Picking a good CNC machining service provider is really important for getting high-quality parts made efficiently. Whether you’re making car parts, airplane parts, or medical equipment, finding a reliable partner can make a big difference. This guide will help you understand what to look for when choosing a CNC machining service provider, so you can make a smart choice that fits your project needs and business goals.

Key Takeaways

- Check the provider’s experience in your specific industry

- Look at their technical abilities, including machines and software

- Make sure they have good quality control and certifications

- Consider their knowledge of materials and where they get them

- Check how quickly they can make parts and how many they can produce

- Look at how good their customer service is

- Compare prices and what you get for your money

- See if they have experience with rules in your industry

1. Evaluate Experience and Expertise

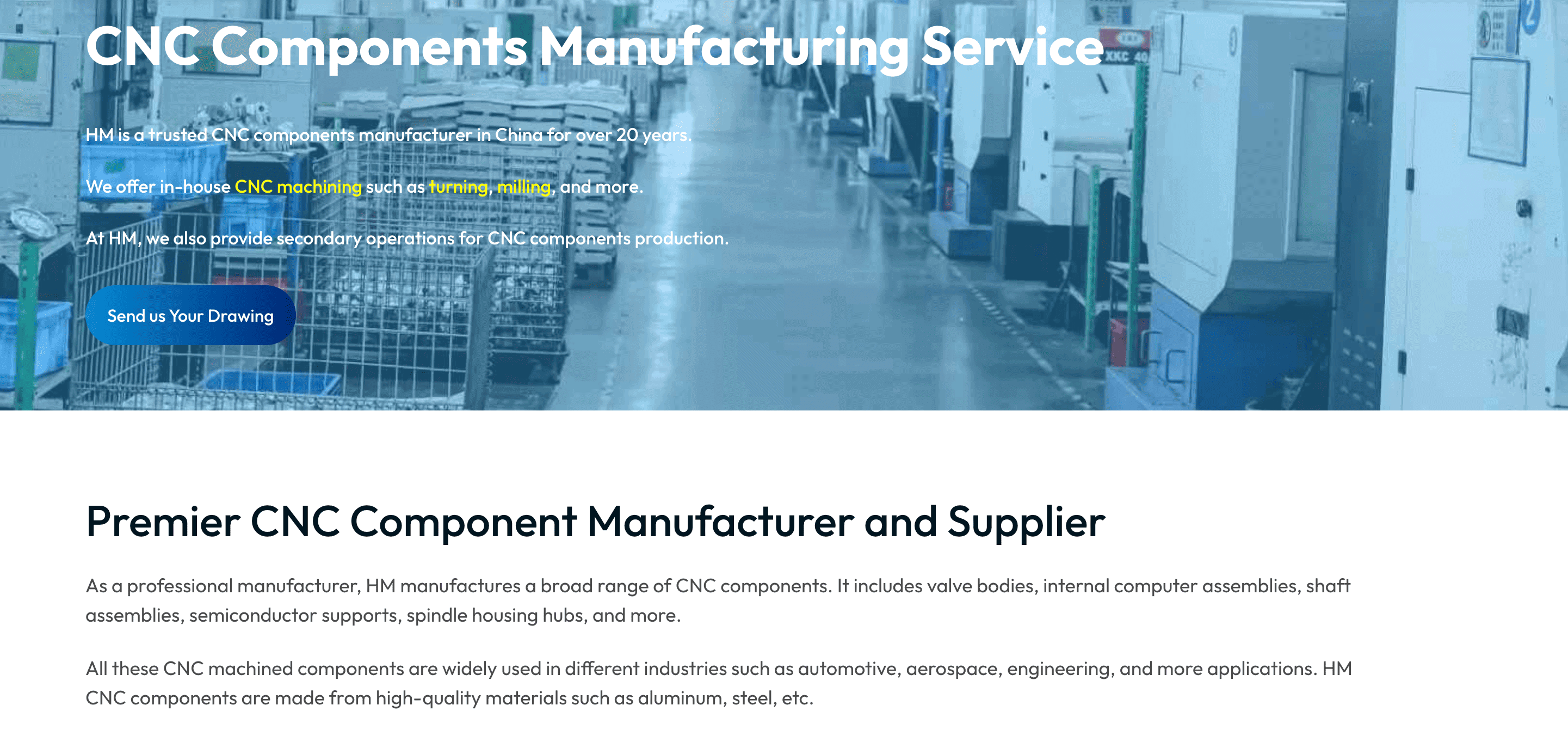

When picking a CNC machining service provider, it’s important to look at how much experience they have. Find companies that have done projects like yours before. Experienced providers are more likely to understand what you need and do a good job. They can also give you helpful tips to make your designs easier to make, which could save you time and money.

Think about what the provider is really good at. Some CNC machining service providers might be great at making certain types of parts or working with specific materials, while others might be able to do lots of different things. It’s important to choose a provider whose skills match what you need for your project.

2. Check Technical Capabilities

The technical abilities of a CNC machining service provider are really important for making precise, high-quality parts. Advanced machines and technology can make a big difference in how accurate and fast the manufacturing process is. Good equipment often means they can make parts with tighter measurements, produce them faster, and handle more complicated shapes.

When looking at technical capabilities, think about:

- Types of CNC machines they have (3-axis, 5-axis, etc.): Different machines can do different things. For example, 5-axis machines can make more complicated parts with fewer setups, which can save time and make parts more accurate.

- Software and design tools: Good software can make it easier to go from design to production, making sure your design files work well with the CNC machines.

- How precise they can be: Look for providers who can consistently make parts with very small differences from the design, especially if your project needs to be really precise.

- Ability to make complicated shapes: Some providers are really good at making parts with tricky shapes that need advanced machining techniques.

- What materials they can work with: A provider that can work with lots of different materials is good because they can meet your specific needs, whether you’re using metals, plastics, or other materials.

3. Assess Quality Control Measures

Quality control is super important in CNC machining to make sure parts are made consistently and accurately. Look for providers that have strong quality checking processes and important certifications. Checking the quality of CNC machined parts should be a top priority for any good service provider. A thorough quality control system can help prevent mistakes, reduce waste, and make sure the final products are as good as or better than what you asked for.

Also, ask about the tools they use to check parts and how they do it. Advanced measuring tools like coordinate measuring machines (CMMs) or optical comparators can make sure quality control is really accurate. Ask how they handle parts that don’t meet the requirements and how they try to keep improving their quality management.

4. Consider Material Expertise

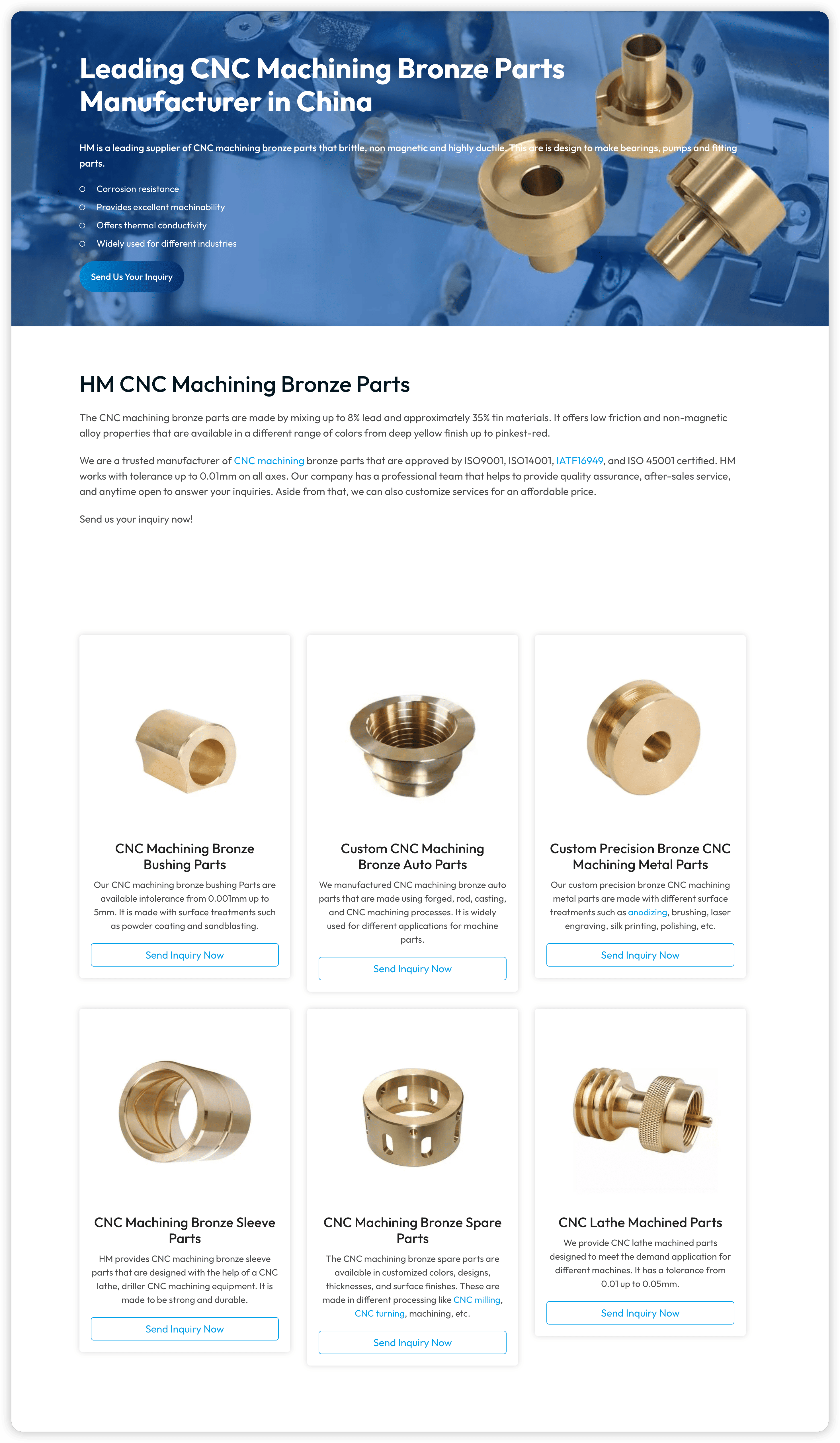

Different projects need different materials, and it’s important to choose a provider who knows a lot about working with the materials you need. Whether you’re looking for aluminum parts, stainless steel components, or plastic machined parts, make sure your chosen provider has experience with these materials. A provider who knows a lot about materials can give you valuable advice on which ones to choose, helping you make your design work better, cost less, and be easier to manufacture.

Ask potential providers about:

- What materials they work with: Being able to work with many different materials shows they’re versatile and can handle lots of different project needs.

- Their experience with the materials you need: Knowing a lot about your chosen material means they’ll know how to handle and machine it properly.

- Where they get their materials and how good they are: Getting reliable, high-quality materials is crucial for making sure parts work consistently.

- How they handle special or unusual materials: Some projects might need less common materials that require special knowledge and equipment.

5. Evaluate Turnaround Times and Capacity

Being able to meet deadlines and handle how much you need to produce is really important when choosing a CNC machining service provider. Quick prototyping and efficient production schedules can give you an advantage in your industry. A provider that can make a lot of parts quickly can help you respond faster to what customers want and get your products to market sooner.

Think about these things when looking at turnaround times and capacity:

| Factor | Importance | Status |

|---|---|---|

| Production Volume | High | Check |

| Lead Times | High | Check |

| Flexibility | Medium | Check |

| Rush Orders | Low | Optional |

| Inventory Management | Medium | Check |

6. Review Customer Service and Support

Good communication and customer support are really important for a smooth manufacturing process. Look for providers that respond quickly to your questions and are willing to work closely with you throughout your project. Good communication can help prevent misunderstandings, solve problems quickly, and make sure your project stays on track.

Key things to look for in customer service:

- How quickly they respond to questions: Fast and thorough answers to your questions and concerns are crucial for managing your project well.

- Clear communication: The ability to explain technical things clearly and give regular, easy-to-understand updates is very important.

- Willingness to give technical advice: A provider that offers feedback on how to make your parts easier to manufacture can help improve your designs.

- Having project managers or dedicated contacts: Having one person to talk to can make communication easier and more consistent throughout your project.

- Support after production and help with problems: Ongoing support after you get your parts shows they care about customer satisfaction and long-term relationships.

7. Compare Pricing and Value

While cost is important, it shouldn’t be the only thing you think about when choosing a CNC machining service provider. Look for a balance between good prices and extra services that add value. Understanding what affects CNC machining costs can help you make a smart decision. Remember that the lowest price isn’t always the best value, especially if it means lower quality, less reliability, or poor customer service.

Consider these things when looking at pricing:

Key Factors for Selecting CNC Machining Services

- Experience with similar projects

- Quality of CNC machines

- Knowledge of materials

- Quality control processes

- How quickly they can deliver

- Price balanced with quality and service

- Good communication and customer support

- Ability to handle complicated projects

- Flexibility to adapt to your needs

- Industry certifications (like ISO 9001, AS9100)

- How much they can produce

- Advanced manufacturing technologies

- How precise they can be (like 0.01mm or smaller)

- What past customers say about them

- Using modern manufacturing standards

8. Check for Industry-Specific Experience

Different industries have different requirements and standards. Choose a provider with experience in your specific industry, whether it’s cars, defense, or medical. This makes sure they understand your needs and can meet the rules and standards for your industry. Experience in your specific industry can be really valuable for dealing with complex requirements, following regulations, and using specialized manufacturing processes.

When looking at industry-specific experience, think about:

- Familiarity with industry standards and certifications

- Experience with materials and processes specific to your industry

- Understanding of regulatory requirements and compliance issues

- Track record of successful projects in your industry

- Relationships with suppliers or partners in your industry

Conclusion

Choosing the right CNC machining service provider is a big decision that can really affect the quality of your products and how efficiently they’re made. By carefully looking at experience, technical abilities, quality control, material knowledge, capacity, customer service, pricing, and industry-specific knowledge, you can find a provider that meets your needs and helps your business succeed.

Remember to ask for quotes from several providers, request samples or case studies, and thoroughly review their capabilities before making your final decision. Consider visiting their facilities or taking virtual tours to see how they work firsthand. With the right CNC machining partner, you can ensure high-quality parts, efficient production, and an advantage in your industry. Take your time to make a good decision, as the right partnership can lead to long-term success and growth for your business.