One of the vital parts of a machine is its gear which allows for its rotational movement. It is a circular body with a series of teeth that transmits the power and motion of one shaft to another shaft. A single gear cannot transmit power alone. It takes two or more interlocking (or meshing) rotating gears to transmit power.

So now, let us step into the terrain of machining gears in depth—what it is, what it is used for, the gear machining processes, and several of its pros and cons.

What Is Gear Machining?

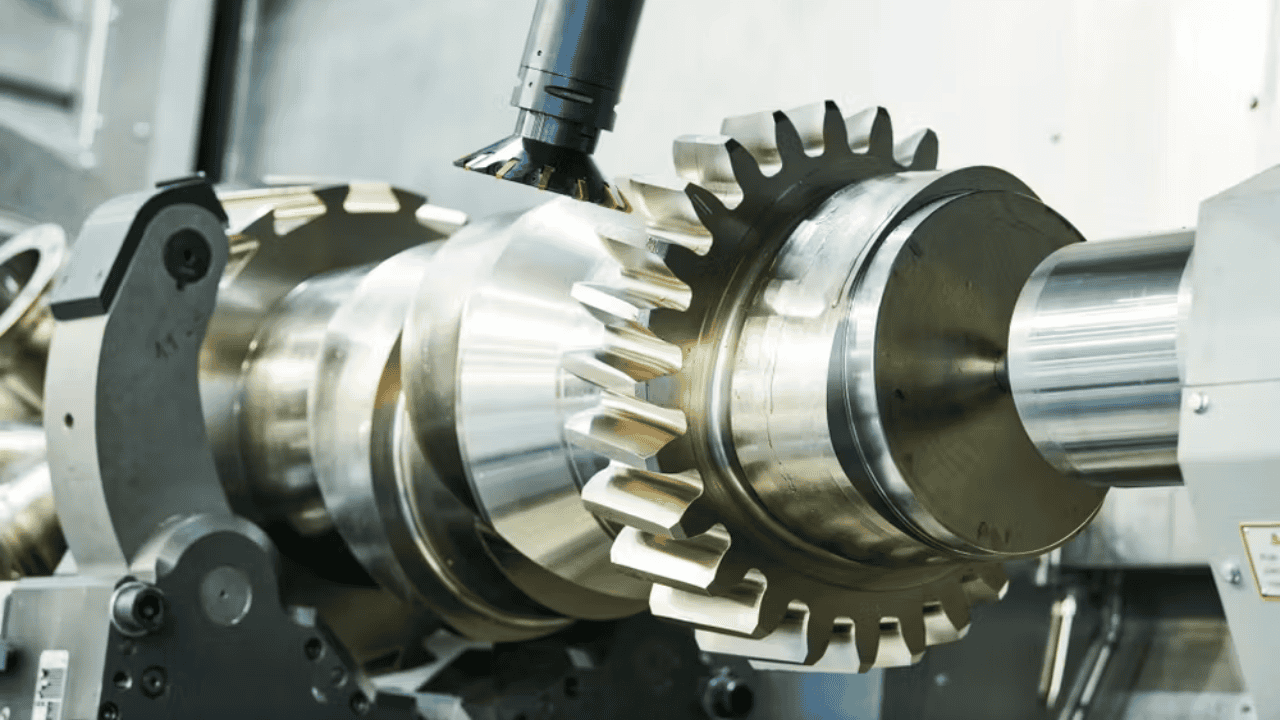

Gear machining is a manufacturing method that involves the removal of unwanted parts from a material to produce a final product called the gear. Such materials could be steel, brass, cast iron, plastics, polycarbonate, nylon, aluminum, or bronze.

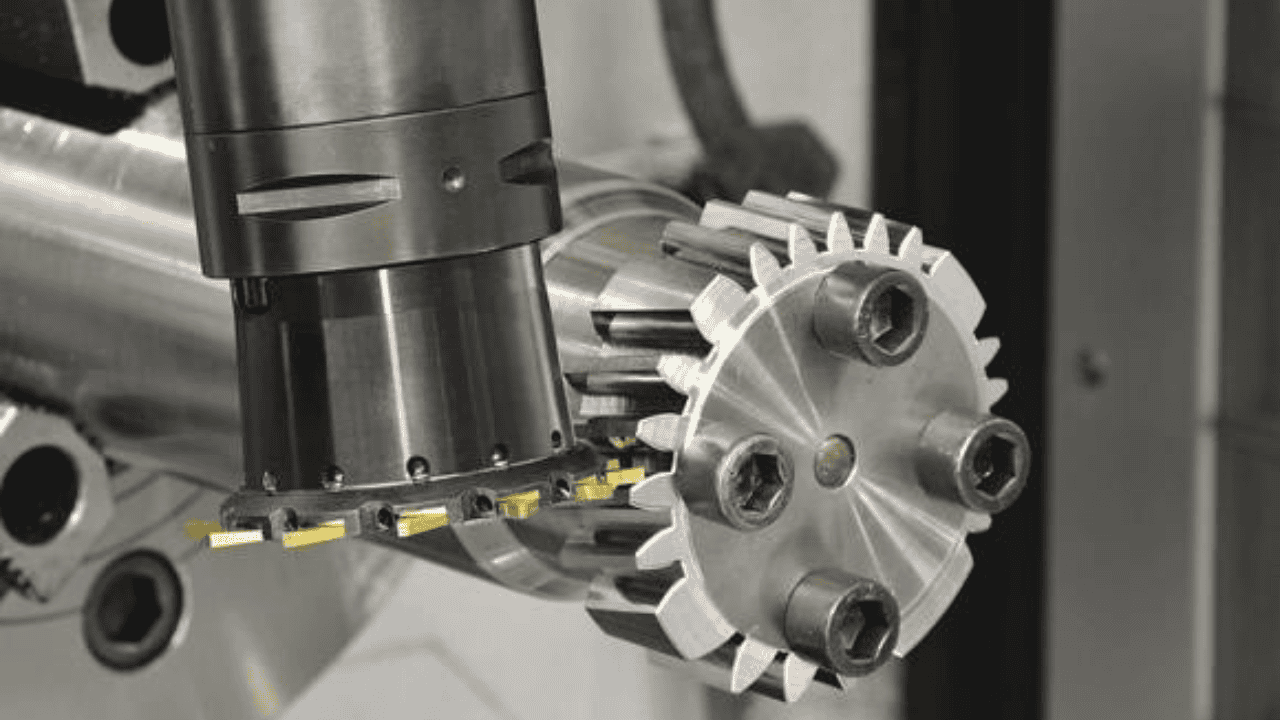

There are several machining processes that can be used to achieve a gear part. They include casting, milling, hobbing, grinding, cutting, and blanking. These gear machining processes require 100% precision for the transmission of power accurately.

How Does Machining Gears Work

The machining gear process has a lot of stages involved, from material preparation, to cutting, heat treatment, and finishing. It is considered a sensitive process because even a slight inaccuracy in set up can throw the machine’s intended function out of order. The actual purpose for the gear machining process is transmitting motion and power to a machine.

5 Stages of Machining Gears

Gear machining process consists of several stages before the final condition of the gear is achieved. We will discuss all the major machining gear processes below:

Preparation of the Gear Blank

The first step is to provide and prepare your gear blanks. Gear blanks are raw materials like steel, aluminum, or other metals that are used to create gears. They are converted into desired shapes to become full-fledged gears.

Cutting and Shaping

This stage requires the setting up of the selected gear blank on the milling machine or worktable. There the cutting is done using tools such as hobs or form cutters to shape the gear teeth into the prepared gear blank. The type of gear you want to achieve determines which of the numerous gear cutting processes on a milling machine you would employ.

Heat Treatment

Heat treatment is not always a necessary stage when machining gears. It is optional and it depends on the material and the purpose of the gear. However, it makes the gear become wear resistant and improves its strength.

Finishing

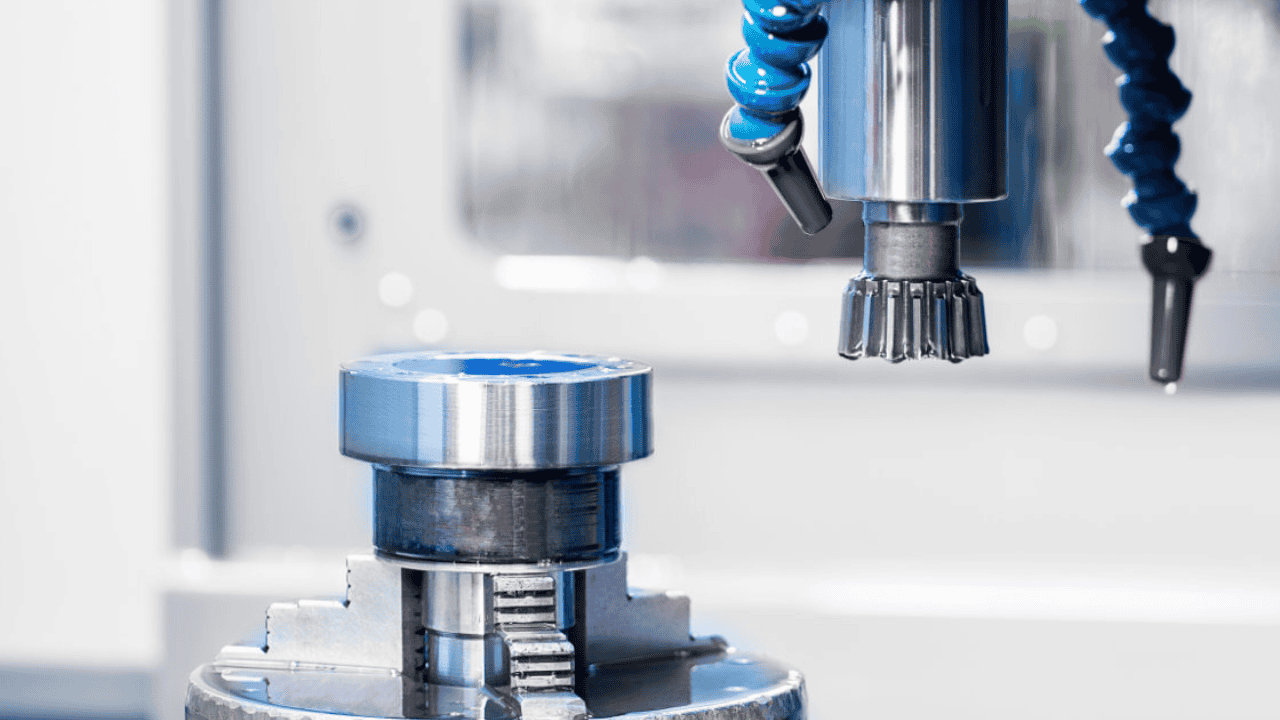

Finishing is a surface enhancing process in gear machining such as grinding, polishing, or coating. This process ensures refined teeth for effective operation and easy fittings with other gears.

Inspection and Quality Control

This is the final stage of gear machining, and it is a wholesome inspection to ensure gear accuracy in all dimensions. To be sure that the machined gears are up to standard for performances before they are incorporated into machines.

What Are the Methods for Gear Machining

You will learn three main methods of gear machining. We’ll go through the different tactics one by one, starting from gear generation.

Gear Generation

Gear generation is the use of cutting tools to remove materials from a blank. There are subtypes of gear generation and they include:

- Sunderland method: In this method, a rack cutter with angular clearance is used to make the tooth profile on a gear blank using a gear machine.

- Gear shaping: This involves the back-and-forth movement of a special cutter which has the shape of the desired gear along a workpiece while the gear blank is in a continuous spin motion around the cutter. Shaping is a more convenient cutting process where others are not efficient enough.

- Gear Hobbing: It is considered to be the most precise and accurate process for gear machining. The helical cutting tool is employed during this process and it provides high precision and a good surface finish especially on spur and helical gears.

Gear Form Cutting

Although it is the preferred gear machining method, gear form cutting has some disadvantages such as low quality and productivity. However, here are some possible methods if you need them:

- Shaping, Planing, and Slotting: In shaping, the tool on the ram moves repeatedly across the workpiece and can be used to make both internal and external gears.

- Milling: The use of this is limited. However, it is best used in creating complex gear geometries.

- Electrical discharge Machining (EDM): This process is suitable for cutting complex geometries of different sizes, but it requires quality control to avoid daming part surfaces like the curved teeth profiles.

Gear Forming

It is the process of producing gear teeth and parts without actually making use of a cutter or removing any materials as in other techniques. It can be achieved through the following methods:

- Rolling: This method involves placing a blank or metal surface between two rolling dies and force is applied to create threads on the blank. Whereas gear cutting is a process similar to what we have seen above, gear rolling presses the material to its desired shape instead of cutting.

- Casting: This involves melting an alloy and pouring the magma into a defined shape. In this case, the shape is that of a gear with the right amount and sizes of teeth.

- Powder Metallurgy: This technique involves making gears from metal powders. These powders are heated through the heating process to form a gear.

- Additive Manufacturing: Unlike most traditional gear machining processes, it is an advanced technological way of using 3D printers or CAD software to create high-quality gears.

Best Materials to Use for Gear Machining

Different types of machined gear need their own special materials to increase performance and durability. Here are the commonly-used materials in gear machining:

- Steel: Steel are perfect for stronger gear machining processes of producing the spur and helical gears. They offer impeccable durability and are wear resistant. They are different types of steel, but carbon and alloy steel are the most ideal for this purpose.

- Cast Iron: These raw materials are mostly used for gears in low-intense applications where durability is important.

Bronze: Bronze usually has low friction properties and they are ideal for the production of worm gears. - Nylon: Gears made from nylon are usually for lightweight and less demanding applications.

- Powder metallurgy materials: These materials are ideal for producing gears of mass quantity with consistent properties.

Machining Gears Cutting Tools

Precision gear cutting tools are necessary in gear machining to ensure seamless and smooth gear profiles for operation in different applications. Some of the essential tools needed for most gear machining:

- Gear hobbing machines: These are essential gear cutting tools used for trimming materials with rapid speed during gear hobbing machining especially to form the helical and spur gears.

- Cutting tools: There are different types of cutting tools, and they include rack cutters, hobs, and skivers to cut the teeth into shape.

- CNC machines: CNC machines are automated gearing tools built for the purpose of consistent mass production of gears.

Broaching tools: These tools are useful in cutting complex gear shapes. They are also used in making internal splines. - Gear shapers: These tools are best for shaping internal gears with unique profiles.

Surface finish tools: They give gear teeth quality finishes needed for power transmission. - Grinding tools: Used for smoothening gear surfaces after cutting and shaping.

What Are the Various Types of Gear?

There are many types of gears, each with their unique functions and applications in different parts of machines, some of which are listed below:

Spur Gear

Used in applications such as electric blenders, washing machines, and cloth dryers. They are shaped in a cylindrical form having horizontal teeth parallel to its axis and are essential for transmitting power between two shafts. One challenge of spur gear is that it is very noisy and causes a lot of vibrations at high speed.

Worm Gear

The worm gear is a screw-like part that moves through a circular gear. It is built for reducing speed but gives more power or force. The worm gear can also be used in changing the direction of motion. Some power source like an electric motor can be used to drive the screw-like gear.

Helical Gear

This is one of the most employed and efficient gears in manufacturing. Helical gears are obtained through the helical gear machining process. It is used in the production of plastics, cement, and rubber, and they remove the disadvantages of the bevel gear machining process.

It is fixed at an angle to the shaft, enabling multiple teeth to be in contact during operation and carrying more load.

In helical gears, the teeth are not parallel to the shaft, but are inclined at some angle less than 50 degrees. This particular type of gears are more powerful and less noisy than spur gear. The main function of a helical gear is speed reduction.

Bevel Gear

Bevel gears are used in applications such as automobiles, steel plants, power plants, and cooling towers. They allow for the intersection of the axis between two shafts at an angle. For instance, If it is required to be applied in y-axis direction instead of x-axis direction in which power are coming in the shaft, it is on the bevel gear to direct the whole force in the desired direction.

Herringbone Gear

Herringbone gears are often referred to as “double helical”. This is because they look like two helical gears placed on the same gear. Herringbone gear is used to transfer power between parallel shafts.

High-end thrust of helical gears had, thus, given birth to herringbone gear design. Herringbone gear decreases noise and operates smoothly.

What is the Importance of Gears in Machining?

We can’t ignore the fact that gears are in almost every machine we use that has moving parts. So the big question is not whether they are important, but how important they are. Here are some of the roles gears play in machining:

Setting the Rotate Speed

Whenever you turn the knobs in your electric ceiling fan or step on the throttle in your car, the motor and engine in both cases fire up. But what they eventually set in motion to give you the increased speed are the gears.

Changing the Power Direction

Machineries that use gears often require the machines to move in different directions. This will be difficult to achieve in the absence of gears. Machined gears helps to change the direction of a rotational motion, redirecting the rotational force from one direction along different axes.ff

Transmitting Power

Power transmission is one of the basic importance of gears in machining. It ensures that power and motion is evenly distributed across a machine.

Changing Torque

The other significance of gears in machining is that they raise or lower output torque and modify the speed of a motor.

Applications of Gear Machining

Robotics

The robots are designed by some mechanisms. Without gears embedded in them, it is impossible for a robot to move. Gears provide support for robot movement and help them achieve accuracy in movement.

Industrial Machinery

All the movement you see in industrial machines such as a tractor, excavator, or even a forklift truck is caused by different kinds of machined gears being embedded in their mechanical structures. To accomplish heavy-duty work with maximum efficiency to enhance production and output, these industrial machineries employ gears that can function in demanding environments.

Aerospace

In aerospace manufacturing, the gears are one of the most important attributes. They have different key purposes, assists an aircraft to lift off, land, or maneuver with ease. Gears also act as a power train between the engine and the propeller of a flight apparatus.

Automotive

In the manufacturing of motor vehicles, machined gears are installed to enable motion and increase speed. They are different types of gears installed in an automotive machine like cars and trucks, playing unique roles.

For example, spur gears are used in making hydraulic pumps that help transmit hydraulic fluids consistently.

Medical Equipment

Some of the highly technical medical machines used in hospitals and other health facilities are powered by machined gears and CNC-machined medical parts. For instance, robots like the da Vinci Surgical robotic system that helps surgeons perform different surgeries have in-built machined gears in their joints and other areas to enable easy motion.

Some Common Limitations With Gear Machining

There are some interesting advantages to gear machining, but there are also some pitfalls associated with them as well. It’s indispensable to know these traps and how to avoid them. Here are the some challenges, the common causes and how to prevent it.

- Surface pitting: This happens in the event of insufficient lubrication or excessive surface pressure. Apply lubricants and review gear design to improve stress distribution.

- Gear deformation: This may arise due to overheating during machining. To prevent heat expansion during machining, control the cutting temperature and use cooling techniques.

- Pitch errors: This can happen when there is an unwanted movement from the machine that is not properly calibrated, leading to inaccurate cuts. Ensure that the machine is always firm for accurate measurements.

- Gear tooth runout: This usually happens due to a wrong or faulty alignment of the gear blank. To prevent this issue from rising, make sure to set up the blank accurately on the centre and calibrate the machine before gear tooth machining.

- Excessive burrs: This can happen in the case of using blunt tools or using the wrong speed to cut. Adjusting the cutting speed and using required tools will simply put an end to excessive burrs.

- Profile deviation: This can be a challenge when the cutting tool is wrongly positioned. Be sure to check the tool’s positioning and confirm that it is accurate during cutting.

Conclusion

Now, if you are getting here till this part of this article you already had some interesting thing about gear machining and what all these skills are utilised for.

If you are not yet done with gear machining, or even if you are awaiting for immediate effort services for gear machining services around, as an innovative brand we have a good expertise in machining gears and manufacturing.

We provide all types of machined gears manufacturing and engineering servicing. Contact us now!