Numerous metals and alloys can undergo die casting. But the one that stands out the most is die cast aluminum alloy. At the end of this reading, you will have a concrete knowledge of what die cast aluminum entails and why it’s such a big deal in machining.

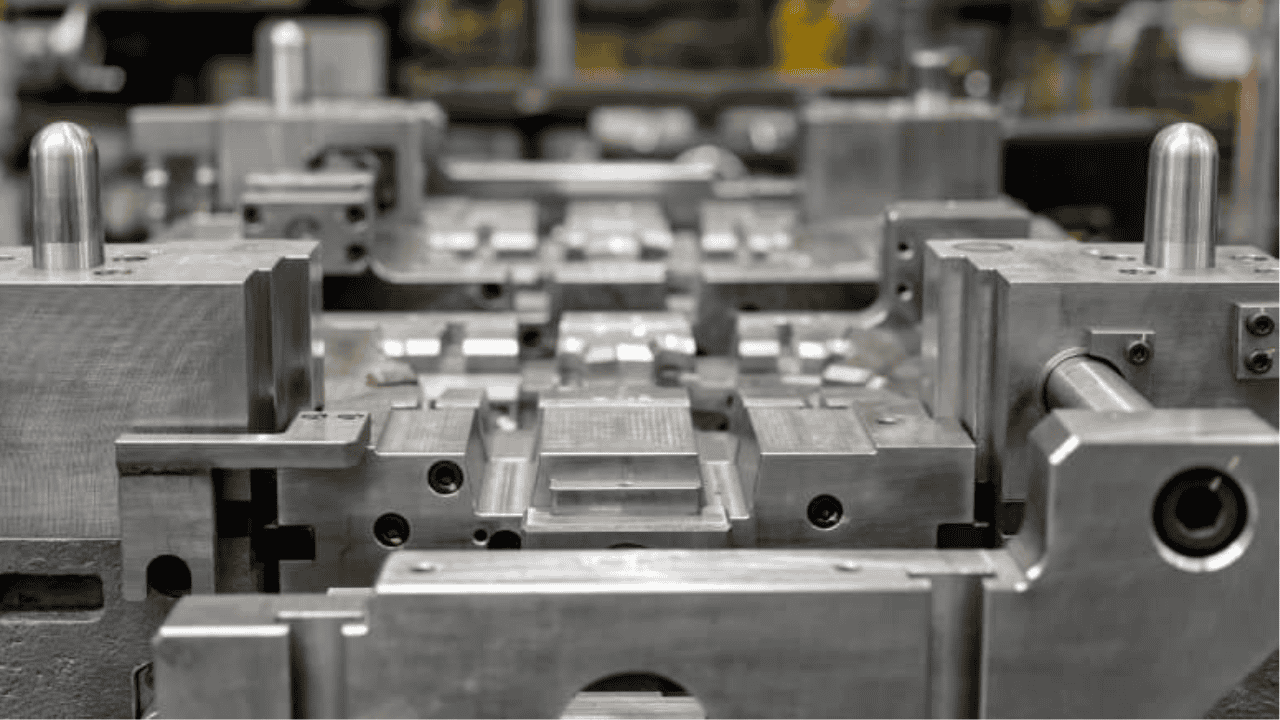

What are Die Cast Aluminum Alloys?

Die cast aluminum alloys are lightweight alloys that have undergone the die casting process. Aluminum type of metal is known for its malleability, which has advantages and disadvantages in CNC machining.

However, die casting aluminum alloys are the solution to the malleability pitfalls as they increase the element’s tolerance levels while maintaining its lightweight nature. These aluminum die casting materials are widely used by different industries, such as automotive and medical.

Common Types of Die-Cast Aluminum Alloys

Die casting works with special aluminium alloys that can mold well and have characteristics required for optimal function of the intended parts. Some of the die cast aluminum alloys include:

A360 Aluminum Alloy

A360 aluminum alloy is an aluminum alloy created primarily with silicon and magnesium it is amongst the best die cast aluminum alloys.

A360 aluminum alloy is famous for its high strength and corrosion resistance, making it an asset for manufacturing industries that require highly durable metals, such as automotive and aerospace.

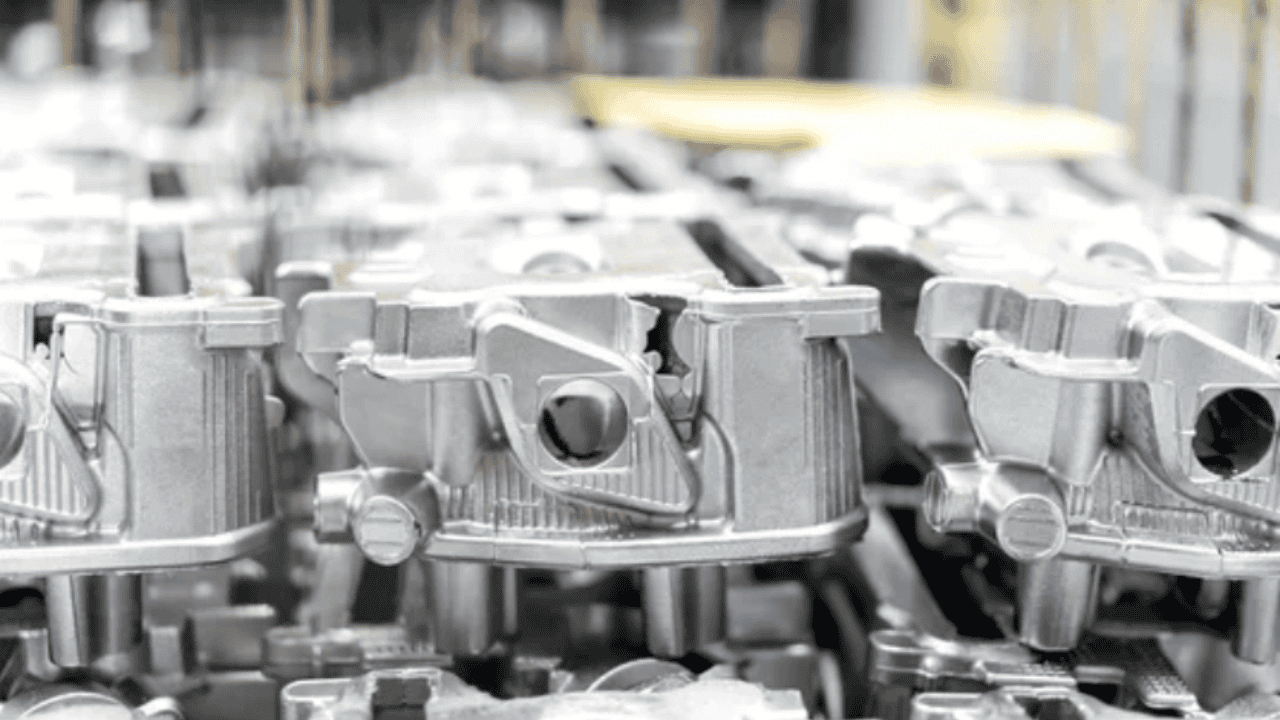

A380 Aluminum Alloy

A380 aluminum alloy is the most widely utilized die cast aluminum. It is a mixture of aluminum, silicon, and other metals like copper and zinc in trace amounts. These alloys are durable and have good corrosion resistance. They are applicable in industries like automotive and electronics.

A383 Aluminum Alloy

A383 aluminum alloy is a popular die cast aluminum alloy formed from the combination of aluminum with higher levels of silicon compared to A380. It also includes traces of other metals like copper and magnesium.

The high levels of silicon in this alloy contribute to the alloy fluidity. A good feature for improving its castability. Besides fluidity, the presence of silicon and copper also gives the alloy other unique features like corrosion resistance and hardness. Thus, it is a good alternative for A380.

A413 Aluminum Alloy

A413 aluminum alloy contains copper, silicon, magnesium, and, of course, aluminum. They aren’t as frequently utilized as the A380 or A360, but they have high strength and good resistance to corrosion. It can play roles in the marine and automobile industries.

Characteristics of Die Cast Aluminum Alloys

Some characteristics of aluminum alloys that make them worth considering for various industrial uses include the following.

Lightweight

Die cast metal has low weight and density. Combining aluminum with other metals improves its strength and preserves its lightweight nature. Their lightweightiness is essential for parts making in various manufacturing industries.

Versatility

Die cast aluminum alloys are extremely versatile. The versatility of aluminum die cast material allows its use in automotive and electronic industries as well as its use in the creation of automobile and medical parts.

Dimensional Stability

A characteristic of die cast aluminum is its ability to maintain its formed dimensions when faced with several factors. This is called dimensional stability. Although die cast aluminum alloys are low-density alloys, they are dimensionally stable.

Resistance to Corrosion

A metal’s resistance to corrosion plays a huge role in its functional efficiency. Hence, metals like silicon are used to formulate these alloys. As a result, the die cast aluminium alloys develop the durability spiking corrosion resistance that makes die cast aluminium alloys a great choice for various uses.

Surface Finishing

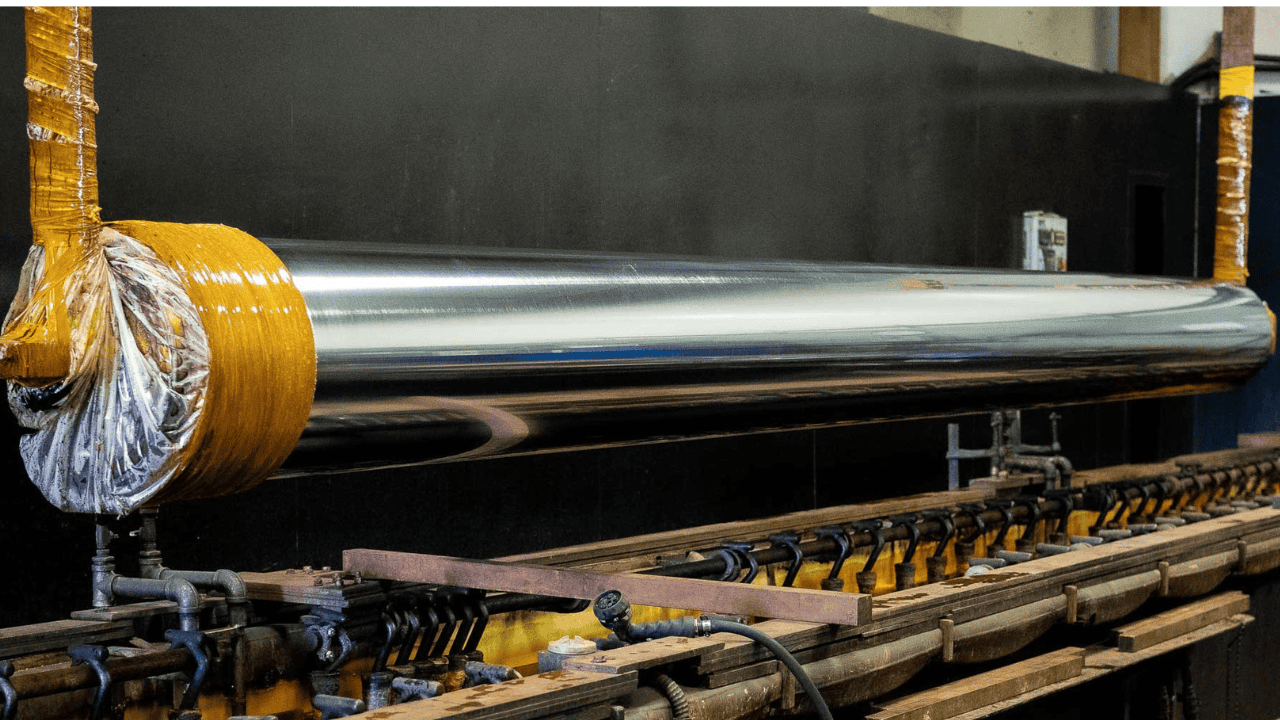

The die cast alloys go well with surface finishing processes like anodising, polishing, chrome plating, etc which improve its appearance, tensile strength, corrosion resistance, and other beneficial features.

Strength

Typically, the stronger the metal, the greater its weight. The strength of die-cast aluminum does not vary directly with its weight. Thus, it has a good strength-to-weight ratio. However, the alloys are extremely strong and durable though they are lightweight.

Heat Resistance

Die cast aluminum alloys have great thermal conductivity. The research progress on thermal conductivity of high-pressure die cast aluminum alloys shows they resist intense heat, which naturally affects most metals.

Advantages of Die Cast Aluminum Alloys

Die casting works for metals like steel, zinc, and copper. However, aluminum die casting materials are one of the most popular ones used in die casting. In this section, we will discuss the benefits that give it an edge over other metals.

Excellent Dimensional Stability

As mentioned earlier, die cast aluminum alloys have excellent dimensional stability. When a metal alloy cannot retain its original shape and size despite environmental interference, they become susceptible to wear and tear.

Superior Repeatability

The repeatability of the process is described as the capacity to produce the same results when tested across different situations. Die casting aluminum alloys have superior repeatability. Hence, they are assets for manufacturing industries.

Manufacture of Intricate Geometry

An advantage of die cast aluminum alloy is its ability to produce parts with intricate geometry. This is used to create materials with unique patterns almost like 3D printing, improving the usability of the metal.

High Precision

Aluminum alloys can produce precise pieces. In essence, the metals produce exact and accurate results for the intended vision.

Recyclability

Recyclability, as the name implies, is the ability of a thing to be used as many times as possible. Die cast aluminium alloys can be recycled repeatedly to make car parts or window frames, without losing its quality.

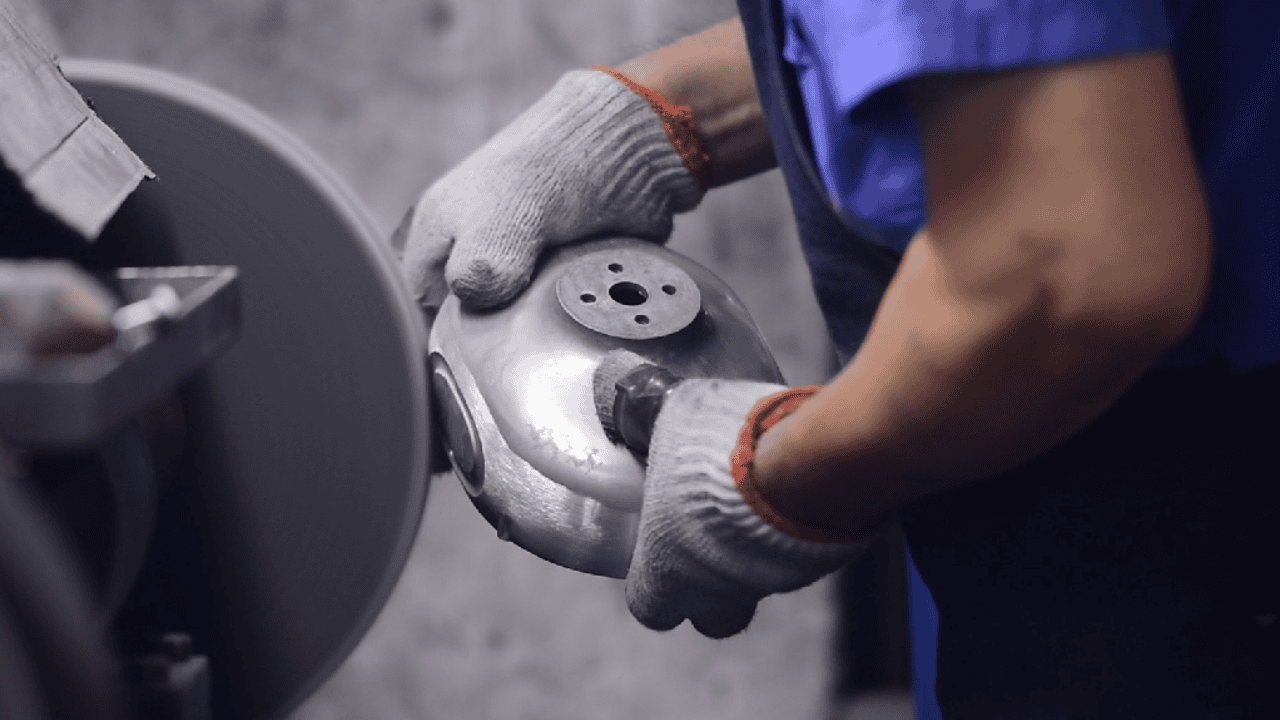

Type of Surface Finish for Die Cast Aluminum Alloys

In alloy die casting, surface finishing makes structural changes to the alloy, enhancing its functionality and performance levels. There are many surface finishing processes. Here are the recommended surface finishings for die cast aluminum alloys.

Anodizing

Starting the list, we have Anodizing. This is an affordable surface finishing involving electrochemical processes where the aluminum alloy is placed in an electrolyte solution and is further acted upon by an electric current; the result of this surface finish is higher corrosion resistance.

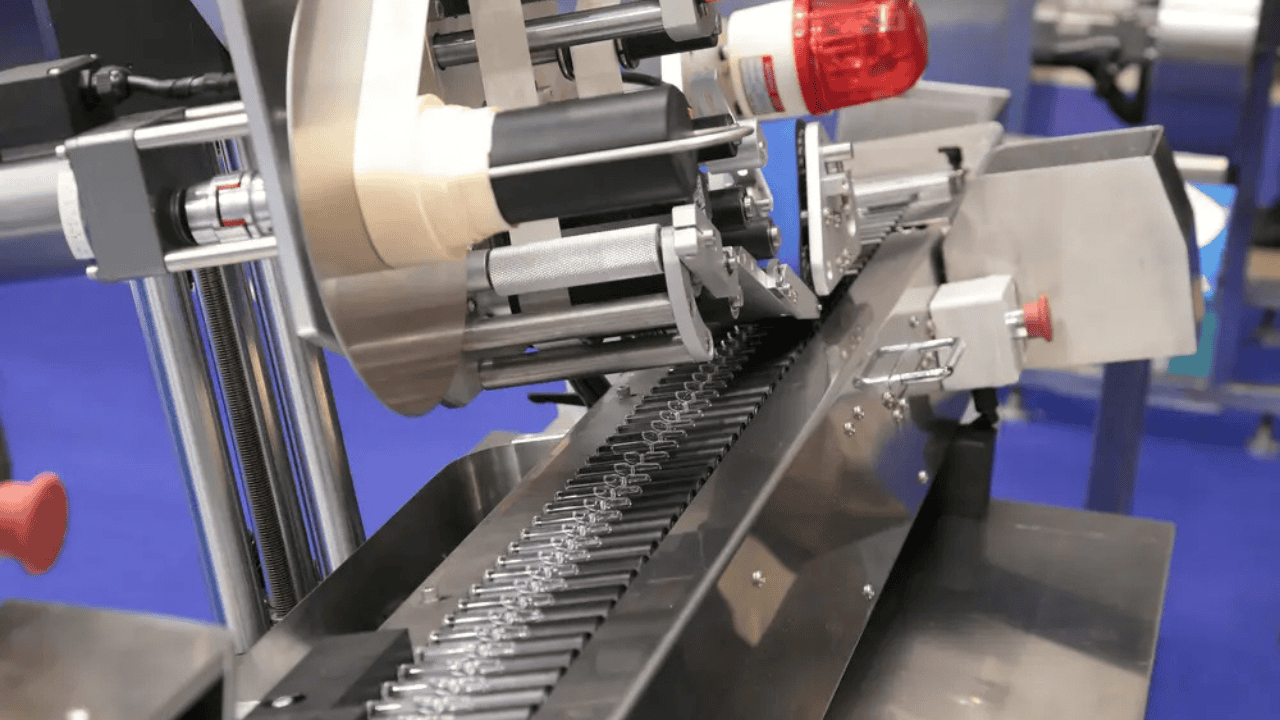

E-coating

E-coating, known as electro-coating, uses electric current to draw paint particles to the surface of the die cast alloy. Here, the die-cast aluminum is dipped into paint and then an electric current is applied to it. When the charge is applied, paint particles are pulled towards the metal, coating it uniformly.

Powder Coating

This is a surface finishing procedure that is highly recommended in the manufacturing of industrial equipment to amplify its resistance to scratch. The process of powder coating applies the powder first to the prepared metal and uses intense heat to complete the adherence of the powder to the metal.

Polishing

Polishing is a rather decorative than functional surface finishing. Polishing is smoothing the surface of the alloy by abrading it. This enhances their shine and finished appearance.

Chrome Plating

This surface finishing is just like electroplating. But uses chromium to coat the alloy. There are two popular chrome plating techniques, namely bright chrome and satin chrome plating. Both techniques not only enhance the appearance of the die cast aluminum but also improve its durab

Chem Film

Chem film, known as chemical conversion coating is a unique surface finish technique. It is “chemical” because it involves a chemical reaction.

Here, you spray the chemical solution onto the cast metal and allow itto cause an alteration on the metal surface. This process means more corrosion resistance, conductivity, versatility, etc. for the altered metal.

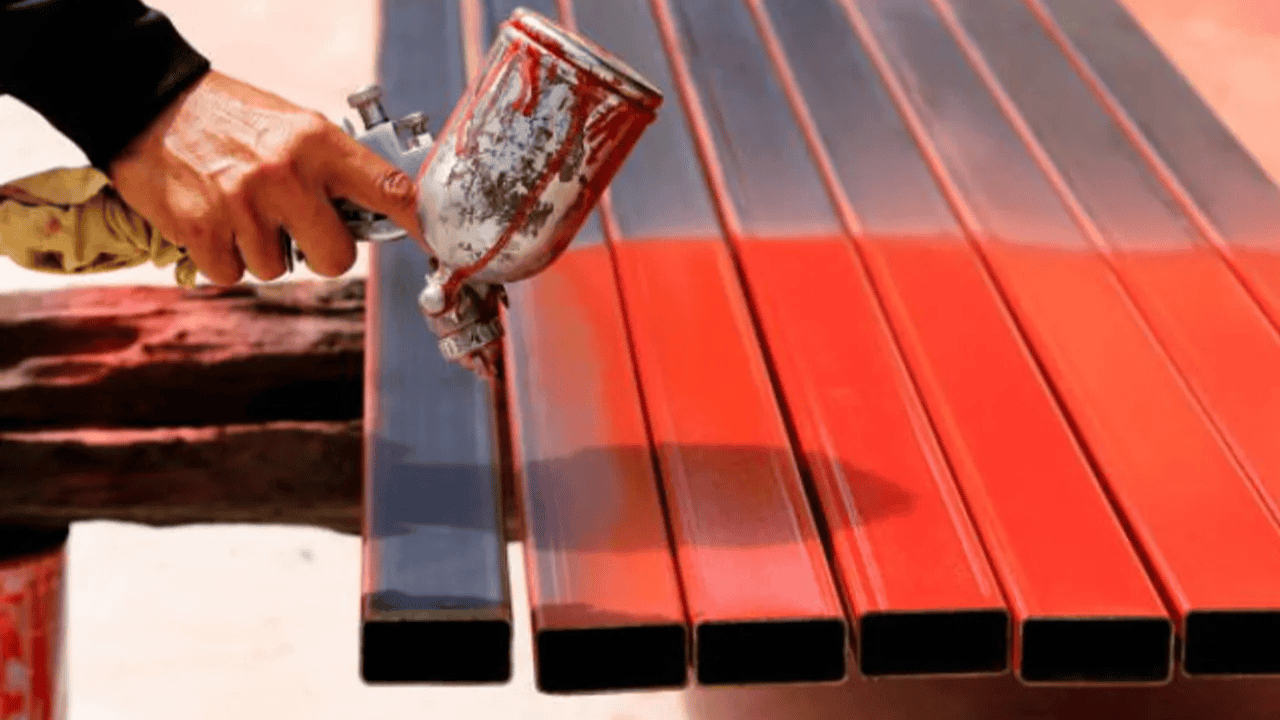

Painting

Painting is a common surface finishing, but besides improving the physical appearance of the alloys, it also forms a protective layer that prevents alloys from deteriorating quicker.

Teflon Coating

Polytetrafluoroethylene (PTFE) or Teflon is a chemical used in coating alloys, especially kitchen wares, because of their ability to confer non-stick characteristics and prevent abrasion, they are good for creating kitchenware.

Two Common Limitations in Die Cast Aluminum Alloys

Despite the many benefits of using die cast aluminum alloys, one may encounter some discomfort with them. Some of these limitations are discussed below.

Internal Defects

The die cast may finish with many different internal defects which may result from different production errors. Some of them are:

- Inclusions: This is an internal defect caused by unwanted liquid particles during the die casting process which solidify inside the metals. Some of these particles include oxides and phosphorus particles.

However, inclusions are more common than we think and don’t usually present a significantly deteriorative effect on the metals, but the severity of an inclusion could lead to the reduction of the metals’ nice physical and mechanical properties. - Gas Porosity: Traces of gases such as hydrogen and nitrogen are present in all metals, but if there is a spike in the concentration of the gases, it produces gas bubbles which get trapped within the solid metals, resulting in gas porosity. The porosity results in a decrease in its structural integrity.

- Shrinkage Porosity: Metals expand when liquifying and shrink when solidifying. Shrinkage porosity is the presence of holes in an alloy from an uneven shrinking rate when solidifying; it is a major defect in die casting as it leads to the weakening of die cast aluminum.

Superficial Defects

Superficial defects of the die cast alloys are those casting defects visible on the surface of your alloys. They are more common than internal defects, some of these superficial defects are:

- Blisters: Blisters on the surface of casted metals form as a result of trapped undissolved gas bubbles, especially hydrogen bubbles, which remain a component of the melted alloy when they solidify. Blisters will affect the performance of the metal.

- Lakes: Lakes in die casting means the appearance of uneven areas on the surface of your casted metal, these areas could either be smoother or rougher than the original surface. They occur due to deficiencies in the solidification process.

- Cold Laps: These are the most common superficial defects in die casting. Cold lap is a condition where the casted metal does not fuse perfectly with the original metal due to improper temperature regulation when casting. Due to the differential temperatures, the metal fails to mold uniformly.

- Cracks: These are the breakings on the surface of your aluminum alloy casts. Cracks on your die-cast aluminum can only get worse. The first initial crack could occur during production or from shrinkage, after which the more stress on the metal further increases the crack until the metal’s function is depleted.

- Lamination: This superficial defect on die cast is similar to cold laps because it leaves holes where fluid and dirt can go. Here, there is a break in continuity during production that remains. However, unlike cold laps, you can experience difficulty finding them unless acted on by sand-blasting surface finishing.

Conclusion

Without a doubt, die cast aluminum alloys are versatile, durable, and strong while being lightweight. To top it all off, die cast aluminum alloys are cheap and readily available; contact us now to get your quality aluminum alloy parts.