Standard machining techniques cannot produce some complicated geometries. In such cases undercut-machining becomes necessary. If you master this method you can get extraordinary accuracy, part quality and performance.

In this blogpost we will cover different undercut-machining tools, types as well as best practices for this machining.

What is Undercut-Machining?

It is a manufacturing process which is used to make recessed features below the surface of a workpiece. This CNC technique uses multi axis machining centers and custom tooling to remove material from difficult-to-reach areas.

You will find this technique necessary in creating complicated internal geometries, for interlocking parts and O ring grooves in medical and aerospace parts.

Types of Undercuts in Machining

a. Internal vs External

Internal undercuts are features such as cavities and internal threads etc that are made on the inside of a part. These features are more difficult to machine as the tool cannot reach them easily.

On the other hand external undercuts are features created on the outside of a surface like surface protrusions & external threads. They are easier to machine because the tool can easily reach them.

b. Common Geometric Profiles

i. T-Slot Undercuts

These undercuts have a T-shaped design containing a flat base and long sides. You can find them in mounting slots, fixtures and interlocking parts where adjustable and secure connections are required.

ii. Keyway Undercuts

A keyway-undercut holds a key inside a shaft or hole. This design assures proper transfer of torque in mechanical systems such as pulleys and gears and stops rotational movement between interconnected parts.

iii. Dovetail Undercuts

These undercuts have an inverted trapezoid shape with a narrow top and a wide bottom. Aerospace or mold components mostly use this design for secure joints.

iv. O Ring Grooves

These are precisely dimensioned grooves to hold the O rings to form a strong seal between the surfaces. You will find these undercuts in pneumatic and hydraulic systems where they are important to maintain pressure and prevent leaks.

v. Spherical Undercuts

These undercuts create spherical or 3-D surfaces that have resemblance to a part of sphere. Bearings and ball joints commonly use these for better rotational motion.

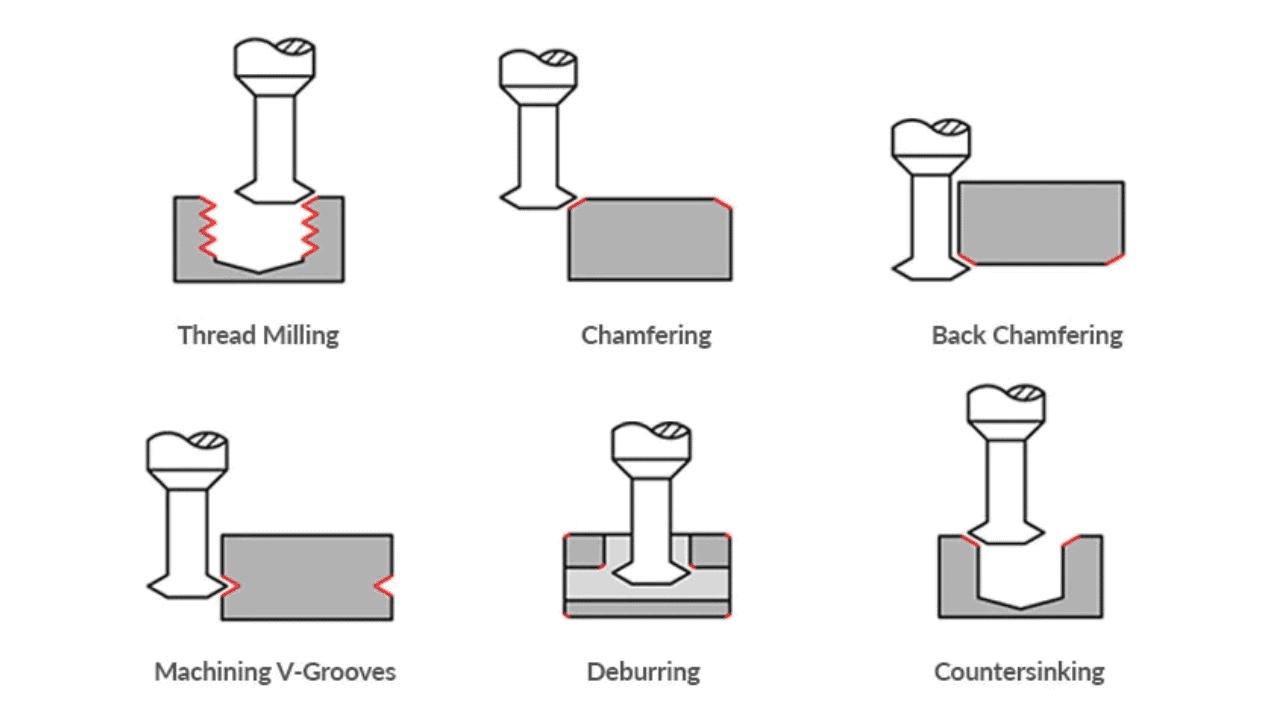

Techniques and Tooling in Undercut-Machining

a. Specialized Cutters

i. Lollipop Cutters

These special tools come with a thin neck and a rounded tip. You can use them to reach hard-to-access areas with cutting angles of 30 to 60 degrees. Its round head can reach deep corners and gives precise finishing and smooth contouring. In aerospace manufacturing, these cutters are necessary to make precision parts and complicated internal geometries.

ii. Dovetail Cutters

These cutters have angled edges which make distinctive dovetail-shaped grooves. The design includes a wide bottom and narrow top section which makes a self locking joint. You can choose between standard angles of 45 and 60 degrees. These cutters work smoothly in manual and CNC machining operations to provide durable and accurate cuts.

iii. T-Slot & Keyway Cutters

T slot cutters have horizontal flat blades which are connected to each other. These blades can cut from all three sides and range from 3 to 40 mm in width. You will find them particularly useful in machine beds for making secure fixtures.

Keyway-cutters are cutters whose edges are symmetrical. These edges balance the radial forces so that key-slots in the shafts can be accurately machined. Also their two flute design lessens chatter.

iv. Undercutting End Mills

These solid carbide tools feature a 270 degree rounded cutting edge. You can choose between a tapered or straight neck for better rigidity. This design allows undercutting, multi-axis machining and deburring in confined spaces. Medical component manufacturers depend heavily on these multi use tools.

b. Tool Coatings & Materials

i. Carbide vs. HSS

Carbide tools outshine in machining coarse abrasive and hard materials because of their greater hardness, thermal resistance and cutting speeds.

HSS tools also have many advantages such as they work better with softer materials and are easy to sharpen. You should use HSS tools for low speed tasks⸴ particularly in low rigidity setups.

ii. TiN/TiAlN Coatings

Tool manufacturers use Titanium Aluminum Nitride (TiAlN) and Titanium Nitride (TiN) coatings to improve cutting results. TiN works well for general machining tasks while TiAlN is more effective in high temperature conditions. Both coatings reduce friction, increase wear resistance and prolong tool life.

Best Practices for Undercut-Machining

a. Selecting Right Tool

The success of undercut-machining depends greatly on picking correct tool. Type of material, undercut geometry & depth are three factors which must be kept in mind when picking a tool. Use lollipop cutters for curved and rounded undercuts, dovetail cutters for angled interlocking features and T slot cutters for working on horizontal grooves.

b. Chip Evacuation

Efficient chip removal prevents many problems such as unwanted heat generation, surface defects and excessive tool wear. Use high pressure air or coolant systems to remove chips from tight places. Choose tools with advanced flute geometries and implement adaptive CAM approaches to hold consistent chip flow.

c. Fixturing & Workholding

Complete stability of workpiece is also essential for difficult undercut operations. Use customized clamps, jigs or soft jaws to prevent any movement during machining and use tooling plates or multi axis fixtures for better reachability to difficult areas. It is important to take care of accessibility in positioning your workpiece throughout this operation.

d. Surface Finish

Feed Rates and spindle speeds must be addressed to get the best surface finish. Keep feed rates low during fine finishing operations because this method lets you make small & accurate cuts that create smooth surfaces. Remember that high cutting speeds generate heat which can affect surface quality.

e. Quality Control

Inspect dimensions & undercut tolerances with laser scanners and CMMs. Check surface finishes regularly to find any irregularity. Moreover monitor processes in real time & keep track of tool wear to maintain same quality across multiple productions.

Overcoming Common Challenges

- Limited tool accessibility is a big challenge in undercut-machining, so use multi axis CNC systems to reach recessed or restricted areas. Carefully plan your approach to assure accurate machining of complicated geometries and collision avoidance.

- Abrasive materials and large cutting forces increase the risk of tool breakage and wear. So choose carbide tools with proper coating to avoid these problems.

- Surface finish can be compromised due to material variations or incorrect cutting parameters, so optimize feeds and create accurate toolpaths to get smooth surfaces.

- Complicated undercut geometries can make programming more difficult and thus increase the chance for error. To avoid this and to generate an accurate toolpath, use advanced CAD or CAM software & stimulate the whole machining process.

To Sum Up

Modern manufacturing needs undercut-machining to make complicated parts with high precision. You can get best results by using advanced techniques and specialized tools. Undercut-machining helps solve common problems like programming complexities and tool accessibility.

If you need any kind of CNC undercut-machining services, then hMaking is best option. You can contact us anytime.

Related Questions

1. How does material hardness impact tool selection for machining aluminum vs titanium undercuts?

Hardness of material directly affects the tool choice. High speed steel tools work best for aluminum undercuts while titanium needs carbide tools with a specialized coating to assure long term durability and withstand heat.

2. Are there cost effective alternatives to custom undercut tools for low volume production?

Yes you can use specialized off the shelf tools like lollipop and T slot cutters in place of custom tools because these options keep costs down and give almost same accuracy as custom tools in low volume production.

3. What role does CAM software play in simulating undercut toolpaths for complicated geometries?

CAM software performs three main functions in undercut-machining. It makes accurate toolpath simulations, identifies potential collisions and develops best possible cutting strategies. These features make your machining process error free and fast.

4. How do safety protocols differ when machining-undercuts in materials like beryllium aluminum alloys?

When machining beryllium aluminum alloys⸴ you must assure proper ventilation, use personal protective gadgets and specialized collants. These protocols protect against the toxic effects of machined beryllium-aluminum particles.