Hard coat anodizing aluminum is one of the best surface finish processes to preserve aluminum and enhance its functionality and durability. A well done hard coat anodizing strengthens your aluminum but it isn’t without some limitations.

Here, we give you an ultimate guide on all you need to know about this new method of anodizing aluminum which is different from the regular anodizing aluminum, its benefits, processes and applications.

What Is Hard Coat Anodizing?

Hard coat anodizing, also, type 3 hard coat anodizing, is an electrochemical process that is used to create a thick, highly durable oxide layer on ferrous and non-ferrous materials. The process is carried out most especially on aluminum, and its alloys to enhance its wear and corrosion resistance while increasing its aesthetic appeal. Other metals that may be considered for this process are titanium and magnesium.

Benefits of Hard Coat Anodizing Aluminum

Cost-Effectiveness

Although it initially costs a lot to run, the hard coat anodizing process offers substantial long-term benefits that will save you the cost of regular maintenance or replacement of the parts. Hence, what you spent in coating the material is recuperated in the long run through the longevity the process confers.

Improved Corrosion Resistance

Aluminum can corrode when subjected to certain conditions or placed in certain environments. Hard anodizing reduces the likelihood of this occurrence by providing the element with an extra layer of oxide. This makes a hard-coated metal about 10 times more resistant to corrosion compared to its plain counterparts..

Enhanced Heat Dissipation

The extra layer of anodized oxide that is deposited on the surface of aluminum during type 3 hard coat increases the heat dissipation ability of aluminum by up to 30%. While the anodized oxide has a higher emissivity for more effective heat radiation, the extra layer also increases the total surface area needed for the transfer of more heat.

Increased Wear Resistance

Every machined part will eventually wear out when it’s used over time. How quick this can happen depends on the thickness of the material and its numerous qualities that accounts for its toughness. By increasing the thickness of the metal in microns, hard coat anodizing makes the parts less susceptible to wear and tear, making it harder while increasing its lifespan for as long as several years.

Dielectric Properties

Hard coated aluminum has dielectric properties, making it behave like an insulator with the ability to withstand up to 1,000 to 2,000 volts of electricity depending on the thickness of the extra oxide layer. This property is taken into cognizance in applications where high voltage resistance is necessary.

Processes Involved In Hard Coat Anodizing

Hard anodized aluminum is created through a string of processes involving special apparatus. For a start, the type 3 hard cost anodizing kit is a noteworthy requirement among others. It’s used to implement some of the integral steps involved in producing this material. That said, these are the processes:

Cleaning

Cleaning is the first step of type 3 hard coat anodizing. Here, the aluminum part to be hard-coated is thoroughly cleaned to remove all specks of dirt and grease. This step ensures a uniform and better-quality coating.

Rinsing

The rinsing process involves using deionized water to wash off all remaining solutions used during cleaning. This ensures that the cleaning solution used does not interfere with the further steps of anodizing.

Etching

In hard coat anodizing, Etching is also a cleaning process that involves the use of chemicals to remove all surface materials from the aluminum part. As with the above steps, etching is important to prevent interference from surface impurities when performing hard coat anodizing.

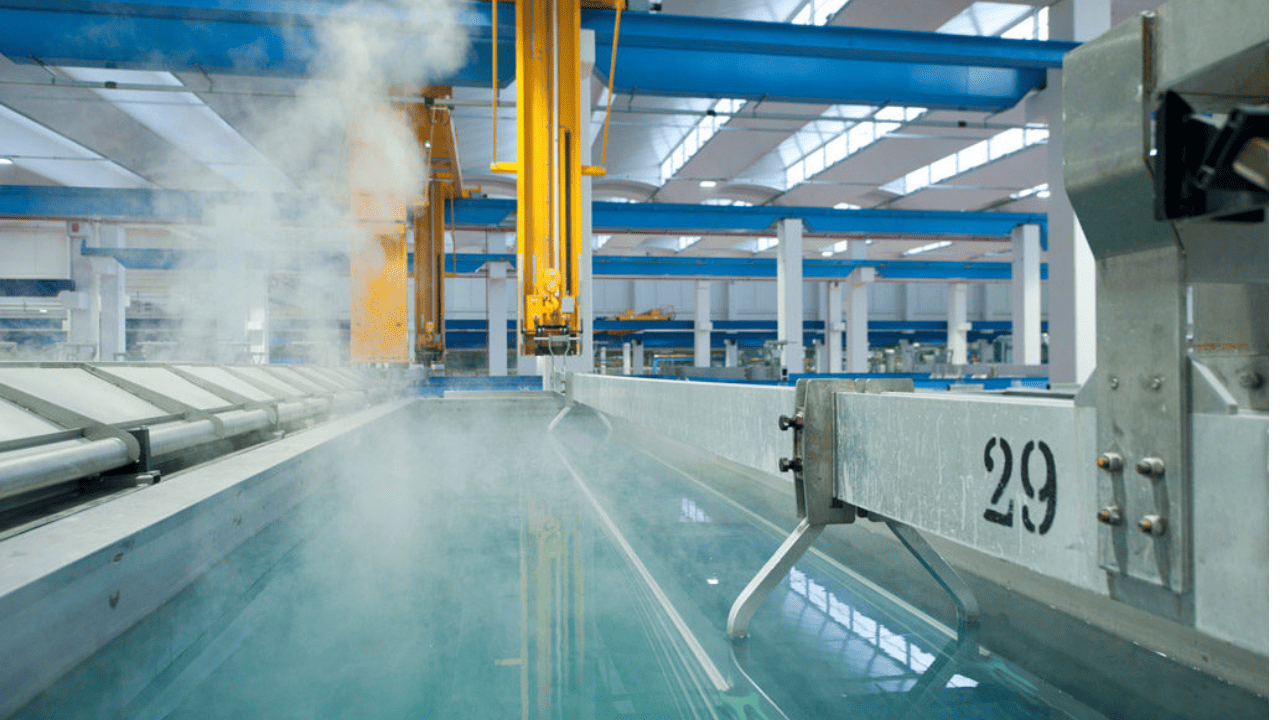

Anodizing

This step is performed after thorough and proper cleaning of the aluminum part. Here, the aluminum part is placed in a bath containing concentrated sulfuric acid. The concentrated sulfuric acid acts as the electrolyte, while the aluminum itself serves as the anode. An unreactive material is then placed in the bath to complete the circuit.

Hard Coating

After placing the anode and cathode in the electrolyte, we pass an electric current through the bath, setting the electrochemical reaction into motion. This step is done under controlled conditions such as temperature, acid concentration, and voltage. During the hard coating process, that is when an additional oxide layer is formed on the surface of the aluminum component.

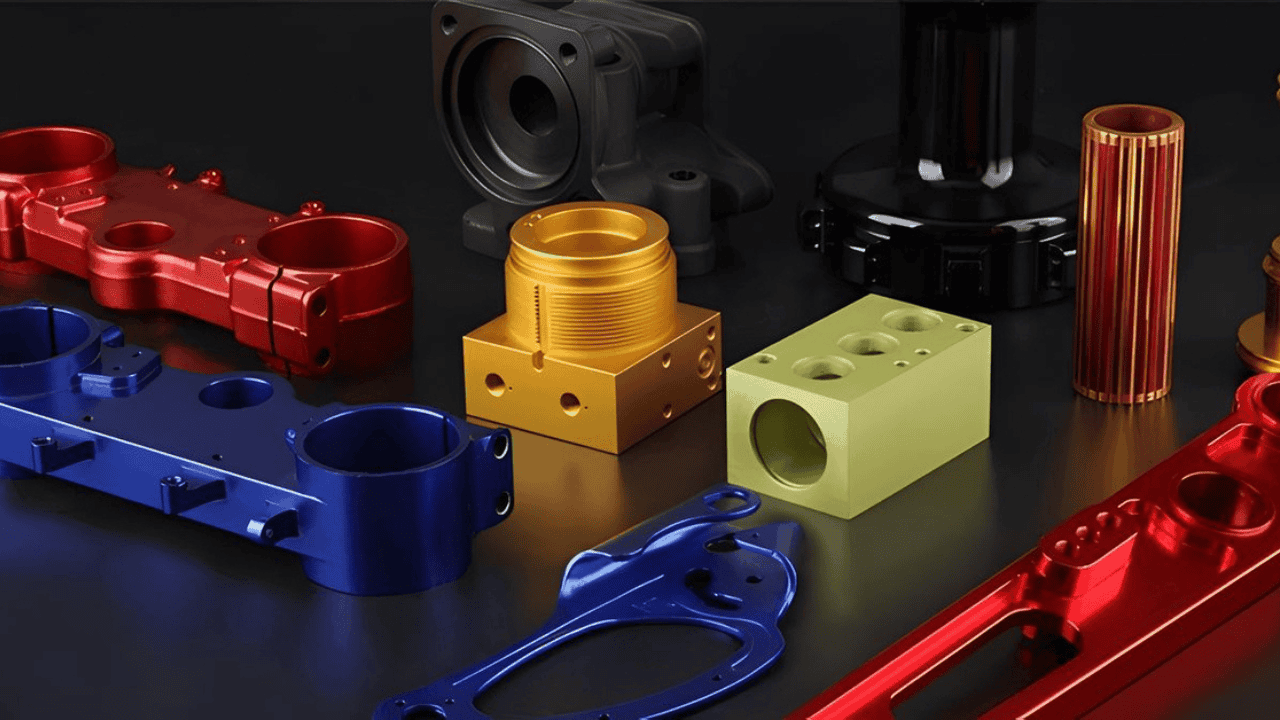

Coloring

In this step of the hard anodizing aluminum process, we add color to the surface of the aluminum material by submerging it in a dye bath. The dye used is absorbed by the pores on the surface, usually giving off darker shades. When coloring, there are a variety of colors you could choose from, we have red, black, blue, and green colors. The color you get depends on the alloy, dye used, and aesthetic appeal you desire.

Sealing

As the name suggests, this step involves closing the pores of the anodic oxide layer. It is usually achieved using sealants like deionized water, nickel acetate solution, epoxy resins, etc. This step is particularly important after coloring to retain the dye used.

Rinsing and Drying

This is the last step in creating hard anodized aluminum. It involves thoroughly rinsing the anodized metal in clean water and leaving it to dry completely.

Materials Used In Hard Coat Anodizing

Several materials are used when performing hard coat anodizing. The type 3 hard coat anodizing kit include the following:

Electrolytic Tank

The main process of hard coat anodizing is performed in an electrolytic tank. The tank contains concentrated sulfuric acid serving as the electrolyte, and so it should be made of acid-resistant materials.

Cathode

The cathode used in hard coat anodizing is made from an unreactive material like graphite, stainless steel, lead sheets, etc. It is important to use an inert cathode to prevent the cathode from being oxidized, ensuring oxidation occurs only at the anode.

Power Supply

Hard coat anodizing is an electrochemical process, and so requires a steady source of electricity. The hard anodizing process uses a power source that is capable of providing a high voltage of up to 120 volts. It should also be a variable DC power supply, as it lets us carefully control the voltage and, in turn, the thickness of the oxide coating.

Air Agitation

Air agitation refers to the process of introducing air into the electrolyte. This is usually achieved using nozzles placed in the electrolytic tank to introduce bubbles of air. The introduced air not only cools the sulfuric acid but also provides the oxygen needed for the anodizing reaction.

Temperature Control System

Hard coat anodizing, as with other electrochemical processes, produces a significant amount of heat. This, however, is counterproductive as this anodizing process requires a low temperature of about 0°C. It is, therefore, important to ensure there is a proper temperature control system capable of dissipating excessive heat and maintaining constant temperature in the electrolyte bath.

Pre and Post-Anodizing Process Equipment

The pre and post-anodizing process equipment are those we use before and after the anodizing process. These include tanks for cleaning, rinsing, degreasing, etching, dyeing, and ovens for drying.

Applications of Hard Coat Anodizing Aluminum Parts

Aluminum hard anodizing finds applications in many industries because of the wide variety of benefits it offers. The following are some of these applications:

Building and Construction

Building and Construction is a branch of engineering with a constant need for strong, durable materials, and hard anodized aluminum meets this specification. Projects built with such materials can withstand the harshness of certain environments for years without corroding.

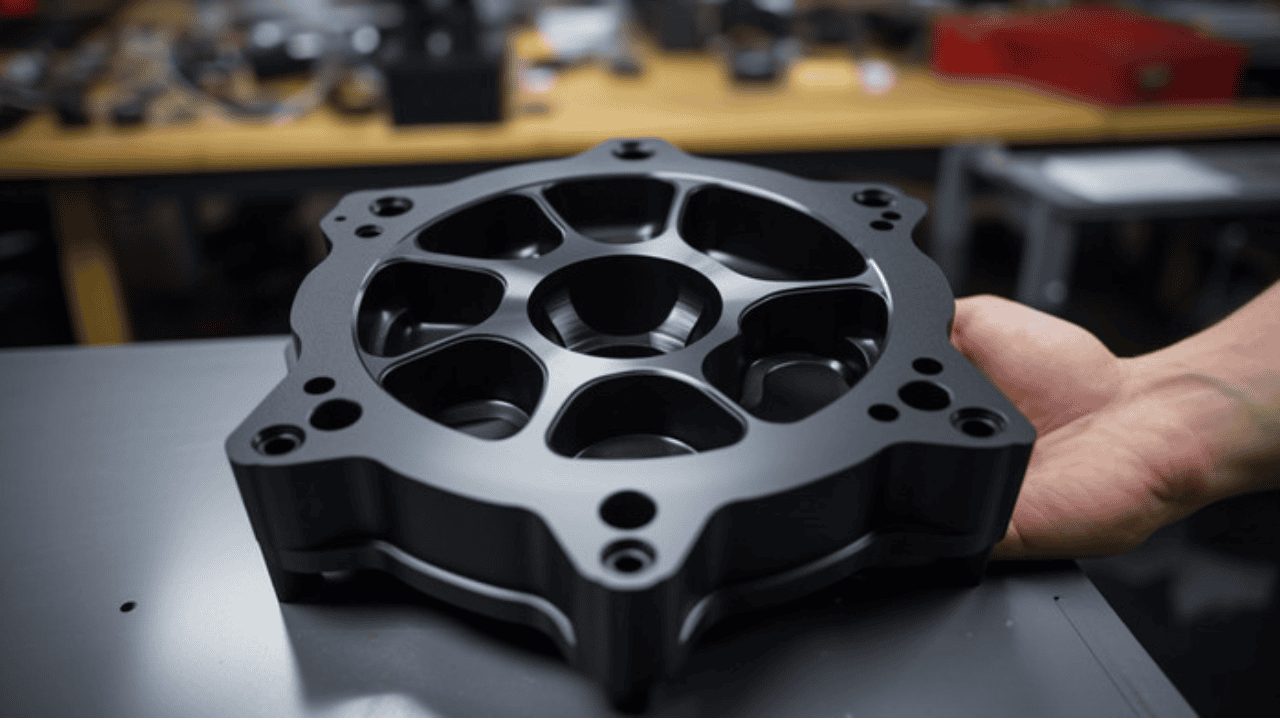

Automotive Components

Hard coat anodizing aluminum parts are widely used in producing engine parts like pistons, gears, cylinders, etc where resistance to wear and tear is important. Its enhanced ability to dissipate heat also makes it ideal for making transmission components that are likely to overheat.

Industrial Machinery

Aluminum parts produced from this process are well-suited for industrial machinery. This is because of their increased durability, resistance to adverse working conditions, and aesthetic appeal. They are, therefore, used in applications such as gears, pistons, shafts, shock absorbers, etc.

Marine Features

The marine environment is notorious for speeding the rate of corrosion in metals. Hard anodizing aluminum, however, offers an increased resistance to corrosion, alongside wear and tear. This makes it ideal for applications in marine engineering and exploration.

Aerospace Components

Aerospace Components are constantly under stress, from extremes of temperatures to crushing pressures. Hard anodized coating thickness is well suited to not only resist these stresses but also make the parts function optimally in the aerospace industry.

Factors that Influence Hard Coat Anodizing Aluminum

Temperature

The concept of temperature is an important factor to consider when hard anodizing aluminum to achieve a uniform coating. It is important to not only reach the required temperature but also to maintain it through the entire hard anodizing process.

Bath Chemistry

Bath chemistry is a critical factor influencing the quality of hard coat anodizing aluminum. Parameters like the PH and concentration of the sulfuric acid, amount of air passed, and voltage introduced must be properly controlled to produce a high-quality and uniform coating.

Surface Preparation

Surface preparation refers to several pre-anodizing processes like cleaning, rinsing, degreasing, etching, deionizing, etc. All these ensure there are no contaminants that can interfere with the hard anodizing process.

Alloy Composition

The composition of the alloy greatly affects the anodizing process. Some alloys, such as the 6061 aluminum, anodize very well, while others, such as the 2XXX, do not anodize well. In all, it is important to choose an appropriate alloy to ensure the highest quality coat.

Limitations of Hard Coat Anodizing

Dimensional Tolerances

The extra layer of anodic coatings deposited on the surface of aluminum greatly affects its dimensional tolerance. This, in turn, affects the overall functionality of the aluminum parts, especially in cases where tight tolerance is required.

Color Variations

Coloring in hard coat anodizing is typically dependent on the pores absorbing color from a dye bath. The extra layer of oxide, however, makes the process hard, and results in dark shades or black. This color variation makes hard coat anodizing unsuitable for specifications requiring a wide range of bright colors.

Potential Defects

The goal of hard coat anodizing is to produce an extra layer of protection against the element. This extra layer, however, results in a rougher surface that is prone to cracks when compared to other types of anodizing.

Low Fatigue Strength

Although the extra coat serves as an added layer of protection, it lowers the overall fatigue strength of the material when compared to other types of anodizing, or even the base form of aluminum. This is because of the porous microstructure of the additional layer, making it brittle and easy to crack when under stress.

Cost

Hard coat anodizing requires more resources and time than the regular forms of anodizing. This is a result of the extra time, electricity, and high-quality equipment needed to achieve the desired finishing. It also costs more to seal the pores we see in hard anodized aluminum.

Hard Coat Anodized Aluminum VS Regular Anodized Aluminum

There are several differences between Hard Coat Anodized Aluminum and regular Anodized Aluminum. These differences greatly influence the choice of their applications, and include the following:

Hardness

The final product obtained from hard coat anodizing aluminium tends to be more stronger and highly corrosion resistant than that obtained from the regular anodizing aluminum. This is because hard coat anodized aluminum now has a hardness similar to tool steel (~60-70 HRC) due to the intensive condition in which the process was performed.

Seal

Sealing is usually not necessary in hard anodized aluminum because of the dense layer of oxide coating that provides enough protection to the material. Regular anodized aluminum, on the other hand, needs to be sealed because of its porous nature. However, in cases where the hard anodized aluminum is colored, it is essential to seal it up in order to avoid peeling or any other defect.

Applications

Hard coat anodized aluminum generally finds relevance in applications where we need resistance to corrosion, electricity, wear and tear, etc. Such applications include aerospace and automotive parts. Conversely, regular anodized aluminum parts are used for more aesthetic purposes with tighter tolerances, including window frames, kitchen wares, etc.

Color

Both hard coat and regular anodizing aluminum processes allow the option of using different colors. It all depends on the dye you used, the alloy used in the process, and the purpose of the finished surface treatment. Beyond this, the natural hard anodized colors you’d find through undyed processes is black and grey.

Conclusion

Hard coat anodizing aluminum is applied in several industries thanks to its many benefits. That’s why, the demand for the process is significantly on the rise. If you’re searching for hard anodizing aluminum near me, you must note that making the most of the process requires state-of-the-art equipment, experience, and mastery.

This is when HM comes in. From world class factories, to highly trained teams, we have all it takes to transform your regular aluminum to hard-coated anodized aluminum. Contact us today to get started.