Do you work on a special project and suddenly need a copper part that fits perfectly? Obviously Copper CNC Machining is the solution. Because this process can fastly create the parts you need.

Moreover, it saves your time and effort. In this article we will explore how exactly this process works. We will also cover its applications and advantages.

What is Copper CNC Machining?

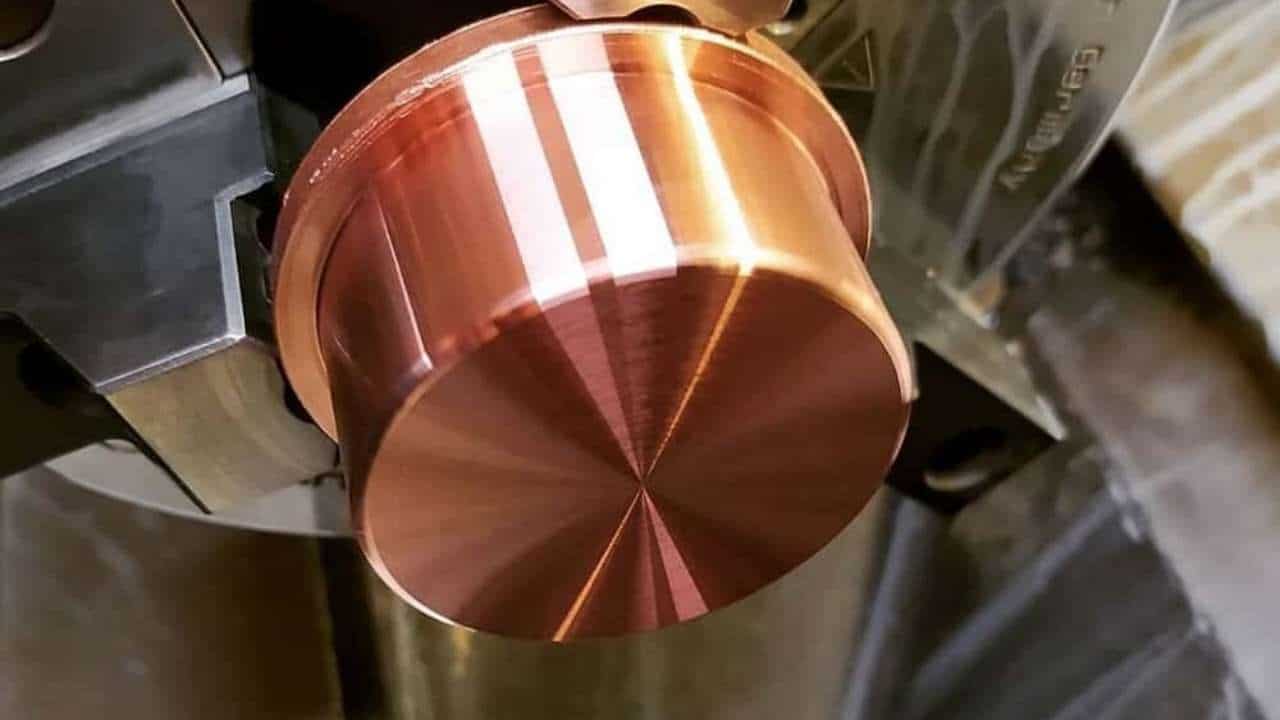

If we talk about CNC machining of Copper, it is basically a process in which you can make different high-precision components and tools for the automotive, electronics and healthcare industries. To achieve your product’s required shape, you can easily do the cutting, milling, grinding and drilling of copper by using CNC.

5 Common Types of Copper for CNC Machining

Oxygen Free Copper

Copper is made refined by using a special process, in which oxygen is removed. OFC(Oxygen Free Copper) has less than 0.001% oxygen. OFC is a better conductor of electricity and heat, making it a much more refined composition.

You can divide OFC into two further grades, one is C10100(Oxygen Free Electronic Copper)OFE and the other is C10200(Oxygen Free Copper)OF. The first one is 99.99% pure and used in highly sensitive areas, such as aerospace and vacuum electronics. The second is 99.95% pure and used in high-end cables and industrial applications.

Beryllium Copper

Beryllium copper is a combination of copper with a small portion of beryllium, which is about 0.5-3%. With the addition of beryllium and other trace elements, it becomes more suitable for machining and industrial uses. If you want a non-magnetic, resistant to corrosion and high-conductivity alloy, then this is useful for you.

There are three grades of beryllium copper: the first is C17200, the second is C17300 and the third is C17500/510. It has wide applications in aerospace, healthcare and defense purposes.

Electrolytic Tough Pitch Copper

This is also known as ETP. In ETP, 99.90% is pure copper and 0.02-0.04% oxygen is added through the electrolyte refining process. ETP is used for electrical transmission in transformers, busbars and switchgears. It has high electrical and thermal conductivity. You can use it easily because of its low cost and wide applications.

Tellurium Copper

Tellurium copper is a copper alloy that contains a small amount of tellurium up to 0.5%. This small amount of tellurium makes it perfect for machining. Although electrical conductivity is compromised a little, however, it has high thermal conductivity. It is classified as C14500 in the UNS system. Tellurium copper has a wide set of applications, including welding tips, switchgear, semiconductors and vacuum tube components.

Top Advantages of Copper CNC Machining

-

Excellent Corrosion Resistance

Copper forms a layer of patina that prevents further corrosion by acting as a protective layer. That means when you manufacture Copper CNC machined products, they will definitely be resistant to acids and alkalis (like sulfates, chlorides and nitrates).

-

Easy to Shape and Cut

Copper is usually soft compared to other metals for cutting into different shapes. Due to its high thermal conductivity, it dissipates heat, so it doesn’t harm the tool as well. However, despite its high machining ability, its gummy nature can cause damage to tools. So you should always try to use carbide or high-speed steel (HSS) tools.

-

Thermal Conductivity

This has a high thermal conductivity of around 385-400 W/m.K. As a result, you can easily shape copper into your required size and geometries during CNC machining. This thing also reduces the tool wear, maintains dimensional accuracy, improves surface finish and enables high-precision applications.

-

Strong and Durable

Copper is a strong and durable material that is ideal for CNC machining. Although it is not as strong as iron or steel, however, you can bend it to the required shape without breaking it.

-

Good Electricity Flow

Lastly, Copper is a strong conductor of electricity. Hence, if you choose to CNC machine Copper, it will be perfect for wide applications. You can use copper to manufacture CNC machined products in aerospace, electrical transmission, automotive, renewable energy and defense.

Practical Applications of Copper in CNC Projects

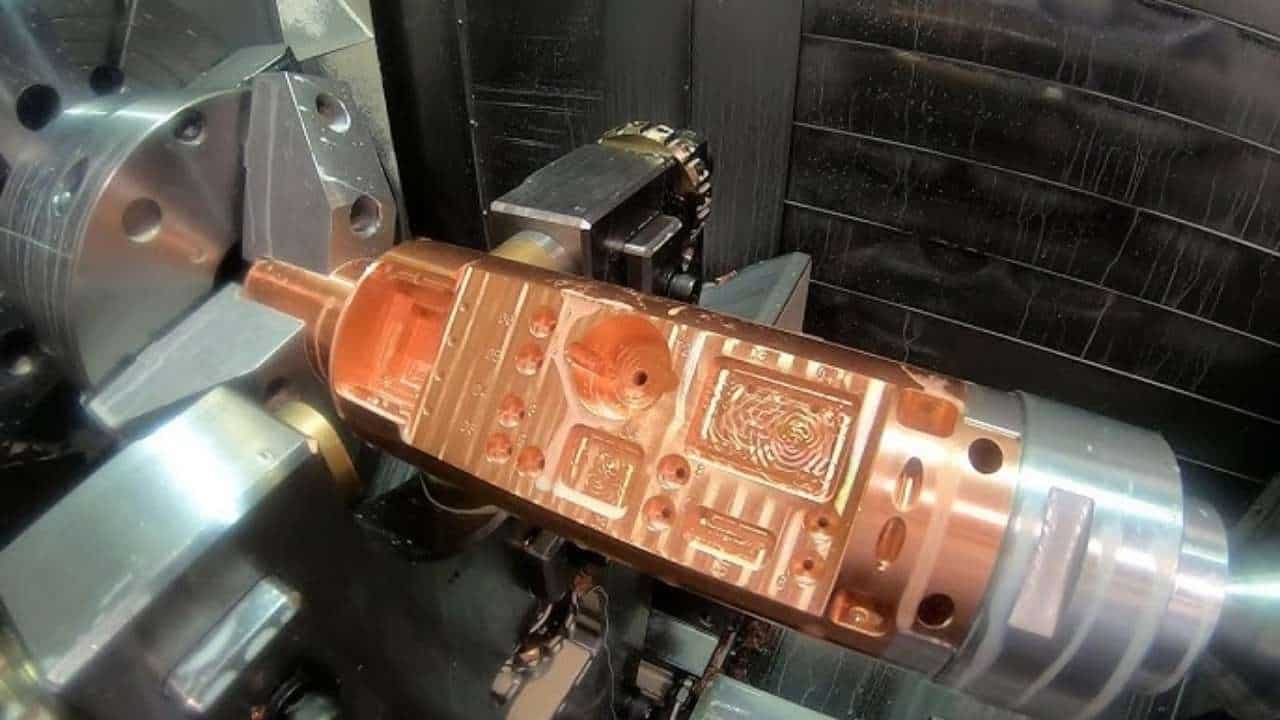

- Aerospace & Automotive Parts

In the aerospace and automotive industry, heat exchangers and cooling systems are made by copper CNC machining. Besides this, microwave components, vacuum, cryogenic components & electromagnetic shielding structures.

In the automotive industry, battery connectors, bus bars, heat sinks for power electronics, welding electrodes, sensors and switch components. Along with this, motor windings and rotors in EV vehicles.

- Plumbing Fittings

In Plumbing fittings, copper pipe connectors, elbows, threaded adapters, compression fittings and flare fittings are used. Some other copper CNC-machined plumbing fittings are sweat fittings and custom water manifolds.

- Electrical Components

There are a wide applications of CNC-machining in electrical components. Some common CNC-machined tools are busbars for electrical panels, copper terminals, lugs, heat sinks, RF, microwave components, battery contact plates and electrical grounding plates.

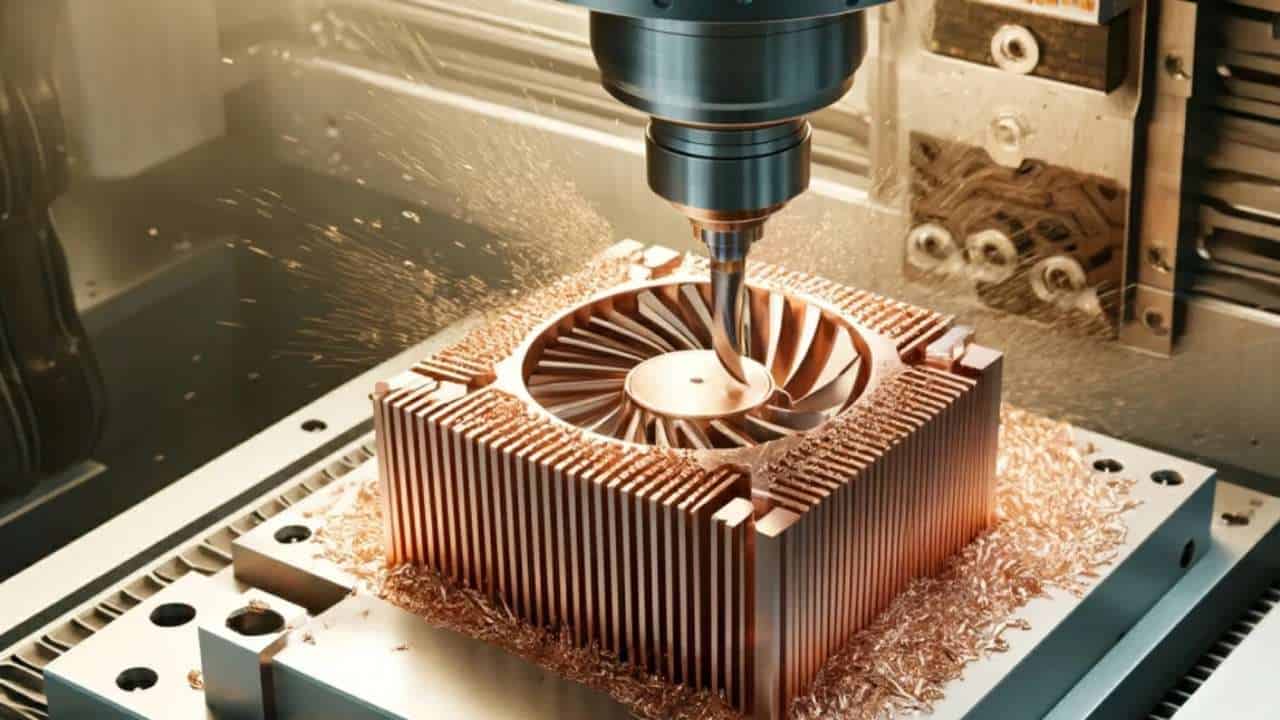

- Heat Exchangers & Radiators

In heat exchangers and radiators, copper-machined copper fins, copper manifold blocks, cold plates for the liquid cooling system, radiator tanks & end caps are used. Besides this, heat exchanger headers, microchannel heat exchangers and brazing-ready copper blocks are also used.

- Decorative Hardware

In the decorative industry, there is a wide applications, including, custom copper door handles, knobs, architectural trim, edging and engraved copper nameplates. There are also some more applications, like copper grilles, luxury light fixtures, custom drawer pulls and cabinet handles.

How Tolerance Affects Copper Machining

Tolerance is the level of deviation from the original dimension and sizes. Low tolerance means that you have a narrow window to deviate from the original dimension & high tolerance is vice versa.

If you set the tolerance level high, then it means you need strong supervision, advanced tools and control over the softness of copper and its thermal conductivity. Tight tolerance is adopted to make highly sensitive parts for the aerospace and marine industries.

Low tolerance is acceptable for making decorative hardware, where ±0.1 mm is allowed. Tight tolerance needs a high budget because of using carbide tools and following tight guidelines.

Considerations You Should Know For Copper Machining

- Copper Grade

Copper grades are important in determining the priorities. You must know how much strength, softness, thermal conductivity and electrical conductivity you require for different applications. Different alloys of copper have different grades, like OFC, ETP, Tellurium Copper, and Beryllium Copper. These alloys are further divided into different grades, depending on their conductivity, oxygen content and softness.

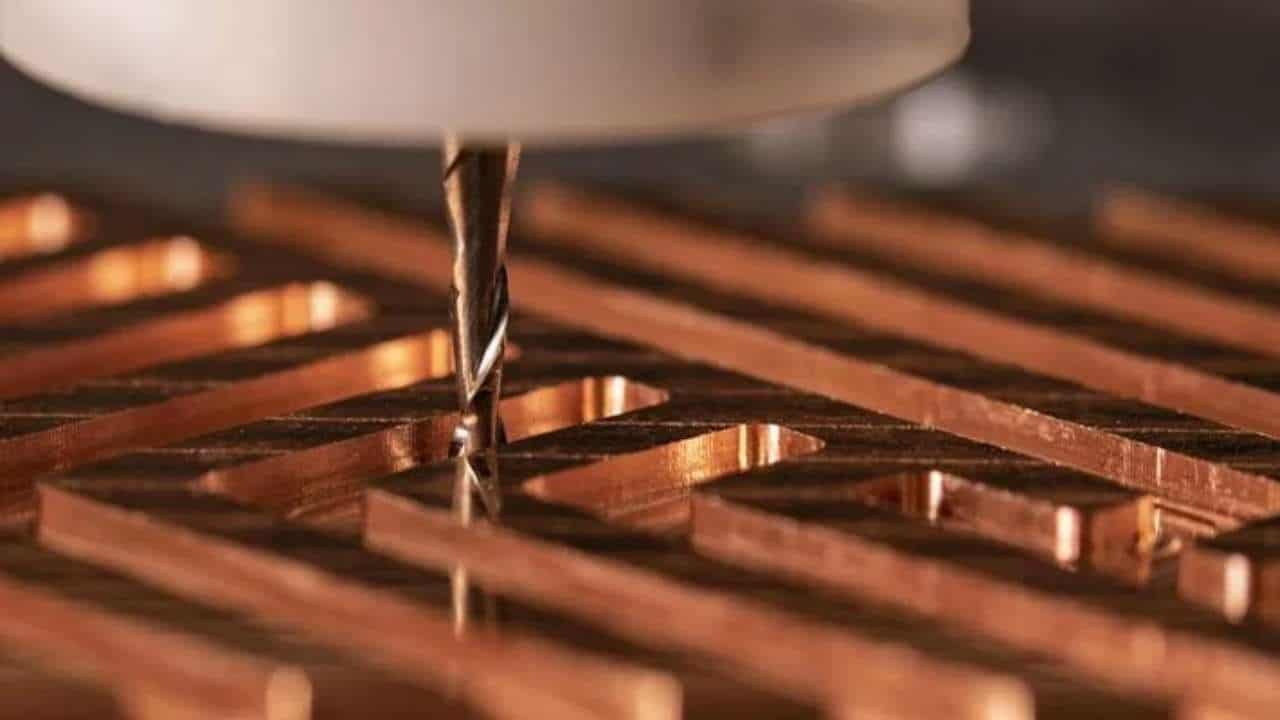

- Tool Selection

Tool selection in copper CNC machining depends on the type of copper grade you are using, the process that you are opting for, the shape you require and the tolerance level. Usually, polished carbide tools are effective for copper CNC machining. ZrN-coated tools are also used in CNC machining.

- Cutting Speed

It is very crucial in CNC machining, as copper is a soft and highly conductive material. So, its cutting speed decides the final surface finish, machining efficiency and tool life. Low cutting speeds can cause a built-up edge and high speeds can reduce friction and result in a better product. The recommended speed for a carbide end mill tool is 200-500 m/min.

- Cooling and Lubrication

Due to thermal conductivity, the heat dissipates from copper, which can cause sticking of copper to tools. Cooling and lubricating the copper can reduce tool wear, increase the surface finish and prevent chip welding and clogging.

- Chip Control

Chip control is important in the CNC machining process. Copper is a soft and ductile metal that can lead to chip generation, which ultimately causes tool wear and poor surface finish. You must control the chip to improve safety, ensure dimensional accuracy & increase the process efficiency.

- Surface Finish Requirements

The final surface finish is important in defining the performance and lifespan of copper components. A refined surface finish improves electrical and thermal conductivity, it also improves sealing and mating with other parts and it has corrosion resistance as well.

- Machine Stability

The machine should be precise to produce refined copper components with a better surface finish. A small vibration in the machine can lead to a poor surface finish, tool wear and other issues. So you must keep your machine fit and stable.

Conclusion

To summarize, we can say Copper CNC machining is a powerful process that you can use in many industries. It doesn’t matter if your business is related to electronics, automotive and others. We are sure this smart technology can help you well in all scenarios.

Related resources:

Choosing the Best CNC Machining Provider – Source: HMAKING

Micro Machining – Source: HMKING

3-Axis CNC Machining – Source: HMKING

Copper Alloys – Source: SCIENCE DIRECT