5 axis CNC machining is a state-of-the-art manufacturing process that enables the efficient and accurate production of very complicated parts. This technology provides better quality, efficiency and less setup time than traditional machining methods. Today we will look at the basic components of this machining, its practical aspects and its benefits too.

What is 5 Axis CNC Machining

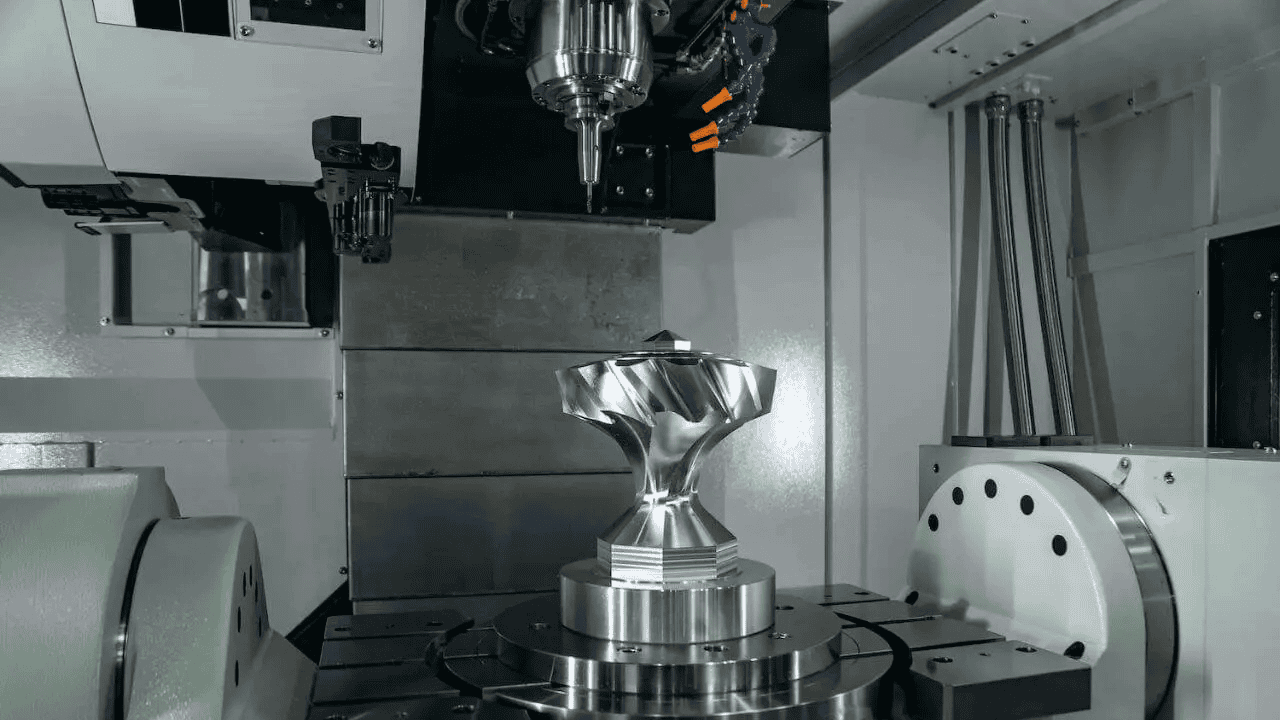

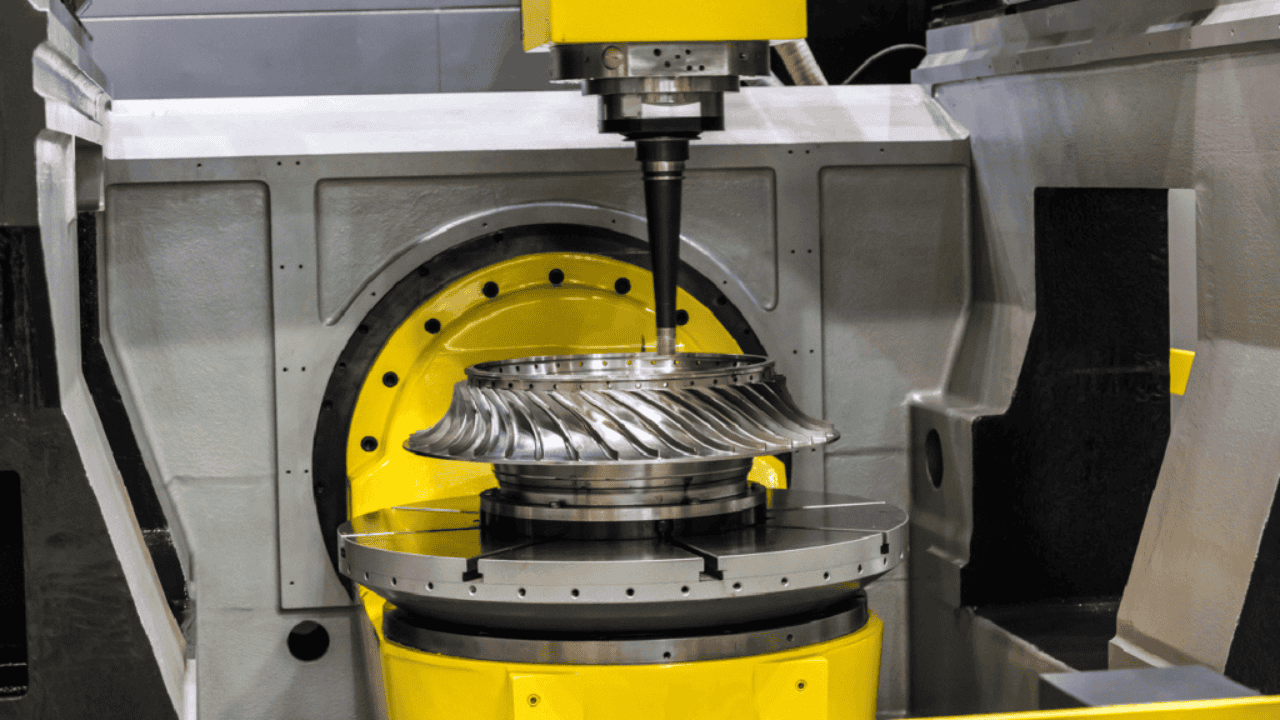

5 axis machining uses five different axes for tool movement. Three of these axes are linear (X, Y, Z) while two are rotary (A, B). This machining process is much better than 3 axis machining in both accuracy and flexibility. In this machining, tools can access the workpiece from multiple angles which makes it possible to manufacture intricate parts in a single setup.

Main Components of a 5 Axis CNC Machine

a. Machine Structure

The base of a five axis CNC machine consists of a very strong frame which is usually made of welded steel or cast iron. This highly stable structure supports all machine components and also absorbs all vibrations effectively.

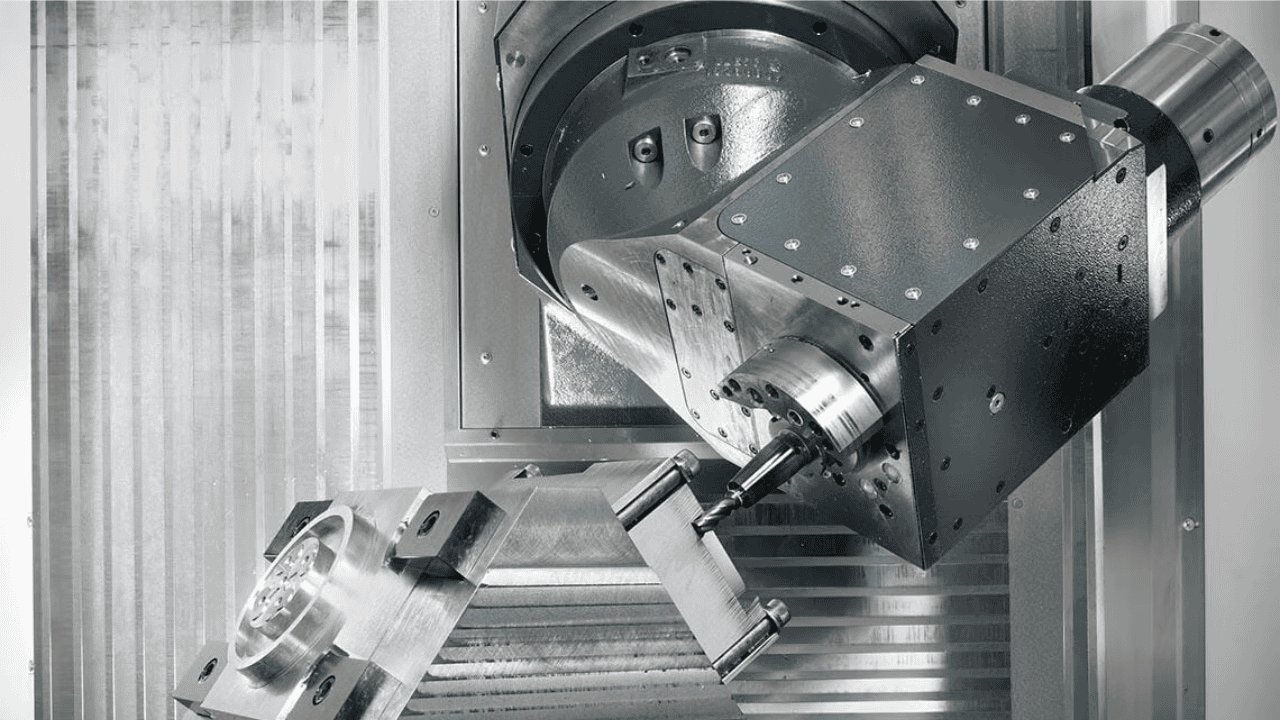

The machine structure also includes a gantry, column and a bed with T-slots. These are designed to withstand cutting forces and support the weight of the workpiece. The machine also has ball screws and linear guides that make sure of accurate movement on all primary axes

There are also two rotary axes to allow complex rotary movements mostly through the swivel head or trunnion table. Servo and stepper motors power this entire system.

b. Control Systems

The machine control unit manages all the operations of the system. The main function of this unit is to process the G code instructions and convert them into motion commands that the machine can understand.

The control system also performs several other functions. It generates commands for axis movements and reads and decodes program information and also manages additional functions such as tool change and coolant control.

c. Spindle

The function of the spindle is tool holding. Today’s advanced machines are using motor spindles with speeds up to 60,000 rpm. Their high speed results in extraordinary surface finishes and accurate cuts.

Some spindles also have built-in motors for better thermal stability and space savings. The design of the spindle should be such that it can maintain stability along with movement in all axes.

d. Feedback Mechanisms

Transducers and sensors are the core of feedback system. They are in charge of controlling real time movement and position of machine.

During this feedback process, the linear encoders monitor three main axes while the rotary encoders track the position of A and B axes.

In this way this closed-loop configuration system continuously verifies the accuracy of the movement and simultaneously implements the necessary adjustments.

Programming and Software Considerations

Let’s talk about some of the essential software and programs that help run an accurate cnc-machining operation.

CAD/CAM Integration

CAD and CAM systems must work together optimally in modern five axis machining.

CAD software’s job is to create detailed 3D models and CAM software’s job is to convert those models into understandable instructions that the machine can understand.

Their direct communication eliminates errors in data transfer between the design and manufacturing stages and greatly reduces programming time.

Simulation and Verification

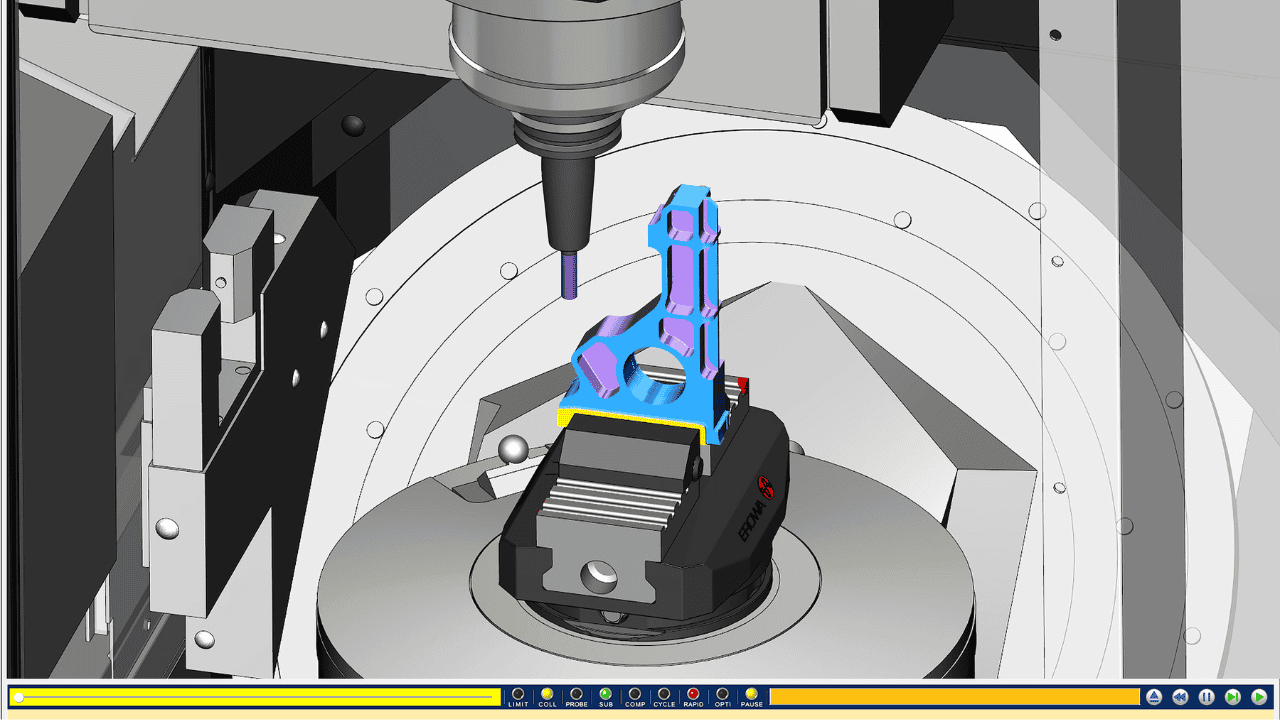

Simulation software validates the compete machining process before the actual machining process begins. This software creates 3D representation of the tool movements and material removal process.

You can identify potential problems through this virtual testing. For example this software can help you identify potential collisions, bad cuts, and programming errors. This early verification thus prevents costly errors that can happen later in the process and reduces production time greatly.

Toolpath Generation

The CAM system plays an important role in creating accurate tool movements on all five axes. It determines the most efficient cutting paths while avoiding collisions through the use of advanced algorithms. This system includes many factors in its calculations including depth of cut, feed rate and cutting speed etc. These calculations lead to better surface quality and better machining time.

Advantages of 5 Axis CNC Machining

- 5 axis machines have additional rotating axes that are capable of producing highly complex geometries in a single setup and such complicated parts cannot be produced by conventional machines.

- These machines keep their cutting tools tangential to the surface which results in a high finish quality. And their precise control also eliminates the need for post-processing and gives you consistently high quality intricate parts.

- Five axis machines can access five face of parts in a single operation. This eradicates the need for multiple setups which greatly reduces errors due to repeated positioning of parts and also greatly reduces production time.

- Machine’s advanced positioning capabilities allow for best cutting angles and smaller cutting tools. These features reduce tool vibration and extend tool life to a greater extent.

Challenges in 5 Axis CNC-Machining

- 5 axis machines are very expensive machines. Their price can range from several hundred thousand to one million dollars. Therefore it becomes very difficult for new companies and small businesses to afford such costly machines.

- The programming complexity of 5 axis machines is much higher than that of 3-axis machines. And to use these machines you must have an understanding of complicated geometry and mastery of advanced CAM software. These requirements increase the chance of programming errors and lengthen the setup process.

- Operators must be proficient in setup procedures, programming and machine operation to operate these machines. Due to the need for these high technical skills, companies have to bear relatively high labor costs.

Maintenance and Operational Best Practices

The life and performance of a 5 axis CNC machine depend on proper maintenance and the methods listed below can ensure the machine’s efficient operation.

Regular Calibration

A regular calibration schedule is vital to maintain accuracy. And for accurate measurements one can use ballbar system or laser interferometer. You should do calibration check at least quarterly and if you see a change in the quality of the parts do it sooner. Through this, you can greatly prevent errors and maintain consistent quality.

Tool Maintenance

Right tool management greatly improves machining quality. So clean every tool thoroughly after use and inspect for damage regularly. And you should use tool presetters for correct diameter measurement and correct tool length. Storing tools in the right way is also very important as it prevents damage and facilitates quick access

Software Updates

CNC software manufacturers continue to release new updates to fix bugs and improve functionality. So stay up-to-date with these updates and apply them. But before applying, make sure to backup your current settings. And test the new software on non-critical projects first so that you can know whether these new updates are compatible with your system or not

Training and Skill Development

Create resources for continuing technical education of your company’s operators by holding webinars, workshops and internal knowledge exchange sessions. Professional certification programs also enhance the skills of your operators and certify their competence.

Conclusion

5 axis CNC machining provides outstanding performance and ideal accuracy in the manufacturing process of very complicated parts. The process combines advanced hardware and software and expert operations to produce highly standardized components across various industries. If you are also in need of custom CNC parts, then HM is your best choice. You can contact us now.

FAQs

- How do simultaneous 5 axis machining and 3+2 axis machining differ from each other?

During cutting, simultaneous 5 axis machining permits movement on continuously all 5 axes. While 2+3-axis machining makes use of 3 linear axes for cutting operation and its two rotary axes remain in fixed positions. - What are the industries that usually benefit most from 5 axis CNC-machining?

Aerospace sector commonly uses CNC technology to make engine parts and turbine blade while medical manufacturers use it to make surgical instrument and implants. - What industries are adopting 5 axis machining for non-metal applications?

Many industries are now using 5 axis CNC technology to machine plastics and composites. The medical field makes custom plastic prosthetics with the help of this machining and automotive sector makes carbon fiber components through it. - In what way does probing technology improve processes of 5 axis machining?

5 axis machining is improved by probing technology through in process measurement and accurate part setup. This technology helps in tool offset calculation, real time quality control and workpiece alignment.