Understanding the costs involved in CNC machining metal parts is critical today.

Metal components that look almost identical on the drawing can receive wildly different quotes. Different materials, tolerances, batch sizes, and finishing choices all change how much machine time, tooling, and risk a supplier must price into your project.

In this guide, you will see how CNC machining costs are built up, which levers you control as an engineer or buyer, and how to reduce cost without hurting performance.

How CNC Machining Costs for Metal Parts Are Calculated?

The core pricing formula

When buyers ask “how much does CNC machining cost?”, the answer always comes back to the same structure. A realistic CNC machining cost calculation combines material, machine time, setup, tooling, finishing, inspection, and logistics. Each machine shop may format the quote differently, but they all recover these elements through their CNC machining price and overall machining rates.

A practical way to think about total machining cost is this simplified formula that many custom CNC machining service providers use:

Total Part Cost ≈ Material Cost

-

(CNC Machine Cost per Hour × Machining Time)

-

Setup and CAM Programming

-

Fixtures and Tooling

-

Surface Finishing and Inspection

-

Packaging and Shipping**

Material cost depends on the metal grade and stock form. The CNC machine cost per hour is driven by the type of machine (for example a 3-axis mill, CNC lathe mill, or vertical CNC machining center) and the shop’s overhead. Setup covers CAM work, fixturing, and trial parts. Finishing and inspection add labor and process cost, while packaging and freight close the loop. When you understand this structure, you can look beyond a single number and have a serious conversation about which levers to adjust to control CNC machining cost.

Why CNC machined metal parts are not priced by weight alone?

Many buyers who are new to CNC machining compare machining prices by weight, because metal stock is purchased by kilogram or pound. However, CNC machining cost is driven by time and complexity, not just the amount of material removed. Two metal parts with the same weight can generate very different quotes from custom machine shops if one is a simple turned shaft and the other is a 5-axis housing with deep pockets and tight GD&T.

Machine time depends on toolpaths, feeds and speeds, tool changes, and setups. A compact part with small radii, thin walls, and intricate features may run for much longer on a mill CNC machine than a larger but simple bracket. Quality expectations also change the cost structure. Parts with strict tolerances, cosmetic surfaces, or full CMM inspection take longer to machine and measure, even though their weight is unchanged.

If you compare only price per kilogram, you punish shops that account for real risk and reward those that under-estimate machinist metal cost and inspection effort. A better benchmark is to ask how many operations the part needs, which CNC vertical milling machine or turning center is used, and how long the program runs. This way you evaluate the logic behind how much CNC machining costs, not just the final number.

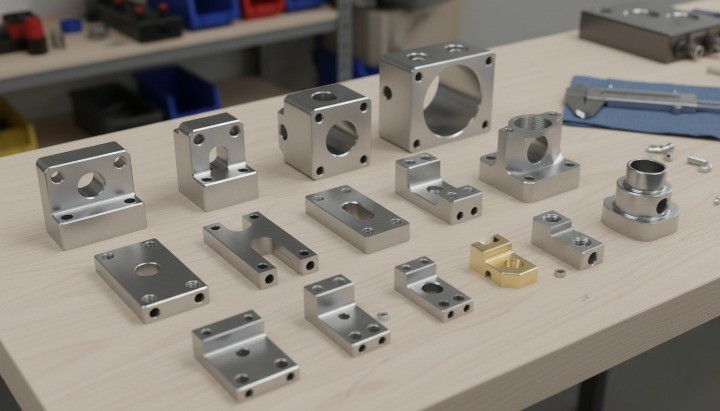

Typical cost ranges for common metal components

Because every CNC machining company operates with different overhead and machine shop rates, exact prices vary by region. Still, it helps to understand relative cost levels for different types of metal parts when you ask “how much does CNC machining cost?” or compare an online CNC machining quote.

| Component Type | Typical Features and Process | Relative Cost Range | Key Cost Drivers |

|---|---|---|---|

| Simple aluminum bracket | 3-axis milling, basic faces and holes | Low–Medium | Material, short machining time, basic inspection |

| Turned steel shaft | CNC lathe mill, grooves, threads | Low–Medium | Bar stock, turning cycle, thread quality |

| Stainless steel mounting plate | Hole patterns, counterbores, moderate GD&T | Medium | Tool wear, drilling cycles, CMM spot checks |

| 5-axis aluminum robotics housing | Multi-side milling, thin walls, complex pockets | Medium–High | 5-axis CNC machine cost per hour, fixturing, QA |

| Titanium aerospace/medical component | Tight tolerances, full traceability, special documentation | High | Material price, tool wear, extended inspection |

Prototype quantities will always sit at the upper end of these ranges because setup and programming time are spread over fewer pieces. As batch size grows and the process stabilizes, CNC machining pricing per part typically falls. Understanding these patterns makes it easier to interpret quotes and distinguish between a fair CNC machining cost and an unrealistic lowball offer.

Material-Related Costs

Raw material pricing and stock form

Raw material is the starting point of every CNC metal cutting machine job. Aluminum, carbon steel, stainless steel, copper alloys, and titanium each carry different base prices and supply chain dynamics. To compare these options effectively, engineers often review a supplier’s CNC machining materials and metal alloy capabilities to understand how material choice influences both pricing and performance. On top of that, the chosen stock form—plate, bar, extrusion, forging, or near-net casting—changes both raw material spend and downstream machining time. A forged blank may carry a higher unit price, but it saves significant machining time on an industrial CNC machine by reducing excess stock.

When you evaluate aluminum machining cost or stainless steel machining cost, you need to consider both the invoice price of the material and how much of that material becomes chips. Larger blocks mean more passes on a vertical CNC machining center or gantry CNC mill, which increases spindle hours and tool wear. For complex parts, the cheapest stock form is not always the cheapest total solution once you add CNC machining cost and finishing.

Machinability differences among metals (aluminum, steel, stainless, copper alloys, titanium)

Machinability is a core factor in CNC machining cost calculation. Aluminum alloys usually machine very quickly on a CNC vertical mill or horizontal machining center. They allow higher feed rates, good surface finish, and predictable chip evacuation, which lowers machining cost per hour. Standard carbon steels are slower but still manageable, while stainless steels work-harden and require more cautious programming and premium tooling.

Copper alloys can be sticky to machine, affecting tool life and requiring careful cutting strategies. Titanium and hardened steels are at the far end of the spectrum. They generate high heat and wear out tools quickly, pushing up both machining cost and tool budget. Even when geometry is identical, titanium parts will cost more on the same CNC machining service than aluminum, simply because the machine must run slower and tools must be replaced more frequently.

This is why a complete CNC machining cost calculation always treats material choice as a major lever. Engineering teams that balance performance requirements with machinability can often lower CNC machining price without compromising function, especially when selecting between several acceptable metallic alloys.

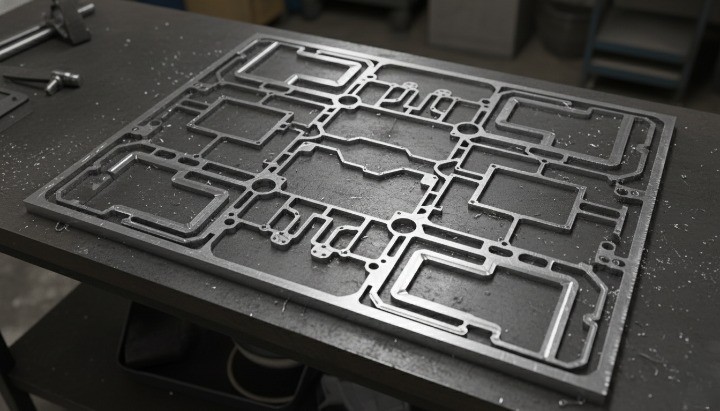

Material waste, buy-to-fly ratio, and nesting efficiency

Material waste can quietly dominate machining cost in some projects. The buy-to-fly ratio, which compares the amount of material purchased to the finished part weight, can range from nearly 1:1 for simple parts to very high ratios for deeply pocketed housings milled out of thick plate. Each point of waste increases both material spend and cutting time on the metal cutting machine.

Nesting efficiency is especially important when programming plate cutting or running multiple parts on a CNC vertical milling machine for metal. Better nesting reduces scrap and spreads setup cost over more parts. When you mill from bar or tube, choosing the right diameter or wall thickness reduces machine time and chips. For higher volumes, switching from a block-machined design to a die casting plus CNC machining strategy can drastically reduce the buy-to-fly ratio and the overall CNC machining cost.

Design and Geometry Impact on Cost

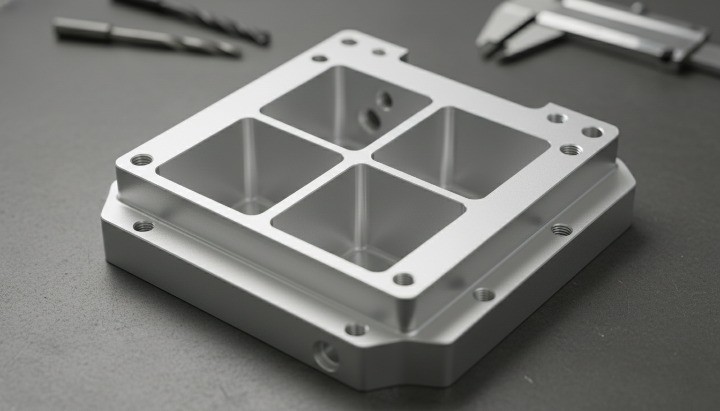

Thin walls, deep pockets, radii, and complex features

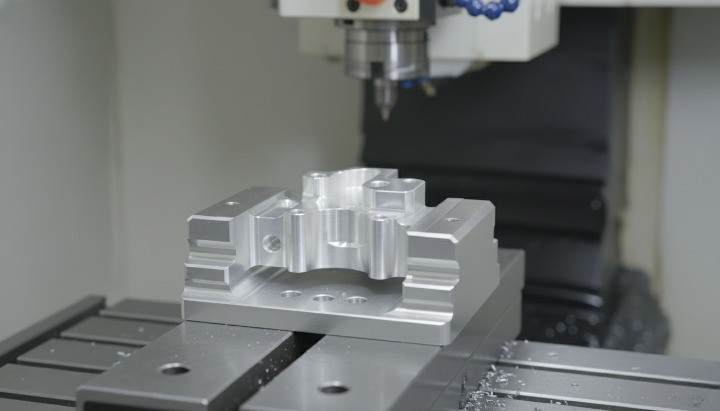

Design geometry is one of the most powerful drivers of CNC machining cost. Thin walls, deep pockets, very small internal radii, and intricate 3D surfaces all require slower cutting speeds, more tool changes, and extra passes on the mill CNC machine. These features often resemble the challenges found in micro precision CNC parts, where tool selection, vibration control, and machining strategy significantly affect total cost. The result is a higher overall machining cost even when the material and overall size remain the same.

Thin walls vibrate and deflect under cutting forces, which forces the machinist to reduce feed rates or use special tooling. Deep cavities demand long, less rigid tools and careful step-down strategies. Tiny inside corners may require micro end mills that increase cycle time. When these elements appear together, they can turn an otherwise simple part into something that feels more like a heavy CNC machining project on an expensive vertical CNC machining center.

Tolerances, GD&T, and feature-to-feature relationships

Tolerances and GD&T transform a drawing from a simple geometry into a true manufacturing specification. Narrow tolerance bands on critical dimensions demand more precise cutting strategies and more time on the machine. If you combine tight tolerances with complex datum schemes and feature-to-feature relationships, you increase not only CNC machining cost per hour but also inspection cost.

For example, a hole pattern with a true-position requirement relative to a datum face may require probing cycles on a CNC vertical milling machine and detailed CMM checks afterward. If multiple datums are involved, the workholding and setup design become more challenging. Each extra complexity is priced into the shop’s CNC machining pricing because it consumes skilled engineering time and reduces the margin for error. When engineers reserve the tightest GD&T only for truly functional features, they often see a clear reduction in overall machining prices.

Threading, hole patterns, and fit requirements for metal parts

Threads, hole patterns, and functional fits can quietly increase CNC machining cost if they are not designed with manufacturing in mind. Fine or very small threads require slower tapping or thread milling, especially in stainless steel or titanium. Deep tapped holes increase tool breakage risk. Complex hole patterns or press-fit seats demand more accurate positioning and often trigger extra verification with gauges or CMM.

Every additional hole or thread requires a tool change, a machining step, and an inspection action. When buyers ask how much does CNC machining cost for what appears to be a simple plate, the answer often lies in the density of holes and the level of precision required for each feature. Standardizing thread sizes, limiting depth to functional requirements, and grouping hole patterns sensibly can have a substantial impact on CNC machining cost calculation and overall lead time.

Machine Type, Axis Requirements, and Cutting Strategy

Turning vs 3-axis vs 4-axis vs 5-axis machining

Different machine types support different geometries and carry different cost structures. Turning machines are ideal when you want efficient machining & fabrication of shafts, bushings, and other rotational parts. A basic 3-axis CNC vertical mill handles most prismatic components. Four-axis and five-axis machines add the ability to tilt and rotate the part, reducing setups and enabling more complex shapes.

Each architecture influences both CNC machine cost per hour and overall productivity. A 5-axis vertical CNC machining center usually has a higher hourly rate than a simple 3-axis machine. However, for complex parts it may reduce total run time and eliminate secondary setups. When you evaluate machining options, you should consider both the cost of the machine and the total number of operations required. In many cases, the right 4-axis or 5-axis strategy is more economical than multiple 3-axis setups at lower hourly rates.

Machine hourly rate differences and productivity

Every machine shop sets its own machine shop rates based on the cost of equipment, labor, and overhead. A compact 3-axis CNC milling machine for sale will have a lower capital cost than a high-end 5-axis gantry CNC mill or a premium brand like a Mazak mill or Haas CNC mill for sale. The higher the investment in a cost of CNC milling machine, the higher the hourly rate typically must be to recover that cost of the machine.

However, productivity can reverse the picture. A more capable machine may run several operations in one setup, reduce human intervention, and cut cycle time per part. If a 5-axis vertical CNC machining center finishes a complex housing in half the time, the higher hourly rate can still produce a lower total CNC machining cost. Buyers should therefore focus on total process time and not only on the posted CNC machine rate per hour when comparing CNC machining pricing.

Multi-operation setups vs single-setup machining

Each time a part is removed and reclamped, you pay for additional setup, alignment, and verification. Multi-operation strategies can increase machining cost even on lower-cost machines because operators must touch the part more often and inspect more frequently. If datum transfer is not managed well, you may also see extra scrap and rework.

Single-setup machining, where a part is clamped once and machined in several orientations, reduces that handling time. This usually requires 4-axis or 5-axis capability or more advanced fixtures on a mill CNC machine. While the underlying CNC machine cost may be higher, the reduction in labor and cycle time often produces a better overall CNC machining cost. For repeat metal components, a robust single-setup strategy is one of the most effective ways to stabilize quality and reduce total machining prices.

Setup, Programming, Fixturing, and Tooling Costs

CAM programming and setup for low-volume metal parts

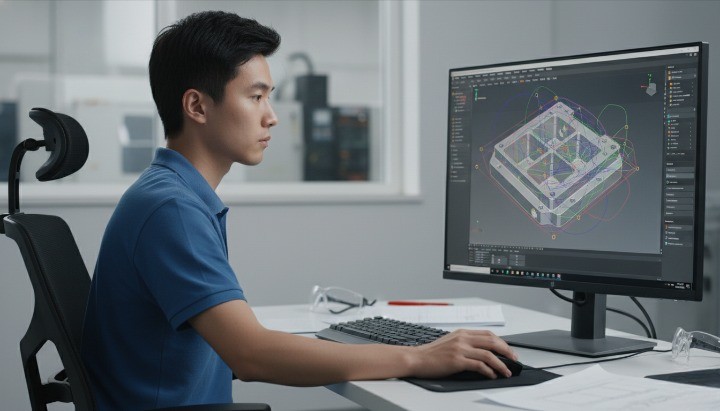

For low-volume work, CNC machining cost is dominated by setup and CAM programming rather than pure cutting time. Programming a part in professional software such as an advanced CAM suite (for example products in the same category as Esprit CAM price level tools) takes engineering time, simulation, and validation. Setup then requires loading tools, aligning fixtures, and producing the first article for inspection.

These steps cost roughly the same whether you run 5 parts or 500 parts, so they heavily influence custom CNC milling cost in prototype stages. This is why CNC machining cost per hour feels higher when you order very small batches or request frequent design changes. Early DFM discussions help reduce rework and minimize unnecessary programming cycles, keeping your effective CNC machining price under control while still protecting quality and lead time.

Custom fixtures, soft jaws, and workholding considerations

Custom workholding, such as fixtures and soft jaws, makes it possible to machine parts accurately and repeatably on a CNC metal cutting machine. Designing and machining these fixtures is itself a small project that uses machine time and material. The cost is typically spread across the entire production run, but for small batches it can significantly increase machining cost per unit.

Soft jaws tailored to a specific contour are common on 3-axis and 4-axis mills. They provide strong support and reduce vibration, but they wear over time and must be remachined or replaced. Multi-axis fixtures on a vertical CNC machining center or gantry CNC mill carry higher upfront cost. When the design allows simple clamping or the reuse of standard workholding, CNC machining cost drops because the shop can avoid building complex setups from scratch.

Tool wear and tool breakage for stainless steel, titanium, and hardened metals

Tooling is another important contributor to machining cost, especially for hard-to-machine materials. Stainless steel, titanium, and hardened steels wear out tools faster than aluminum or mild steel. Shops must budget for more frequent tool replacement and slower feeds and speeds. This raises both the CNC machining cost per hour and the overall cost per part.

When tools break—such as taps in small threads or end mills in deep pockets—the cost increases again. Broken tools can damage workpieces, scrap material, and consume extra machine time. Shops that specialize in heavy CNC machining and hard metals select premium cutters and coatings, which are more expensive but improve stability. For buyers, this means that the same geometry will have a higher CNC machining cost in titanium than in aluminum. Selecting materials thoughtfully is therefore one of the most effective ways to control tooling-driven machining prices.

Production Volume and Stage

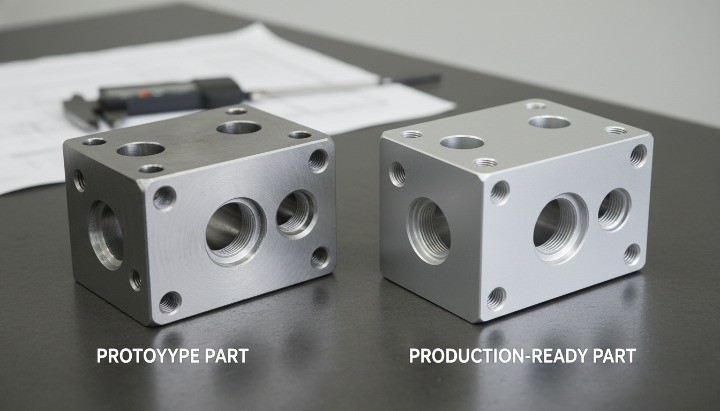

Prototype vs production cost structures

Prototype work feels expensive because all setup, programming, and fixturing costs are absorbed into a very small number of parts. In early development, teams often rely on small batch CNC machining services to validate form, fit, and function, but this also means every hour of setup and engineering is spread across only a few units. In this phase, CNC machining cost per unit is high, even when the geometry looks simple. Shops may need to stop ongoing production, load new tools, and run one or two proof pieces, which drives up the effective CNC machine cost per hour on that job.

During production, the cost structure changes. Toolpaths are optimized, fixtures are reused, and inspection becomes more focused. Machine utilization improves, and per-part CNC machining price falls as the initial engineering work is amortized. When teams plan prototypes and production volumes together instead of in isolation, they can better interpret CNC machining cost calculation results and choose the right route for each project stage.

How batch size shapes unit pricing?

Batch size is one of the easiest levers for buyers to understand, yet it is often misaligned with design maturity. A run of 10 pieces might show a very high unit machining cost, while a batch of 500 pieces looks far more reasonable on the same quote from the same CNC machining company. The reason is straightforward: setup and programming are spread over many more parts.

Larger batches also allow for better scheduling and fewer changeovers, which improves machine utilization and lowers effective CNC machine cost per hour. However, over-ordering before the design is stable can lock you into scrap if changes appear later. The smartest approach is to align quantity tiers with project milestones, then use data-driven CNC machining pricing for each tier to support internal budgeting and sourcing decisions.

When CNC vs die casting + CNC finishing becomes cost-effective?

For low and medium volumes, pure CNC machining is often the most flexible and economical solution. As volumes grow, however, the economics change. At a certain annual demand, the cost of CNC stock removal plus machine time becomes higher than a hybrid strategy that uses die casting or forging followed by custom die cast parts with CNC machining on critical surfaces.

In a hybrid approach, the casting provides the bulk of the shape at low incremental cost, while CNC machining cleans up key faces, bores, and threads. This reduces both buy-to-fly ratio and machine hours. The crossover point depends on part size, tolerance requirements, and the cost of CNC machine time. Engineering teams that evaluate both options early can model how much does CNC machining cost at different scales and decide when tooling investment for casting is justified.

Surface Finishing Costs for Metal Parts

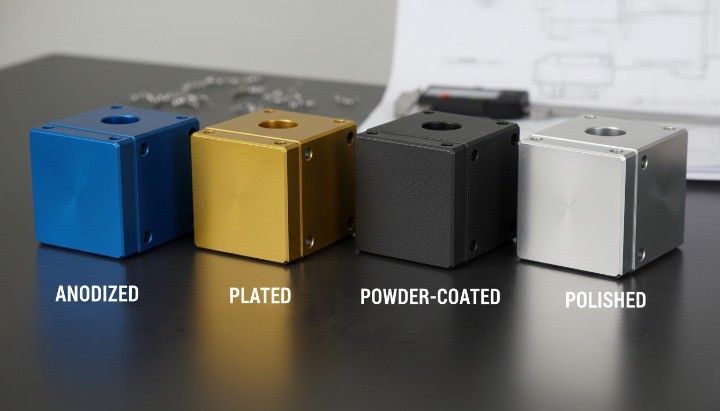

Anodizing, plating, powder coating, polishing, blasting

Once the core CNC machining cost is defined, surface finishing often becomes the next major driver of total price. Anodizing, plating, powder coating, polishing, and blasting each add their own process steps and quality criteria. For aluminum components, anodized aluminum parts are a popular choice, often applied after machining on a CNC milling machine for metal. Hard anodizing costs more than decorative anodizing because it requires tighter process control and often supports functional wear resistance.

Plating processes such as zinc, nickel, or chrome are widely used on steel and copper alloys. Powder coating offers a durable coating for enclosures, brackets, and structural parts. Polishing and grinding improve surface finish on visible metal components but are labor intensive. Blasting creates homogeneous textures yet introduces extra handling and masking work. Together, these operations can add a notable percentage to what started as a purely cutting-focused CNC machining price.

Cosmetic vs functional finishing considerations

Not all finishes serve the same purpose. Cosmetic finishes focus on appearance, uniform color, and visible surface quality. These are common on robotics covers, visible machine enclosures, or precision assemblies where customers will see the metal every day. Cosmetic criteria usually increase inspection effort and reject rate, which raises effective CNC machining cost per accepted piece.

Functional finishes emphasize durability, corrosion resistance, or conductivity rather than appearance. Black oxide on steel or hard anodizing on aluminum are typical examples. They may allow wider cosmetic variation while still protecting performance. When you answer internal questions about how much does CNC machining cost, it is important to separate cosmetic requirements from functional ones so that the shop does not over-apply finishing controls that you do not actually need.

Multi-step operations, masking, and edge preparation

Many real-world parts require multiple finishing steps, and each layer adds time, complexity, and cost. A component might be bead blasted before anodizing, then partially masked for selective coating, and finally laser marked for traceability. Each action requires careful handling, and any error can damage a batch of parts, driving up effective machining prices and rework cost.

Masking is especially important when threads, sealing surfaces, or grounding points must remain free of coating. This is labor-intensive and can be difficult to automate. Edge preparation adds another dimension. Sharp edges may cut through coatings or trap plating; therefore, deburring and chamfering are critical. If the original CNC design includes sensible edge breaks and accessible features, finishing becomes more reliable and the combined CNC machining cost plus finishing cost remains under better control.

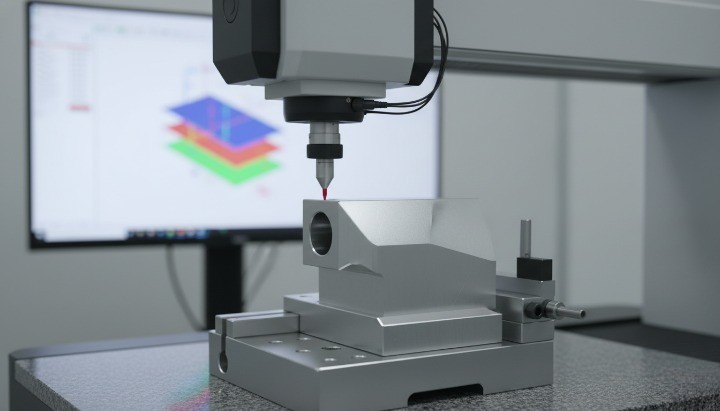

Quality Control and Inspection Costs

CMM inspection, gauges, and sampling plans

High-quality CNC machining service always includes a structured quality control plan. CMM inspection, handheld gauges, and sampling strategies all contribute to the final CNC machining cost. A simple part may only need caliper and gauge checks on a small sample. A complex, safety-critical part often requires full CMM reports and tighter sampling plans. Each dimension measured takes time, and CMM programming itself is an engineering task.

Machine shops set their machine shop rates to cover both machining and inspection capability. When you request 100% CMM inspection on every piece, you add a quasi “CMM cost per hour” element to your total project. Smart sampling plans balance risk and cost by increasing checks for new or unstable processes and relaxing them once statistical capability is proven. This is a key factor when you compare CNC machining pricing from different suppliers.

Cost impact of tight tolerances and critical datums

Tight tolerances and critical datums do not just influence machining; they also reshape inspection. When feature size or location tolerances become very narrow, CMM programs become longer and gauge usage increases. This step is built into the final machining cost. For each critical feature tied to a datum scheme, measurements must be precise and repeatable, often with full documentation.

In many industries, engineers specify small tolerance bands by default. This leads to higher CNC machining cost per hour, longer CMM cycles, and more scrap when parts slightly miss aggressive targets. By identifying which features truly require premium control and which can accept more generous limits, design teams can materially reduce both CNC machining cost and inspection cost without sacrificing function.

Material certificates, traceability, and compliance requirements

Beyond dimensions, many projects require documentation and traceability that contribute to total CNC machining cost. Material certificates confirm the chemical and mechanical properties of alloys. Traceability requires marking and recordkeeping that links each part or batch back to a specific heat number or supplier. For industries like aerospace, medical, and automotive, these steps are non-negotiable.

Compliance with standards such as ISO 9001 or sector-specific systems demands calibrated equipment, controlled processes, and routine audits. The administrative work behind this compliance is reflected in CNC machining company overhead and, ultimately, in the CNC machining price. When buyers ask how much does CNC machining cost for a certified part versus a non-certified one, the answer often lies in these hidden documentation and system costs rather than the visible machining alone.

Packaging and Logistics

Export packaging for precision metal parts

Export packaging is an often overlooked part of CNC machining cost. Precision metal parts cannot simply be thrown into a box and shipped. They need protective packaging that prevents impact, vibration, and surface damage while they move through international freight networks. Foam inserts, custom trays, dividers, and strong outer cartons add direct material cost and handling time at the machine shop.

For heavy parts produced on a CNC metal cutting machine or vertical machining center, wooden crates or reinforced pallets are sometimes required. These solutions protect parts during loading and unloading, but they also increase dimensional weight and handling charges. When you compare CNC machining prices across suppliers, it is important to check whether robust export packaging is included or if it will appear later as a separate line item.

Weight and dimensional impact on shipping cost

Even if two suppliers offer the same CNC machining cost, the total landed cost can differ because of freight. Carriers use both actual weight and dimensional weight to calculate shipping charges. A large but light aluminum housing may be billed as volumetric freight, while a compact stainless steel block from a heavy CNC machining process is charged mostly by mass. In both cases, the choice of packaging and palletization directly affects the logistics bill.

For international shipments, buyers should understand how batch size, packaging style, and transport mode interact. Air freight is fast but very sensitive to volume and weight, whereas sea freight favors larger consolidated loads. When you evaluate CNC machine prices or ask for an online CNC machining quote, it is wise to consider how often parts will ship, how many can fit per box, and whether your design can reduce bulk without compromising protection.

Surface protection and corrosion prevention

Surface protection is another contributor to the final machining cost of metal parts. Untreated steel and even some aluminum alloys can corrode during long transits or in humid environments. To prevent this, machine shops use oil films, VCI papers, desiccant bags, or sealed plastic bags that add small but cumulative costs to each shipment. These measures are especially important for components with tight fits, precision bores, or cosmetic finishes.

Parts that have already undergone anodizing, plating, or powder coating still benefit from careful handling. Abrasion during transport can ruin a cosmetic face and turn a finished part into scrap. Clear requirements in your CNC machining quotation about acceptable packaging and corrosion protection help align expectations and keep both CNC machining cost and quality risks under control.

How to Reduce CNC Machining Costs for Metal Parts?

Optimize tolerances and simplify GD&T

One of the fastest ways to reduce CNC machining cost is to review tolerances and GD&T with a critical eye. Many drawings carry legacy dimensions or overly conservative limits that no longer reflect real functional needs. Each tight tolerance forces the shop to slow down cutting, use premium tooling, and spend more time on inspection. This directly increases machining cost per part and can also raise scrap risk.

A structured design review that distinguishes between critical, important, and non-critical dimensions often reveals opportunities to relax certain tolerances. Features that do not control assembly, sealing, or safety can usually accept more generous bands. When you simplify GD&T schemes and reduce the number of ultra-critical datums, you make it easier for a custom CNC machining service to quote a competitive price without sacrificing reliability.

Improve material selection for machinability and stability

Material choice influences both performance and cost. Swapping from a difficult alloy to a more machinable one can significantly lower CNC machining price and lead time. For example, choosing a free-machining carbon steel instead of a tough stainless grade, or a well-known aluminum alloy rather than a niche variant, allows higher cutting speeds and longer tool life. This reduces CNC machining cost per hour on the shop floor.

Engineers must still respect functional requirements such as corrosion resistance, strength, and temperature behavior. However, in many applications several alloys can meet those needs. A collaborative discussion with your CNC machining company can identify options that maintain safety and durability while improving machinability. The result is a more balanced design that controls both lifecycle performance and direct CNC machining cost.

Standardize hole sizes, threads, and radii

Standardization is a powerful but underused approach to reducing machining cost. When you standardize hole diameters, thread types, and corner radii across related parts, shops can reuse tooling, streamline programming, and reduce setup changes. For example, using common thread sizes such as M6, M8, or ¼-20 across a family of parts avoids the need for multiple taps and gauges.

Similarly, standard internal radii that match common end mill sizes reduce tool changes and simplify toolpaths on a CNC vertical milling machine. This is especially important for parts that move through different operations, such as turning plus milling, or machining plus assembly. A coherent standardization strategy makes it easier for custom machine shops to optimize cycle times and offer better CNC machining pricing across the full product range.

Consolidate orders and plan quantity tiers

Batch planning is closely tied to how much CNC machining costs over a program’s life. Splitting orders into many small releases forces repeated setups and changeovers, inflating the effective CNC machine cost per hour. Consolidating demand into fewer, well-planned batches reduces the number of changeovers and improves machine utilization.

Quantity tiers in your RFQ—such as 50, 200, and 1,000 pieces—help suppliers show you the cost curve. This allows you to compare inventory carrying cost against lower unit machining prices at higher volumes. The right balance depends on demand stability and design maturity, but without visibility into volume scenarios, even the best CNC machining cost calculation cannot optimize your total spend.

Limit finishing to necessary areas

Surface finishing often feels binary—either a part is finished or it is not—but cost-effective practice is more nuanced. Many projects specify anodizing, plating, or powder coating over the entire part when only certain faces are visible or functionally critical. By limiting finishing to the necessary areas, you reduce masking, chemical usage, and inspection, which lowers overall CNC machining cost.

For internal components that never see the customer and do not face corrosive environments, a simple deburr and light oil may be sufficient. For visible faces, you can use higher-grade finishes while allowing more basic treatment on hidden features. Clear notes in your drawing about which surfaces require which finish help your CNC machining service avoid over-processing and price the job accurately.

Use early DFM collaboration with your supplier

Early design-for-manufacturability (DFM) collaboration is one of the most effective tools for controlling CNC machining cost. When you involve your manufacturing partner while the design is still flexible, you can address issues around material choice, wall thickness, tolerances, and workholding before they create expensive problems. Many custom CNC machining service providers will review your 3D models and suggest small changes that preserve function while reducing machining cost.

This collaboration becomes even more powerful when you plan transitions between prototype and production stages, or between full machining and processes such as die casting plus CNC finishing. Instead of asking “how much does a CNC machine cost per hour?” in isolation, you discuss the entire cost structure and identify the most efficient route. That strategic view often delivers bigger savings than any single line-item negotiation.

RFQ Requirements for Accurate CNC Machining Quotes

Drawings, 3D models, materials, tolerances, and quantity tiers

A precise RFQ is the foundation for an accurate online CNC machining quote. Clear 2D drawings, step files or 3D models, and unambiguous material descriptions help avoid guesswork. Including tolerance information, surface finish requirements, and heat treatment notes enables the shop to perform a realistic CNC machining cost calculation. Quantity tiers show how many parts you plan to order at different stages, which influences the allocation of setup and programming cost.

When these details are missing, shops either add risk into their CNC machining price or make assumptions that may not match your expectations. A complete RFQ allows a CNC machining company to select the right mill CNC machine, turning center, and inspection plan without padding the quote. The result is more consistent CNC machine quotation data across suppliers and more reliable budgets internally.

Identifying critical vs non-critical features

Not every dimension on a drawing deserves the same level of scrutiny. Identifying critical features—those that affect safety, alignment, sealing, or load transfer—helps your supplier prioritize machining and inspection efforts. Non-critical surfaces can accept wider tolerances and simpler measurements, which reduces machining cost and inspection time.

You can use notes or a simple legend to mark priority features in your drawings. This is extremely useful for machining breakdown engineers who decide which tools to use and how much time to allocate to each operation. It also gives you more leverage when discussing CNC machining pricing, because you show that you understand where cost and risk actually sit within the geometry.

Sharing end-use and performance requirements

Suppliers can estimate how much CNC machining costs more accurately when they understand what the part does in the final assembly. Knowing whether a part lives in a clean lab, a dusty factory, or an offshore environment informs material and finishing recommendations. Understanding load paths, motion requirements, or sealing conditions helps the shop suggest tolerance changes that maintain safety while reducing machining cost.

Sharing end-use information also helps when the supplier chooses between pure machining and hybrid processes such as casting plus custom CNC metal cutting. If they know your application and demand profile, they can propose routes that improve both performance and cost. Many buyers hesitate to share context, but controlled transparency often generates better designs and more competitive CNC machining prices.

Why consistent RFQs lead to comparable supplier quotations?

Inconsistent RFQs make it difficult to compare CNC machine prices or select the best vendor. If each supplier receives slightly different information, they will assume different tolerances, materials, or inspection levels. The quotes may look like apples and apples, but in reality they mix different scopes of work and risk levels. This can lead to surprises later when hidden assumptions surface as change orders or quality disputes.

Using a standard RFQ template that covers drawings, models, quantities, material specs, finishing, inspection, and packaging creates a common baseline. Suppliers can then focus on their strengths: efficient processes, reliable capacity, and transparent CNC machining cost

FAQs About CNC Machining Costs for Metal Parts

Why do quotes vary among suppliers?

Quotes vary because shops use different equipment, carry different overhead, and make different assumptions about risk. One supplier may use older 3-axis mills with low hourly rates, while another invests in advanced vertical CNC machining centers and premium tooling. Their CNC machine cost per hour is not the same, and neither is their productivity. Some include full packaging and inspection, others expect separate line items.

Shops also interpret incomplete RFQs differently. One may assume tight tolerances and high-end finishing, while another assumes more basic requirements. That is why a clear specification and consistent RFQ template are essential if you want CNC machining pricing that is comparable and stable across multiple vendors.

Typical hourly rates for machining metal components

Typical hourly rates depend on geography, shop size, and machine type. A small shop running older 3-axis mills has a very different cost of CNC machine ownership than a facility with large gantry mills, 5-axis centers, or robot milling cells. As a result, CNC machine prices per hour can range from relatively modest figures to premium levels in high-spec industries.

The critical point is not to chase the lowest posted CNC machine rate per hour but to evaluate total part cost and quality. A more efficient shop with higher rates but shorter cycles can deliver a lower CNC machining cost for the same part. Comparing sample jobs and discussing cycle time openly with potential partners is usually more productive than negotiating on posted hourly rates alone.

Why stainless steel and titanium parts cost more?

Stainless steel and titanium are harder to machine than aluminum or mild steel. They generate high cutting forces, build heat quickly, and wear out tools faster. Shops must run slower feeds and speeds and use more expensive tooling, which raises CNC machining cost per hour for these materials.

Stainless and titanium parts also frequently appear in demanding industries such as aerospace, medical devices, and high-end industrial equipment. These sectors often require strict GD&T, full CMM inspection, and detailed documentation. The combination of tough machining conditions and stricter quality control explains why CNC machining prices for stainless steel and titanium parts are consistently higher than for more machinable alloys.

How tolerance requirements affect CNC machining cost?

Tolerance requirements affect CNC machining cost because they dictate how precisely a part must be produced and measured. Narrower tolerances demand more controlled toolpaths, slower passes, and often secondary finishing operations. They also require more detailed inspection with gauges or CMM, which increases both machine and labor time.

If you tighten tolerances across an entire drawing as a default, you raise the cost of every feature, not just the critical ones. By carefully identifying which dimensions truly need tight control, you can target machining cost where it matters and avoid overpaying for non-critical features.

When CNC machining is preferable to casting or forging?

CNC machining is preferable when volumes are modest, when you need rapid design changes, or when your geometry is too complex for cost-effective casting or forging. It avoids upfront tooling cost, reduces lead time, and offers excellent flexibility for engineering changes. For many industrial projects, a CNC on demand approach through a trusted CNC machining service is the fastest route to real parts.

As annual volume climbs and the design stabilizes, casting or forging followed by custom CNC metal cutting on critical features can become more economical. The decision point depends on part size, geometry, and the cost of CNC versus tooling plus secondary machining. Evaluating both paths early in the design phase ensures you do not stay with full machining for too long or commit to tooling before the design is ready.

Conclusion

Understanding how much CNC machining costs requires more than reading a unit price on a quote. Material selection, geometry, tolerances, machine choice, finishing, quality control, packaging, and logistics all play a role. When engineers and buyers treat CNC machining cost calculation as a structured problem, they can identify which levers to adjust and where collaboration with suppliers will have the greatest impact. Early DFM engagement, realistic tolerance strategies, and well-designed RFQs help you secure reliable quality at a competitive CNC machining price.

Why early cost analysis prevents production issues?

Early cost and manufacturability analysis reduces the risk of surprises once production begins. By discussing materials, volumes, and process routes before locking the design, you avoid last-minute changes, delivery issues, and unexpected machining cost escalations. If you are planning new metal components or looking to benchmark existing parts, you can request a CNC machining cost review and quotation that breaks down material, machine time, and finishing in a transparent way and turns a generic CNC machine quotation into a clear technical and commercial decision tool.