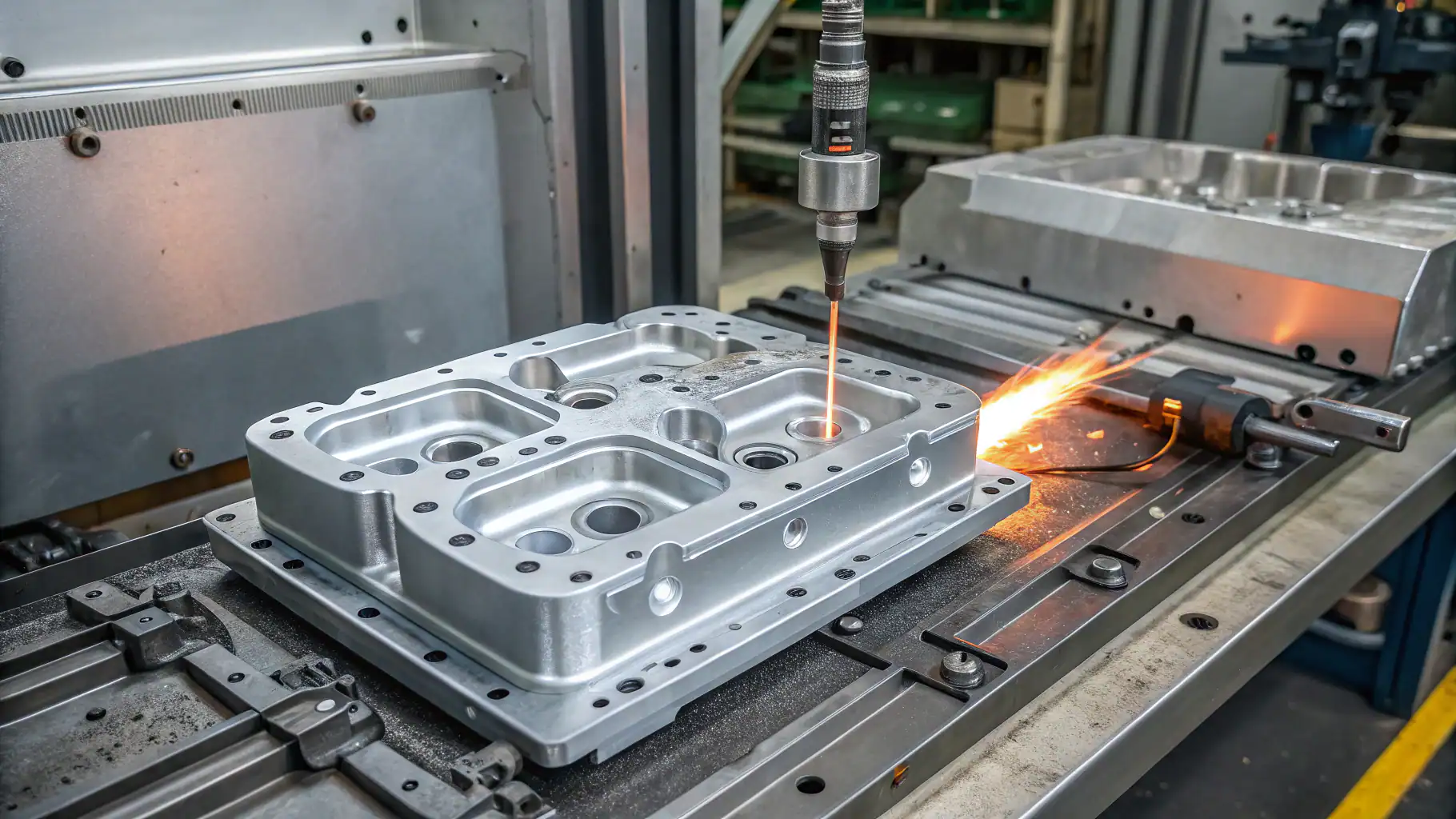

Die casting technology in action

Die casting is a powerful manufacturing method that shapes metal into precise parts. It combines speed and accuracy, making it essential for many industries.

Die casting involves injecting molten metal into molds under high pressure. This process creates strong, detailed components used in automotive, aerospace, and electronics sectors.

As we explore die casting further, you will discover its advantages, challenges, and various techniques that make it a preferred choice for manufacturers worldwide.

Die casting creates strong, detailed components.True

High pressure molds produce precise and durable parts.

Die casting is essential for all industries.False

Not all industries require die casting processes.

Die casting is a powerful method for creating metal parts. It uses high pressure to inject molten metal into molds, producing precise and durable components.

Die casting is a metal casting process that involves injecting molten metal under high pressure into a mold cavity created by two hardened steel dies. This technique is ideal for mass production of small to medium-sized parts, primarily using non-ferrous metals like zinc, aluminum, and magnesium.

Die casting process overview

Overview of the Die Casting Process

The die casting process consists of four main steps: die preparation, filling with molten metal, ejection of the casting, and shakeout to separate scrap material. First, the dies are cleaned and prepped for use. Next, molten metal is injected into the mold at high pressure. After cooling, the part is ejected from the mold. Finally, any leftover material is removed during shakeout.

Key Materials Used in Die Casting

Common materials used in die casting include aluminum, magnesium, and zinc alloys. Aluminum is favored for its lightweight properties and corrosion resistance. Magnesium offers excellent strength-to-weight ratios while zinc provides good fluidity during casting. Each material has unique benefits that make it suitable for different applications.

| Material | Properties | Common Uses |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Automotive parts |

| Magnesium | High strength-to-weight ratio | Aerospace components |

| Zinc | Good fluidity | Electrical housings |

Advantages of Die Casting

Die casting offers several advantages over other manufacturing methods. It provides excellent surface finish and dimensional consistency in produced parts. The process allows for rapid production rates which reduce costs per item when producing large quantities. Additionally, die-cast parts often require little to no machining after production.

Challenges in Die Casting

Despite its benefits, die casting faces challenges such as porosity in castings and high initial costs for equipment and dies. Porosity can lead to weak spots in finished products if not managed properly. Furthermore, companies must invest significantly upfront to set up their die-casting operations.

Industry Applications of Die Casting

Die casting plays a crucial role in various industries including automotive, aerospace, and consumer electronics. In automotive manufacturing, it produces lightweight yet strong components that enhance vehicle efficiency and performance. Aerospace applications benefit from precision-engineered parts made through this method due to their reliability under extreme conditions.

Overall, understanding die casting helps businesses choose the right manufacturing processes for their needs while recognizing both its strengths and limitations.

Die casting is ideal for mass production of small to medium-sized parts.True

The process allows rapid production rates.

Die-cast parts often require extensive machining after production.False

They usually need little to no machining.

How Does Die Casting Benefit Various Industries?

Die casting is a game-changer for many industries. It offers speed, precision, and cost-effectiveness that can transform production processes.

Die casting benefits various industries by providing high-quality, durable parts with excellent dimensional accuracy. This process is essential in sectors like automotive, aerospace, and consumer electronics due to its efficiency and versatility.

Die casting process overview

Overview of the Die Casting Process

Die casting involves injecting molten metal into a mold under high pressure. The main steps include die preparation, filling the mold with molten metal, ejecting the casting, and shakeout to remove scrap material. This method primarily uses non-ferrous metals such as aluminum, zinc, and magnesium. These materials are favored for their strength and lightweight properties.

The two main techniques are hot-chamber and cold-chamber die casting. Hot-chamber is suitable for low melting point metals while cold-chamber works well with higher melting point alloys. Innovations like the Acurad process have improved quality and efficiency in die casting applications.

Applications in the Automotive Industry

In the automotive sector, die casting plays a crucial role in producing lightweight components that enhance vehicle performance. Companies like Ryobi Group focus on creating high-quality aluminum die cast products that improve fuel efficiency and reduce emissions.

Parts such as engine blocks, transmission cases, and structural components benefit from die casting’s precision manufacturing capabilities. The ability to produce complex shapes quickly makes it ideal for meeting the demands of modern automotive design.

Aerospace Industry Benefits

The aerospace industry also relies heavily on die casting for producing critical components that require high strength-to-weight ratios. Parts made through this process include brackets, housings, and other structural elements.

Using aluminum or magnesium alloys helps reduce overall aircraft weight while maintaining safety standards. The dimensional accuracy achieved through die casting ensures that these parts fit perfectly within larger assemblies.

Consumer Electronics Applications

In consumer electronics, die casting is used to create intricate housings for devices like smartphones and laptops. The smooth surface finish provided by this method enhances aesthetic appeal while ensuring durability.

Manufacturers benefit from reduced production costs due to the efficiency of mass production techniques associated with die casting. This allows them to meet consumer demand without sacrificing quality or increasing prices.

Challenges Faced in Die Casting

Despite its advantages, die casting does come with challenges such as porosity issues and high initial equipment costs. Manufacturers must invest significantly in dies and machinery upfront.

Additionally, achieving consistent quality can be difficult if proper controls are not maintained during production processes. However, advancements in technology continue to address these challenges effectively.

| Challenge | Description |

|---|---|

| Porosity | Air pockets can form within cast parts |

| Initial Costs | High investment needed for equipment |

| Quality Control | Maintaining consistency requires strict oversight |

Overall, understanding how die casting benefits various industries helps businesses make informed decisions about their manufacturing processes.

Die casting provides high-quality, durable parts with excellent dimensional accuracy.True

Die casting achieves precision and durability through controlled processes.

Die casting primarily uses ferrous metals like steel and iron.False

Die casting mainly uses non-ferrous metals like aluminum.

Who are the Leaders in Die Casting Technology?

Die casting is revolutionizing manufacturing. Discover how industry leaders like Ryobi Group and Fictiv are shaping this technology with their innovations.

Firms like Ryobi Group and Fictiv lead die casting technology by developing advanced processes and high-quality products. Their contributions enhance efficiency, precision, and sustainability in manufacturing.

Die casting technology

Overview of Die Casting Technology

Die casting is a metal casting process that injects molten metal into molds under high pressure. This method primarily uses non-ferrous metals such as aluminum, zinc, and magnesium. It is ideal for producing small to medium-sized parts at a low cost per item. The process includes four main steps: preparing the die, filling it with molten metal, ejecting the casting, and separating scrap material. Die casting offers excellent surface finishes and dimensional accuracy but requires significant investment in equipment.

Innovations by Ryobi Group

Founded in 1943, Ryobi Group focuses on innovative die casting technologies for the automotive sector. They produce lightweight aluminum components that improve vehicle performance and efficiency. Ryobi emphasizes sustainable practices while maintaining high quality in their products. Their commitment to transparency ensures stakeholders receive timely information about corporate activities. By investing in research and development, they continue to enhance their die casting processes.

Fictiv’s Approach to Die Casting

Fictiv provides various manufacturing services including die casting alongside CNC machining and 3D printing. Their goal is to streamline product development by integrating people and processes for efficient sourcing of custom parts. Fictiv’s platform allows users to obtain instant quotes for die-cast parts while ensuring tight tolerances and quick turnaround times. This approach helps eliminate bottlenecks in production, making them a key player in the industry.

Challenges Facing Die Casting Companies

Despite its advantages, die casting faces challenges such as porosity issues and high initial costs for equipment setup. Companies must invest significantly upfront to ensure quality production over time. Additionally, maintaining consistent quality across large volumes can be difficult due to variations in materials or process conditions. Addressing these challenges requires ongoing innovation and adaptation within the industry.

Future Trends in Die Casting Technology

The future of die casting technology looks promising with advancements like the Acurad process improving efficiency further. As industries demand higher precision components at lower costs, companies will need to adopt new techniques such as vacuum or low-pressure die casting methods to enhance part quality while reducing defects. The growth of electric vehicles also presents opportunities for lightweight components made through advanced die casting techniques.

Ryobi Group produces lightweight aluminum components for the automotive sector.True

Ryobi focuses on die casting for automotive efficiency.

Fictiv only offers die casting services.False

Fictiv also provides CNC machining and 3D printing.

What Are the Advantages and Challenges of Die Casting?

Die casting offers precision and efficiency, but it also presents challenges like porosity and high initial costs. Understanding these factors is crucial for manufacturers.

Die casting process

Overview of Die Casting Process

Die casting is a metal casting method that injects molten metal into a mold under high pressure. This process mainly uses non-ferrous metals such as aluminum, zinc, and magnesium. It is ideal for producing small to medium-sized parts in large volumes due to its low cost per item. The main steps include die preparation, filling with molten metal, ejection of the casting, and shakeout to remove scrap material. Each step requires careful control to ensure quality.

Advantages of Die Casting

One major advantage of die casting is its ability to produce parts with excellent surface finishes and dimensional accuracy. This makes it suitable for industries like automotive and aerospace where precision is critical. Additionally, die casting allows for rapid production rates, which can significantly reduce lead times compared to other methods. The process also minimizes waste since excess material can be reused in future casts.

Challenges Faced in Die Casting

Despite its benefits, die casting has notable challenges. Porosity is a common issue where air pockets form within the cast part, leading to weaknesses. High initial costs are another concern; investing in equipment and molds can be substantial. These factors may deter smaller manufacturers from adopting this technique despite its long-term advantages.

Industry Applications of Die Casting

Die casting plays a crucial role in various industries including automotive, aerospace, and consumer electronics. In automotive manufacturing, it produces lightweight yet strong components that enhance vehicle efficiency and performance. Aerospace applications benefit from precision-engineered parts made through this method due to their reliability under extreme conditions. Additionally, die casting is integral to the production of high-quality LED displays used in a variety of settings, from advertising LED displays to LED video walls, providing durability and visual impact for industries like retail, transportation, and entertainment. Manufacturers like NSELED leverage advanced die-casting techniques to produce robust, reliable products that meet the demands of modern display technology.

Innovations in Die Casting Techniques

Recent innovations have improved die casting processes significantly. Techniques such as vacuum die casting reduce defects by minimizing air entrapment during production. Low-pressure die casting enhances part quality while allowing for complex geometries that traditional methods struggle with. These advancements help manufacturers achieve better results while addressing some inherent challenges of the process.

| Technique | Key Features |

|---|---|

| Hot Chamber Die Casting | Suitable for low melting point metals |

| Cold Chamber Die Casting | Ideal for high melting point metals |

| Vacuum Die Casting | Reduces air entrapment |

| Low-Pressure Die Casting | Allows complex shapes |

Die casting produces parts with excellent surface finishes and dimensional accuracy.True

The process allows precise control, ensuring high-quality finishes.

Die casting has low initial costs for equipment and molds.False

High initial investment deters smaller manufacturers.

How Does Die Casting Compare to Other Manufacturing Methods?

Die casting is a powerful method for producing metal parts. But how does it stack up against other methods like sand casting and investment casting?

Die casting involves injecting molten metal into molds under high pressure, making it efficient for mass production. In contrast, sand casting uses sand molds and is better for larger parts, while investment casting offers intricate designs but at a higher cost.

Casting methods comparison

Overview of Die Casting Process

Die casting is a precise manufacturing process that injects molten metal into steel molds. This method primarily uses non-ferrous metals such as aluminum, zinc, and magnesium. The process includes four main steps: die preparation, filling the mold with molten metal, ejecting the finished part, and shakeout to remove scrap material. Die casting is known for its excellent surface finish and dimensional accuracy. However, it requires significant upfront investment in equipment.

Comparison with Sand Casting

Sand casting is an older technique where sand molds are used to create parts. It allows for larger components but lacks the precision of die casting. The sand mold can be reused multiple times but may not provide the same surface quality or dimensional consistency as die cast parts. Sand casting also has longer lead times due to the manual nature of creating molds.

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Precision | High | Moderate |

| Surface Finish | Excellent | Fair |

| Production Speed | Fast | Slower |

| Cost | Higher initial costs | Lower initial costs |

Investment Casting Insights

Investment casting involves creating a wax pattern coated in ceramic material. Once hardened, the wax is melted away, leaving a cavity for molten metal. This method excels in producing complex shapes with tight tolerances but comes at a higher cost than both die and sand casting. Investment casting is suitable for small runs of intricate designs often found in aerospace and medical applications.

Applications Across Industries

Die casting finds extensive use in industries like automotive and aerospace due to its ability to produce lightweight yet strong components efficiently. Parts such as engine blocks and transmission housings benefit from this method’s speed and accuracy. On the other hand, sand casting serves well in heavy machinery manufacturing where large components are needed.

Conclusion on Choosing Methods

Choosing between die casting, sand casting, or investment casting depends on specific project requirements such as part size, complexity, volume needs, and budget constraints. Each method has unique advantages that cater to different manufacturing needs across various industries.

Die casting is known for its excellent surface finish and dimensional accuracy.True

Die casting provides high precision and smooth surfaces.

Sand casting allows for larger components with the same precision as die casting.False

Sand casting lacks the precision of die casting.

Conclusion

Die casting efficiently produces precise metal parts, ideal for automotive and aerospace industries, but faces challenges like porosity and high initial costs.