigerators, electric ovens, and cookers have die-cast parts that provide high thermal conductivity. These are in the form of connectors, electric casings, or furniture fittings.

Conclusion

Copper die casting requires a comprehensive understanding of Cu and its alloys.

To produce high-quality die-cast parts with high strength, corrosion resistance, and appealing outer finish, you must choose the alloy that suits parts specifications.

Working with an expert is critical in ensuring that your production fulfills project demands.

HM is your one-stop shop for custom die-casting parts and much more!

For inquiries on how we can assist you deliver parts that suit your project needs, contact us.