Steel can consist of varying compounds at varying concentrations and these compounds determine its magnetic properties and magnetic strength.

Ferritic steel demonstrates magnetic features while non-ferretic steel is essentially non-magnetic.

Generally, Steel is magnetic. However, there are some intriguing issues about magnetic steel that you need to know.

Properties that Make Steel Magnetic

· Iron Presence

Iron or ferrite is typically the main compound found in most types of steel. Since it is essentially ferromagnetic, its presence and concentration, determine the magnetic capabilities of steel. A higher ferrite concentration translates into stronger magnetic properties.

· Crystalline Structure

Steel has a characteristic crystal-like configuration and the type of crystal structure heavily impacts the magnetic capabilities of steel. Steel with a body-centered cubic structure demonstrates superior magnetism while steel with a face-centered cubic structure exhibits non-magnetism.

· Carbon Presence

Of all the alloying compounds used to reinforce steel, carbon is the most common. Steel with comparatively higher carbon concentrations exhibits stronger magnetic properties.

· Magnetic Susceptibility

Steel, especially iron-based steel becomes easily magnetized when exposed to robust magnetic fields. The magnetic susceptibility of this steel is approximately 14 and this is a testament to its strong magnetic properties. However, the magnetic susceptibility of non-ferromagnetic steel is one.

Different Types of Steel and Their Magnetic Properties

Based on magnetic properties, steel can be categorized into three; Ferritic, martensitic, and austenitic steel. Here is a breakdown of their distinct magnetic behaviors.

· Ferritic Steel

Ferritic steel is known for its high iron content and it also exhibits a relatively higher chromium concentration at 10-30%. Owing to the high content of these two compounds, ferritic steel is considered to be magnetic. This magnetic steel has a crystalline structure and its magnetic behavior makes it a valuable tool in magnetic fasteners and kitchen appliances.

· Martensitic Steel

Martensitic steel has the highest carbon concentration and it also features other ferromagnetic alloys like nickel. As such, it demonstrates strong magnetic behavior. With a chromium content of approximately 12-18%, martensitic steel comes in handy in magnetic applications prioritizing hardness and strength.

· Austenitic Steel

Austenitic steel is comprised of austenite and this makes it essentially non-magnetic despite featuring magnetic alloys like nickel and manganese. It has a characteristic face-centered cubic configuration, which limits magnetism. It can, however, be magnetized through various treatments like cold working.

Advantages of Magnetic Steel

- Impressive Magnetic Features: With varying magnetic properties and strengths, steel provides you with a viable solution whenever you need soft or even strong magnetism.

- High Magnetic Susceptibility: You can easily turn steel into a magnet since its magnetic properties are easily activated in the presence of strong magnetic fields.

- Strong Magnetic Shielding: Owing to its high magnetic permeability, you can utilize magnetic steel to shield sensitive areas and machines from external magnetic forces.

- Fairly Affordable: Compared to other magnetic materials, steel is relatively cheaper and more durable, thus guaranteeing more service life.

- Extremely Strong: You can deploy magnetic steel in volatile settings, without having to worry about abrasion. It draws its strength from its crystalline structure.

- Easy to Recycle: You can easily and cost-efficiently repurpose your magnetic steel for other uses thereby fostering sustainability.

Factors That May Impact Magnetism in Steel

· Heat Treatment

Subjecting steel to heat treatment can result in strange magnetic behavior. For instance, heating it and subsequently cooling it can shrink the magnetic susceptibility of your magnet. However, heating martensitic steel can elevate the magnetic permeability of your steel magnet due to the formation of martensite.

· Composition

Varying grades of steel are characterized by distinct elements as alloying compounds. The distinction in these compounds and their concentrations accounts for the distinct magnetic behaviors of different types of steel. For instance, steel with a manganese alloy tends to be more permeable.

· Temperature

Temperature has the same effect on magnetic steel as it has on other magnetic objects. Excessive heat or temperature disconfigures the magnetic domains of the magnetic steel resulting in inferior magnetic properties. Once you subject the steel to temperatures beyond its curie point, it loses its magnetism.

· External Magnetic Forces

Once you expose the steel to more robust external magnetic forces, its magnetic domain alignment will imitate that of the stronger magnet.

This will result in magnetized steel since ferritic steel is highly susceptible. However, exposing magnetized steel to stronger magnetic forces can lead to loss of the magnetic features.

· Microstructure

Magnetic steel is made of a myriad of tiny grains, whose size and configuration may vary in distinct steel grades and types.

Steel with relatively small-sized grains can be endowed with magnetic powers easily and they also have a low coercivity. Steel with large-sized grains, on the contrary, is difficult to magnetize and has a comparatively higher coercivity.

· Mechanical Stress

Mechanical stress, which can include hitting with a heavy object or the bearing of excessive weight can greatly decrease the productivity of your magnetic steel. This stress may disarrange the aligned domains resulting in magnetism loss.

· Deformation

Deformation directly impacts the magnetic behavior of magnetic steel by distorting the crystalline configuration of your steel. Cold working, for instance, can turn your austenitic steel into martensitic steel, which is capable of fulfilling magnetic functions. Other deformation techniques capable of altering the configuration of steel are drawing and rolling.

· Foreign Impurities

The presence of unwanted elements or impurities in magnetic steel also disrupts its magnetic properties. Common impurities include phosphorous, which typically interferes with domain configuration and movement. The presence of such impurities can make it difficult for you to magnetize and demagnetize steel.

Common Uses of Magnetic Steel

Thanks to its ferromagnetic feature coupled with its strength, magnetic steel is highly used and appreciated in varying industries.

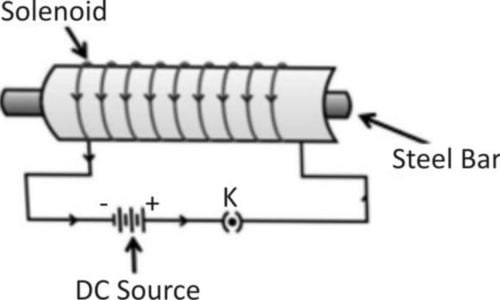

- Making Electromagnets: Modern electromagnets, which are common in lifting magnets and transformers often consist of a steel core. Steel is preferred due to its corrosion resistance and strength.

- Transmitting Electricity in Transformers: In transformers and electrical grids, steel is utilized to transfer energy and transfigure voltage.

- Magnetic Data Storage: Magnetic steel is commonly used to manufacture hard drive platters because it is magnetically receptive. This facilitates data capturing and preservation.

- Making of Motor Cores: Magnetic steel is a great material for manufacturing electric motors because of its magnetic capabilities.

- Making of Magnetic Separators: Steel is also broadly exploited to manufacture magnetic separators responsible for extracting magnetic elements from mixtures.

- Manufacturing of Magnetic Actuators: Ferromagnetic steel provides dependable magnetic fields when used to produce actuators for automotive systems.

- MRI Machine Manufacturing: Most MRI magnets are made from steel since it can generate stable and robust magnetic fields, thereby eliminating the threat of harming patients.

- Making of Compass Needles: Magnetic steel offers a strong and durable material for manufacturing magnetic needles to help compasses determine direction.

- Manufacturing of Maglev Tracks: Most magnetic tracks are made from steel because it is strong and can generate powerful magnetic forces to facilitate smooth train rides.

- Railway Industry: With a crystalline structure, steel is often exploited to manufacture train wheels and other components that necessitate strong materials.

More Resources:

Magnetic Steel – Source: SCIENCE DIRECT

Is Stainless Steel Magnetic – Source: UMD

Steel Melting Point – Source: HM