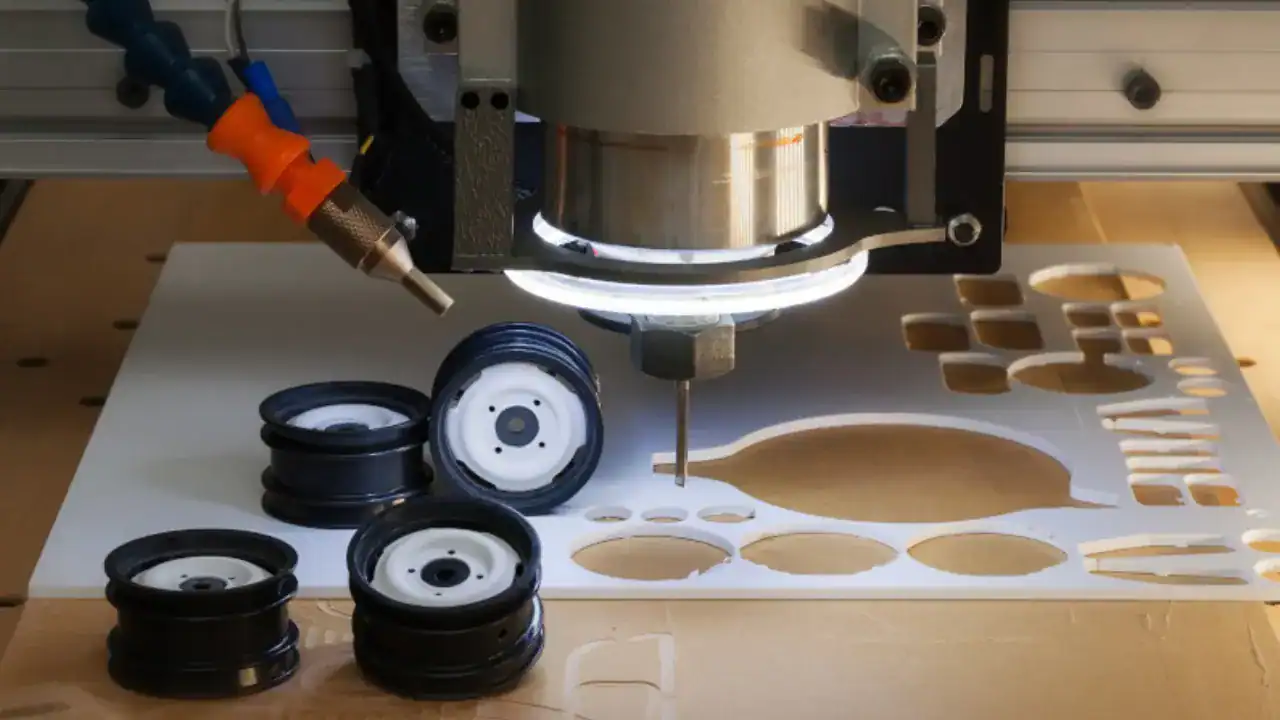

ABS CNC machining is a cost-effective manufacturing process that is used to produce ABS parts more efficiently.

These CNC machined ABS parts have been widely utilized in various industries because of its cost effectiveness, toughness, versatility, high strength impact and other properties.

However, there are specific and important guidelines to consider in order to achieve optimal results when machining ABS plastics.

What Is ABS?

Plastic components

ABS, also acrylonitrile butadiene styrene, is a common thermoplastic material that is used in 3D printing, injection molding, and many other applications.

The CNC machine plastic parts are used in components like washing machines, dashboards, electrical enclosures, vacuums, furniture, prototypes, and others.

Also known for its excellent toughness, good electrical and chemical resistance, relatively low cost, high strength impact and resilience, ABS material machining has been proven to be a good choice for structural and engineering applications.

It is constituted of three major monomers including acrylonitrile, providing chemical resistance and rigidity, butadiene, which are elastic particles providing strength and ductility, and the styrene which offers a high-quality smooth and glossy finish to the polymer.

Benefits of ABS CNC Machining

Having exceptional and versatile properties makes ABS CNC machining service an ideal choice for engineering applications that requires the use of cost effective hardware parts.

Below are some of the many benefits of ABS CNC machining service across industries:

- It is cost-effective and offers diversity

- ABS plastics have high tensile strength

- It is suitable for quick and low-volume production

Plastic molds

General ABS Material Machining Properties

These are the major characteristics of an ABS CNC machine plastic parts:

Tensile Strength, Yield (MPa):

It is the ability of a plastic material to withstand maximum tensile stress and strain when being pulled or stretched, while CNC machine plastic parts yield strength is the point at which the plastic begins to undergo permanent deformation as a result of stress.

The tensile strength of ABS CNC machining plastic ranges from 29.6- 60 megapascals (MPa).

Elongation at Break (%)

Measured in percentage, it is the ratio of actual and final length of a plastic before it exceeds its breakpoint and snaps multiplied by 100%.

An extensometer is a device that is used to calculate the changes in the length of an object.

Hardness (Shore D)

The Shore D hardness test, also called Durometer Hardness Test, is carried out in ABS CNC machining plastic parts to determine the hardness of the plastic.

This is achieved by penetrating the durometer indenter foot into the sample material under a defined spring force.

The letter D indicates the exact type of durometer used, just like there are Shore A which are used for flexible plastics, Shore R is employed for harder materials such as polystyrene, polycarbonate, and nylon, while Shore D is used to determine the hardness of semi-flexible plastic materials.

CNC machining, plastic parts

Heat Deflection Temperature (°C)

Also known as heat distortion temperature refers to the temperature at which a plastic material deforms under a specified load (a stress of either 0.455MPa or 1.82MPa).

Melting Point (°C)

ABS material machining parts have a relatively low melting point ranging from 190°- 270° making it a desirable material for creating and designing complex and customized parts. Its melting point is usually measured by a dynamic differential calorimeter.

Typical Applications of ABS CNC Machining Plastic Parts

Due to its many versatile properties, CNC machined ABS parts are used in various industrial sectors, especially for constructing hardware prototypes and structural materials.

A few industrial applications of ABS CNC machining services include:

Plastic parts

Automotive

ABS CNC machine plastic parts are employed in the automotive industry because of their rigidity, low weight, high level of shock absorbance, durability, and strength, making it useful in the manufacture of dashboard components, protective bumpers, fenders (the part of a car that covers the wheel).

Electronics and Electrical

The electronic manufacturing industries make use of ABS CNC machine plastic parts in the manufacture of many consumer appliances such as remote controls, phone cases, computer keyboards, power plugs, etc. because of their excellent electrical insulation properties.

Medical

ABS CNC machining parts are of great importance in the medical field because of its ability to withstand various medical sterilization processes like gamma radiation or ethylene oxide (EO). CNC machine plastic parts are used in ultrasound equipment, tendon prostheses, tracheal tubes, compressors, and lab equipment.

Food processing

ABS material machining parts are utilized in the manufacture of food dryers, ovens, refrigerator linings because of their ability to resist strain and abrasion, high insulating, chemical and heat resistance properties.

Expert Tips for Effective ABS CNC Machining

Despite the many benefits and excellent balance of components, there are several pitfalls related with ABS CNC machining.

In this segment of the article, we discussed useful tips for the effective operation of ABS CNC machining services.

1. Use Machine-Grade ABS Plastic

ABS plastics are of various grades including the general-purpose ABS, high-impact ABS, heat-

resistant ABS, and flame-retardant ABS, etc.

However, for more efficient operations, it is important to use the machine-grade ABS plastic when drilling, turning, milling, and precision machining of ABS structural parts.

Machine-grade ABS plastics give a better chip formation, are easy to paint, and leave a smooth surface finish because of its excellent dimensional stability.

2. Use Appropriate Cutting Tools

Selection of tools is a crucial part of CNC machining processes. There are different tools with unique features that are used for different material types and purposes.

Take for instance, the tools that are ideal for cutting titanium alloys or high-strength steel are not suitable for cutting ABS CNC machine plastic parts. This is because both materials have varying tensile strength, hardness and heat deflection temperature.

So for ABS CNC machining service, cutting tools such as carbide end mills, high-speed steel (HSS) tools, and single-flute end mills are recommended because they give fine precision and accuracy, while ensuring good surface finish on the material.

Importantly, always ensure that these tools are always sharpened before use to prevent surface damage of plastic parts especially when working with thin materials.

3. Use Suitable Cutting Fluid

Cutting fluids, also called coolants, are liquids that reduce heat build-up in the cutting zone of a workpiece. It also functions as lubricants, reducing friction between the CNC cutting tools and the chips being removed.

The use of appropriate coolants when carrying out ABS CNC machining service on plastics is of high necessity as it helps in alleviating overheating and the risks of plastic deformation.

This measure here cannot be overlooked, as a use case of wrong coolants can create possible complications during operations.

A typical example could be using the coolants specifically made for metals or ceramics on your ABS plastic machining, this here could lead to contamination of your products leading to wastage.

So, it is highly recommended that you use a non-aromatic, water-soluble coolant such as Cimstar 40B (CimCool Milacron, Cincinnati, OH), Trim 9106CS (Master Chemical, Perrysburg, OH), Polycut (Tullco, Savannah, GA) when fabricating ABS plastic parts.

4. Consider Annealing the ABS Plastic

Annealing is the process of transforming the properties of a material through heating and allowing for cooling to occur slowly, in order to remove internal stress thereby making it easier to machine.

This procedure reduces the hardness of the material while increasing its ductility. It is crucial to anneal ABS CNC machine plastic parts because it lowers the material stress which most times is not visible but causes warping or cracking and affects the final physical properties.

Conclusion

ABS CNC machine plastic parts are widely adopted in various industries because of the many versatile characteristics they possess. However, you need to ensure you get only the highest quality of ABS parts at the best deal possible.

That’s why you should trust HM for all your ABS CNC machining needs. Contact us now to get a quote on various CNC machining services to get you started.