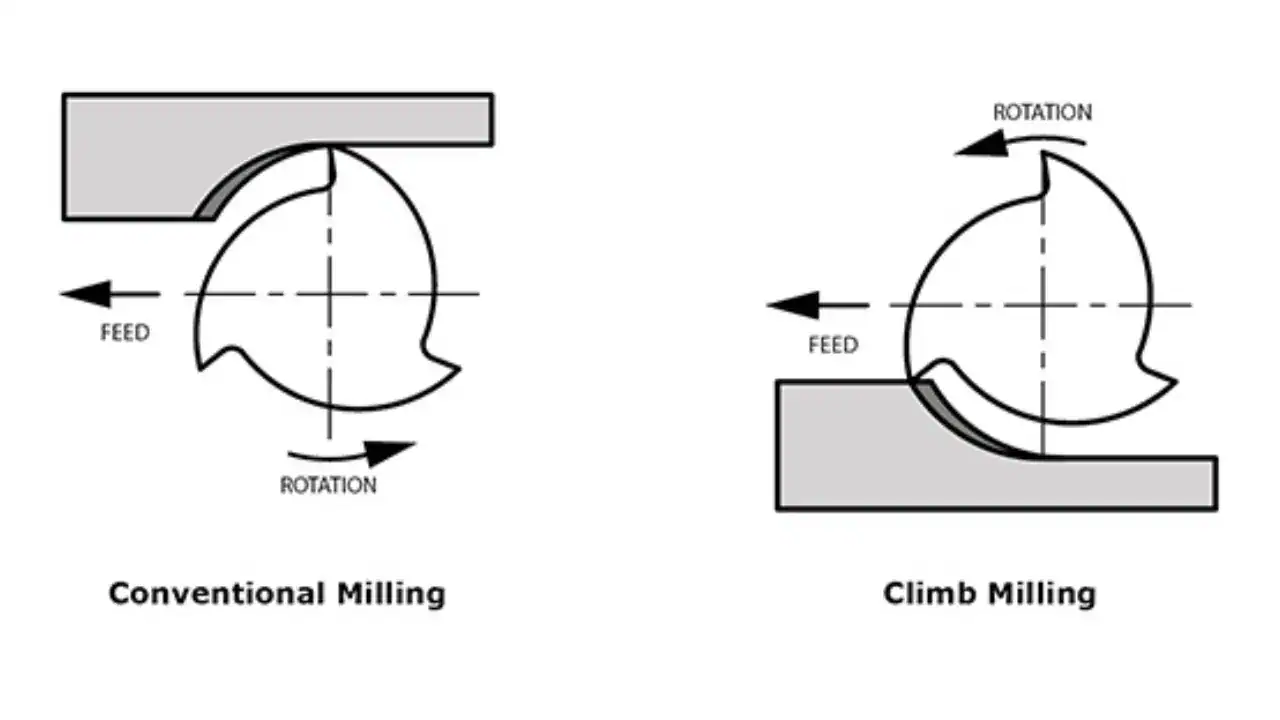

There are two common techniques you can use to chip off metals from a workpiece. They are climb milling and conventional milling.

Both techniques have been a subject of consistent debates over their accuracy and overall benefits. This article covers the main points of focus in the climb milling vs conventional milling discussion.

Read on to discover when to choose either of these milling processes.

What Is Climb Milling?

This is a technique in which the cutter rotates in the same direction as the workpiece. The cutting edge can be said to be climbing the surface of the material, thereby gradually removing small layers.

One of the major benefits of climb milling technique is the fine and smooth finishing it guarantees. You can call it a filing process that eventually reduces the width of workpieces.

Manufacturers have their different reasons for choosing climb milling but tight tolerance and smooth surface finish top the list. One of the best advantages of climb milling is its superior finish rank.

Conventional vs Climb Milling

What Is Conventional Milling?

This opposite rotation of the tool feed or workpiece means that the cut follows an upward direction and is a complete opposite of the climb milling process.

This method has little workpiece movement and better control and it is superb for older machines and hard materials.

Main Differences Between Climb and Conventional Milling

Conventional milling and climb milling offer different benefits to machinists or manufacturers when used. Here are the main differences between them:

Chip Formation

How the chips are formed from the feed is a key part of the conventional vs climbing milling debate. Climb milling’s chip formation begins with a lot of thickness. However, that thickness reduces as the cut progresses. For the conventional cutting technique, the chip emergence gradually increases starting from nought.

milling, cutting, machining, chip, metal

Tool Direction of Motion

In climb machining, the cutter drags the workpiece or tool feed in its movement direction when it cuts. For instance, suppose the cutter is vertically pointing upward or downward and moves in a clockwise direction. In that case, the workpiece will move horizontally forward as the mill cutter’s spiral edge pulls it.

But the reverse is the case when it comes to conventional milling. Here, if the cutter moves in a clockwise direction, the workpiece would move horizontally backwards against the direction of the cutter’s edge.

Cutting Forces

When it comes to cutting forces, conventional milling processes produce a higher cutting force thanks to gradual chip formation and a balance of friction. Meanwhile, climb milling has low cutting force and this is down to great chip thinning and smoother engagement.

Surface Finish

Climb milling process takes the cake when it comes to surface finish. In a bid to reduce material tearing and friction, the climb milling process engages the material with a full cut right from the beginning of the process.

For conventional milling, the surface finish isn’t as smooth. This is because the cutting tool engages the material by rubbing the workpiece before eventually cutting. The more friction it creates, the more chances it will roughen the material.

milling, machining, cutting, chip, metal

Backlash

Backlash often occurs in CNC machining tools due to several factors. It’s a significant variable as it affects the cut accuracy. Conventional milling doesn’t give rise to any form of backlash whatsoever.

But in climb milling, it’s a different ball game. As long as you’re using older machines for climb chipping, you’re bound to experience backlash. This is unless you use any of the practicable backlash eliminators. However more modern machines have more sturdy architecture that prevents backlash irrespective of the milling technique you adopt.

Heat Generation

In conventional milling, you’re doing work against the feed, requiring more torque. As a result, it generates a significant amount of heat compared to its climb counterpart. Nonetheless, both climb cut and conventional machining still generate a significant amount of heat that can lead to wear if left unchecked.

CNC, machining, turning, metal, industry

Tool Wear

Wear and tear always occurs when two surfaces grind against each other repeatedly. So the more the friction between them, the more the likelihood for the tool to break down.

During down (or climb) milling, lesser friction and heat is generated because of the low amount of pressure exerted on the chip during cutting. It also produces a high surface quality.

Whereas in the conventional milling process, excessive heat is produced due to frictional and upward forces. This process reduces tool life by 50% when used heavily.

Material Removal Efficiency

Both climb and conventional milling removes chips from the feed. While the former does this gradually, the latter takes off significantly larger chunks per second. However this speed and its obvious anti-directional movement makes the chips fall on the workpiece’s surface, making it rough and untidy.

Climb cutting is significantly different. This is because it removes only fine layers of surfaces per time, allowing them to fall off instead of returning to the workpiece’s surface. The former will give you faster results but poor finishing. The latter is slower but excellent.

When to Choose Climb or Conventional Milling Processes

It’s one thing to know the differences between climb milling and conventional milling. But it’s another thing to know when to use them.

Also, one of the amazing things about the conventional milling vs climb milling debate is that both techniques have their strengths and weaknesses and still find relevance till date. Climb milling process is great for:

drill, metalworking, machining, tool, workshop

- Older machines with backlash eliminators

- Modern machines that doesn’t have backlash phenomenon

- Small workpiece that requires excellent finishes

Conventional milling process is great for: - Fast milling procedures, especially when the workpiece is large

- Older machines

- If cut accuracy is not the utmost priority

Conclusion

Renowned brands like HM have mastered the art of using climb cutting and conventional milling techniques for manufacturing high-quality machine parts.

From specific metallic parts to electronic and auto components, HM has a massive factory that mass produces any kind of item you need for your CNC machines in record time. Contact us now for the best CNC components manufacturing service.