Aluminum-coating performs an important part in improving durability and performance of parts. It provides outstanding corrosion resistance, reflectivity and lightweight nature. In this blogpost we will cover the different types of aluminum-coating, their benefits and applications in different industries.

What is Aluminum Coating?

Aluminum-coating is a surface treatment process in which different methods like electroplating, conversion coatings and anodizing are used to create protective layers on aluminium. This engineered surface modification either generates a barrier oxide layer or deposits pure materials to improve material properties of aluminium.

Types of Aluminum-Coatings

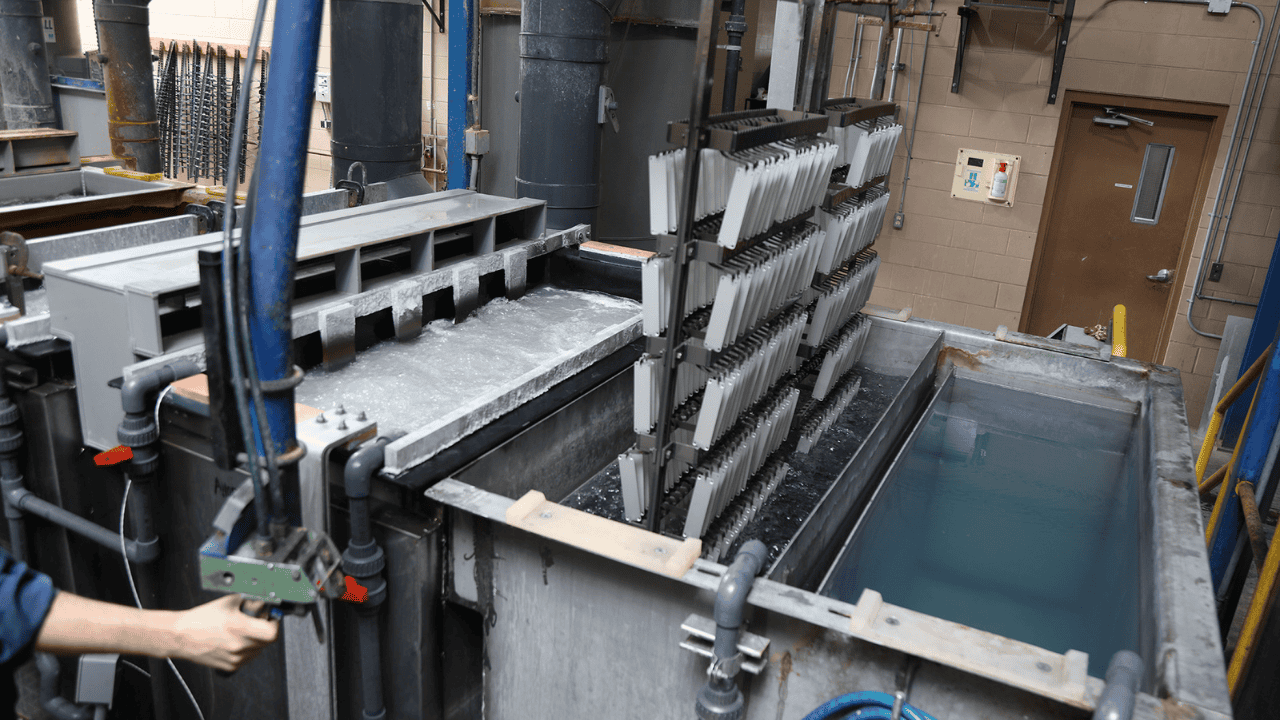

1. Anodizing

Anodizing is an electrochemical process that produces an integrated oxide layer on the surface of aluminum by electrolytic passivation. It involves submersion of aluminum in an acidic electrolyte bath and passing direct current to form a hard coating. This provides a durable, non delaminating finish which provides better corrosion resistance and has the ability to accept different dyes for aesthetic improvement.

2. Fluoropolymer Coatings

In fluoropolymer coatings, high performance resins are combined with fluoropolymer lubricants to produce a smooth, hard surface on aluminium with extraordinary properties. These coatings will provide you low friction and better corrosion resistance as well as thermal stability up to 500°F. Because of their salt spray resistance and dielectric strength of 1400 volts per mil, they are perfect for harsh environments.

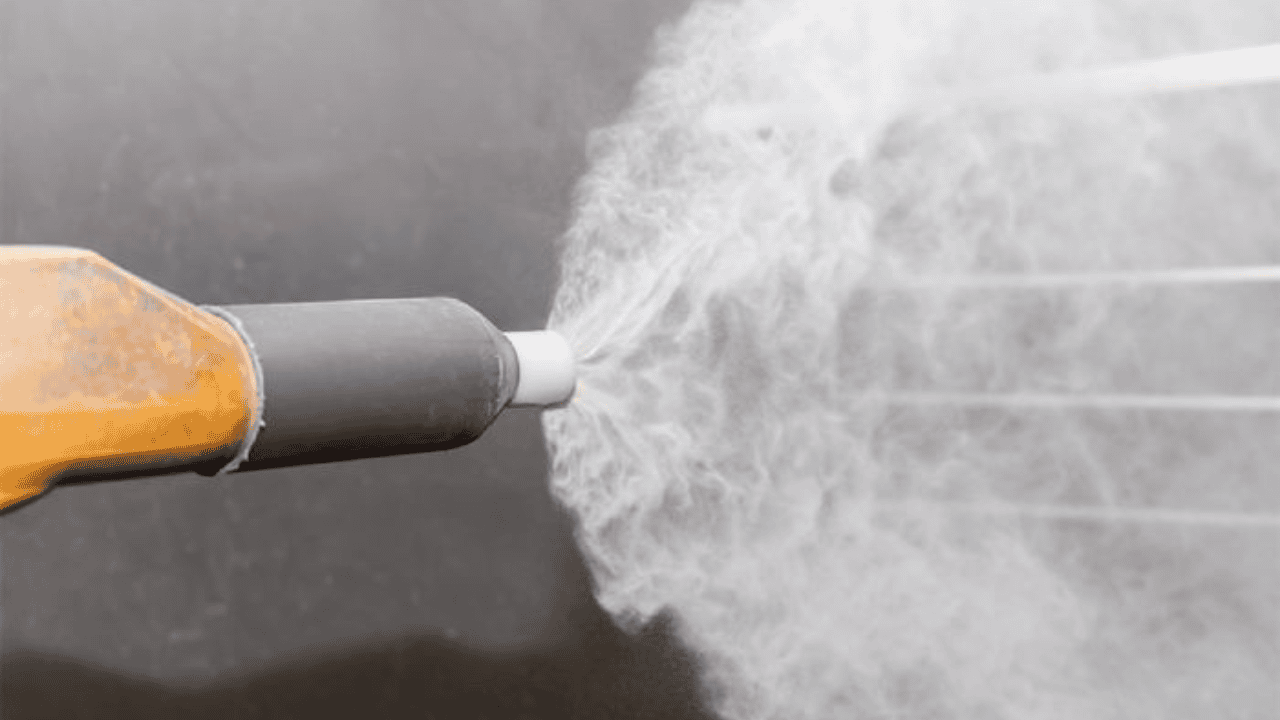

3. Conversion Coatings

Conversion coatings form a protective layer with better paint adhesion and corrosion resistance to chemically altered aluminum surfaces. Chromate-based coatings that are applied by dipping or spraying at 60 to 100 F form a thick layer. Some of today’s modern alternatives to chromium, such as TCP, offer exactly the same performance with less environmental impact.

Also these coatings are appropriate for aerospace applications because they pass salt spray tests and are electrically conductive.

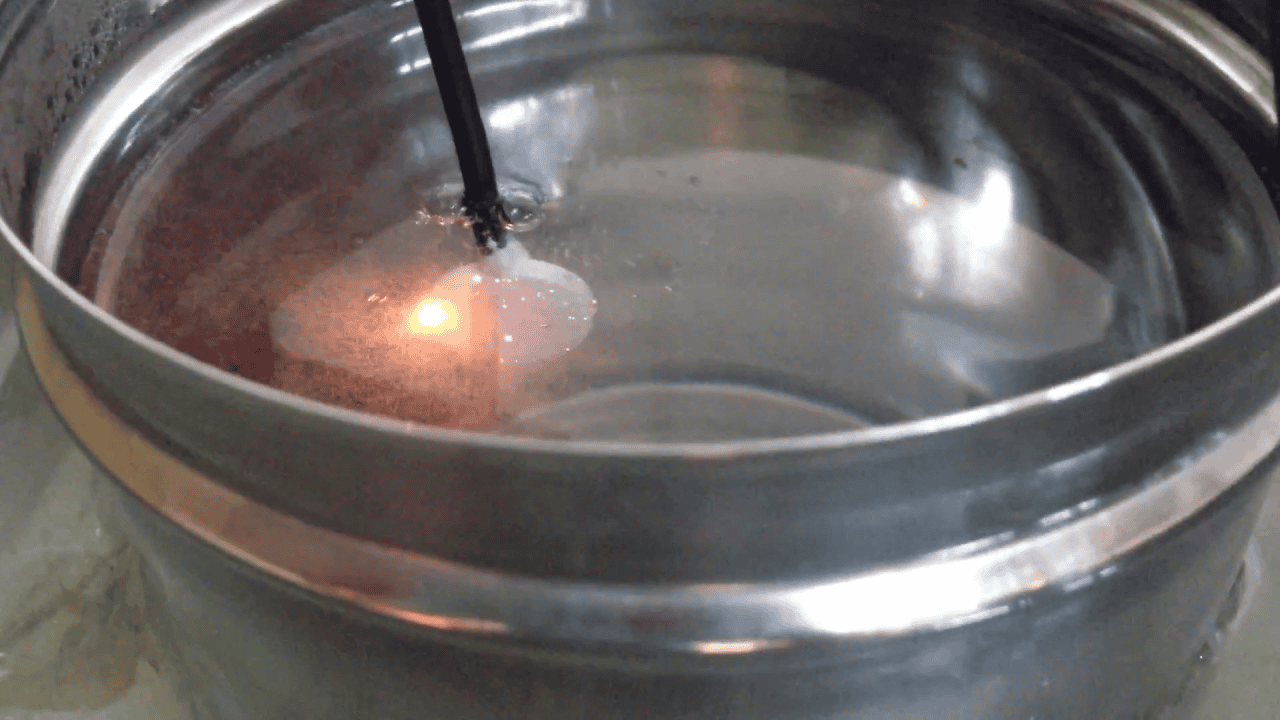

4. Electroplating

Aluminum electroplating is carried out in an electrolytic bath containing aluminum halide and dimethyl sulfone at 60–100°F. The process deposits a 200-1000 Å thick pure aluminum layer which improves conductivity and corrosion resistance. Using this technique, you can get uniform coating on complicated shapes even in barrel plating method. While in electronics and aerospace applications, it provides precise thickness control and customizable finishes for both functional and aesthetic purposes.

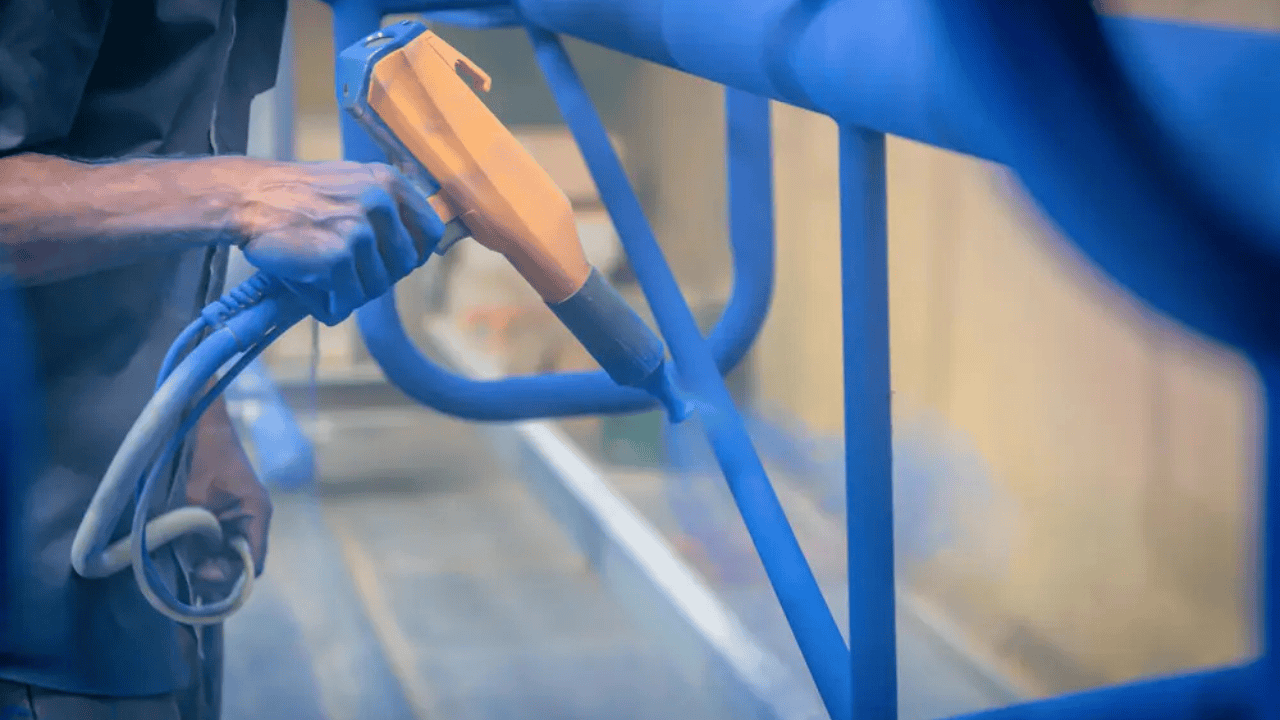

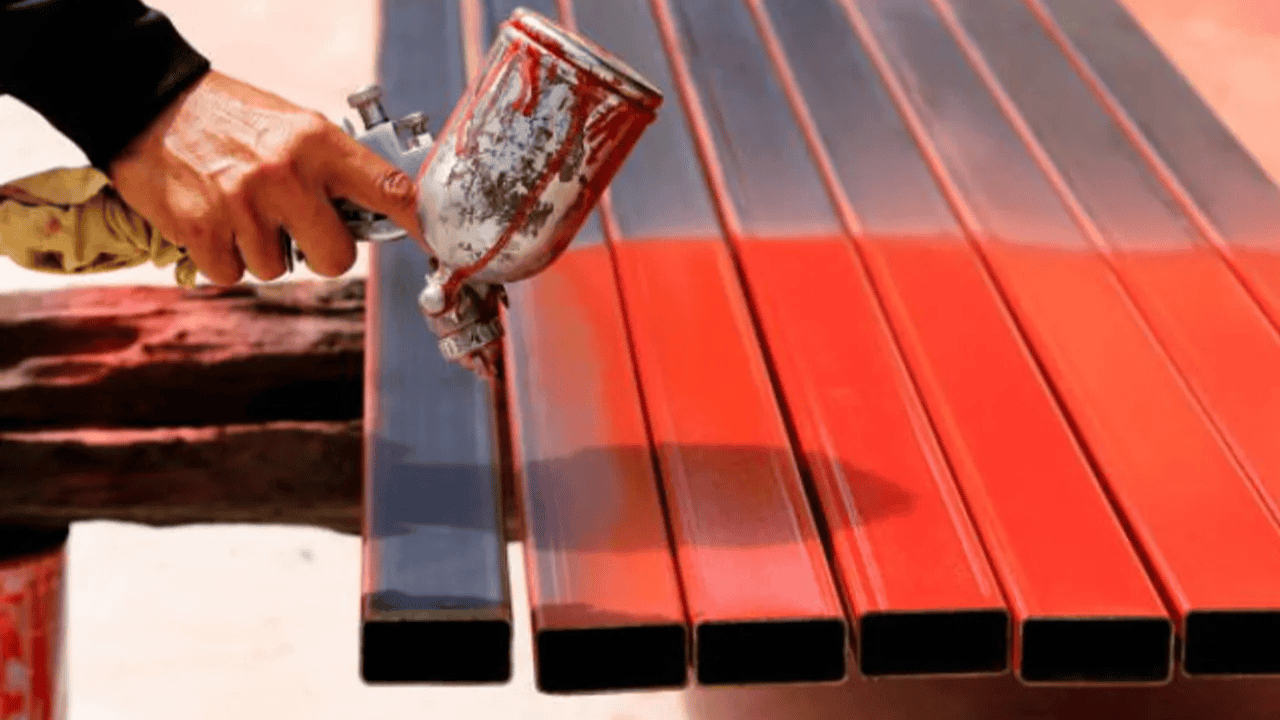

5. Powder Coating

The durable finish created on aluminium surfaces by electrostatic application of dry powder (which is then cured by heat at 700 to 750°C) is referred to as powder coating. Moreover the thick, uniform layer that is formed by this solvent free process also meets AAMA 2605 and 2604 specifications. The coating gives you outstanding corrosion protection and UV resistance along with a broad range of finish options through special pigments and resins.

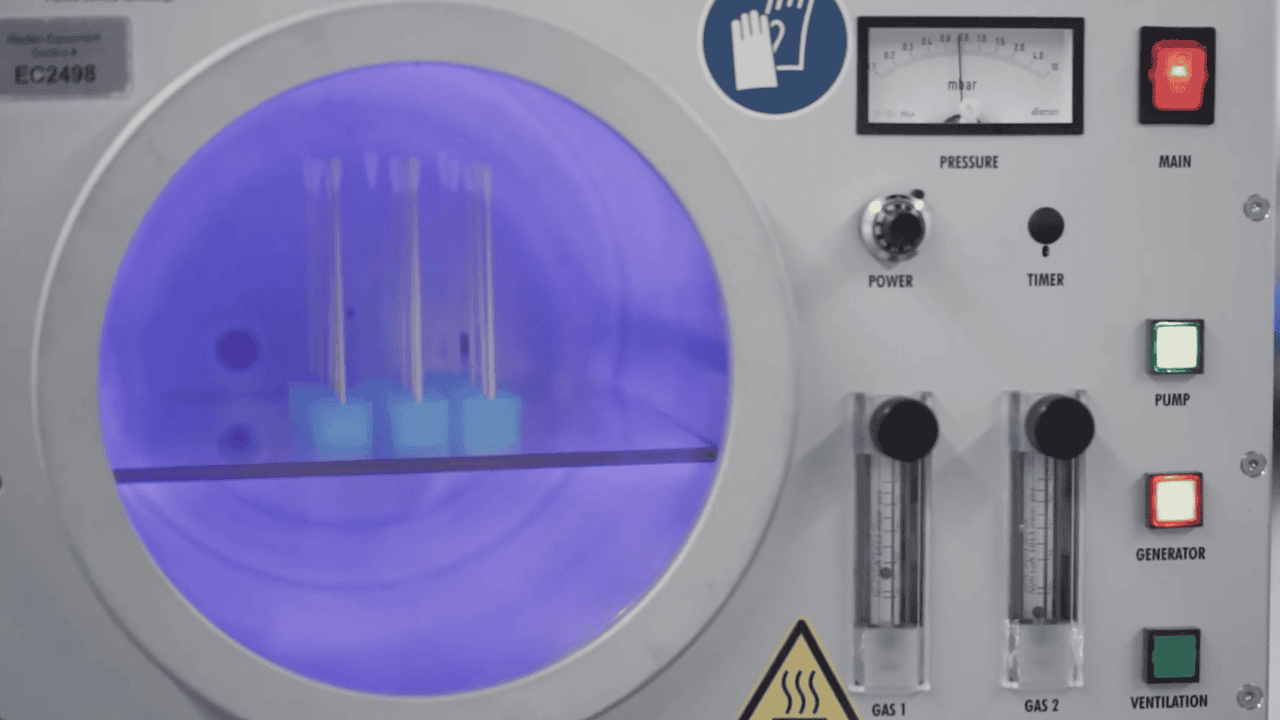

6. Plasma Electrolytic Oxidation (PEO)

PEO is an advanced electrochemical process that uses micro discharges on aluminum surfaces to produce dense ceramic oxide layers. The treatment creates very hard coatings with hardness values of 2000 HV which in turn gives you accurate control over crystalline structure and porosity. This nano-ceramic coating provides outstanding wear resistance as well as thermal stability up to 800°C.

7. Painting

In this, aluminum is painted using a chromate pre treatment followed by lacquer application at 65°C for 30 to 60 minutes. It is an ideal process for coating large dimension aluminium components and helps you obtain a smooth, decorative finish with unlimited color options. While the technique is slower than other coating methods, it gives you impressive transfer proficiency with minimal overspray.

8. Physical Vapor Deposition (PVD)

PVD vaporizes solid materials in a vacuum chamber at temperatures from 250-450°C to create ultra thin metallic coatings. In this advanced process, atoms are deposited directly by cathodic arc or sputtering methods onto aluminum surfaces. It permits you to produce hard films with outstanding corrosion as well as wear resistance. Apart from that, it usually works at lower temperatures than competing methods to preserve aluminum’s base properties while allowing you to control thickness accurately.

Benefits of Aluminum-Coatings

- Aluminum-coatings provide a self healing oxide barrier to protect the coatings from SO3, H2S, and SO2 attacks. The dense, pore free structure of the coating allows it to withstand harsh environments and provides impressive corrosion protection in industrial acidic and salt conditions.

- The aluminum-coatings provide high gloss to matte surface finishes with unlimited color choices and special effects such as metallic or wood grain finishes. These finishes preserve their visual appeal because of uniform application techniques and UV resistant properties.

- Aluminum-coatings are a protective barrier to impacts, abrasions and scratches. In addition, with this coating, you can lower maintenance requirements and prolong the component life because of increased surface hardness.

- At room temperature, aluminum oxide coatings provide dielectric strength of 300-400 volts per mil thickness. This insulative barrier helps you avoid your critical components from static buildup and electrical shorts.

- Aluminum-coatings can withstand temperatures up to 800°C—even higher than the base aluminum melting point—and provide thermal insulation with conductivity values of 0.7 W/m/K. In extreme thermal environments, the oxide layer formation and reflective properties of coating provide better heat management.

Applications of Aluminum-Coatings

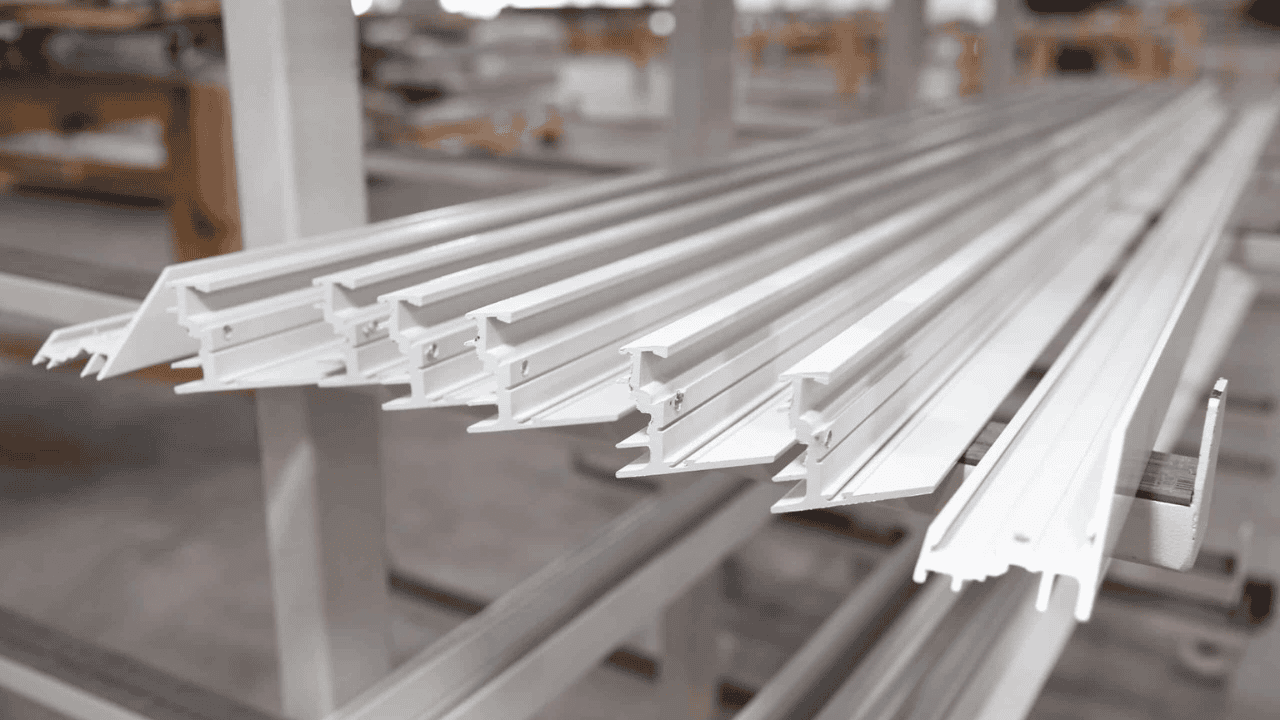

Architectural Applications

Aluminium-coatings are particularly used in facades, roofs, bridges, buildings and windows. In outdoor environments subjected to harsh weather conditions, these coatings improve aesthetics, durability and corrosion resistance

Aerospace Sector

In aerospace industry, aluminum-coatings are used to protect components from corrosion and extreme temperatures. Such parts are landing gear, engine parts, airframes, aircraft wings, turbines and fuselages.

Automotive Industry

Body panels, exhaust systems, engine parts, wheels and chassis are all coated using aluminum-coatings. These coatings help protect important parts operating at elevated temperatures while decreasing under hood temperatures.

Consumer Electronics

Aluminium-coatings are used in electronics to protect laptops, smartphones, gaming consoles and electronic enclosures. They not only provide a durable finish but also increase the lifespan of your electronic devices.

Food & Beverage Sector

Food-grade aluminum-coatings usually applied to beverage cans, containers and processing equipment form a protective barriers of 1–10 micrometers. You can preserve taste, maintain product safety and prevent corrosion with the help of these FDA approved coatings.

Conclusion

Aluminum-coatings through advanced application technologies provide necessary surface protection with outstanding thermal stability up to 800°C and corrosion resistance. These treatments continue to evolve to cover industry needs and provide aesthetic and functional benefits across different applications.

If you require any kind of aluminium coating services, then hMaking is best option. You can contact us anytime.Common Questions

- How do aluminum-coatings affect the recyclability of aluminum products?

A majority of the aluminum-coatings can be removed by using heat treatment or solvent processes. After coating removal, the aluminum base is fully recyclable, preserving its inherent material properties and environmental sustainability.

- How do aluminum-coatings affect the recyclability of aluminum products?

- What factors should be considered when choosing the right aluminum-coating for a specific application?

You should consider required surface hardness, operating temperature range, electrical conductivity requirements and environmental exposure conditions. - Can aluminum-coatings be reapplied or repaired after wear and tear?

Yes aluminum coatings can be reapplied if existing coatings are properly removed and surface preparation is done. - What advancements in aluminum-coating technologies are shaping the industry today?

The recent innovations include environment friendly chromate free alternatives, nano ceramic coatings and advanced PVD processes that produce better hardness values along with adhesion strength.