Your CNC machining of parts requires suitable metals or ABS materials to produce components. However, some projects require Polyetheretherketone (PEEK) CNC machining to produce high-performance components, especially for medical, aerospace, and electronic industry applications.

This article explores all you need to know about PEEK plastic Computer Numeric Control (CNC) machining, including its pros and cons. It also highlights key application areas and provides valuable tips to ensure you are at the top of your machining game!

Understanding PEEK CNC Machining.

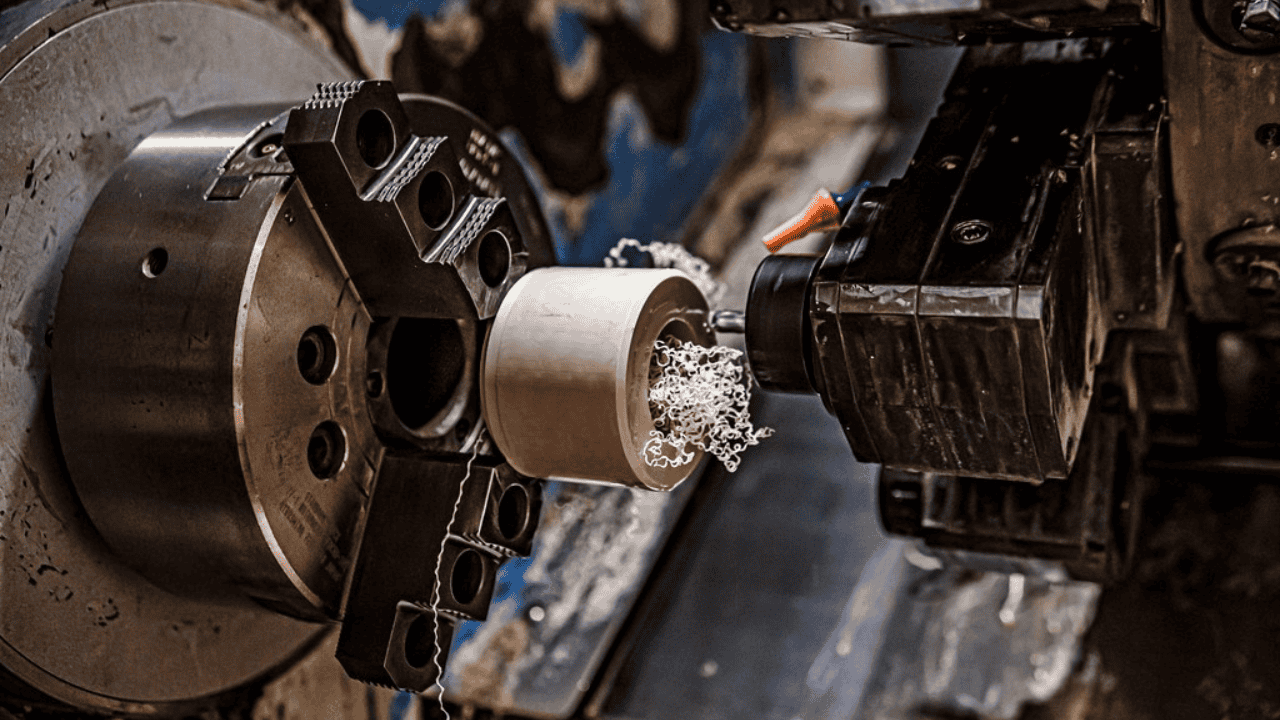

Unlike the metal CNC machining needed to produce high-precision metal parts, PEEK CNC machining is a computerized approach to cutting or shaping a thermoplastic polymer or plastic material to suit the desired application needs.

The machining technology, therefore, requires that the tools you use for plastic machining processes such as drilling, cutting, or shaping your plastic parts are programmed.

This technique is useful if your project requires superior engineering thermoplastic to produce automotive, medical, electrical, or aerospace components.

There are two main grades of PEEK to use for your CNC manufacturing processes. These are: Industrial PEEK and Medical PEEK.

Benefits and Drawbacks of PEEK CNC Machining Technology

Before you adopt PEEK CNC machining for your parts production, you must be aware of its benefits and limitations in two aspects:

Firstly, the benefits and limitations of choosing PEEK as your main production material.

Secondly, the benefits and limitations of embracing the CNC machining technology to produce the desired PEEK components.

The Benefits of PEEK Material for CNC Machining

PEEK is a superior form of plastic favored for high-performance applications, especially in harsh working conditions.

Choosing PEEK as your production material has advantages linked to its favorable properties. These include:

- High-temperature Stability: PEEK materials can withstand constant higher temperatures than any other form of plastic. Parts made of the material can operate efficiently at temperatures as high as 482°F (250°C).

- Chemical Resistance: PEEK has an excellent tolerance to chemicals and is known for its low absorption of water or moisture. Therefore, it is a perfect material for use in harsh chemical conditions.

- High Mechanical Strength: This enables PEEK parts to operate under heavy loads.

- Lightweight: PEEK has a low density compared to metals, making it an ideal choice if you are looking for light but strong components for parts, such as medical implants, aerospace, or some automotive components.

- Biocompatibility: Some PEEK grades are biocompatible. This implies they are non-toxic and human-body friendly. It is, therefore, a perfect choice for producing intricate body implants.

- Excellent Resistance to Wear: Parts made from PEEK material boast superior resistance and, so, will serve you for longer.

- Bio-degradation Resistance: PEEK material does not break down easily.

- Perfect Insulation Property: PEEK components offer excellent resistance to heat or electricity. This makes the material suitable for making parts that offer adequate protection against heat or electricity risks.

- Machinability Ease: PEEK is an easy-to-machine material if you use the right tooling for the right material grade.

- Durability: Parts made from PEEK materials are highly durable as they remain stable under different working conditions.

The Benefits of Adopting CNC Machining To Produce PEEK Parts

So, apart from the excellent properties of PEEK, why should you choose CNC machining for your parts production and not manual machining?

These are the reasons:

- CNC Machining Compatibility & Flexibility: Plastic materials are easily machined by CNC machines. Therefore, the PEEK CNC machining approach provides the flexibility to produce components to suit different industry needs.

- Fast Material Feed/High-Speed Machining: Because of the PEEK’s high-temperature tolerance, CNC machining allows you to achieve faster machining speeds compared to other plastics. This allows you to produce more parts without worrying about high-temperature risks.

- Tight Tolerance and High Accuracy Level: Like with other CNC productions involving other materials such as brass, PEEK CNC machining guarantees you high machining precision with tight tolerance. So, it ensures that your products conform to their design parameters with no wastage because of rejects.

- Automation Ease | Repetitive Production Ease: PEEK CNC machining allows you to automate your production process because once your CNC machine is programmed, it will save you time and resources when producing PEEK parts that require repetitive machining processes.

Limitations of Plastic CNC Machining

Save for its colorful advantages, the adoption of PEEK CNC Machining technology also has the following key drawbacks or limitations.

- The High Cost of PEEK Material: Compared to other plastics, PEEK is costly. This can be a major limitation if your production budget is low.

- Limited to Specific Part Designs & Applications: Plastic CNC machining is limited to specific parts designs that require complex parts or details with small wall thickness. Therefore, in common instances, you may find the use of CNC machining with other metals more popular than PEEK.

- Demands Effective Heat Management: Even though PEEK has excellent heat resistance, it requires effective heat management to avoid potential damage. Effective heat management and suitable machining tools are important to limit heat-related stress that can cause cracks.

- Requires Expertise & Machining Caution: Though PEEK is easy to machine, trying to machine your parts much faster than is necessary can cause irreparable damage.

- Required Annealing: Your PEEK workpieces require heat treatment or annealing before the machining process to produce defectless parts. If a product’s machining process is demanding, more annealing may be necessary before the part’s completion. This increases the production cost while limiting the quantity of parts you can produce.

- Tear and Wear On CNC machining tools: If you plan to use basic tools for your PEEK CNC machining, then be ready to replace them more frequently. This is because PEEK tends to be abrasive causing basic tools to wear out much faster.

- Deep-Drilling Risks: If you are not careful, drilling deep holes in your PEEK component, especially if not effectively annealed, can cause it to crack. This is because of its poor heat conductivity, resulting in the drilled part melting or getting deformed.

What are the Applications of CNC PEEK Machining?

Through CNC machining, you can use industrial or medical-grade PEEK material to produce components targeting different industries. Below are some of the industries that benefit from plastic CNC machined or produced parts:

PEEK Parts In the Aerospace Industry

With the plastic CNC manufacturing process, you can produce light, durable, and high-performance products for the aerospace industry.

These components are designed for efficient performance under varying conditions. Examples of such products include but are not limited to seals and fittings, gaskets, and thrust washers.

The Automotive Industry

PEEK CNC machining is also used in producing automotive parts that are resistant to wear and tear and can perform in high-temperature conditions.

Such components include engine seals, bearings, clutches, pistons, gears, and electrical connection housings.

Electronics Industry

As already mentioned, PEEK is resistant to high temperatures and are perfect heat or electrical insulator. As such, its CNC-produced parts find their use as safe and effective cable insulators in electronic circuit boards of high-performance devices.

Oil & Gas Industry

The oil and gas industry uses heavy machines that operate in harsh chemical environments. PEEK CNC machining is used to produce high-performance seals, bearings, and bushings. These offer excellent resistance to both chemicals and high temperatures to ensure stable operations.

Further reading on PEEK applications in the oil and gas industry is here.

Medical Sector – Healthcare & Dentistry Applications

Through the use of medical-grade PEEK and CNC machining technology, the production of body-friendly medical devices has become a reality. Some of the PEEK products include medical implants, orthopedic devices, spinal fusion devices, dental healing caps, etc.

Valuable Tips for Effective PEEK CNC Machining

If you plan on successful implementation of PEEK CNC machining projects, here are valuable tips you must keep in mind:

Keep Your Workpiece & CNC Machine Clean

Contaminants on your PEEK material’s surface can affect your machining precision. Therefore, you must ensure your material is clean and free from particles.

Your CNC machine, especially the cutting tool, must be perfectly clean before commencing the machining process.

Have The Right and Effective Cooling System

Because PEEK materials are excellent at maintaining heat, excess heat during machining can adversely affect its mechanical integrity or cause localized melting.

Therefore, before undertaking any PEEK machining operation, you must have the right coolant for your PEEK CNC machining process. Your PEEK grade should determine your choice of coolant.

For instance, if your project requires industrial-grade PEEK material, mineral-based liquid coolant is safe.

However, when working on medical-grade PEEK material, avoid using mineral-based liquid coolant as it will affect its desired biocompatibility. Instead, use pure water or compressed air.

Note: During your machining process, ensure that the coolant you use provides a uniform cooling effect on the PEEK component you are working on.

Choose Premium Tooling

Invest in PEEK machining tools that are resistant to the abrasive nature of PEEK material.

To maintain the high-quality finish of your produced components, and to avoid the inconvenience of having to frequently replace your worn-out tools, invest in premium tooling.

For standard PEEK-grade parts that require limited machining durations, go for carbide tooling for high-performance efficiency.

However, if your project demands superior PEEK grades with glass fiber reinforcement for an intense CNC machining process, Polycrystalline diamond (PCD) tooling is your ideal option.

Avoid High-speed Machining

Even though PEEK material is known to resist high temperatures, machining at high speed has high risks. Extreme heat can melt your workpiece or affect its shape.

So, to maintain your part’s mechanical property, and to ensure it conforms to its desired specifications, adopt a slow and steady machining approach.

Correct CNC PEEK Machine Configuration | Tool Setting

Before beginning your PEEK machining operations, such as milling or drilling, ensure that you have correctly set your machine for the part you intend to produce.

Your PEEK material grade and CNC machining process must determine your selection of the most suitable feed rate and cutting speed.

When using end mills for PEEK CNC machining, set them at a higher helix angle to facilitate the movement of chips away from your workpiece.

Proper setting will also enhance your machining efficiency while reducing heat accumulation on your workpiece.

Heat-treatment/Annealing of PEEK Material

If your PEEK parts machining process is demanding, you should begin by annealing your workpiece.

This is a heat treatment that involves subjecting the workpiece to a predetermined temperature depending on its grade. You then allow the material to cool at a gradual rate.

The process helps in improving crystallinity and eradicating internal stress that would result in surface cracks or deformation of your PEEK workpiece during the machining process.

For complex PEEK parts that require extended machining periods, you may need to anneal your workpiece multiple times during the process.

Annealing can also be a post-machining process to maintain the mechanical property of your final PEEK component.

Conclusion

PEEK CNC machining demands that you have adequate knowledge of different PEEK grades and their application areas. It is a complex process that requires expertise and suitable tooling.

At HM, we have the experience and the capacity to produce a wide range of CNC machining parts for different industries using metal and plastic materials, including PEEK.

Do you have a project you would want to discuss with us to help you implement? Contact us today!