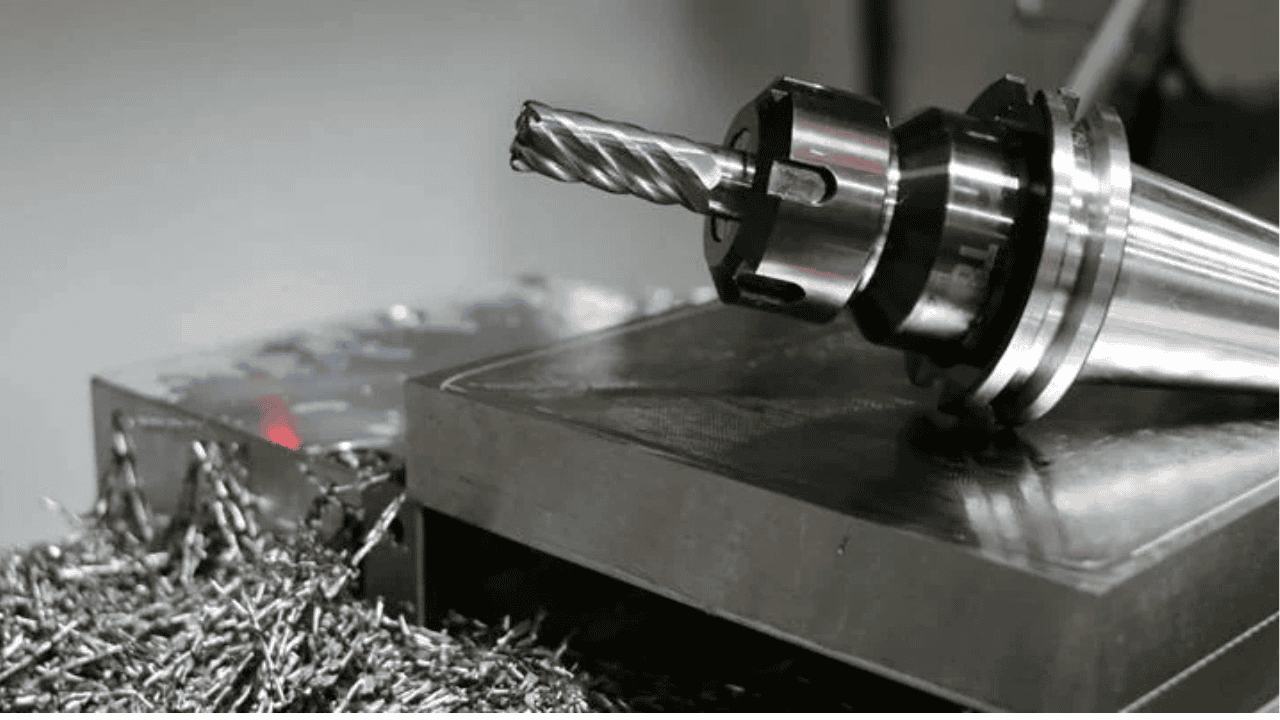

The end milling process proves to be a significant precision machining technique with relevance in diverse industries. This is because it ensures the proper removal of chips while reducing tolerance.

This article explains the end milling process step by step, its advantages, how to use an end mill, and where it is mostly applicable when compared with the drilling parts technique.

What Is the End Milling Process?

The end milling process is one of the most versatile CNC machining processes that involves the use of a fast rotating cutter called an end mill to cut and form materials into different shapes and sizes. It is mostly employed in metalworking, woodworking, and other material making industries.

End milling process can be used to carry out a variety of operations such as slotting, plunging, profile milling, and contouring. It provides high precision cuts, excellent surface finish, and intricate geometries of a workpiece. This process is said to be versatile because it can be done on different materials such as metal, wood, plastic, glass, etc.

How to Execute the End Milling Process?

Below are the various steps necessary to carry out an end milling operation:

Setting up the Workpiece

To ensure an efficient end milling process, it is important that the workpiece is tightly and firmly clamped onto the worktable of the milling machine using the clamp or vice. This action is necessary to prevent shiftings and malpositioning of the workpiece during end milling operations. Also, your selected cutting tools are to be securely placed in the spindle.

Choosing the Right Tools

When selecting CNC machining tools for an end milling process, there are several factors to be considered, such as material type, the depth of cut, and desired surface finish, as they all determine the type of tool suitable for a project.

For instance, when milling aluminum and softer non-metallic materials like plastics, the two flutes, three flutes, and high speed steel (HSS) end mill cutter are more suitable because the large valley space of a two flute allows for aluminum materials to be removed in large quantities and at a very high speed.

Two flute end mill cutters are also used for plunging cuts and shallow depths. But when milling a metal, like steel, a carbide end mill is the most suitable as it can withstand high temperature, resist heat, and perform at a high cutting speed.

For a smooth surface finish in milling, the ball end mills are best to achieve it. Choosing the right tool makes the end milling operations easy, fast, enabling high accuracy, precision and a desired surface finish of the final product.

Adjust End Milling Speed and Feed Rate

This stage determines the overall speed at which the cutter cuts through a workpiece. While working with a metal or very hard material, the cutting speed is required to be low with a lower feed rate in order to achieve a smooth finish and also prevent tool wear.

For soft materials, a higher end milling speed and feed rate can be applied because they can be easily cut through without any mechanical resistance offering faster removal of materials and low generation of heat.

It is advisable to start with a minimum end milling speeds and feeds, then gradually adjust it to obtain maximum productivity. This helps achieve optimal machining and milling effect while maintaining a balance between the rate of heat generation and the removal of material.

Apply Coolants

Coolants and lubricants are very essential in the end milling process, it prevents overheating of the workpiece, reduces the wearing of cutting tools during machining, and allows for a smooth surface finish of material.

Also ensure to apply the proper coolants during the end milling process. The most suitable being the water-soluble fluids also known as soluble oils.

Removal of Chips

While an end milling operation is going on, it is crucial to remove chips that may build up around the cutting edge of the end mill machine overtime using a chip brush, to maintain its overall performance and prevent excessive damage to the workpiece.

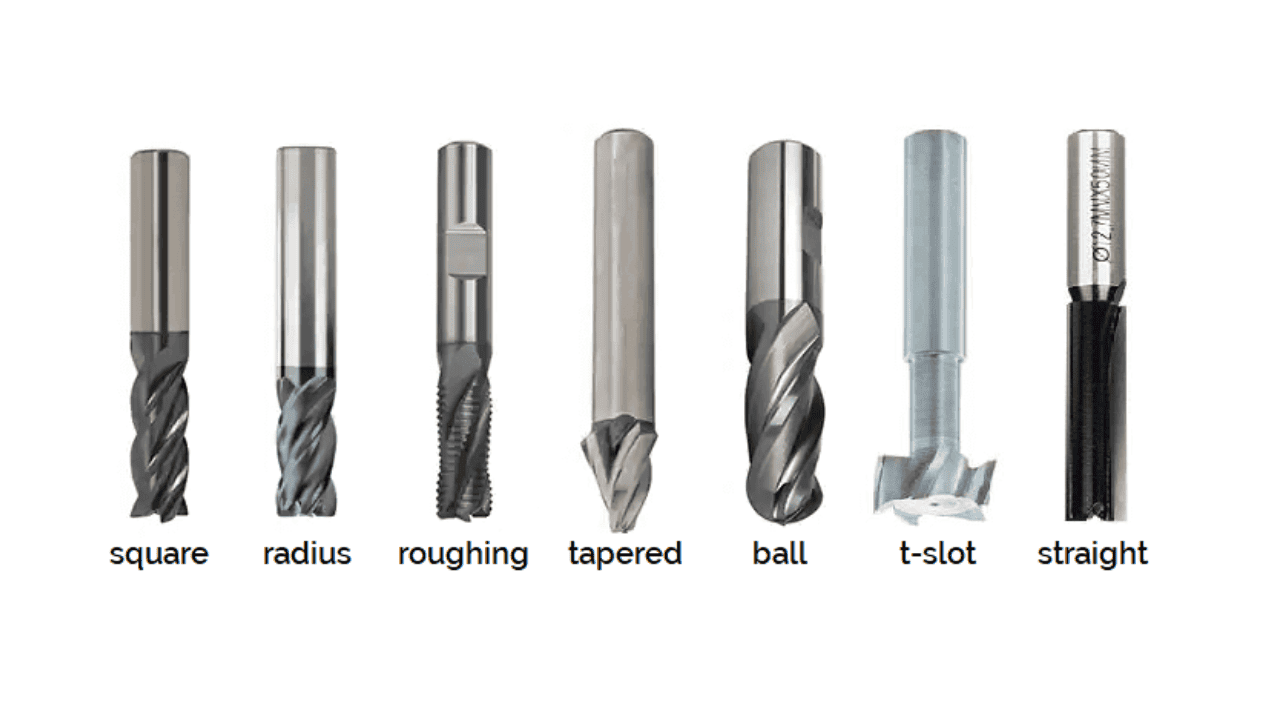

Types of End Mills

There are many types of end mill cutter, each with their distinct role in machining. Having a better understanding of how these tools work and when to use any would help in selecting the required tool for a work and improve efficiency.

Ball End Mill Cutter

Deducing from its name, the ball end mill specification and purpose is for milling curved surfaces. It is also applicable for 3D contouring, intricate and precise surfaces. Ball end mills are designed in single flute, two flute, and more to accommodate various machining needs.

Square End Mill Cutter

The square end milling capacity allows for the machinist to be able to shape solid materials into flat surfaces, pockets, and slots with corners of 90°. They are suitable for general end mill purpose unlike the ball end mill which are used mainly for curved surfaces.

Roughing End Mill

Referred also as hog end mill, is a tool that is employed for heavier operations. Its numerous teeth allow for the fast evacuation of large amounts of chips at a time. From its name, the surface finish is usually rough and requires an additional surface smoothening process.

Corner Rounding End Mills

It is important to know the differences between corner rounding and ball end mill cutter specifications. They both have different use cases. Corner rounding end mills are basically used to create specific radius, remove sharp edges on a workpiece, while ball end mills are used to mill contoured surfaces.

Advantages of End Milling Process

High Precision and Accuracy

Due to the various machining components involved, the end milling process provides highly precise and accurate final features on a CNC part after milling. These features include holes, pockets, intricate contours, and slots.

Versatility

The broad end milling capacity of an end mill machine allows it to perform various operations such as drilling, cutting, contouring, profiling, and many more. Its versatile nature and ability to create intricate shapes with precise features makes it applicable in the manufacture of auto parts, aerospace components, wood, and mold making.

Better Surface Finish

When comparing end milling vs face milling and other milling techniques, the end milling process provides a better surface finish. This is due to the controlled environment in which the milling process takes place offering room for little or no additional surface finishing.

Disadvantages of the End Milling Process

There are several disadvantages of carrying out an end milling process which includes a high cost for operating high-quality end mills. End mills can easily wear out and require frequent changing most especially when working with abrasive materials.

Also, when the necessary cutting tool prerequisites like tight clamping of the workpiece, accurate tool length and width are not properly fixed, it could lead to chatter and vibration which is an irritating noise/vibration between the cutter and the workpiece causing a poor surface finish.

When to Choose the End Milling Process?

An end milling operation is a versatile manufacturing technique that is used in various industrial applications. Most especially in cases where the goal of operation is achieving intricate geometries, slots, contours, aerospace parts, and housing of a material.

Also, the end milling process is of high value in getting higher accuracy, precision, and tight machine tolerance during milling. Additionally, you can use this process to perform milling and cutting of channels with a more defined dimension.

It is more applicable than the drilling process especially when you want to create holes that don’t go through the other end of a workpiece, holes with flat bottoms or different diameters.

Conclusion

The end milling process proffer many benefits such as advanced manufacturing techniques for achieving complex designs and shapes on a workpiece more efficiently. It is also very important to understand the best time to utilize this process, and its working mechanism to achieve optimal high-quality results and final products.

At Hmaking, we have the best set of engineers and technicians with a great depth of expertise in using their techniques and several others to machine parts and fabricate machines. Contact us now to get started.