In the early 1960s, laser beam machining (LBM) emerged shortly after the invention of the laser. It came as a technological improvement for the applications of lasers, which was primarily marking and engraving. That invention has set the tone for laser beam technology in processing metal and non-metal materials. Would you want to know about its components and how it works? This article is your ultimate guide to laser beam machining.

What Is Laser Beam Machining?

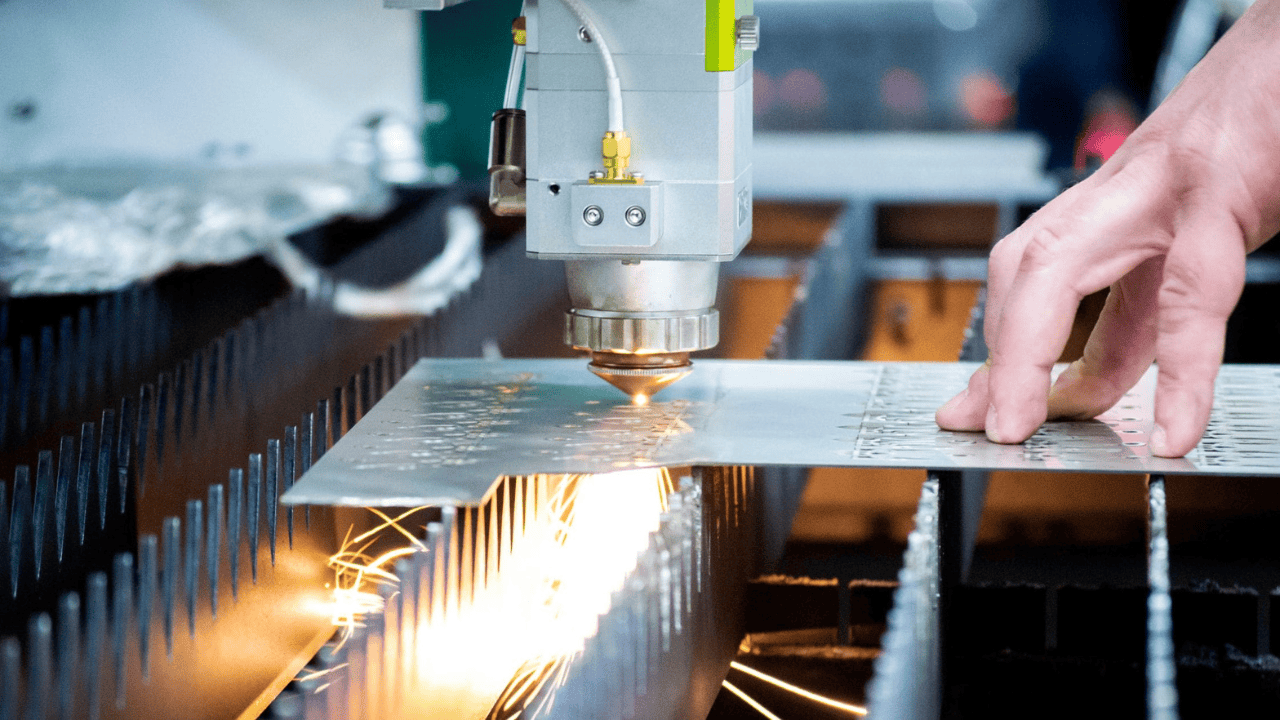

LBM is a non-conventional machining process that makes use of a highly focused laser beam to cut and remove material from a workpiece. This method is known to provide high precision cutting, drilling, and engraving on the material.

This is why it serves the energy sector, aerospace, automotive, research, and several industries where high precision machining is important. The LBM process is controlled by advanced computer numerical control (CNC) systems which ensure that the laser beam precisely follows the desired path and maintains consistent quality.

How Does Laser Beam Machining Work?

Laser beam machining is an effective tool for the removal of material from a workpiece. It is serving several high-level manufacturing industries thanks to how it optimizes and non-traditional machining processes. But how does it work?

Laser Generation

The laser generation process involves the production of a laser through a medium such as CO2, fiber, or solid-state materials. It occurs when this medium absorbs energy from electricity and amplifies the light energy. The process is prevalent in CO2 devices where extra supply of energy excites gaseous mixtures whose end product is laser light.

Although this method isn’t applicable for the generation of fiber lasers. Instead, the laser is produced through diodes and is amplified via fiber optics.

Material Interaction

After the laser generation, there is a material interaction stage where things get interesting. During the material interaction with the laser beam, an intense heating occurs which melts, vaporizes, or ablates the material. Thanks to controlled material interaction, manufacturing engineers, machinists, researchers, and other professionals can effect precise engravings or cuts.

Beam Manipulation

Beam manipulation requires the use of lenses and mirrors to help direct and focus the laser beam from a laser beam machine operator, ensuring that it strikes the workpiece directly and accurately with the desired intensity.

Process Control

The process control is less mechanical and more computational thanks to the help of advanced computer systems. This stage manages and enforces precision and repeatability of processes during production.

Types of Lasers Used in Machining

CO2 Lasers

These lasers are used for cutting non-metallic materials like wood, plastics, and glass due to their high efficiency and power. They offer a power range of 1 kilowatt to 20 kilowatt, depending on the power required to cut, weld, or engrave. CO2 lasers serve different use cases and industries where materials like glass, metals, and plastics are part of the workpiece being machined.

Solid-state Lasers

Solid-state lasers utilize solid-state gain media like glasses or crystals. These materials are combined with transition metal ions or even rare earth to give the desired energy output. They are capable of generating output powers from 1 milliwatt to several kilowatts. In higher power versions of solid-state lasers, a continuous beam power output can reach thousands of watts.

Fiber Lasers

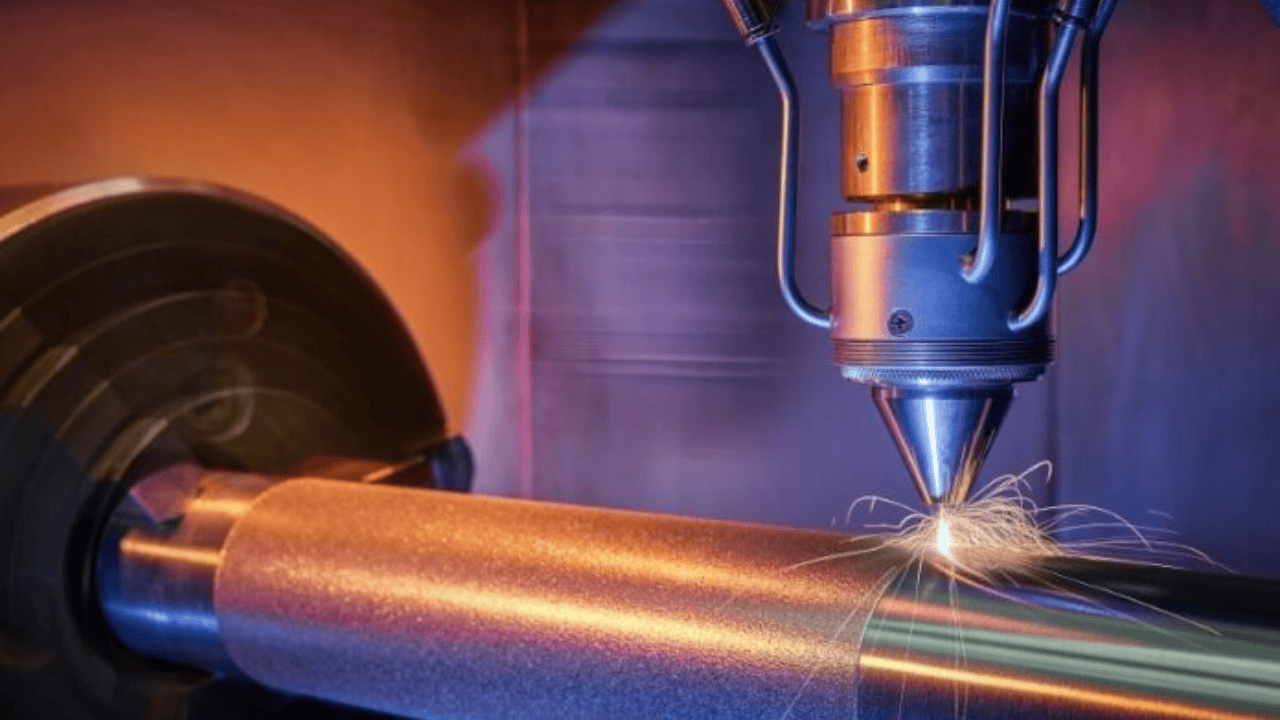

Fiber lasers are considered more advanced in the laser cutting industry. This different approach to cutting relies on banks of diodes amplified via some form of fiber optics to generate laser light. They are relatively more efficient and easy to maintain thanks to a wavelength of about 1070 nm.

If you are after precision machining for engraving or fine cutting, this might be a top option. Depending on the choice of manufacturer or the application, fiber lasers can reach power levels of 10 kW to 100 kW.

Liquid Lasers

Liquid lasers are used in machining lasing materials by producing laser light thanks to adjustable wavelengths. This type of laser uses organic dyes and the adjustable wavelengths fall within a specific area on the electromagnetic spectrum.

Liquid lasers have application in laser medicine and spectroscopy and can give a power output of 1 W to several kilowatts depending on the choice of manufacturer or the application.

Semiconductor Lasers

Semiconductor or diode lasers are lasers that use little chips as their active media. These chips are made of semiconducting materials. The semiconductor laser is capable of giving off several kilowatts of power output even up to 50 mW. These lasers are wanted for optical disc recording or Blu-ray applications.

Materials Used for Laser Beam Machining

Beam machining handles different kinds of materials and the laser beam is no different. Its adaptability means that it is a must-have for a variety of manufacturing set ups that use multiple work materials. Here are the materials used for laser beam machining:

Metals

| Metal type | Quality | Use |

| Aluminum | Lightweight, strength | Automotive, aeronautics |

| Stainless steel | Durable, corrosion resistant | Architecture, medical parts |

| Copper | Electrical conductivity | For electrical components |

| Titanium | Great strength-to-weight ratio | Aerospace parts, medical implants |

| Nickel | Corrosion and high temperature resistant | Energy sector components |

| Brass | Zinc and copper combination | Plumbing, decorative materials |

Non-metals

| Non-Metal type | Quality | Use |

| Wood | Hard and fibrous | Complex art and decor designs |

| Glass | Soda-lime and borosilicate glass | Etching and cutting, architecture |

| Ceramics | High-temperature resistance, brittle, hard | Etching and cutting, home appliances and furniture |

| Plastics | ABS, acrylic, polycarbonate | Several applications including electronics, energy, and automotive, etc. |

| Composites | carbon-fiber-reinforced | Aerospace and automotive industries |

Specialized Materials

| Specialized Material type | Quality | Use |

| Foam | Polyurethane | E-commerce industry for insulation and packaging. |

| Photo Machinable glass | Machinable via light, silver or copper components | Microfluidics uses healthcare devices, pharmaceutical, food and beverage, aerospace, chemical processing. |

| Textiles | Light | Industrial and fashion use |

| Rubber | Special rubber, elastic | Seals and gaskets in several industries |

What are the Components of a Laser Beam Machining System?

Many important parts go into making the laser beam machine a functioning system for cutting or engraving and other use cases.

Power Supply

The power supply is a crucial component of the machine. It provides the adequate amount of electric energy needed to power the machine and generate laser beams.

Flash Lamps

To produce the kind of heat necessary for conversion into a high-intensity beam, the flash or arc lamp is vital. This lamp is topped with gases that will be converted to ions. This conversion is necessary for the generation of ample energy to melt or vaporize the materials.

Laser Light Beam

The laser light beam radiation that is focused and controlled. An optical amplification process produces this very crucial component thanks to the coherence of light produced from focusing on active materials.

Lenses

The lenses help the beam to focus on the material to be machined for the best precision. The light enters the lens at different levels. It enters as an expanding lens or a collimating lens, while aligning in a parallel way. The machinist can adjust the laser beam to the perfect size with the expanding lens.

Capacitor

Capacitors are another important component of the laser beam machining process. They charge and release the generated energy during a process called flashing. The capacitor functions as a charged memory device in a pulsed mode. It ensures effective and consistent charge and discharge of energy.

Reflecting Mirror

This component is either the external or the internal type. The internal options are necessary for amplifying or maintaining the generated laser beams. Just like the lenses, they also direct the laser beam towards a workpiece for processing.

Workpiece

The workpiece is considered the most important part of the laser beam machining system. It can be either non-metallic or metallic when going through a process that handles a variety of material types like plastic, stainless steel parts, wood, titanium, and more.

What are the Key Parameters in Laser Beam Machining?

When it comes to laser beam machining, certain factors stand between a good outcome and a great outcome.

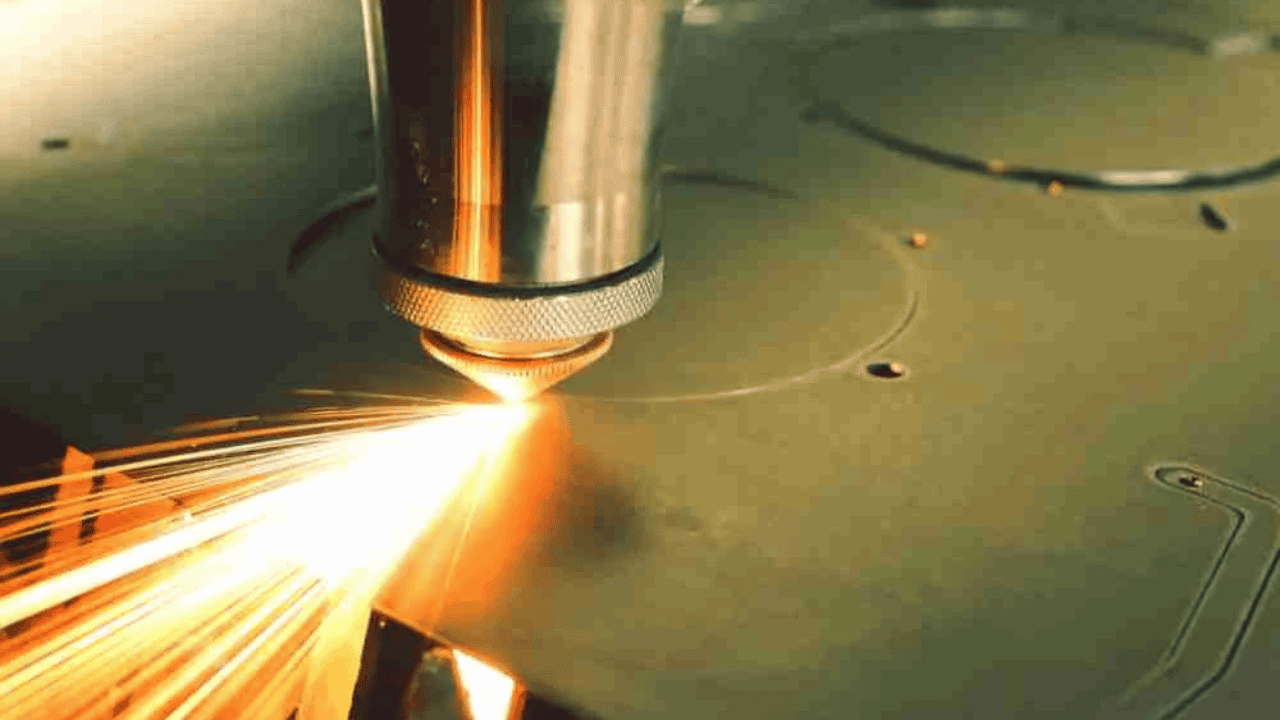

Beam Power

The beam power measures the amount of laser heat directed at the workpiece. This measurement is recorded in Watts. For example, 2000W and above is the energy range required for thick materials like titanium and stainless steel. While for medium size material like plastic, an energy range of about 500W to 2000W is needed.

Cutting Speed

It is important to understand the speed rate that is more suitable for a material during the laser beam machining. As the cutting speed directly affects the quality of the cut and the overall efficiency of the machining process.

Tolerance

The tolerance level of the laser beam machining system is a great asset for its durability in diverse tedious applications. The tolerance level can range from general manufacturing tolerance to high-precision and then ultra-precision manufacturing.

Surface Finish

The laser beam machining system offers great surface finish thanks to accuracy and versatility in operations. This lowers the need for extra processing steps.

Advantages of Laser Beam Machining

Laser beam machining has top ratings for speed and safety but how much benefit do you stand to gain? Let’s look at the many advantages of LBM:

Precision and Accuracy

Laser beam cutting is capable of great accuracy and precision levels. This feature is great when working on difficult designs. Such precision in creating fine features serves the microengineering industry well. Laser micromachining is used to achieve finely precise and accurate surface finish on a workpiece at a microscopic level.

Versatility

Laser beam machining is adaptable enough to serve a variety of materials, including non-metals like plastics, glass, or wood. No matter the density or thickness of the material, laser beam machining maintains operational dynamism.

Non-contact Process

Laser beam machining is a non-contact process. This simply means that cutting, shaping, marking, and engraving can be carried out on a workpiece without any physical interaction or collision of the parts of a laser beam machine. It reduces the risk of contamination when used in food processing and also minimizes mechanical wear and tear of machine parts.

Customization and Design Flexibility

Laser beam machining enables the manufacture of complex and intricate designs that can be difficult to make with conventional machining. Such creative freedom for customization and design flexibility means the laser beam cutting machine will create unique geometries or engravings for different use cases.

Energy Efficiency and Sustainability

Laser beam systems are energy efficient due to their lower energy consumption levels. This uniqueness helps produce minimal waste during manufacturing, making LBM an environmentally friendly machining process.

Speed

Laser beam machining is a very fast method of machining. This speed makes high-volume production and low cost of production possible. You spend less time, money, or labor in the process.

Enhanced Safety and Ergonomics

With laser beam machining being a non-conventional technique where non-contact methods are used, there is zero chance of interacting with sharp or heavy objects. It reduces the risk of workplace accidents.

Laser Beam Machining Applications for Industries

The efficiency and precision of the laser beam cutting machine serve both low-level and high-level purposes in the following applications below.

Aerospace

The aerospace industry requires accurate laser machining to build complex air or spacecraft parts that obey the laws of aerodynamics. It also helps in the customization of space equipment and satellite system components.

Architecture and Building

In architecture and building/construction, laser beam cutting machines allow professionals to deliver precisely cut building materials such as glass or steel. Finely cut complex materials or prototypes boost the aesthetic appeal of buildings.

Automotive

So many intricate and delicate parts go into an automobile that a laser beam machining process easily caters to. Some of these parts are external or internal, and their fabrication boosts fuel efficiency for the car. Bodywork and chassis, EV battery connectors also benefit from a laser beam.

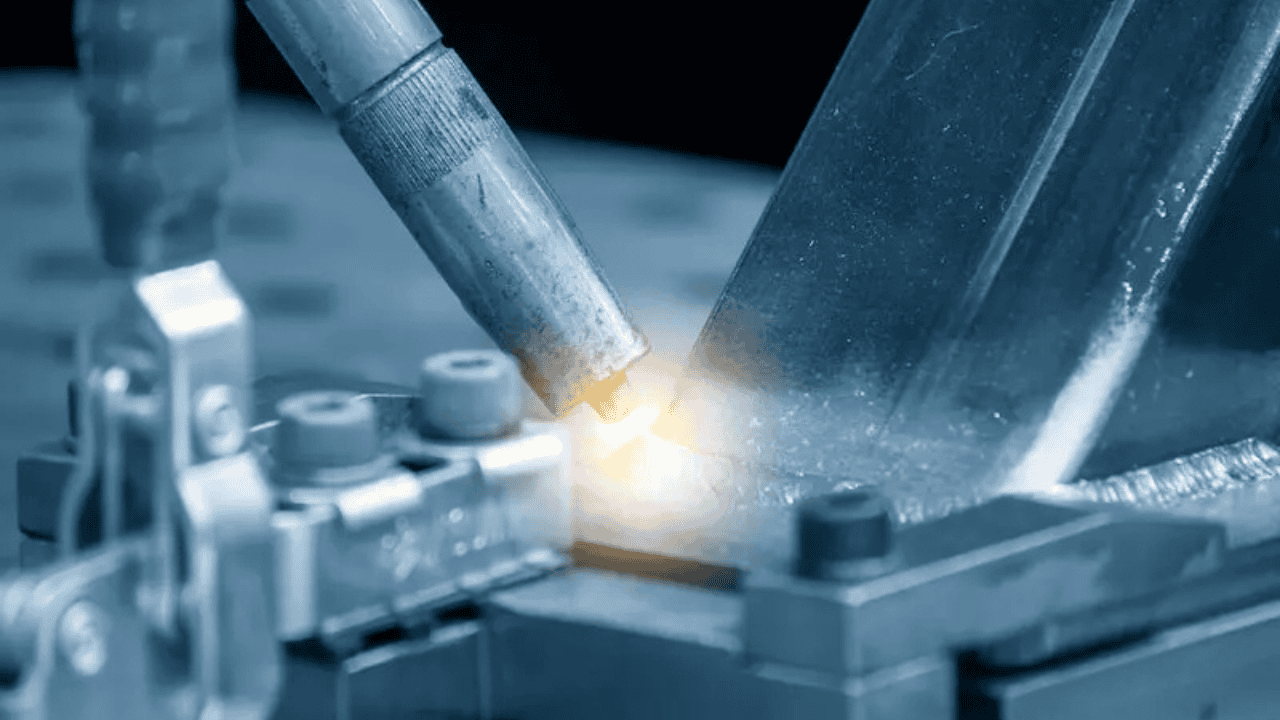

Micro Hole Machining

Laser beam welding is great for further precision drilling of micro holes and or lightweight joint constructions. This is the ideal machining tool for high-stress components.

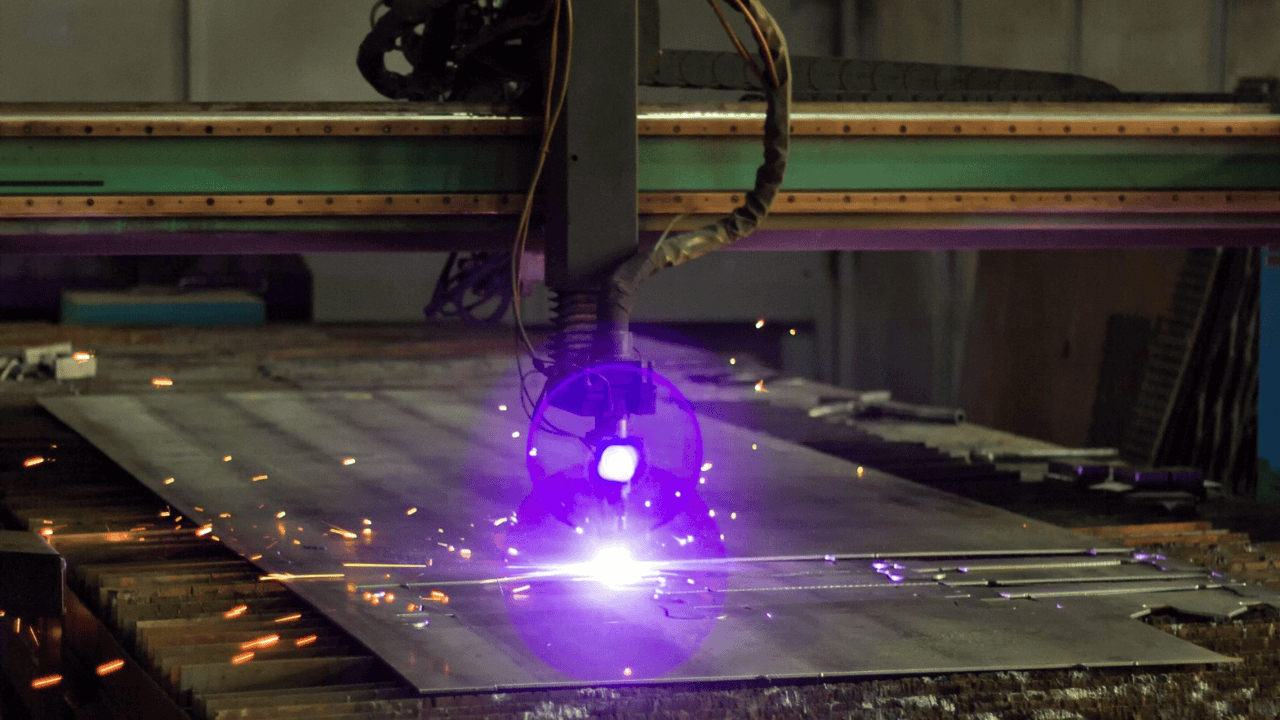

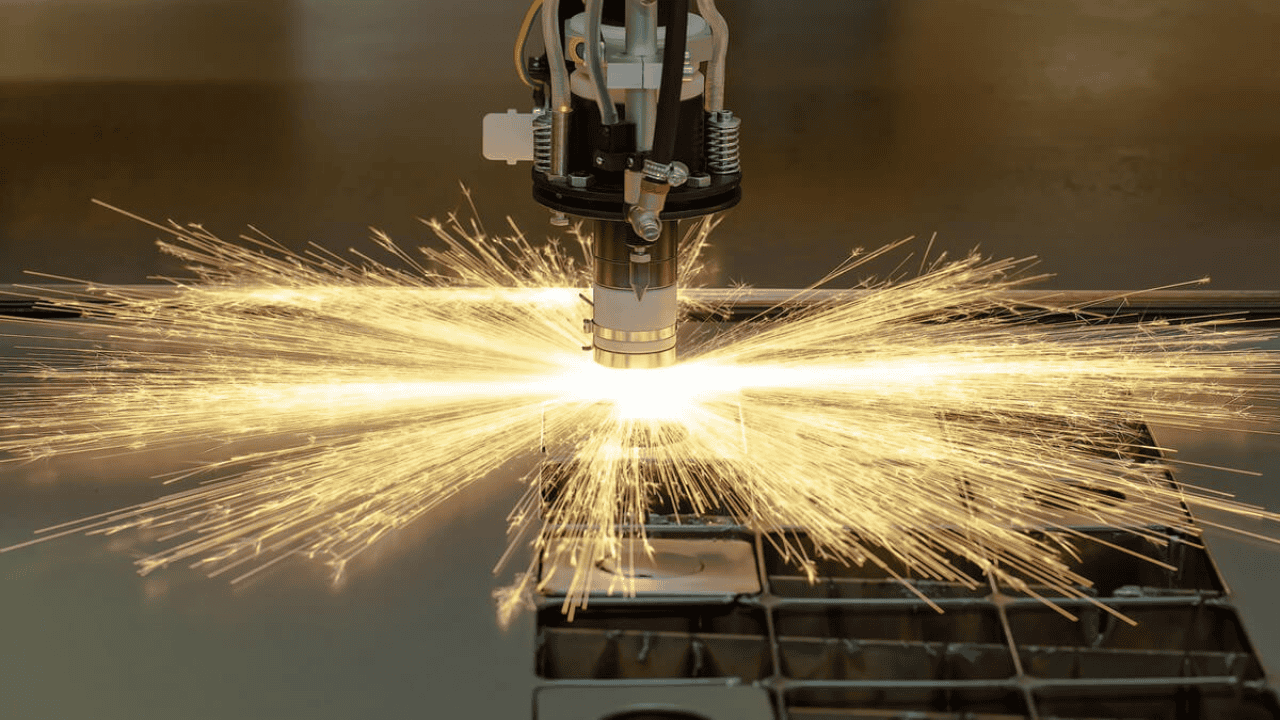

Macro machining production

In macro machining production, a high-power laser beam is used to modify, cut, or shape big features on whatever workpiece you work on. The features and dimensions created by macro machining production are relatively larger and require more power than micro machining.

Electronics

In high-precision processes, the laser beam is used to build parts for nuclear energy facilities or to laser-cut pipelines, and also manufacture turbine and solar components.

Energy Sector

The global energy sector has a demand for laser beam machines that can cut or weld circuit boards. They also help etch serial or ID numbers on delicate electronic components. Manufacturers of computers, smartphones, tablets, and printed circuit boards use the precision cutting and laser drilling of laser beams too.

Research and Development

The laser beam machining is essential for prototyping and developing new technologies in various industries. Some specialized laboratory components need to pass through a laser beam machine for quality control in order to ascertain their fitness for commercial use.

Limitations of Laser Beam Machining

Despite its many advantages to several industries, this technique has some limitations to its implementation and prolonged usage. The high initial cost is one of the most crippling challenges to setting up the laser beam machining.

However, this high cost depends on several factors, including procurement and installation of computer control systems, lenses, workpiece, or capacitor.

Differences Between Laser Beam Machining and Electron Beam Machining

In comparing laser beam and electron beam machines, the two defining factors are in their application and operating principles. Laser beam machining involves the cutting, engraving, and welding of workpieces using laser beams. While the electron beam machining process uses electricity for machining. The most important difference is in how laser machining requires concentrated light energy to function while an electron beam uses electrons.

Conclusion

LBM is a revolutionary technique that offers unmatched precision, efficiency, and versatility across numerous industries. With continuous improvements in laser technology, the process is becoming an indispensable tool in modern manufacturing. Need a quote to get you started on laser beam machining? Get a fast and easy quote when you contact us.