Surface finishing plays an important role in increasing the quality of die-cast products. It improves functionality, aesthetics and durability which lead to better performance in multiple applications.

This blog post will cover common finishing techniques, their importance and best practices so that you can achieve a better finish.

What is Die Casting?

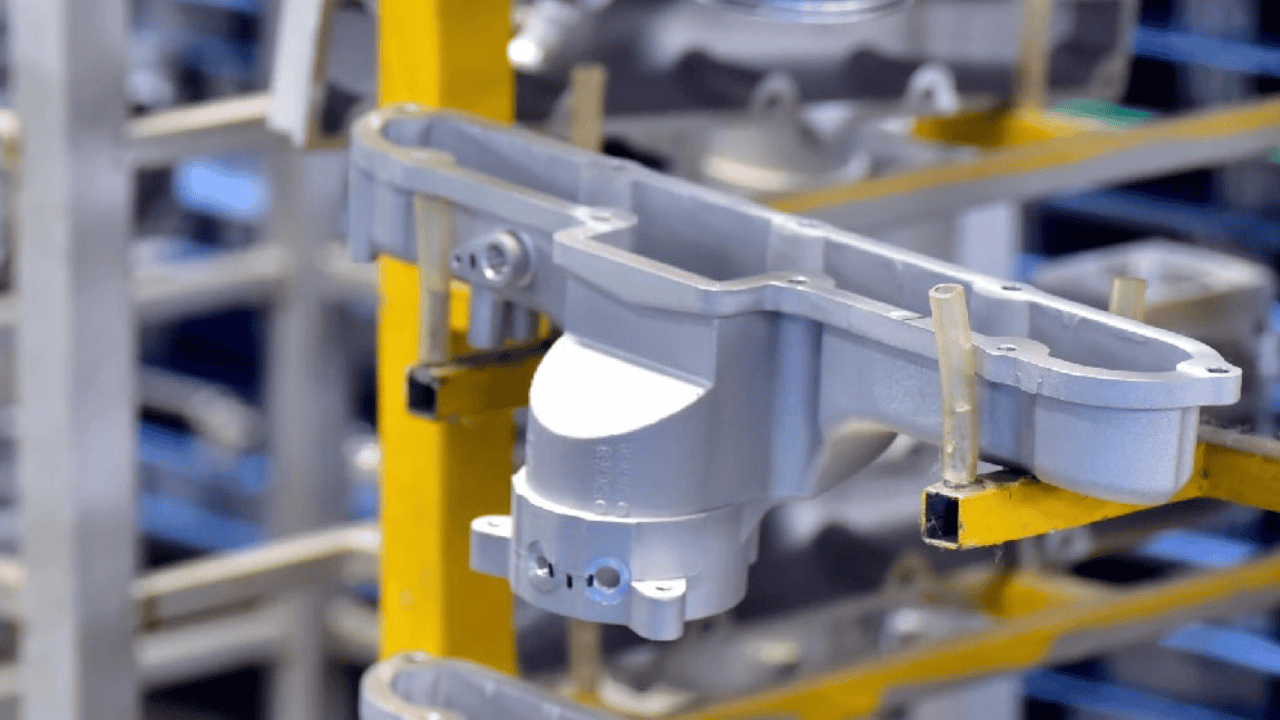

In die-casting process, molten metal is injected under high pressure into precision-engineered molds. These molds, called dies, then create complex parts with precise measurements.

Industries such as aerospace and automotive rely on this process to produce robust parts that feature smooth surfaces, fine details and precise measurements.

Importance of Surface Finishing

1. Increasing Visual Appeal

Die-cast parts require finishing to achieve a professional appearance. This process creates uniform texture & smooth surfaces. The result is a high quality finish that meets visual quality requirements.

2. Better Corrosion Resistance

Protective layers derived from surface-finishing protect die-cast parts from corrosion. For example finishes like electroplating and anodized oxide coatings.

Such treatments give long term durability under extreme conditions and protect parts from environmental damage.

3. Sealing Porosity

Surface finishing addresses the microscopic pores found in many materials that capture contaminants & moisture. A combination of special sealants and a vacuum impregnation closes these pores. This treatment prevents contaminants and moisture from entering the material.

4. Facilitating Paint and Coating Adhesion

Proper surface-finishing removes impurities and makes surface conditions better for adhesion of paint & coating. It creates microtextures that permit strong mechanical interlocking. These properties prevent coating peeling and delamination which extends product life.

5. Great Wear Resistance

Special surface treatments such as electroless nickel plating and anodizing increase wear resistance. These processes reduce friction between parts and prevent abrasion. Die-cast parts treated in this way last longer under tough use.

Common Surface Finishing Techniques in Die-Casting

1. Mechanical Finishes

i. Shot Blasting

Shot blasting uses high velocity abrasive particles on die-cast surfaces. This technique removes oxide scales, cleans impurities and removes defects.

It produces a uniform surface texture with Ra 1.6 to 6.3 μm roughness. Structural parts, automotive parts, and precision die-casting benefit from the process where consistent & clean surfaces are required.

ii. Grinding

In grinding⸴ abrasive wheels or belts remove excess material from die-cast surfaces with great accuracy. This process achieves a surface finish of Ra 1 to 2.5 mm.

Flash defects and parting lines can be effectively removed by grinding. This is particularly beneficial for hydraulic parts, automotive components and aerospace applications where precise dimensional tolerances are necessary.

iii. Polishing

Polishing materials effectively remove surface irregularities from cast parts. This process requires a systematic progression from coarse to fine grits. This method achieves a surface roughness between Ra 0.8 to 3.2 μm. The end result is a uniform finish which makes it particularly suitable for decorative applications.

Its common applications include electronics, medical devices and car trims.

2. Chemical Finishes

i. Anodizing

The anodizing process creates protective oxide layers on a die-cast surface through electrochemical oxidation in a sulfuric acid bath.

It has three different types, Type-I, Type-2 & Type-3.

- Type-I uses chromic acid to create thin layers.

- Type-II uses sulfuric acid for better dyeability.

- Type-III (hardcoat) produces the thickest oxide layer with the best wear resistance.

This process allows custom coloring through dye absorption while providing excellent wear protection.

ii. Electroplating

This technique uses an electrolytic setup to form a precise metal layer on die-cast surfaces. Metal ions are continuously transferred from the anode to the die-cast cathode in a controlled chemical bath under an electric charge. Multiple plating layers create an excellent cosmetic finish. High-end consumer products and automotive often use this process.

iii. Chromate Conversion Coating

In chromate conversion⸴ a 200 to 300 nm thick protective layer is formed through redox reaction between metal surfaces and hexavalent chromium. The coating maintains electrical conductivity and has self-healing properties. It guarantees excellent paint adhesion as well as improved corrosion protection.

3. Coating Processes

i. Powder Coating

This solvent-free process deposits electrostatically charged particles (2 to 50 μm) to die-cast surfaces. Then it is cured at 200°C to ensure better adhesion.

This technique produces uniform coatings with high chip resistance and durability. Appearance is uniform on vertical and horizontal surfaces.

Finished product offers excellent wear and chemical resistance.

ii. Cerakote

Cerakote gives excellent protection through its ceramic based composition. This ultra-thin, single-layer coating can withstand over 1200 hours in salt chamber testing. It provides excellent corrosion protection while maintaining part tolerances.

The coating is available in custom colors with a VOC-compliant formulation and is ideal for high wear applications.

iii. E-Coating

The E-coating process applies uniform organic coatings through electrophoretic deposition. Components are immersed in a bath of paint solids suspended in deionized water.

The process can form films as thin as two microns. This technique provides uniform coverage in hard-to-reach areas and areas with complex geometries.

Factors Influencing Surface Finish Quality in Die-Casting

1. Die Design & Maintenance

Several die design elements affect surface finish quality. These include parting line position, radii and venting channels.

Correct positioning of parting lines ensures easy ejection and decreases flash formation which enhances finish. Round radii enable better metal flow and reduce stress that results in fewer surface defects.

Regular die maintenance includes replacement of worn parts & stress relief tampering. These methods maintain consistent finish quality and thus extend life of the die.

2. Material Selection

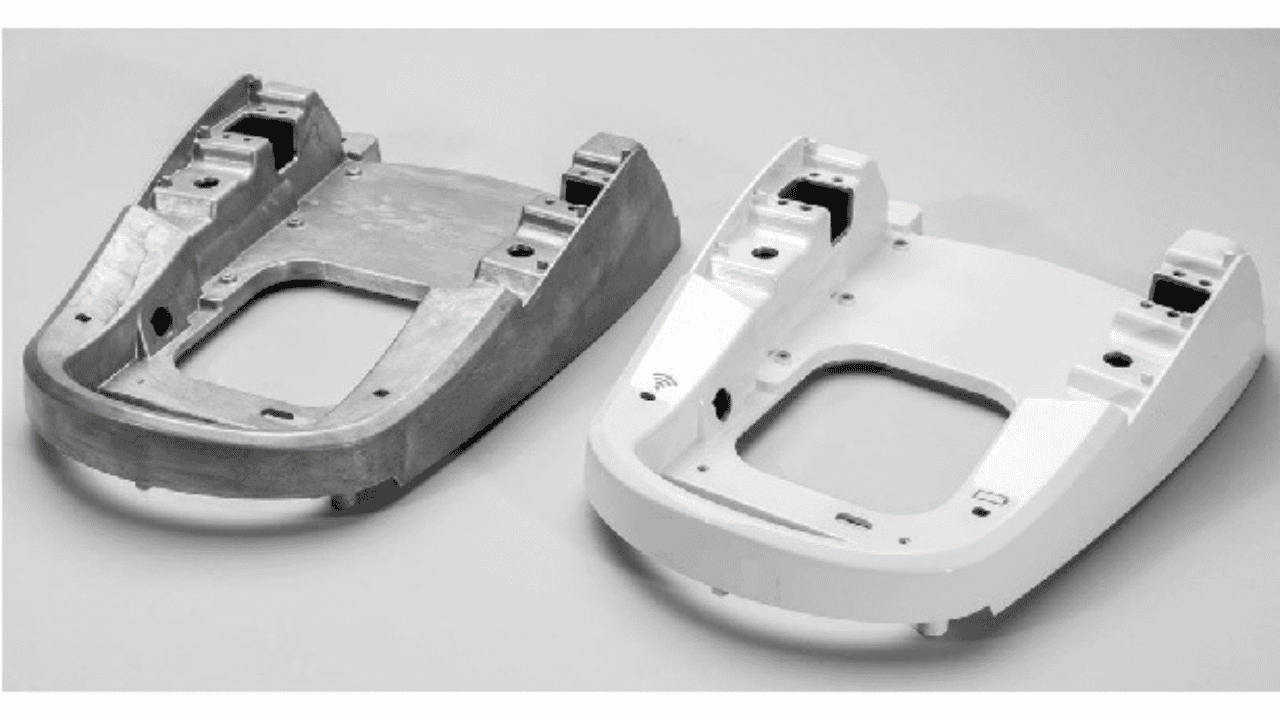

Surface finish quality also depends on the material selected. Each material has different surface porosity & roughness. Aluminum alloys produce the best surface finish due to their fine grain structure. In contrast some plastic materials require additional surface treatments in order to achieve a smooth surface due to their high surface roughness.

3. Post-Casting Treatments

Postcasting treatments greatly improve finish quality. These include deburring, conversion coatings and surface cleaning.

Deburring removes burrs & sharp edges from cast components. Conversion coating removes surface roughness and creates a perfect base for final finishing.

These treatments improve surface integrity and guarantee proper adhesion for subsequent finishing processes.

4. Process Parameters (e.g., Pressure, Temperature)

Pressure and temperature play an important role in surface quality.

The ideal mold temperature range is between 150 to 300°C. Temperatures below 130°C result in flow marks and cold shut. Conversely temperatures above 700°C lead to shrinkage & porosity issues.

On the other hand, the ideal range for injection pressure is 80 to 105 MPa. Pressures below this range result in surface defects & incomplete filling.

Challenges in Getting the Desired Surface Finish

Surface Flaw and Their Causes

Die-cast parts often develop surface defects such as bubbles, flow marks and cold shuts. These problems affect both functionality & appearance of the parts. Several factors cause these defects such as material flow turbulence, improper mold release agents and process contamination.

Porosity and Its Effects

In die-cast components, porosity results in internal voids & surface voids. These defects are usually found within 0.5mm of the surface. The presence of porosity causes a number of problems including low corrosion resistance, low tensile strength and complications during machining.

Balancing Functionality with Aesthetics

Die-cast parts require finishes that serve both functional and visual purposes. Decorative finishes enhance the appearance. However these finishes must maintain essential functional properties like dimensional accuracy, wear resistance & thermal conductivity.

Best Practices for Better Surface Finishing

Selecting Right Finishing Techniques

Material properties and end-use requirements determine the choice of your finishing techniques.

Polishing is best for decorative aluminum that requires a mirror-like finish.

Hard anodizing creates protective layers up to 100 µm thick that are perfect for parts requiring wear resistance.

Association Between Manufacturers & Designers

Designers & die-casters should work together from the beginning of the project. This initial collaboration helps to optimize surface finish requirements. Early tooling design should focus on important features such as parting line placement and draft angles. Proper die design and finishing specifications reduce post-processing costs and help to achieve Class-A finishes.

Quality Control Measures

Dimensional measurements and surface testing are the basis of quality testing.

You can use specific instruments that meet different inspection requirements. For example⸴ Coordinate measuring machines (CMM) check for dimensional accuracy. The profilometry confirms surface roughness. Visual inspection systems detect surface defects such as cracks & scratches.

These measures make sure that your parts perform well & meet the standards.

Conclusion

Die-cast parts require excellent surface finishing for optimum stability, performance and visual appeal. Successful finishing also depends on effective collaboration between manufacturers and designers. This association helps you to get the desired finish quality in various applications.

If you require custom die-casted parts with outstanding surface finishes, then hMaking is best option. You can contact us at any time.

Related Questions

Why are design features such as parting line placement and radii important to improve finishing results?

Partline placement and radii are important because they control the flow pattern of the molten metal. They also reduce the formation of defects, especially porosity.

What is impregnation and how does it solve porosity in high pressure die-casting?

Impregnation seals porous metal structures using reinforcing acrylic resins. This process uses vacuum pressure to inject the sealant into the voids. The sealant then cures into a solid polymer that forms a permanent seal against leaks.

Can automation in vibratory finishing or short blasting reduce costs while maintaining uniformity?

Yes they do. These processes eliminate human errors and decrease labor costs as well. They provide faster production times and maintain consistent finish quality across all components.

What is the role of laser polishing in improving the surface integrity of additive-manufactured die-cast parts?

Laser polishing works by controlled melting of surface material. This process redistributes the material from peaks to valleys. The result is a great reduction in surface roughness by 80% to 90%.