Motor shaft machining is one of the intricate machining processes that can be used in the production of various types of shaft with high precision. To get very familiar with this machining process and also obtain maximum output, there are several concepts that you need to understand. This guide explains many of these concepts to help you get started. Read on!

What Is Motor Shaft Machining?

Motor shaft machining is a process that involves transforming metal rods into cylindrical rotating components called shafts. These shafts are highly used in making engines. The transformation process of metal rods can be achieved with the aid of specific cutting tools and techniques.

These machined shafts are critical parts in motor machines. They enable the transmission of energy from one end of a machine to another. However, it is very important to pay close attention to the various processes involved in carrying out motor shaft machining, because the slightest variation in its dimensions, surface finishing, and overall quality can alter a machine’s efficiency.

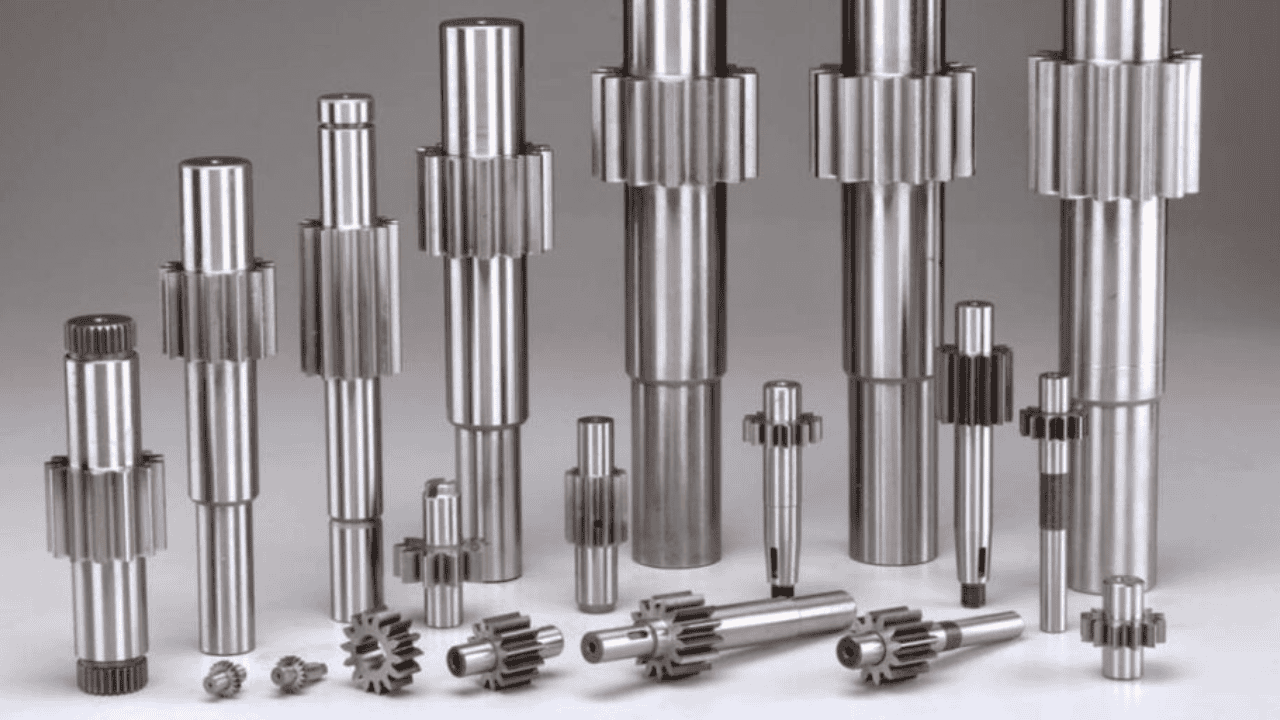

Types of Motor Shafts

Below are the major different types of motor shafts and their uses:

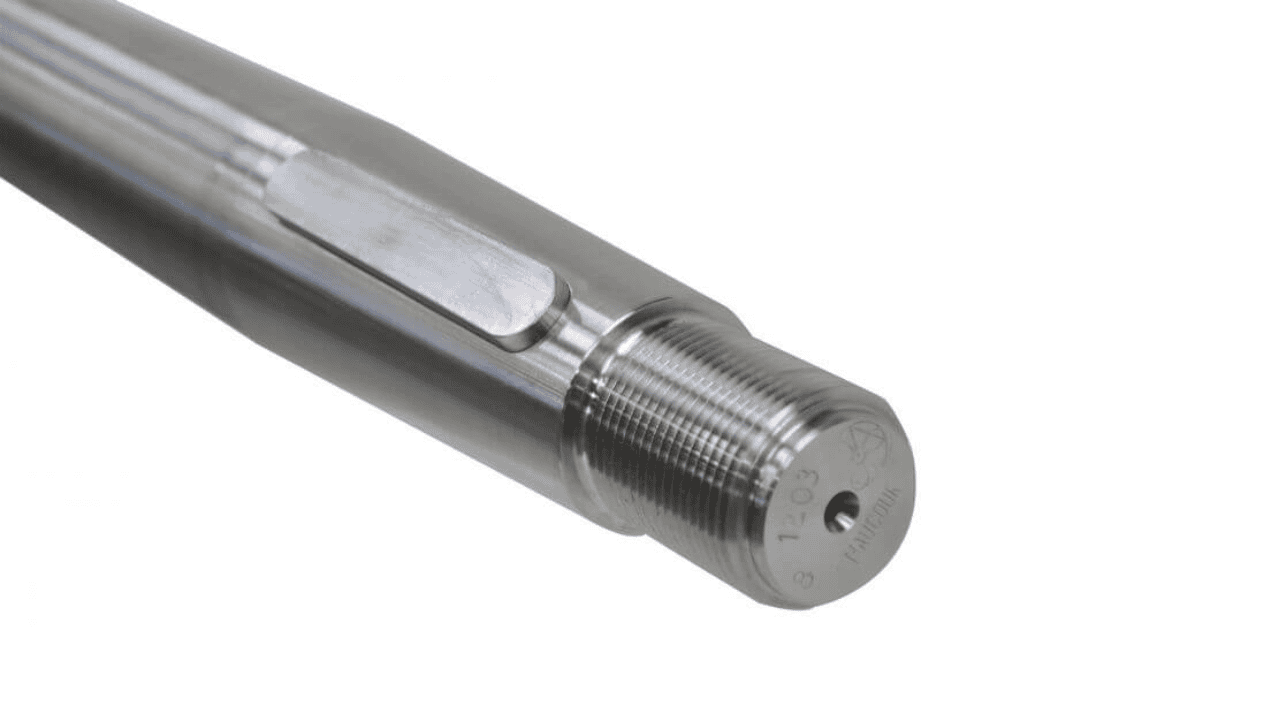

Threaded Shafts

Threaded shafts are shafts that have spirals which are called threads running over their entire length or, to a certain extent, i.e., they can be fully threaded or partially threaded on one or both ends. These types of shafts are used in various industries for holding two or more materials together. They are also similar to bolts and screws which are used to secure fastening.

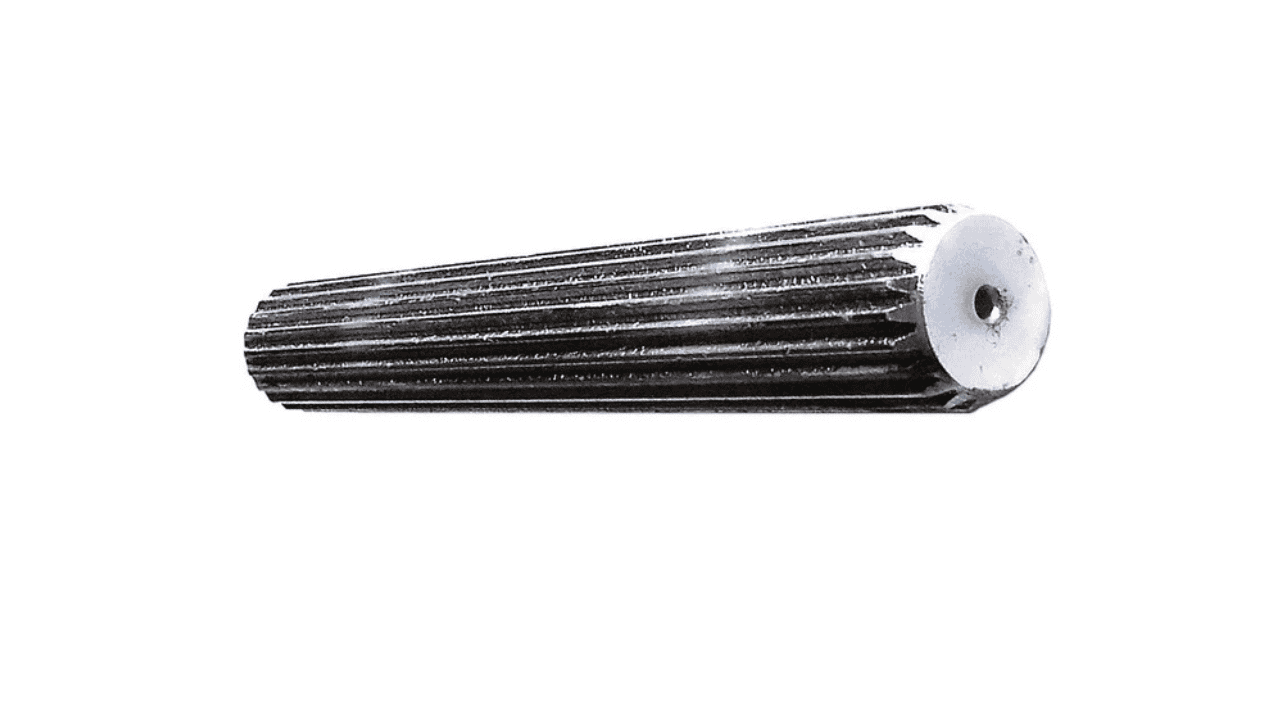

Splined Shafts

Splined shafts are motor shafts with multiple grooves or ridges. They are designed to interlock with their connected component, eliminating unwanted rotation whilst permitting linear motion, which helps transmit high levels of torque. They are used by the automotive and aerospace industries in the production parts that require disassembling and relative motion.

Hollow Shafts

Hollow shafts are lightweight shafts that are used by machinists in applications where strength, rigidity, lightweight material with robust performance is highly necessary. Their lightweight property is due to the hole within the motor shaft. This interior empty space could be used for the passage of fluid or wires.

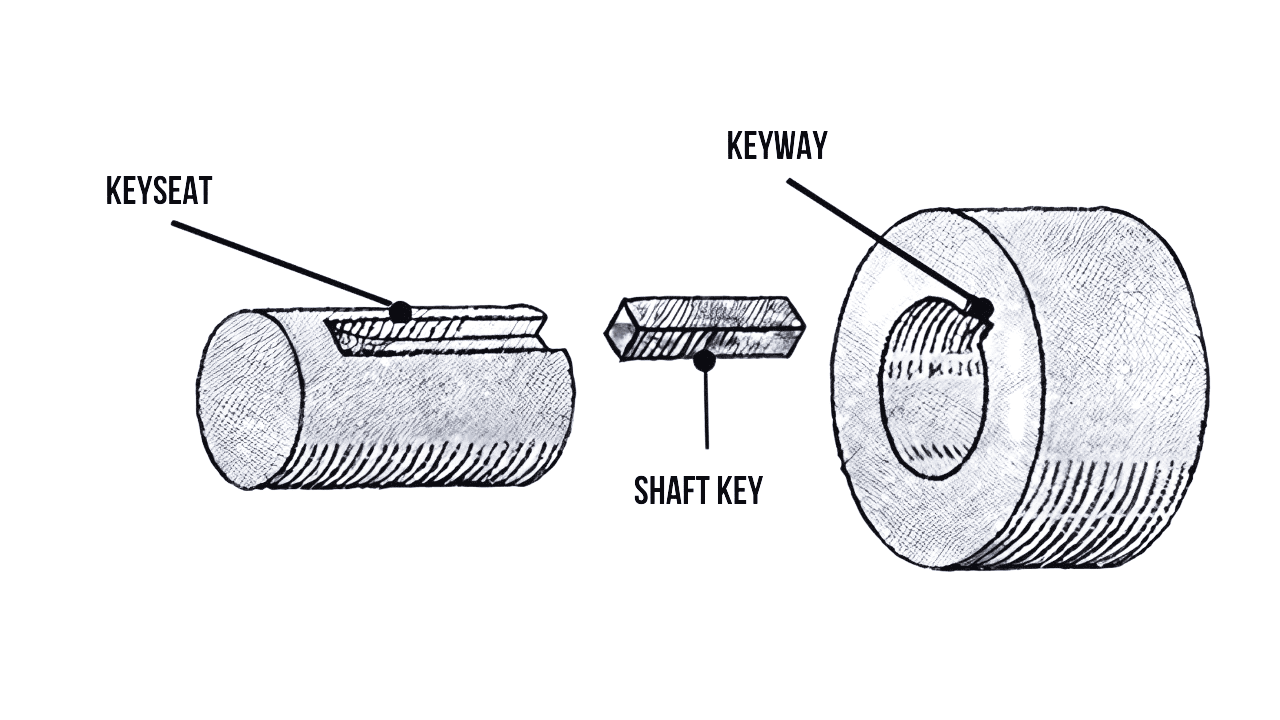

Keyed Shafts

Keyed shafts are motor shafts with a single groove, called the keyway. It is designed with four major components. These are the keyway, bore, keyseat, and the key. All of these parts have their different functions, but work hand-in-hand to ensure a tight fitting between two parts of a machine. Keyed shafts have a very good torque transmission.

Tapered Shafts

These are motor shafts that diminish or reduce in thickness along their length on one end to allow them to fit into another part. They are utilized in specific applications like automotive industries for the wheels of a vehicle.

Processes Involved in Motor Shaft Machining

These are the step-by-step machining processes involved in the manufacturing of shafts.

Load and Torque Calculation

Load and torque calculation is the first step to take in manufacturing shafts to ensure efficient and proper system operation. It is the process of determining the amount of load and torque a shaft will handle, because the higher the load, the higher the torque requirement. These calculations help determine the appropriate material, diameter, and design specifications.

Design on CAD

This is the next processing step involved in motor shaft machining. After calculating the load and torque a shaft can handle, the calculations are inputted into computer-aided design (CAD) software to create a 3D design model that allows you to visualize and design further. They serve as blueprints for machining motor shafts where precise modification can be done before large production.

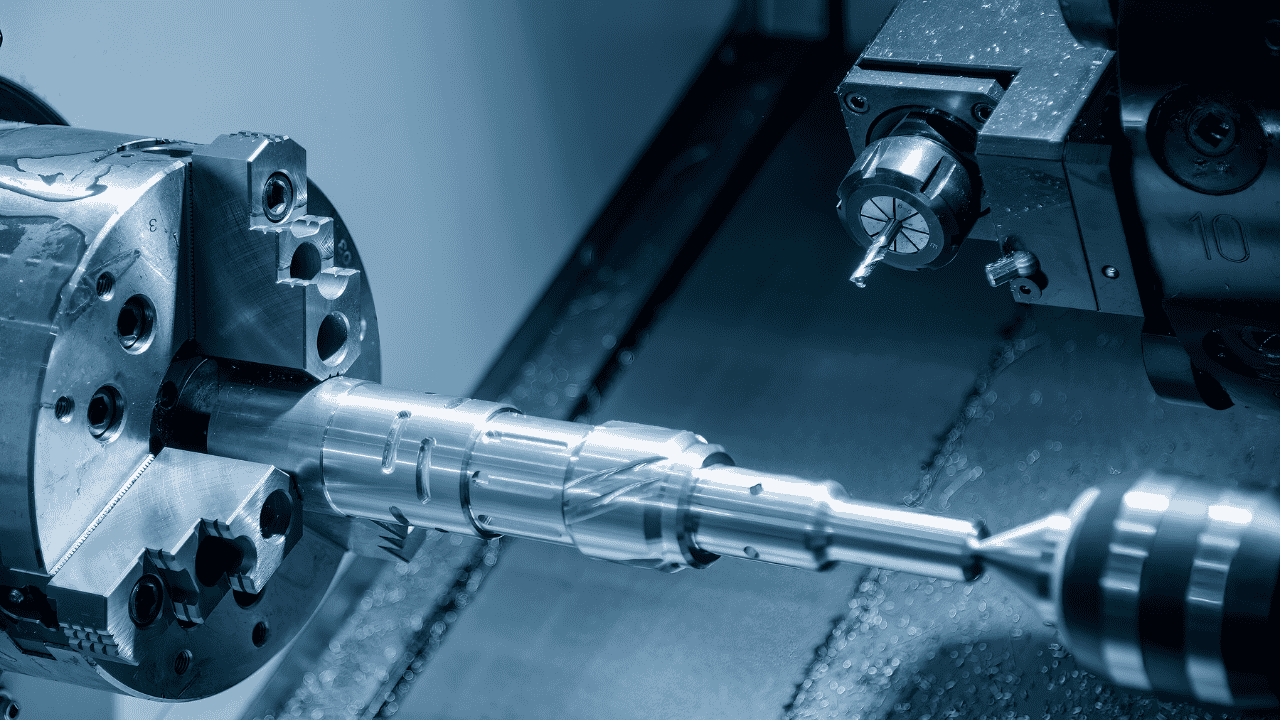

Actual Motor Shaft Machining

This stage is where the actual shaft machining is carried out on the metal rod using any of the different machining techniques such as CNC turning, CNC milling, and EDM. Here, the specific design, shape, and type of shaft required can now be achieved.

To continue this process, the CAM software containing the guideline and pathway for machining shaft which was created during the CAD design is inputted into the CNC machine and used to achieve precise cutting without material waste.

Surface Finish

The last step is the post-machining process. They are final finishes carried out on the machined shafts to enhance its tolerance and quality. Several surface finishing processes, like anodizing, bead blasting, and phosphating ensure the shafts’ physical and mechanical features are at their peak.

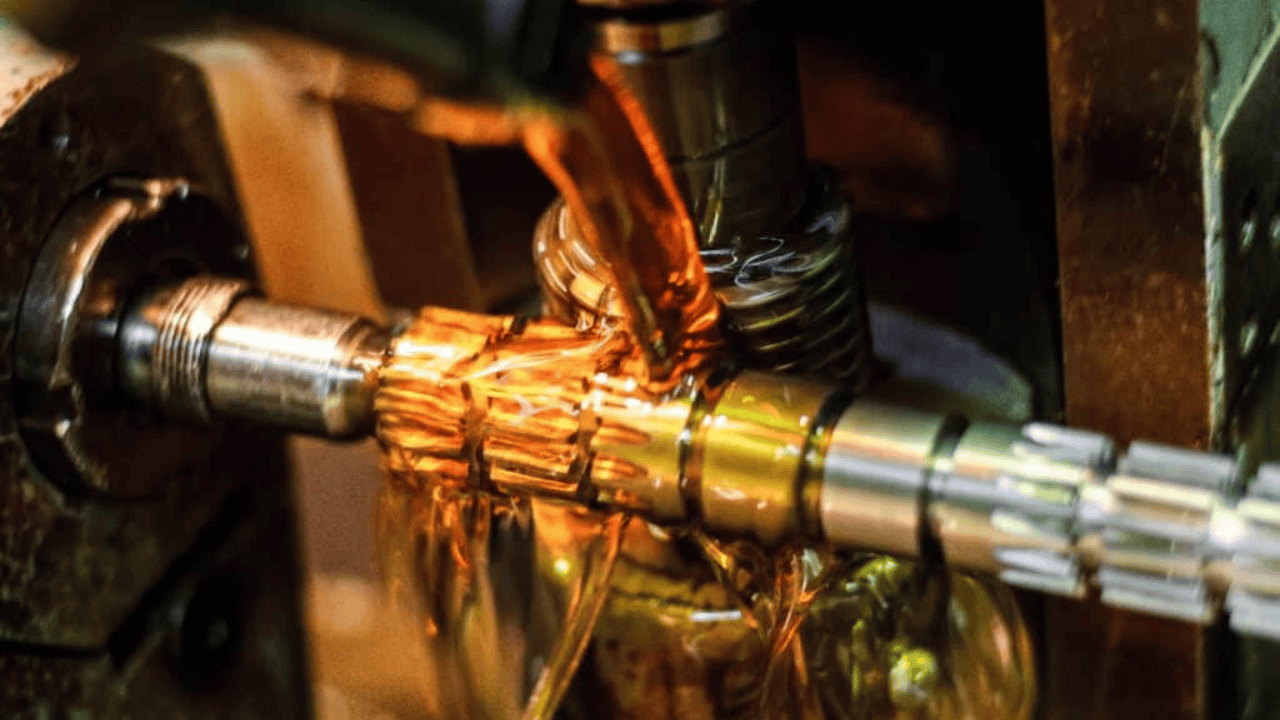

Various CNC Machining Techniques in Motor Shaft Machining

For increased efficiency and optimal functionality of a machined shaft, it is important to know the technique that is more useful when manufacturing any type of motor shaft. Below are some of the various CNC machining techniques used for manufacturing shaft motors:

CNC Turning

CNC turning involves the formation of the cylindrical shape of a motor shaft. It can be achieved by placing the motor shaft on a lathe machine while it rotates around a cutting tool removing excess material to achieve the desired shape and diameter. This technique is suitable for making tapered and cylindrical shafts.

CNC Milling

CNC milling in motor shaft machining is the movement of a cutting tool along multiple axes of a motor shaft in order to create shapes or grooves. CNC milling is used to create intricate features such as keyways, splines, and slots. It is best for creating keyed motor shafts.

CNC Drilling

This is a technique not used by many industries. However, if your motor shaft requires holes, CNC drilling is the way to go. In CNC drilling, an automated drill is used to perforate holes into the shaft for attachment purposes or the passage of wires.

CNC Grinding

CNC grinding is achieved when a rotating wheel rubs against the surface of the motor shaft to smoothen it. As the wheel rubs against the shaft, it removes unwanted parts, ensuring the accurate size needed is obtained

Electrical Discharge Machining

Electrical discharge machining (EDM) is a machining technique that uses an ED machine to discharge electric sparks for the precise cutting of motor shaft materials. EDM is more precise but not without risks like electrocution. Hence, they are typically utilized when CNC machining techniques aren’t efficient.

Types of Materials Used In Motor Shaft Machining

The type of material used for your machined shafts will greatly influence the efficiency of the machine. In this section, we will discuss the various materials and their properties which will serve as a guide in material selection:

Aluminum

Aluminum alloy is a widely used metal in motor shaft machining due to its remarkable properties. They are lightweight and highly corrosion-resistant, making them ideal for industries like robotics, where weight is vital. There are many types of aluminium shafts, they include; telescopic aluminum shaft, extruded aluminum shaft, and many more.

Carbon Steel

Carbon steels are very easy to cut, making them a good material choice in motor shaft machining. Carbon steels are graded based on their carbon content into low, medium, and high. An example of carbon steel is grade 1045.

Stainless Steel

It’s safe to say steels make good materials for motor shafts. Stainless steel grade 304 and 316 are known for their strength and high corrosion and wear resistance. When it comes to being cost-effective in manufacturing, grade 304 is a great option.

Alloy Steel

Alloy steels are steels known for their toughness. Motor shafts that are used for heavyweight duties such as crankshafts, drive shafts, and turbine shafts need to be hard, tough, wear-resistant, and durable. Hence, their materials are preferably alloy steels.

Brass

Brass is an alloy formed from the combination of zinc and copper. Its properties include corrosion resistance and machinability, making it a great material choice for motor shafts applied in lightweight machines.

Titanium

Ti is a lightweight, high-strength metal. It has an excellent strength-to-weight ratio, which makes it a great pick for this process. It comes in handy in industries like aerospace that prioritize such properties.

Nickel Alloys

These metal alloys offer exceptional heat and corrosion resistance. They are highly demanded by industries due to their high-temperature strength. Inconel is a kind of nickel alloy used for motor shaft machining.

Factors to Consider During Motor Shaft CNC Machining

Material Costs

It has been emphasized that the type of material your shaft is created with will determine the results given. Here, the cost of the materials will further determine which materials to utilize. It is crucial to select a cost-friendly material that meets the specific property requirements.

Why is this important? It helps reduce the overall costs which in turn boosts operational productivity. However, don’t go picking metals with poor properties because of cost, that’ll lead to failure. Metals like carbon steel are significantly cheaper than high-grade ones such as titanium.

Machining Processes

There are several machining processes to choose from, like CNC turning, CNC milling, or Electrical Discharge Machining (EDM). The EDM process, though effective, is also more expensive than the standard processes. Having earlier discussed the various machining techniques and what they are suitable for in this article, it should be easier to make your decision.

Cost of Tools

When accounting for the cost of tools, especially CNC cutting machines, it is crucial to account long-term. Even the best tools are still susceptible to defects, and machining will need a replacement. Hence, purchasing expensive tools today increases your overall cost of tools.

Cost of Labor

The cost of labor in the machining process is another key consideration. The more advanced and complex machining or post-processes required by the motor shaft will result in an increase in costs

Heat Treatment

Heat treatment involves several processes like annealing, hardening, quenching, and stress relieving. It is a major consideration in motor shaft machining which results in boosted strength, wear resistance, and hardness of the shaft.

Quality Control

The management of your motor shaft determines its longevity. This involves additional time investment in inspecting the hardness, roughness, dimension accuracy, and even the surface treatments of the shaft, which might also affect the overall cost.

Surface Finishing Processes In Motor Shaft Machining

Surface finishing processes are also called post-machining processes since they are done after the machine has been created. Some of the surface finishing processes are:

Anodizing

This is a post-machining process that involves the use of an electrolytic solution, it is a major surface finishing for machined shafts formed from aluminum. In this electrochemical process, the shaft is dropped in a solution that is flooded with electric current resulting in a colour change of the shaft and increased oxidation resistance.

Electroplating

Electroplating involves the addition of a layer of another metal to the surface of the shaft. In this process, the desired component is placed into a solution bath containing dissolved metal ions. Then a current is passed through the solution, inducing a reaction that sends thin layers of the ions onto the component. The electroplating method of finishing serves as a decorative and protective layer.

Phosphating

Phosphating as a surface finishing process is the coating of the shaft surface with phosphate to create a hard layer. This phosphate coating improves the corrosion resistance of the shaft, beautifies it, and allows for future paintings to be done.

Passivating

Passivating is the chemical treatment of the motor shaft to eliminate free ions on its surface making them less reactive to air or water. This process is done primarily for stainless steel and is carried out by using an acid to clean the surface of the motor shaft.

Nitriding

Nitriding is a surface hardening process involving heat treatment of the shaft from the diffusion of nitrogen into its surface. This process is more suitable for applications that require high wear resistance properties and durability.

Thermal Spraying

In thermal spraying, a coating material, maybe powder, is heated to a molten state. It is then sprayed onto the surface of the machined shaft, enhancing its strength, corrosion resistance, and thermal insulation.

Quality Control in Motor Shaft Machining

How well you handle your machines to minimize defects is a key factor in its result efficiency and accuracy. Here are a few quality control tips to ensure your motor shaft is working at its best.

-

- Periodic Quality Checks: This is proven to be the safest quality control method for your motor shafts. When you check your shaft at intervals, it is expected that you’ll pick up the first signs of a defect, allowing you to eliminate it before it escalates.

- Material Testing: In the machining process, it is crucial to match and create your motor shaft with materials that fit its task. Testing the properties of the materials, if they are hard, strong, or resistant to corrosion and high temperature is required.

- Dimensional accuracy: The slightest abnormal variation in the dimensions of the motor shaft will result in impaired performance. Ensuring the dimensions of the shaft are precise with tools like micrometers is essential.

Other quality control tips include surface finish inspection, measurement checking, inspections for scratches or wear, and documentation to help you keep track as you progress.

Conclusion

Motor shaft machining is an overlooked machining process but its importance cannot be overemphasized. Motor shafts often play an unseen role in the efficiency of machines across various industries. At HM, we offer the best motor shaft and the best quality control processes. Contact us today to get a quote for your motor shaft machining.