Die casting is the formation of different components of a machine, usually by melting a metal material and then using high pressure to pass it through a die cast. It is one of the widely used techniques in the manufacturing industry.

But with the constant advancement in the technological landscape, this technique seems to be lacking in some areas of its functionalities, and that has led to the adoption of vacuum die casting. This article is an in depth scrutiny on vacuum die casting, how it works, and how to make the most out of it. Read on.

What Is Vacuum Die Casting?

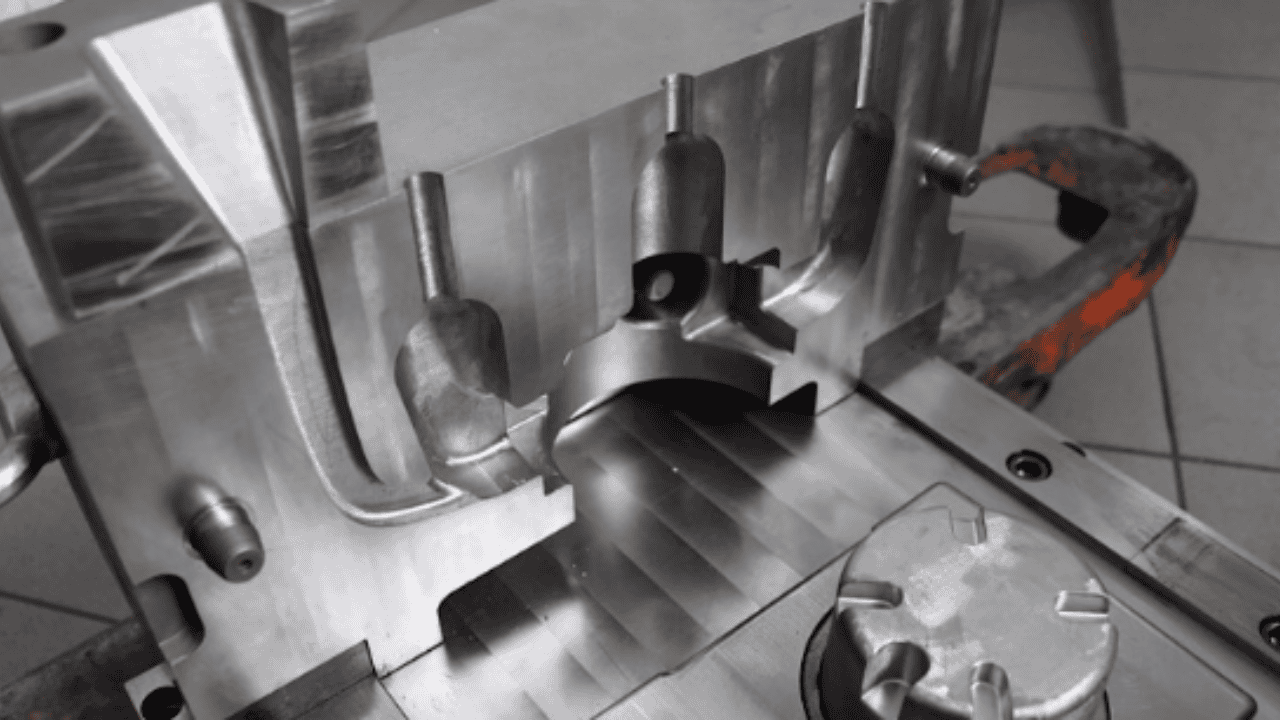

Vacuum die casting, also gas-free die casting, is a conventional die casting method. It comprises all the techniques involved in die casting which simply is the filling up of a die cast or mold with molten metal using pressure to form a structured part or component.

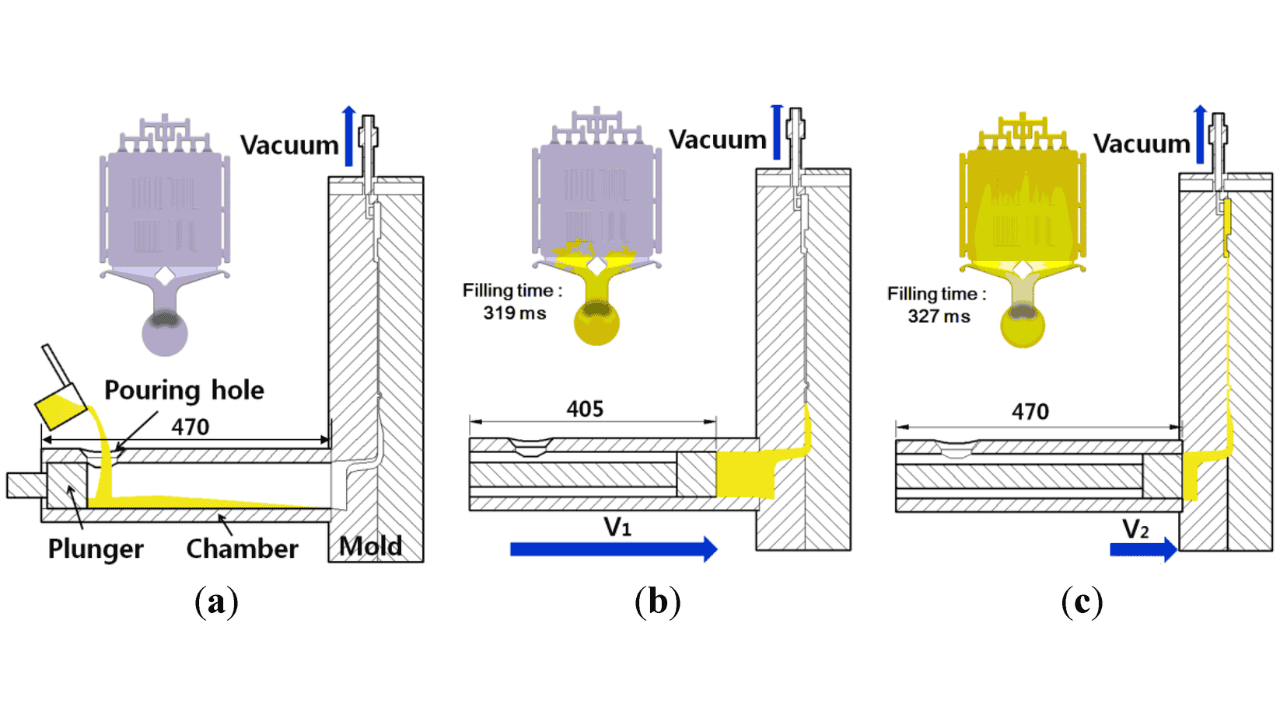

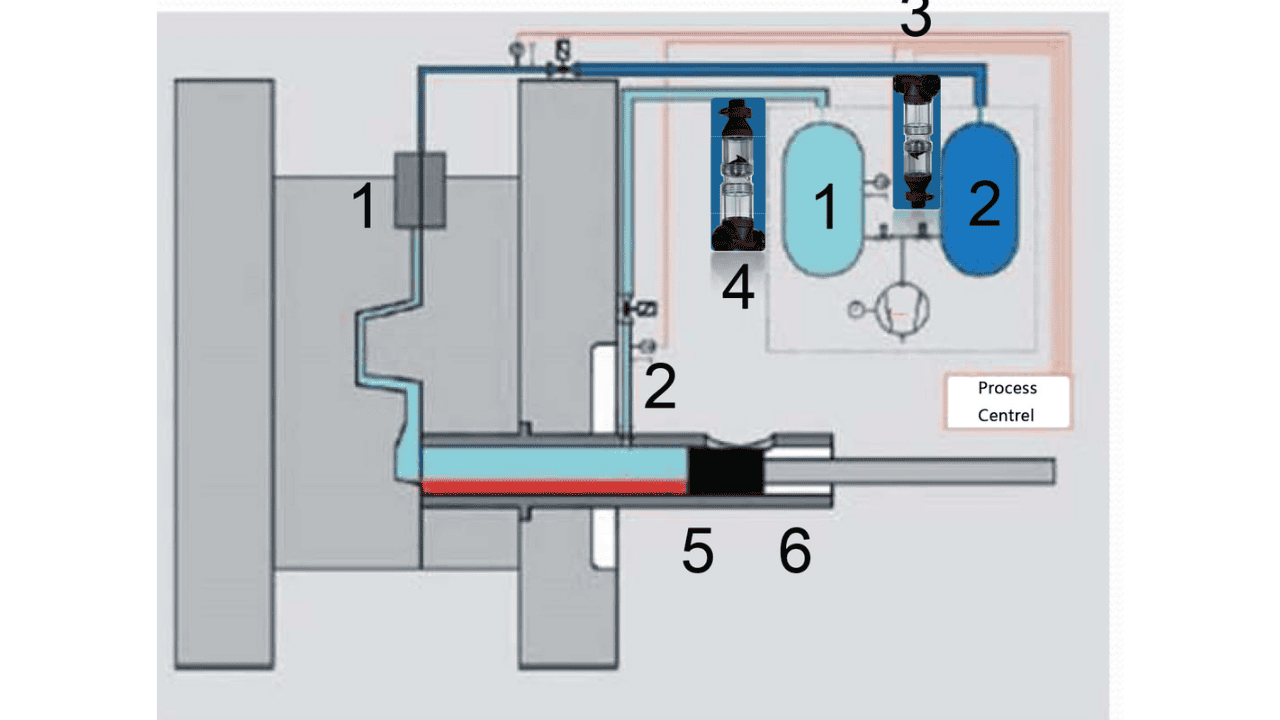

The main difference between this and the traditional die casting is the addition of a vacuum system. This system removes air and gases from the mold in preparation for and during the injection of the molten metal.

This prior step goes a long way in reducing porosity, thereby preventing the passage of unwanted liquid substances like water during production. It also helps increase the parts structural integrity and provides a smoother surface finish.

Vacuum Die-Casting Processes

If you are familiar with the custom die casting processes, then the following steps shouldn’t be alien to you. This is because both processes are very much alike except for the introduction of a vacuum system, which we mentioned earlier. Let’s get into it right away!

Mold Preparation

Casting is the number one step to take in a vacuum die casting process. It involves the formation of a replica, i.e. a pattern or prototype of your desired final part that is then used in creating a mold or die cavity.

The casting is usually made of steel due to its malleability and high strength. At this stage, it is important to add a removing agent into the die cavity to ensure a smooth removal of the casting after production.

Melting the Metal

The next step is to get your desired metal material which could either be aluminum, zinc, copper, or magnesium alloys and make use of a furnace or other heating technique to subject it under the required temperature to get the metal into its molten state.

Creating a Vacuum

This particular procedure is what entirely differentiates the vacuum die casting from traditional die casting. A vacuum system is used to suck out trapped air and gas from the die cast, reducing porosity.

Injection of Molten Metal

The hot metal in its liquid or semi-liquid state is then transferred into the mold cavity using the required high pressure. Injection is carried out under close supervision to minimize defects such as cold shuts, shrinkage, and blowholes that could occur at this point.

Solidification and Ejection

After injection, the mold cavity is kept aside for cooling and hardening to take place. This process should be carried out under a regulated cooling system in order to avoid shrinkage or cracks which are possible defects during solidification.

When the molten metal is fully formed into the solidified component, it is ejected from the die cast. Because of the removing agent that was applied during the mold preparation and the vacuum operation carried out, it makes the ejection process easy.

Now that the cast has been successfully ejected, it may not be in the perfect state and might require some trimming and finishing.

Metals Used in Vacuum Die Casting

Aluminum Alloy

The most widely used aluminum alloy for die casting are the A356 and A380. The A356 is utilized in the aerospace industry for making impellers, aircraft, pump housing, because of its high strength, light weight, good casting and machining properties.

The aluminum grade A380 identical to the ADC 10 is known for its resistance to wear and its exceptional casting and mechanical properties. Used in the manufacture of gear cases, motor shells, and tool parts.

Magnesium Alloy

Magnesium alloy is mostly suitable for casting structural components that require high strength-to-weight-ratio especially in the aerospace, automotive, and electronic industry. It has a lower melting point than the aluminum alloy making it more excellent in terms of energy consumption during the heating process.

Zinc Alloy

Zamak 3 alloy also called Zinc Alloy 3 is popularly employed in the US for die casting due to its excellent physical and mechanical properties. It offers a long-term dimensional stability and good surface finishing that makes painting, plating, and coating very easy to apply to final products.

Copper Alloy

An example of this is the copper-tin alloy, also called bronze. It has a high corrosion, wear, and saltwater resistance, and a load bearing capacity that makes it suitable for use in the marine industry for manufacture of pump shafts, valve bodies, and ship fittings.

Because bronze is a copper alloy and does not consist of a large amount of zinc, it is not prone to rusting in harsh environments. Instead surface stains and discoloration can be cleaned and removed by ordinary cleaning methods.

Advantages of Vacuum Die Casting

There are many benefits of high- pressure vacuum die casting when compared to traditional die casting. They include:

Reduced Porosity

Vacuum die casting involves the extraction of air and gas from a mold before injection. This allows the consistent flow of the molten metal into every nook and cranny of the die cast ensuring that no part is left unfilled or with holes.

When there’s a reduction of pores during die casting, the final product always has a smooth surface finish. Additionally, it enables heat-treatment to be carried out more efficiently without a risk of obtrusion from trapped air.

Improved Quality Parts

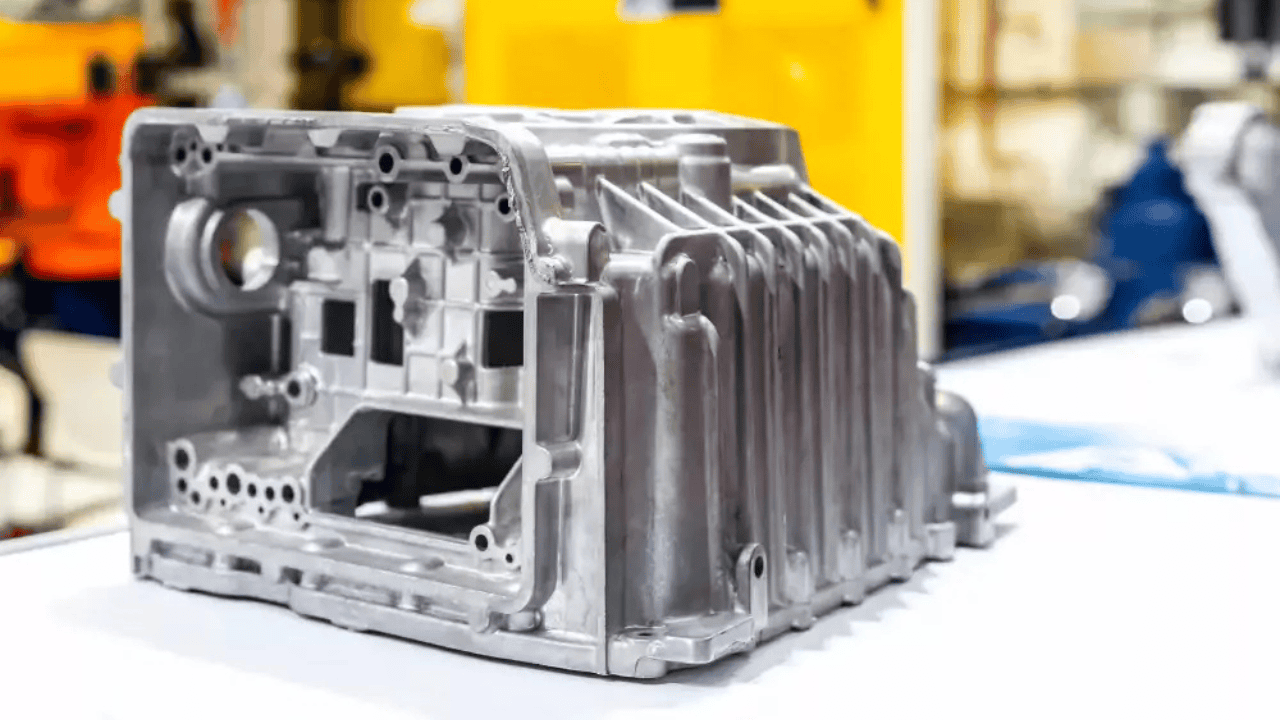

Vacuum Die casted components tend to have very few defects and might not require a post process. They are usually known to exhibit compatible mechanical and physical properties such as enhanced density and structural integrity across all body parts.

High Precision and Accuracy

This is one of the many benefits of vacuum die casting over traditional die casting. It allows for the formation of complex and intricate geometries, accurately filling up the die cavity with the molten metal, while reducing inconsistencies and defects.

It is recommended for applications that require high-performance components, tight tolerance and precise specifications.

Increased Strength and Toughness

Reduction in porosity and entrapment of air during the die casting process makes up for the increase in the strength of components. Vacuum die casting parts can easily undergo heat treatment like welding and machining without any surface defects.

Applications of Vacuum Die Casting

Automotive

A high vacuum die casting system is used in the manufacture of automobile components that requires dimensional accuracy, high precision, and excellent mechanical characteristics.Some of these components include transmission cases, cylinder heads, suspension components, dashboards, and other structural body parts.

This process is widely employed in the automobile industries because of its ability to produce high quality identical components consistently in large volumes.

Aerospace

High-pressure vacuum die casting of anodizing aluminum can be employed in the production of aircraft components. Due to its high accuracy and precision, and capacity to create complex designs, the parts formed using this process are known to exhibit excellent durability and high-strength.

Some aircraft parts that are formed using vacuum die casting include fuel systems, turbine blades, air ducts, and thin walls systems.

Medical Equipment

When fabricating biocompatible metal parts like titanium, stainless steel alloys, and platinum, all of which are utilized in production of medical implants and devices, the vacuum die casting process can be applied.

Consumer Goods

A major benefit of this technique that cannot be overemphasized is the ability to create complex and intricate designs with high precision. It ensures that no matter the shape of your prototype the molten material is evenly distributed while reducing porosity and air interference.

The process is used in the manufacture of toys, sport equipment, kitchen appliances, and consumer hardware components .

Common Defects That Can be Removed by Vacuum Die Casting

Porosity

Porosity is a major defect that occurs during die casting. It is the entrapment of air bubbles in a cast and if not discovered on time could lead to the rise of other defects. Vacuum die casting is used to eradicate the trapped gas and air from a die mold before injection of the molten metal.

It significantly reduces internal voids and gas pockets in the final part formed. This process also helps increase the strength and durability of the component, while providing a smooth surface finish.

Cold shuts

Cold shuts are caused by the improper fusion of two streams of molten metal resulting in cracks or weak points and forming visible lines on the material. This defect can be associated with low melting temperature, slow injection speed, or poor gating system.

There are several ways to control and prevent cold shuts, which include increasing the melting temperature and injection speed. Also, the controlled pressure in vacuum die casting enhances metal fluidity and reduces turbulence during injection.

Shrinkage Defects

This defect is caused by inconsistent flow of the molten metal into the cast. Shrinkage also occurs if proper care is not taken during the solidification process, because metals are known to contrast after cooling.

So to avoid these contractions and shrinkage defects, it is important to ensure an adequate gating setup before injection. Additionally, carrying out a vacuum die casting helps ensure that there’s a uniform flow into every intricate part of the cast thereby reducing shrinkage.

There are many other defects that can be encountered during die casting. They include inclusion, run out, misruns, warping, slag, blisters, etc. It is essential to know all of this and their causes in order to ensure an efficient die casting process and also achieve excellent final products.

Limitations of Vacuum Die Casting

Despite its advantages over the traditional die casting processes, vacuum die casting is not without its limitations. Some of which are listed below:

Incompatibility with all Metals

Just like traditional casting, vacuum die casting cannot be achieved with all metals. There are particular metal alloys that are suitable for this process which include zinc alloy, aluminum alloy, and magnesium alloy.

While ferrous metal like steel tends to react with the die material making them less suitable. Additionally, vacuum die casting cannot be used in applications that require very high-temperature.

High Cost of Equipment

Production of die casting molds and the initial setup cost can be very expensive due to the additional vacuum system consisting of several new valves and pumps.

Time Consuming

The vacuum die casting is a little slow and technical process. It requires constant monitoring and supervision to complete one part of a product. Therefore, it does not offer adequate efficiency for production of large quantities of parts.

Conclusion

Vacuum die casting is an innovative manufacturing technique that enhances the metal part and provides a smooth surface finish by decreasing the porosity rate during casting and increasing the mechanical properties of complex designs.

At HM we provide a conducive and regulated environment for high vacuum assisted die casting operations. Contact us to get you started on your vacuum die casting project in our state of the art factory.