One striking need technicians crave for when using CNC machines is an unalloyed ease of use. This means if it’s possible to get a machine that would allow them to get cleaner cuts and save time, they will absolutely love it.

This is where 4-axis CNC machining comes in. It’s a great improvement on the popular three axes variant, allowing operators to cut metal pieces at four possible directions or angles. Read on to learn more about this machine and its applications.

What Is 4-Axis CNC Machining?

Typically, a traditional CNC machine cuts in three main directions:

- Up and down – vertically

- Right and left – horizontally

- Front and back – horizontally

Each of these three directions accounts for the three primary geometric axes – X, Y, and Z. And they reflect the modus operandi of the 3-axis CNC machining.

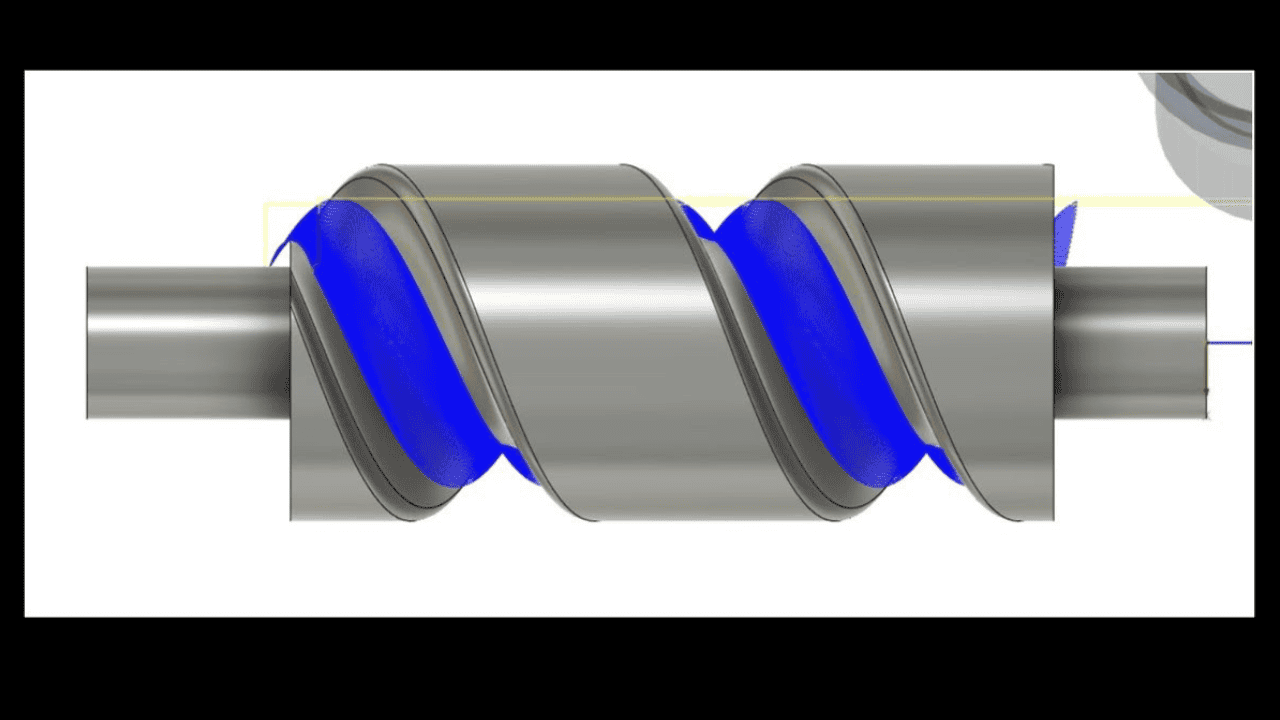

As the name suggests, it involves the movement of a workpiece on the three geometric axes and a fourth A axis which is the additional axis that allows the workpiece to rotate along the X-axis during machining.

Processes of 4-Axis Machining

Having a wider understanding of the processes involved in a 4-axis machining helps you obtain maximum results.These are the various steps you can to make ensure the final result of your workpiece is excellent:

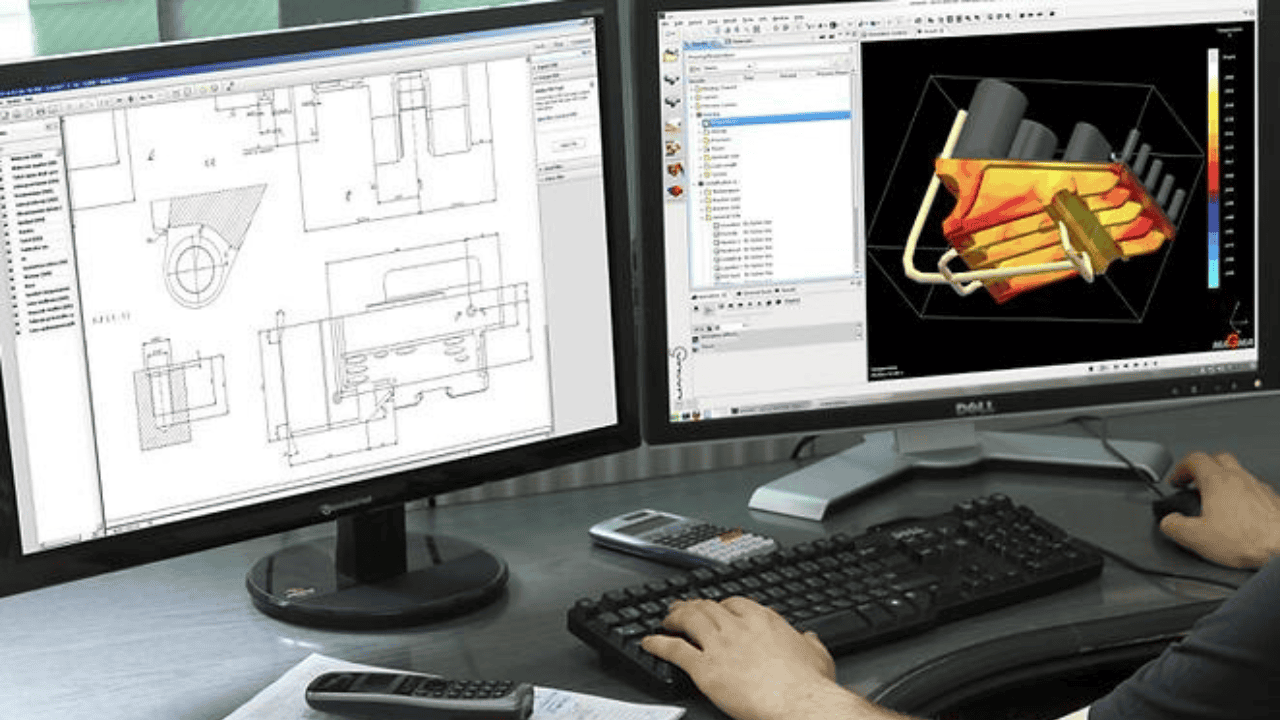

CAD Designing

This process involves the use of a computer or desktop PC to generate 2D and 3D graphical representation of construction layouts, blueprints, vehicle components, floor plans, and other documentation of the work to be done.

After the product prototype has been designed having all the necessary features, dimensions, and shape of the final product, the CAD file is converted into a machine language like G-code and imputed into the CNC machine that would be used to achieve 4-axis CNC machining.

CAD helps reduce the error rate that could happen during manual drafting. It also makes it easier to present and share the work plan with clients and workers while ensuring proper storage and documentation for future referencing.

CAM Programming

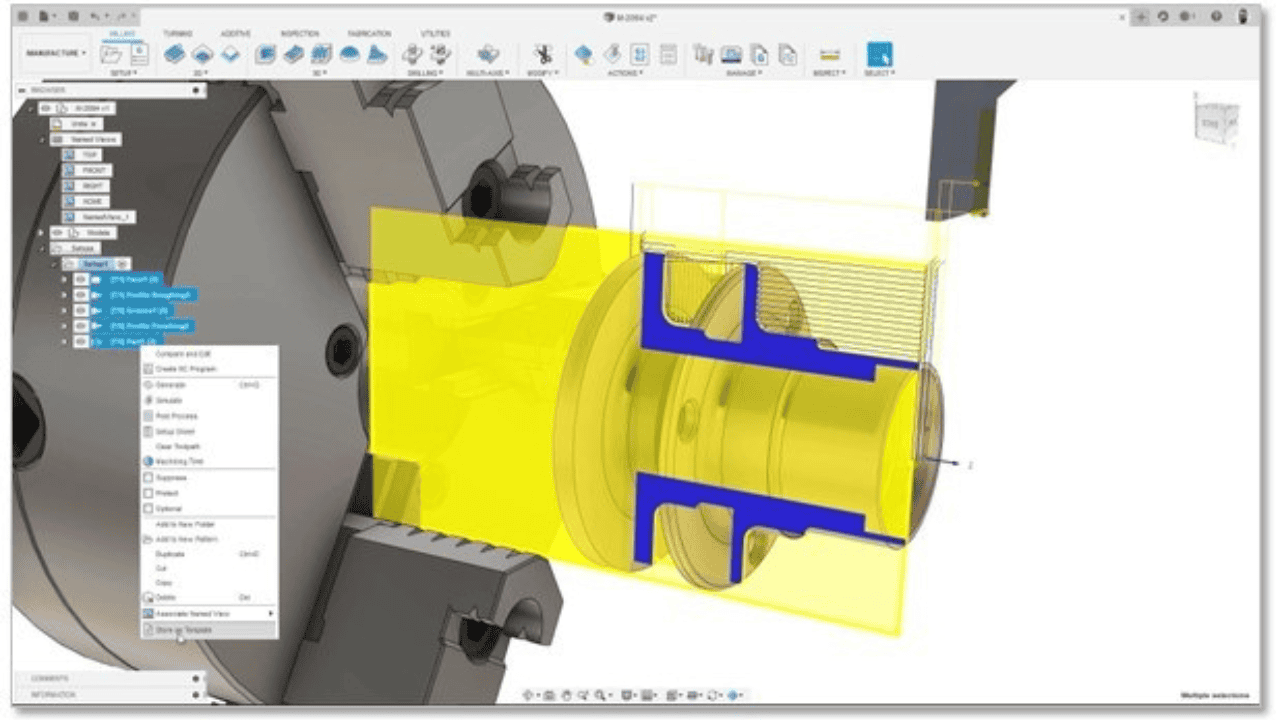

Once the product design has been achieved with the CAD, the next thing you need to do is to create instructions and program the toolpath for your CNC machine using computer-aided manufacturing (CAM) software.

This instruction shows how the cutting tool is to move along and across the workpiece,helping the machine achieve exactly what you require while maximizing efficiency. Usually the toolpath is programmed using the following parameters like feed rates, tool selection, and cutting speed.

When your toolpath has been carefully created, it is then relayed to the shop floor through the direct numerical control (DNC). Computer-aided manufacturing programming has several benefits, from optimizing efficiency to reducing energy consumption, and minimizing waste rate during production.

Additionally, it is a secure method of manufacturing with excellent precision and repeatability, helping manufacturers produce large quantities of products with speed, while maintaining high quality, and streamlining operation.

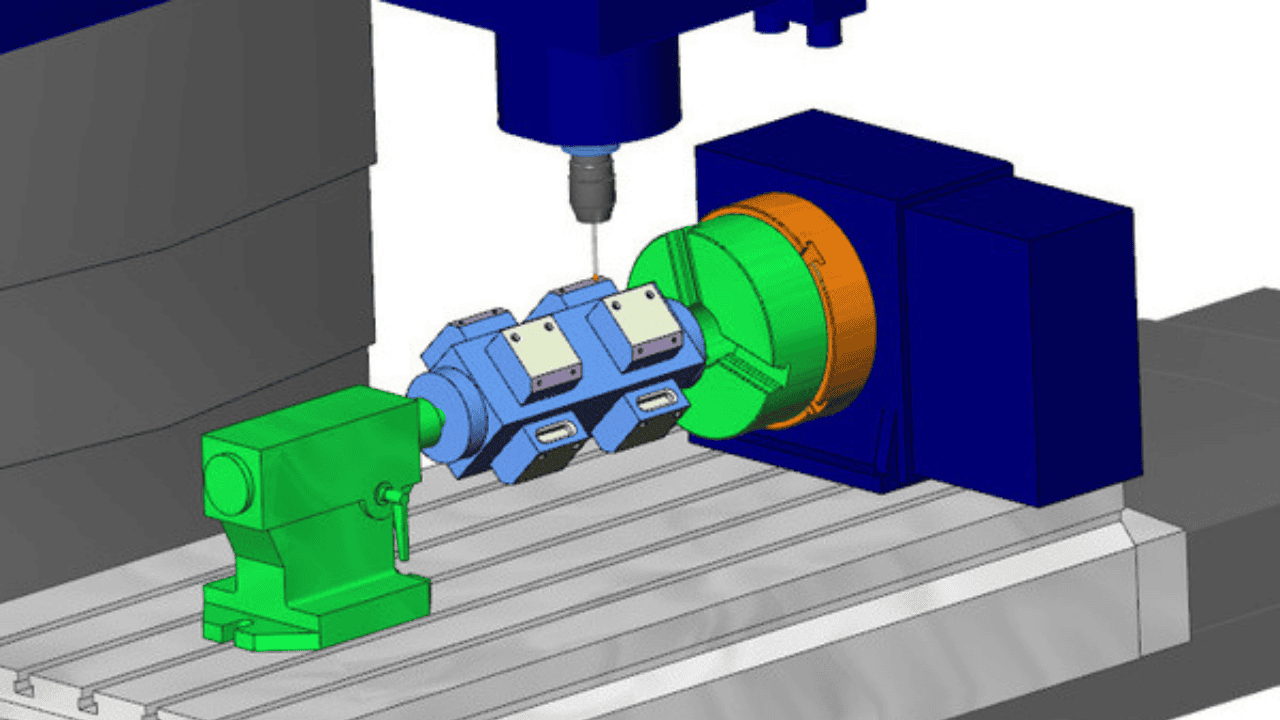

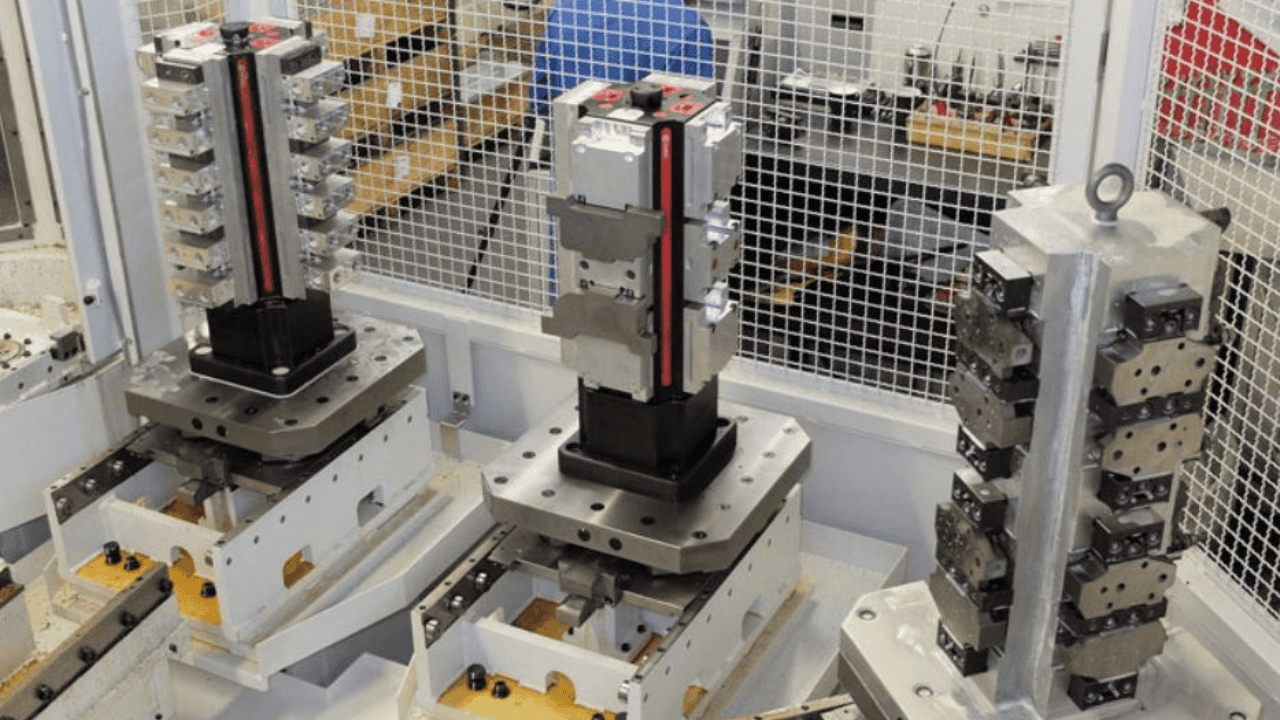

Machine Setup

After transferring your CAM program to the CNC machine, the next step is to set up the machine by placing your workpiece in position and installing the various cutting tools and fixtures required for 4-axis machining to take place.

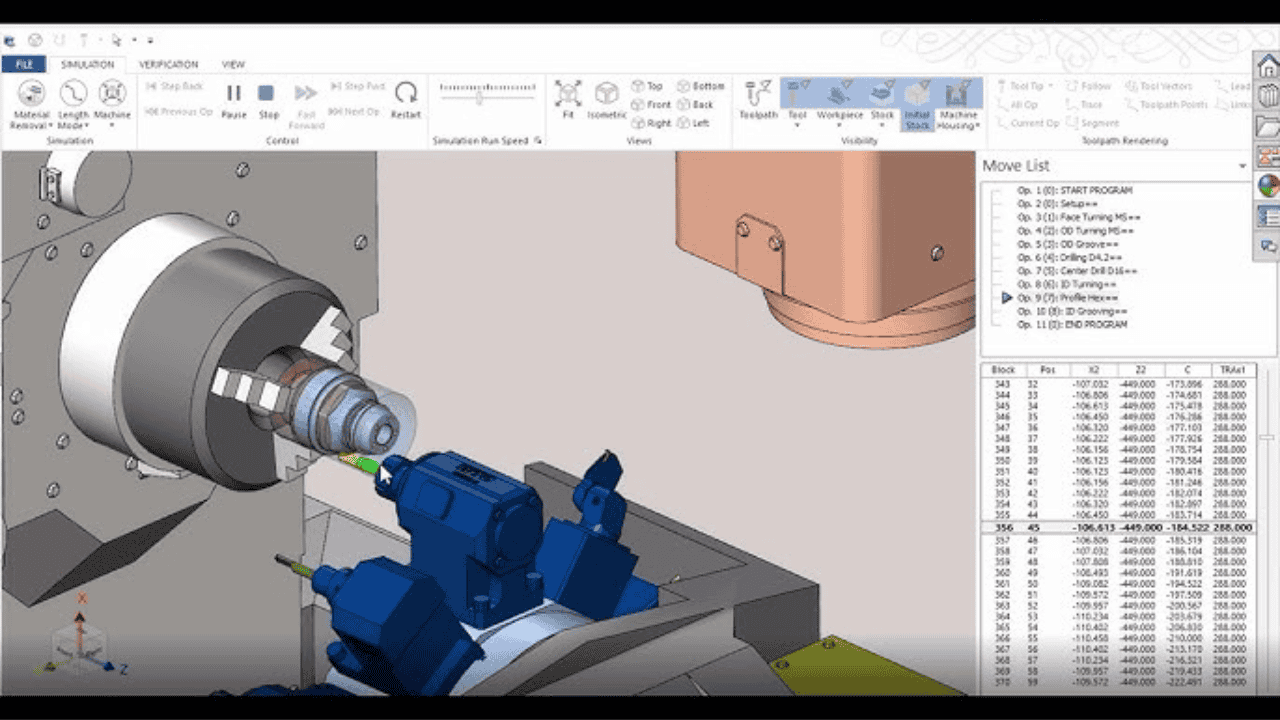

Machining

The next stage after setting up is machining, this is where the actual work is carried out on a workpiece. Here, the cutter is set into motion across the workpiece working from all the 4-axes.

It is important that machining is done under close supervision ensuring adjustment and repositioning is done when needed. Also have it in mind that the machine follows the toolpath that has been designed and fed into it.

Finishing

After the machining, you have to unclamp the workpiece and check if it’s as excellent as you need it to be. You may have to clean it with a cloth to remove any remaining chips on the body. After careful inspection, you can add it back to the CNC machine for any final touch, if necessary. Else, clean up your machine and prepare it for the next operation.

Types of 4-Axis CNC Machining

There are three major types of CNC machines that allows operators to cut in four axes, and they are:

Milling Machines

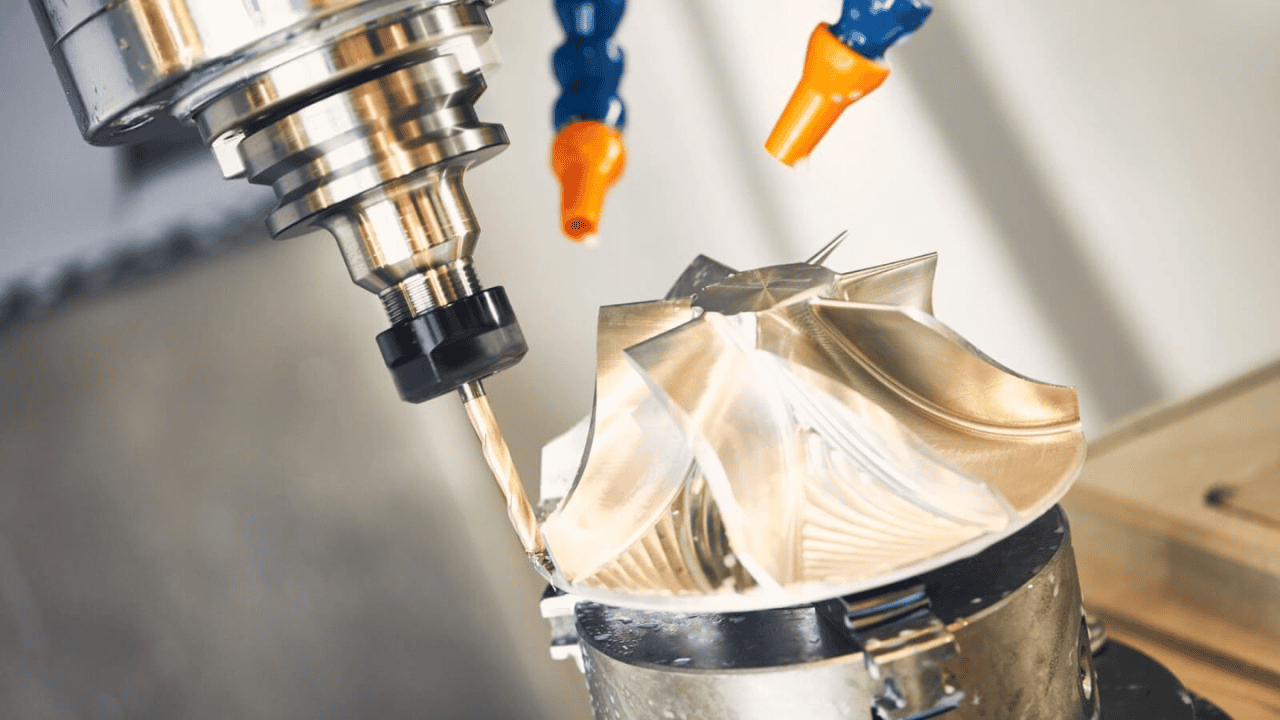

The modus operandi of a 4-axis milling machine is such that the workpiece is firmly fixed while the cutter rotates around a defined diameter on it, creating circular cuts on it. You can use this machine to create holes and mill slots on the workpiece from any angle without needing to change its position.

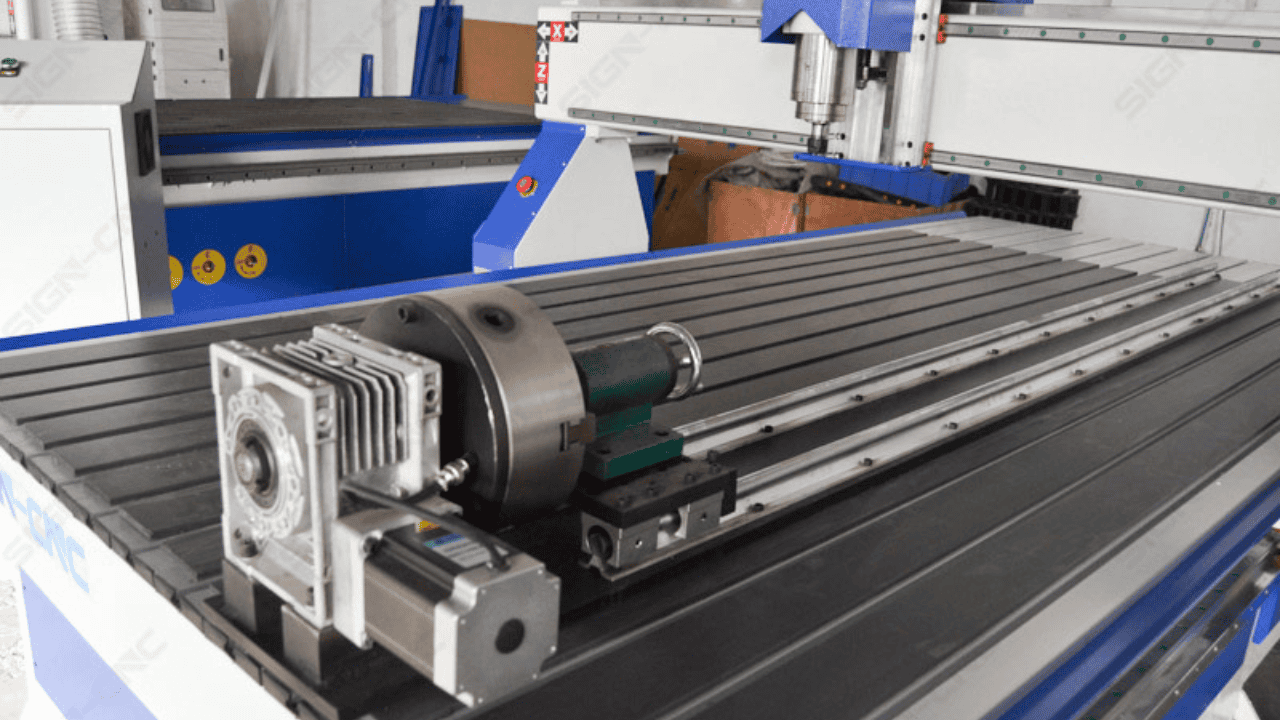

Routers

These machines are popularly used for various woodworking activities. They provide accuracy and precision during the machining process because of the instructions that have been imputed into the machine.

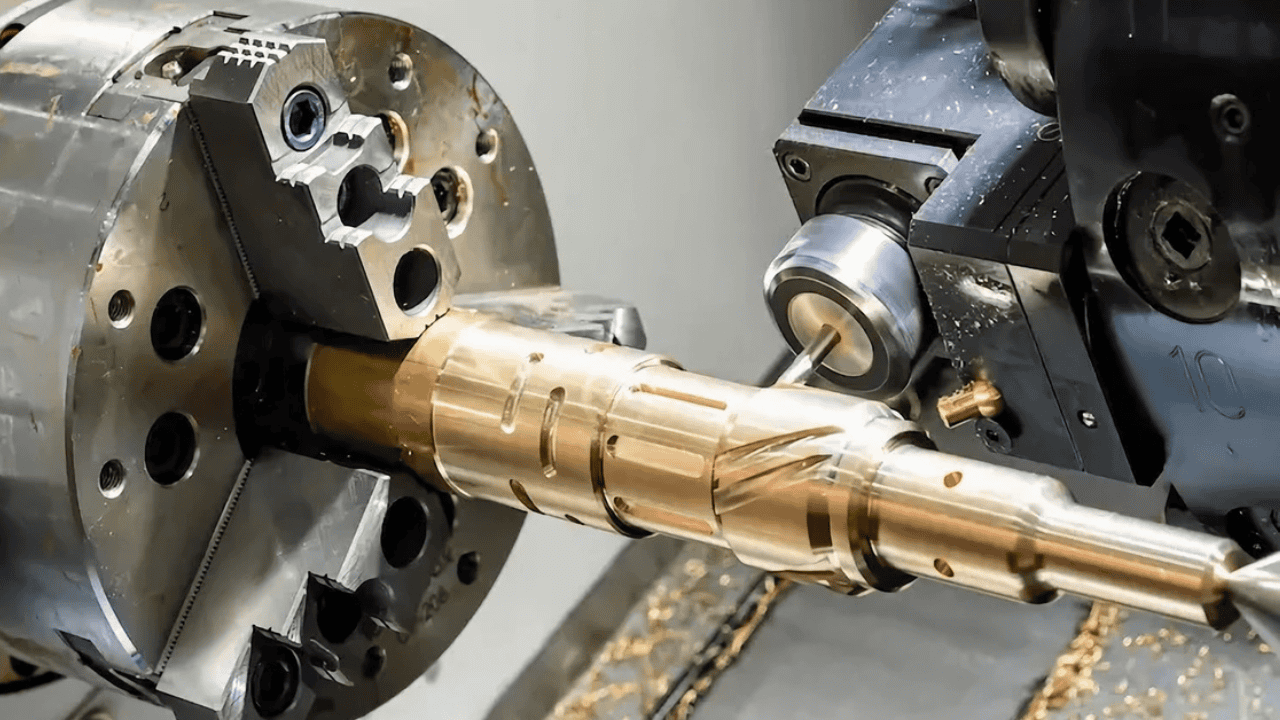

Lathes

The 4-axis CNC lathe is the most popular machine among the three types we’ve discussed so far. In fact, both CNC lathe and milling machines help you achieve cylindrical patterns on your workpiece.

The only difference between them is that in the former, the workpiece rotates against the cutting tool while in the latter, the cutting tool rotates against the workpiece. You can use this machine for a wide array of turning operations.

Benefits of 4-Axis CNC Machining

Now, let’s consider the various advantages of using the machining process:

Enhanced Capabilities

Where production of components with complex shapes is not possible, 4-axis machining has made it possible with an additional A-axis to the system enhancing machining capabilities and productivity.

Increased Efficiency

One of the foremost goals of CNC machines is to improve the speed of cutting processes while enhancing the final result. This machining process is quite fast as it reduces the time of production for large quantities in a few steps.

Compared to the 3-axis variant, the 4-axis masterpiece allows you to cut workpieces in more directions and angles. This significantly affects the quality of your finishings, especially because you don’t have to alter the positions of the workpiece during the process.

Higher Precision

4-axis CNC machines are so precise that they allow you to comfortably shave off thin layers of your workpiece at an incredibly high accuracy rate. This could be as thin as 0.5mm off the overall thickness of your workpiece, resulting in greater precision and accuracy of machined parts.

Versatility

This particular machining technique has many usefulness and can be used to work small parts or very large parts of a material. Also they can be used with varieties of material making them an important machine for manufacturing industries.

Improved Surface Finish

Because machining is done simultaneously and in a coordinated rotatory manner, the surface finishing of the machined part is usually good, also, due to the close proximity of cutting tools to the workpieces, not much rough mark is left on the surface.

Disadvantages of 4-Axis CNC Machining

Costly Setup

The 4-axis CNC machine is quite very expensive to purchase and set up most especially for small businesses. Regardless of the many benefits it holds, it could take months or years of investment to purchase this machine making it difficult for startup businesses to meet up with the upgrade.

Requires Skilled Operators

A major limitation of 4-AXIS CNC machining is that only trained and skilled operators can use, setup, and programme the machine. Although work done using CNC machines is usually automated, it still requires the supervision of a trained personnel. This, however, increases the cost of production.

Limited by Geometry

There seems to be more room for creative innovations in the ever evolving technological landscape. When there tend to be lapses in some machining processes, a new product or system is introduced to the market.

Take for instance, the 3-axis machine with its many benefits still had some limitations because it couldn’t be used to form very complex shapes from all angles. And that’s where the introduction of the 4-axis machine came to play.

However, there are still certain angles and complex geometries that cannot be handled by the 4-axis machines, in such cases, the 5-axis CNC machines can be alternated.

Applications of 4-Axis CNC Machining

Aerospace

It is used to manufacture intricate components of a plane such as turbine blades, engine parts, and different structural parts with maximum precision and accuracy.

Automotives

Majorly used because of its ability to manufacture intricate geometries at odd angles. They are used in the making of engine components, vehicle body parts, and transmission components.

Electronics

It is also employed in the electrical industry for producing circuit boards, casing, and other components that require high precision.

Oil & Gas Industry

Heavy duty parts that can withstand extreme conditions are majorly required in the oil & gas industry, and the 4-axis CNC machines are the right tools for manufacturing strong, durable, and high quality parts.

Packaging Industry

CNC machining is increasingly used in the packaging industry due to its ability to produce high-precision components for packaging machinery. Our CNC services not only involve precision processing of metals and plastics but also offer customized solutions, including fully automated machines for manufacturing high-quality non-woven bags. These machines ensure that non-woven bags are produced with maximum efficiency and top-notch quality, meeting the growing demands of the

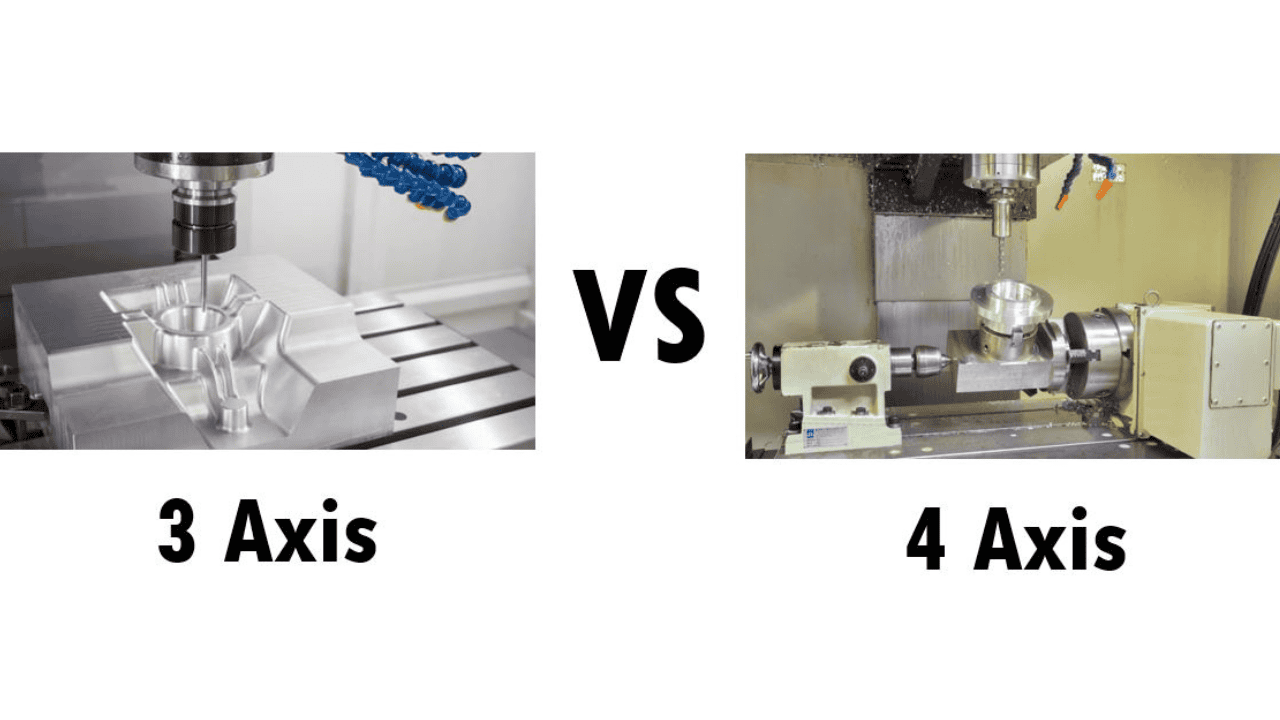

Comparing 3-Axis and 4-Axis CNC Machining: Key Differences

While they both share similarities in their functionality, they are different in terms of their capability, efficiency, and applications.

A 3-axis machine is more suitable for machining components that do not need to be rotated but can be operated on along the three axes. It is also used for machining simple geometries and flat surfaces milling.

As explained earlier, it’s similar to its 4 axes counterpart, the only difference being that the latter performs operations in an additional direction, known as A-axis and is more preferred for complex operations.

Also, a chuck or a tombstone fixture block is used for mounting workpieces in 4-axis machining, while a 3-axis machine has a flat block.

Who Are the Best Manufacturers Offering 4-Axis CNC Machining Solutions?

HM is your one sure bet when it comes to the best CNC machining manufacturers in China. With over 20 years of professional experience, HM has some of the best experts in the industry.

We have more than 1,000 clients in China, Europe, America, and beyond. Whether it’s die-casting, CNC machining, or simply CAD designs for your project, you can count on HM to offer you the highest standard of services.

Conclusion

4-axis CNC machining allows for the manufacture of complex parts, a feat that could not be efficiently handled by the traditional 3-axis machining. It gives businesses a competitive edge by optimizing workflows and improving production speed.

With technological advancement in the manufacturing industries, it is vital to keep ahead and stay on the trend in order to achieve high quality maximum output. And you can rest assured that HM has some of the best operators proficient at running and handling these machines. Get in touch today so we can help you with your manufacturing needs.