You just bought a CNC router for your business. Congratulations on your big purchase. Now you’re all set and ready to start using it. But before that, you need to learn the basics of your router, including the accessories and components you need to produce your desired results.

This article seeks to educate you on essential CNC router parts, accessories, and tools.

What Is a CNC Router

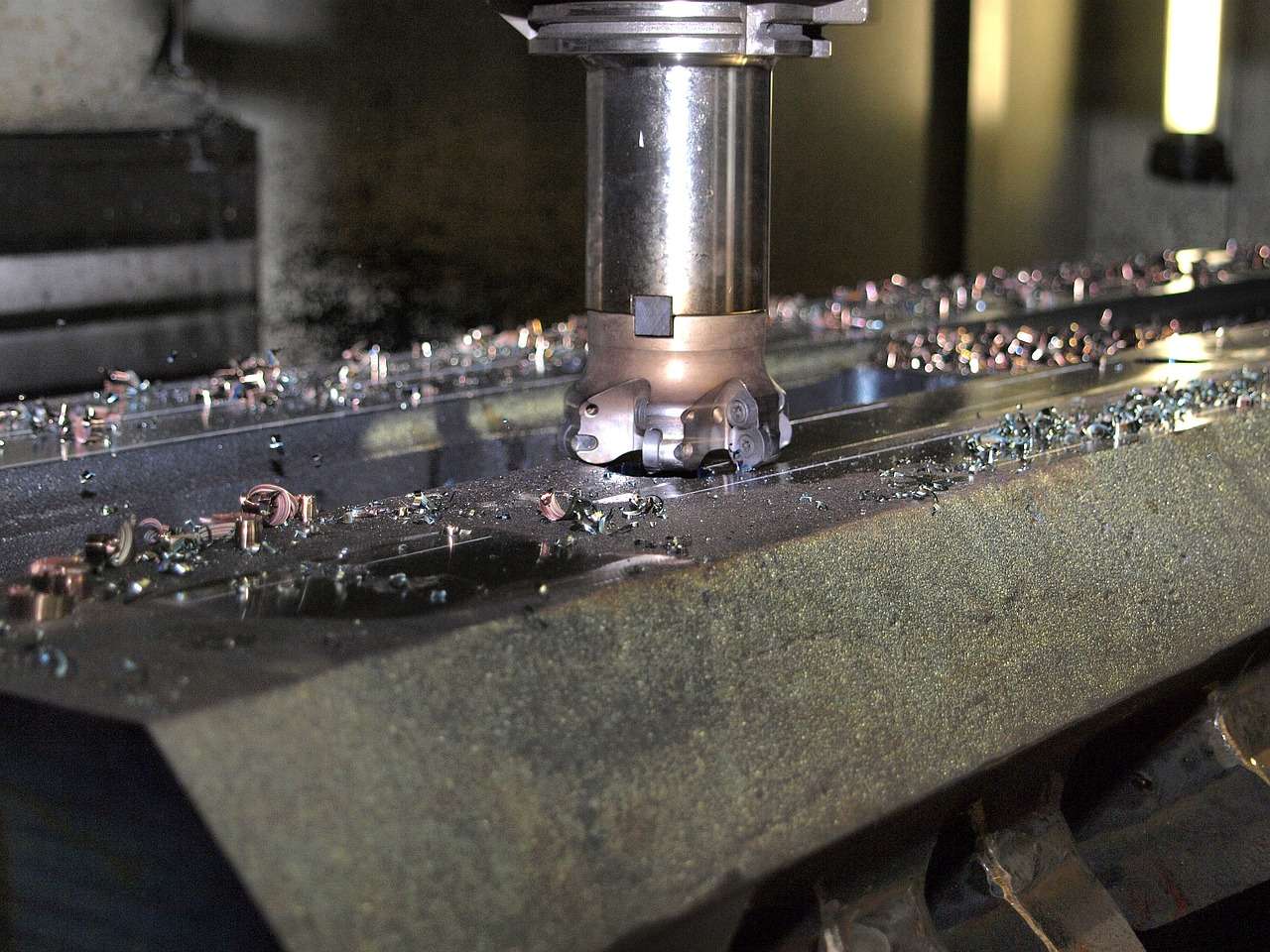

A CNC router is a computer-controlled machine used for routing, drilling, cutting, engraving, and milling a workpiece. It relies on rotational speed to cut and shape materials. It produces complex and high-quality shapes and cuts by moving along the X, Y, and Z axes.

This machine is primarily used to cut softer materials such as wood, plastic, acrylic, and foam

Applications of a CNC Router

CNC routers have numerous applications in the woodworking industry, including engraving, carving, and shaping. These machines are used in the prototyping and creation of cabinets, signs, and musical instruments, among others.

Parts of a CNC Router

If you’re looking to buy a CNC router, there are specific components and parts you should prioritize. They include:

Frame

The frame is the CNC router’s support. Ideally, the frame of your CNC router should be as stiff as possible. Remember, the cutting tool moves at very aggressive speeds. If the frame isn’t stiff enough to hold everything in place, it becomes impossible to achieve precision. A flexible frame leads to various issues, such as cross-bridge flexing, chatter, and displacements on one of the three axes.

Table

Tables differ when it comes to construction and locating systems. The most flexible tables are made with integrated T-slots, vacuum pulldown, or both. These tables allow you to clamp diverse workpieces anywhere.

Tables with aluminum extrusion construction are also quite common in the market. They offer a perfect balance of stiffness, adaptability, and low weight.

You can also make your own T-slot table using a wide range of machined strong materials. The table can have slots on both sides of the axes.

Spindle

The spindle is the heart of the CNC machine and its most crucial component since it plays a major role in the CNC machine’s performance. The low-cost spindle construction method is where it’s built into the motor shaft and relies on the motor bearings. However, this mechanism leads to premature wear and tear, unless the motor bearings are strengthened.

Spindles/motor bearings have items that require occasional maintenance. Loose bearings result in a loose cutter. Such a cutter has minimal accuracy. On the other hand, stiff bearings make the machine work harder and result in more heat in the process.

Sliding Ways

The sliding ways, also referred to as the ways or slides, are the motion tracks that allow movement in the X-Y-Z axes. The precision of the job and the quality of the final product depends on the sliding ways, frame, and lead screws.

There are several types of sliding ways you’ll find in CNC routers. V-grooves use a ball bearing with wheels locked on both sides of the track. These wheels ride on a rail that could be a triangular edge extruding or the edge of an angle iron piece.

The wheel of the V-groove doesn’t have to be v-shaped. For example, it could also be cupped to ride on a curved edge or on a round shaft.

While V-grooves are the cheapest, they’re also the most prone to backlash and the least accurate. They also frequently require adjustment to maintain quality performance.

Round shafts use ball bearings and perform a bit better compared to V-grooves. Linear slides are the highest-performing sliding ways.

Axis Drive

The axis drive system in a CNC router converts the rotary motion produced by the stepper motors to linear motion. Entry-level CNC machines often use toothed axis drives or timing belts for this function. While they may be less ideal, toothed and timing belts can be durable for decades if well maintained.

On the other hand, more expensive machines use recirculating ball screws. While they have more advantages, such as more motion, they have the same wear issues that other similar systems suffer. As such, cleanliness and good maintenance should be a top priority.

Here are a number of factors to consider when choosing a drive system:

- Cost

- Loss motion or backlash

- Motor’s torque and RPM

CNC Controller

The CNC controller is the brain of the CNC router. It executes the G-code fed into the system and converts it into stepper and spindle motor motion. In short, it produces the electrical signal that moves the cutting tool as required.

There are numerous CNC controllers for you to choose from. There are single-board controllers without PC interfaces, single board with PC interfaces, or PC controllers with accessory boards for motion control.

Dust Collector

A CNC machine doesn’t just have to operate. It’s also important to ensure the machine keeps running smoothly and safely. That’s how you maximize the machine’s potential lifespan.

When the machines cut through and shape metal, wood, or plastic, tiny pieces and bits of the material fly in every direction. Since these bits and pieces land anywhere, they can compromise your view of the work being done. This is dangerous since it can lead to injuries.

You can also inhale the pieces which could irritate your nose or compromise your health and lead to infections and diseases.

A dust collector keeps the workspace free of dust, bits, and debris. It should be a necessity when working with any material.

Scanner

With the right CNC router accessories, it’s possible to reverse engineer and create products that are rare to find or currently out of production. A CNC scanner helps you achieve this. A 2D optical scanner is sufficient to convert your CNC router into a reproduction tool.

For example, let’s say you want to reproduce a gasket with an intricate design. You simply need to use the optical scanner to scan the sample and generate the code outlining the dimensions, edges, lines, and shapes.

Once you have achieved a nice digital sketch, you can send the data to the CNC controller, and the router will cut a duplicate of the sample.

An optical scanner is an essential tool to have if your CNC business majors in the restoration, repair, or reproduction of parts that are produced in limited quantities.

Tool Holder

CNC machines have cutting tools, such as mills, drill bits, cutters, taps, saws, and engraving tools. For the spindle to control the cutting tool, the tool needs to be held by a tool holder.

A CNC tool holder is the connection between a cutting tool and the spindle. It keeps the tool steady and allows the spindle to execute accurate machining. While they need to grip the tool firmly, some holders allow the tool to “float” to avoid wear and tear to the spindle, tool, or workpiece.

Like many other CNC parts and components, tool holders also wear out. This can destabilize the CNC machine’s accuracy. It’s important to stay on top of your tool holder’s maintenance and repairs.

Automatic Tool Changer

Simple CNC machines for simple tasks are primarily made to work with one tool. However, more complex tasks require more than one tool. Manually changing the tool can be one of the most time-consuming tasks for a CNC business, especially if the machine is a slow-production one.

More advanced and complex CNC machines have automatic tool changers (ATCs) that help you seamlessly change the tool fast without having to stop production. The best thing about CNC machines with ATCs is that they don’t even require a manual operator to initiate the process.

An ATC can hold up to 10 different tools at once and change them seamlessly as needed. This comes in handy during mass production since you don’t have to stop production, detach the tool, and replace it with a new one.

With an ATC, you just input commands into the computer and the tool changing happens automatically.

Touch Probe

If reverse engineering is an important factor in your CNC business, having a kinetic touch probe will improve your router’s efficiency.

A kinetic touch probe allows you to locate, copy, and measure the edges of parts to help you with reproductions. The touch probe is directly connected to your CNC machine and can be used on plastics, wood, and metal workpieces.

If you’re measuring the parts and angles of a workpiece with a perfect shape, a touch probe would be a perfect alternative to a scanner.

Router Bits

If most of your tasks involves a lot of drilling, it would be great to have extra router bits for your CNC machine. It’s common for drill bits to go bald when frequently used or break when used on hard material for the first time.

Having a 10-piece starter bit is great for a start. However, we recommend you go the extra step and have at least two or three more pieces of the bits you regularly use.

This is especially important if you’re located in a market with no local stores nearby and you have to wait a few days or weeks for a replacement.

Key Takeaways

It’s important to know the essential parts and components of your CNC router. We’ve looked at what CNC routers are and the important parts you should know about. Most importantly, it’s important that you work with a CNC part provider that you can rely on.This is where hmaking comes in. We’re your one-stop shop for custom parts across a variety of industries. We have a broad selection of metal alloys such as stainless steel, carbon steel, aluminum, brass, zinc, copper, and many others for you to choose from.