Owing to its ability to form high precision, complex and thin-walled parts, Zinc (Zn) alloy 3 is highly sought after in the manufacturing industries. Its capacity to maintain consistent quality and intricate details in mass production further enhances its value in automotive, electronics, and consumer goods manufacturing. Read on to learn more about its other properties and applications across industries.

What Is Zinc Alloy 3?

This is a top-in-demand alloy used for die casting and other operations. Definitely one of the most coveted alloys, it’s preferred for the incredible finishing it exudes in a casting operation. The alloy came into existence in 1929 and before long, it got a new name that encompasses the different elements it’s made of.

It’s composed of Zn, Al, Mn, and Cu. But when written in German, their periodic names can be abbreviated as Zamak. Hence, most technologists and engineers, including non-English speakers, refer to it as Zamak 3. Its extended dimensional stability has made it the preferred zinc alloy for about 89% die-casting operations in the U.S.

Zamak 3 Mechanical Properties: Physical, Chemical, and Mechanical Compositions

Mechanical Compositions of Zinc Alloy 3

- The elongation at break of the zinc alloy 3 is 10%

- Zamak 3 has a yield strength and tensile strength of 221 MPa and 283MPa respectively

- It also has a Poisson ratio of 0.27 with Young’s elasticity at 96GPa

- Zinc alloy 3 has a fatigue strength of 48MPa and 415 MPa compressive strength

Chemical Compositions of Zinc Alloy 3

These are the material composite of a substance that allows it undergo chemical transformation and they are responsible for its reactivity.

Zamak 3 chemical composition has the the following elemental components in their percentage ratio, aluminum (3.8-4.2), copper (0.03), magnesium (0.02-0.05), iron (0,02), nickel (0.001), silicon (0.02), lead (0.003), cadmium (0.003), and tin (0.001)

Physical Properties of ZAMAK 3

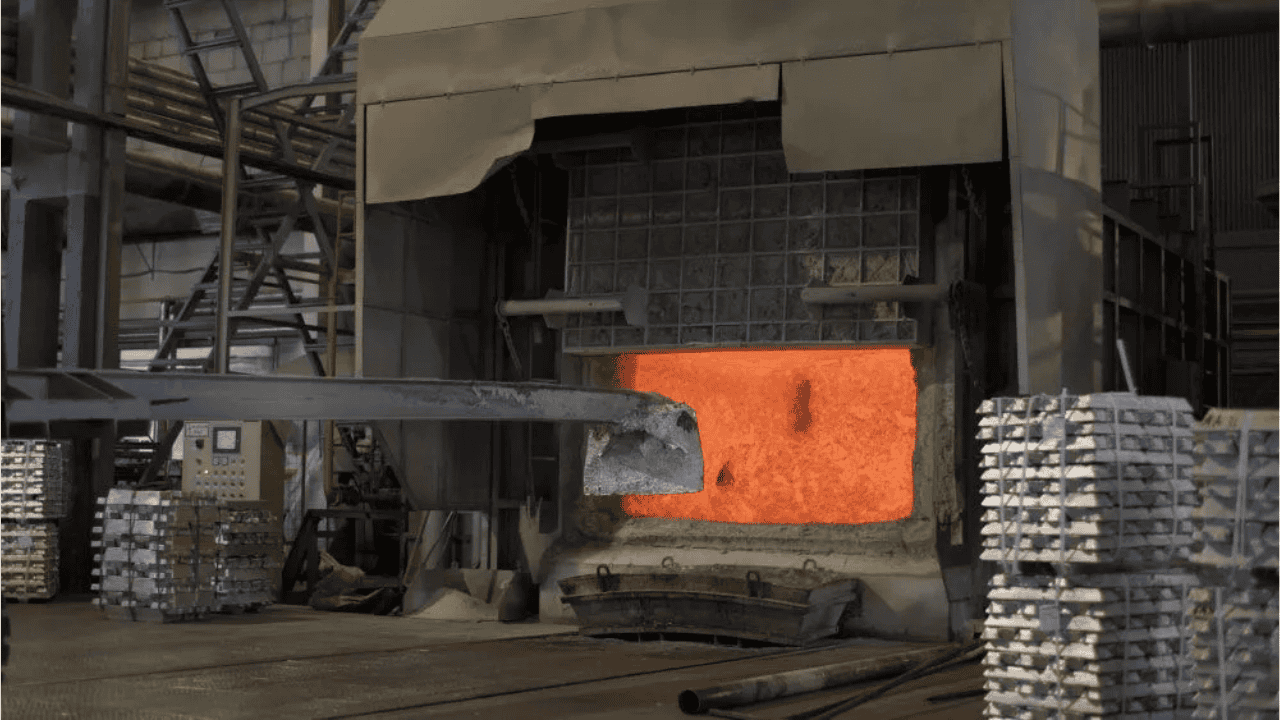

- The Zamak 3 melting point, which is the temperature at which it melts under the application of heat, ranges from 381-384°C.

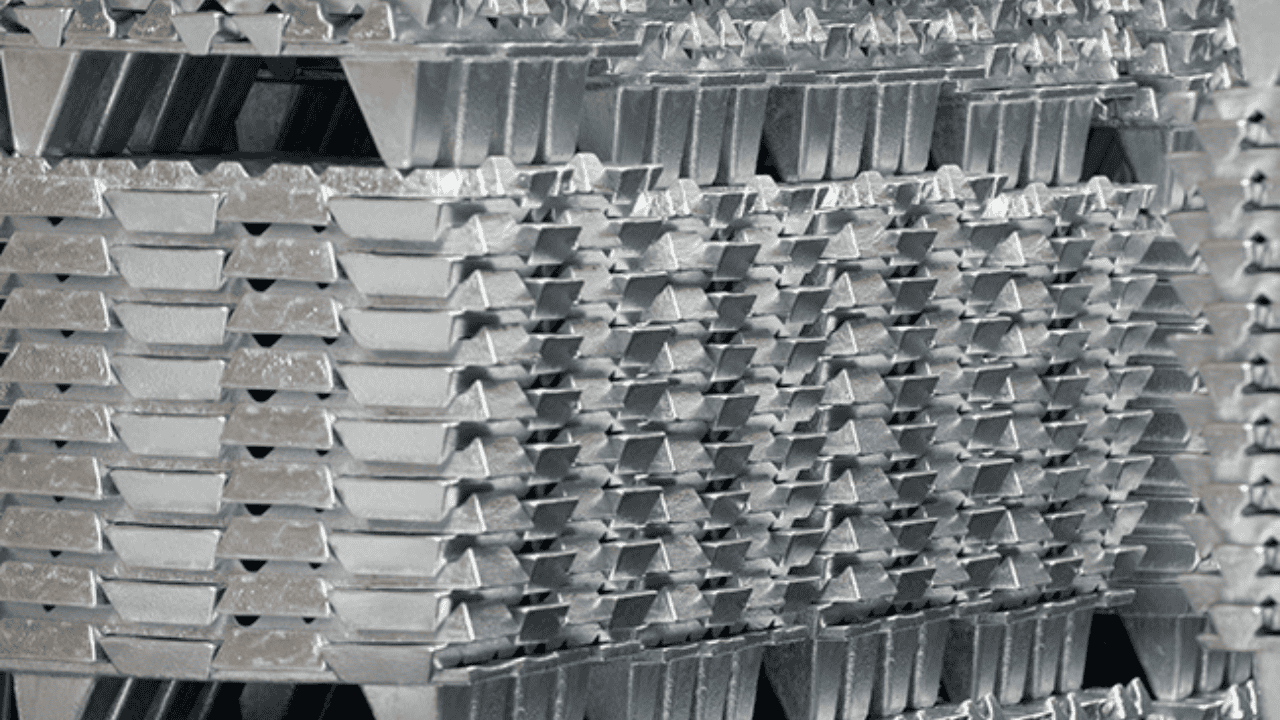

- Zinc alloy 3 has a natural colour of silver but can appear in reddish colour when combined with other elements.

- Zamak 3 requires a latent heat of fusion of about 110J/g and has a density of 6.60g/㎤

- Another physical property of zinc alloy 3 is that it has an electrical conductivity of 27% IAC

Although Zamak 5 contains the same components as the zinc alloy 3, the only difference in a Zamak 3 vs Zamak 5 is the additional 1% copper constituent of Zamak 5 which makes it stronger.

Advantages of Zinc Alloy 3

Low melting point and high fluidity

During the processing of zinc alloy 3, lots of energy can be conserved due to its ability to melt at a very fast rate requiring a low temperature. Also, its high flow rate makes it easy to form different and complex shapes of CNC parts.

Castability

It has a high propensity for undergoing casting making it excellent for molding intricate designs and parts. It allows for casting in thinner molds when compared with other die casting alloys, offering accuracy, precision, and a tighter dimensional tolerance.

Excellent Surface Finishing

One of the major advantages of zinc alloy 3 that makes it widely used for die casting parts is its final surface finish, your product can either be utilized in its natural form after casting or can be anodized, painted or coated.

Corrosion Resistant

Known for its ability to resist corrosion and wear due to the formation of a protective zinc oxide layer on material surfaces, zinc alloy 3 is utilized in various industries like automotives, electricals, consumer goods, and also used as a surface finish for other materials.

Environmental Friendliness

This particular grade of zinc alloy does not emit harmful particles or residues into the environment during processing. It is efficient and suitable for both small and large production.

Dimensional Stability

Its high dimensional stability makes zinc alloy 3 of great importance in the application and manufacture of infrastructure and equipment that requires long-term durability. For example, Zamak 3 is used in the making of bridges, automotive parts, building rooftops, and industrial machines.

Limitations of Zinc Alloy 3

Low Melting Point

Although the Zamak 3 melting point being low serves as one of its advantages when compared with other metals, it also poses a challenge and a limitation in applications where high temperature greater than its melting point is required thereby limiting its use case.

Load Bearing Capacity

Zinc alloy 3 has low strength and load bearing capacity. This means that its structure cannot support a very huge amount of weight, it gets easily deformed and out of shape when much force is applied on it making the alloy not suitable for high structural integrity applications.

Applications of Zinc Alloy 3

Chromate Treatments

It can be used as a protective surface layer for other metal surfaces. This increases their durability, resistance to corrosion, and enhances aesthetic appeal.

Medical Equipment

Utilized mostly in the manufacture of surgical instruments, dental tools, orthopedic implants, and diagnostic devices. Zamak 3 has proven to be of huge importance in the medical industry due to its biocompatibility; means that it is safe to use on the human body, and its ease of sterilization.

Die Casting

It’s one of the best materials for die casting. It helps in the formation and manufacture of parts with simple and intricate geometries. It is used for door handles, engine parts, enclosures, and faucets.

Electricals and Housing Components

Manufacturers make use of Zamak 3 for house appliances and electronics like valves, bibcock, furniture accessories, ornaments, and many other plumbing fittings. It is also applicable in the toy industry.

Conclusion

Zamak 3 is well known for its excellent dimensional stability, corrosion resistance, and ease of finishing. This has made it a preferred material for the manufacture of high-precision and durable CNC parts for die-casting applications. Whatever your desired application for this alloy may be, you need to work with renowned and seasoned manufacturers to get the best results.

Here at Hmaking, we offer you free consultation and all the technical support you need if you’re considering using Zinc alloy 3 for your next manufacturing project. Reach out to us today for the best materials and manufacturing services.