Over the past few decades, Computer Numerical Control (CNC) machines have become a top choice for companies with fabrication needs. Their popularity can be attributed to their ability to cut complex shapes with high precision and at breakneck speeds.

If you’re in the market for a CNC machine, what should you actually be looking for? In this blog post, we look at some features of top-rated CNC machines.

Large Work Area

Top-rated CNC machines have large work areas to allow business owners to work with large workpieces. The work area which is also referred to as the “envelope”, is the travel limits of the cutting tool within the X, Y, and Z axes.

Various factors determine the ideal work area size for your business. The leading one is your uses and applications.

For example, if you own a woodwork business and you’re looking for a machine to help you make signs with 4ft by 8ft plywood pieces, you’ll need a machine with a work area to accommodate the plywood. Ideally, you’ll be looking for a machine with a 4’ by 8’ or 5’ by 10’ work area.

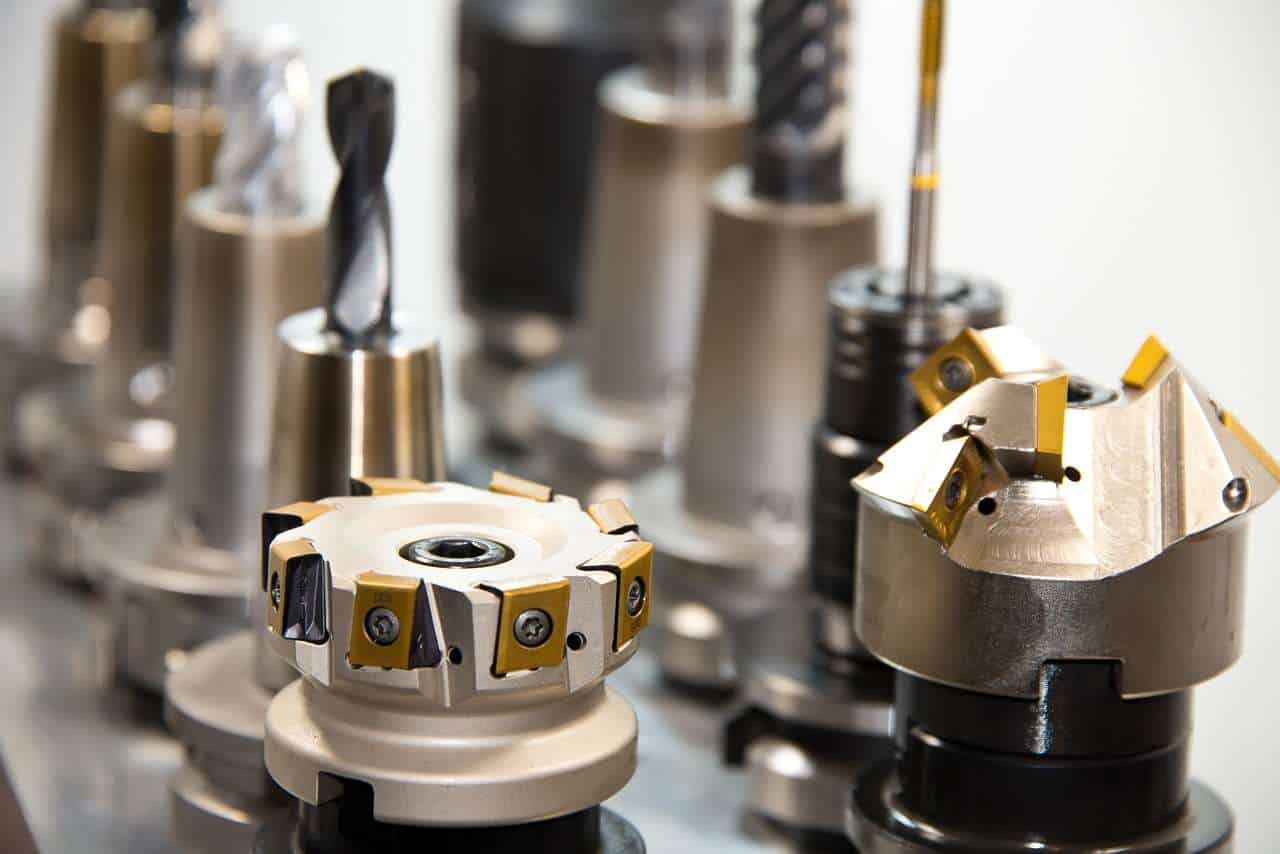

Dedicated Spindle

You typically have two choices when it comes to how the machine spins the router bits; an integrated spindle or a router.

Here’s a comparison table to help you understand how they differ:

| Spindle | Router |

| Consistent torque | More affordable |

| Greater accuracy | Slower productivity |

| Less noise | Consistent spindle speeds |

| Adjustable speeds | Less prone to breakage |

A CNC machine with a dedicated spindle starts automatically when the toolpath begins and stops when the toolpath ends. You don’t have to be there to turn it on manually.

If you’re going to get a machine with a dedicated spindle, also get one with an automatic water cooling system pump. The automatic cooling pump starts on and off based on the feedback from the spindle.

The only time you may choose a CNC machine with a router is when affordability is a priority. Otherwise, go for a dedicated spindle for a longer lifespan and higher accuracy.

Great CNC Software

CNC software is the brain of the CNC machine. It issues commands to the spindle on how to move the cutting tool to achieve the desired shapes and cuts on the workpiece. In short, it transforms the model drawing into motor movement.

Having the right software for your business needs is essential. You also need to conduct in-depth research before choosing CNC software.

Some companies have dedicated software for design and toolpath that comes with the CNC machine. Others may not have machine-specific software but will recommend third-party software that goes well with your needs.

A-Axis

You’re already aware that most machines allow the tool to move along the X, Y, and Z axes. Top-rated CNC machines have a provision for a fourth axis, known as the A-axis. This is great for businesses that produce parts beyond the 3-axis model.

The A-axis is a rotary axis. Machines with this axis allow you to produce rectangular and square pieces on the same workpiece without having to stop production to move or reposition the workpiece.

However, keep in mind that the fourth axis comes at a higher cost. This might be a bit limiting for hobbyists or small businesses without a huge budget.

Ball Screw Drive

When it comes to the ball screw drive system, you get to choose from three options. They are:

- Rack drive– This drive is more efficient, and accurate, and has a longer lifespan. It’s more suitable for demanding projects but is also more expensive.

- Belt drive– Belt drives are effective and faster, but they’re prone to dust buildup which can affect belt engagement. However, they can handle heavy loads and the accuracy can be compromised when the belts stretch. You can replace or tighten the belts when this happens

- Screw drive– Screw drives can either consist of lead screws or ball screws. Ball screws are more accurate and can carry a heavier load than lead screws. Lead screws also have more friction.

Servo Motor

There are two options to choose from when it comes to the motor that drives the axes; servo and stepper motors. You’ll notice that servo motors are more expensive than stepper motors, but also offer more advantages.

For example, they run on a closed-loop system which ensures that the motor makes the right moves based on the signal sent from the CNC software. They are also faster and can maintain consistent torque depending on the CNC machine’s speed range. In addition, they’re also more accurate than stepper motors.

On the other hand, stepper motors operate on an open-loop system which assumes the motor is moving as instructed. They’re affordable, easy to use, reliable, and great for basic and average projects.

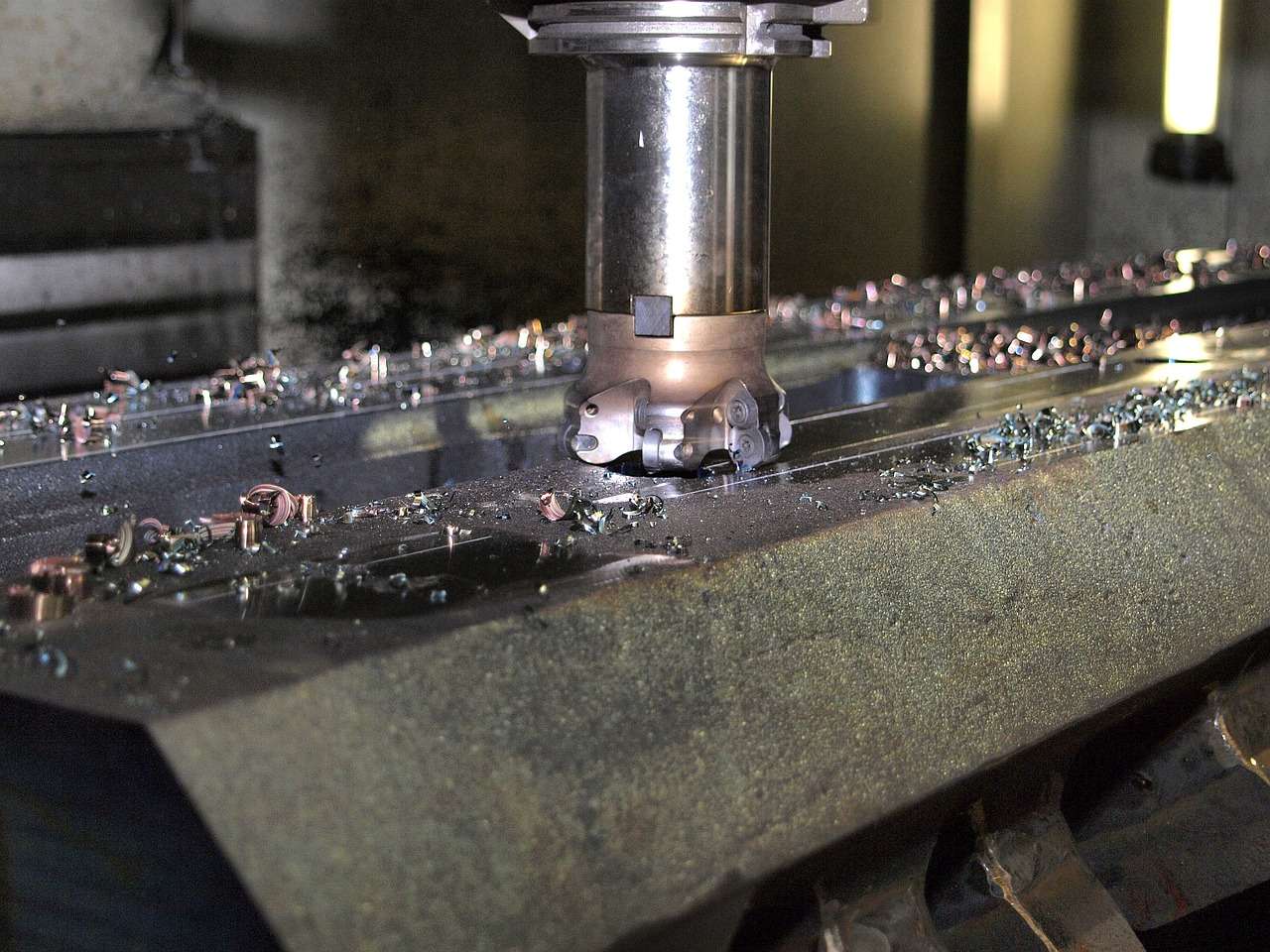

Dust Collection System

CNC machines produce a lot of dust and debris. Dust can accumulate anywhere which can compromise the machine’s functionality and the quality of the output.

Top-rated machines come with an in-built dust collection system surrounding the cutting tool so that it can collect the dust from the tool. If your machine doesn’t come with one, you can also purchase a standalone dust collection system.

Dust collection systems are affordable and effective in the long term.

Suitable Table Type

There are three types of CNC machine tables:

- T-slot table– This table is made of aluminum and you use clamps to firmly hold the workpiece and prevent it from moving during the machining operation. This type of table is durable, wear-resistant, easy to maintain, and anti-corrosive.

- Vacuum table– Full CNC vacuum tables give business owners a suitable way of holding workpieces without having the clamp get in the way of the tool. It’s a great choice for high-production businesses since they don’t have to spend extra time clamping and unclamping the workpieces.

- T-slot & vacuum table– This table combines both the T-slot and vacuum tables. It’s mostly designed for working on irregular shapes.

Affordability

While you want a top-rated CNC cutting machine with the right features for your business needs, you also want one that you can afford. One that you can run comfortably without negatively affecting your business cash flow and profits.

CNC machines can go from as low as $5,000 for entry-level machines, $30,000 for mid-range machines, and up to $500,000 for advanced machines.

At the end of the day, it’s not about buying the most affordable or most advanced CNC machine on the market but purchasing one that suits your business needs. This is why you need to first evaluate your business needs before making a purchase decision.

Do you need a machine for cutting, milling, or grinding? What size of workpieces will you be working on?

Once you’ve answered these questions, you can then conduct comprehensive market research and come up with a budget based on your needs and financial situation.

Keep in mind that based on your business needs, some enter-level and mid-level machines will often perform the job just as well as advanced ones.

Conclusion

Buying a CNC machine could be one of the most important steps in your business. Most importantly, choosing the right one with the right features for your business needs could make or break your business.

When making this investment decision, don’t forget to consider CNC machine spare parts. This is where hmaking comes in. We’re your one-stop shop for custom parts across a variety of industries. We have a broad selection of metal alloys such as stainless steel, carbon steel, aluminum, brass, zinc, copper, and many others for you to choose from.