Sometimes, CNC parts manufacturing, including prototype CNC machining, requires high-precision parts that you cannot achieve using standard 2-axis CNC machines. In that case, a cost-effective solution is investing in 3-axis CNC machining.

This post discusses the types, advantages, drawbacks, and industry applications of 3-axis machining.

Understanding 3-Axis Machining

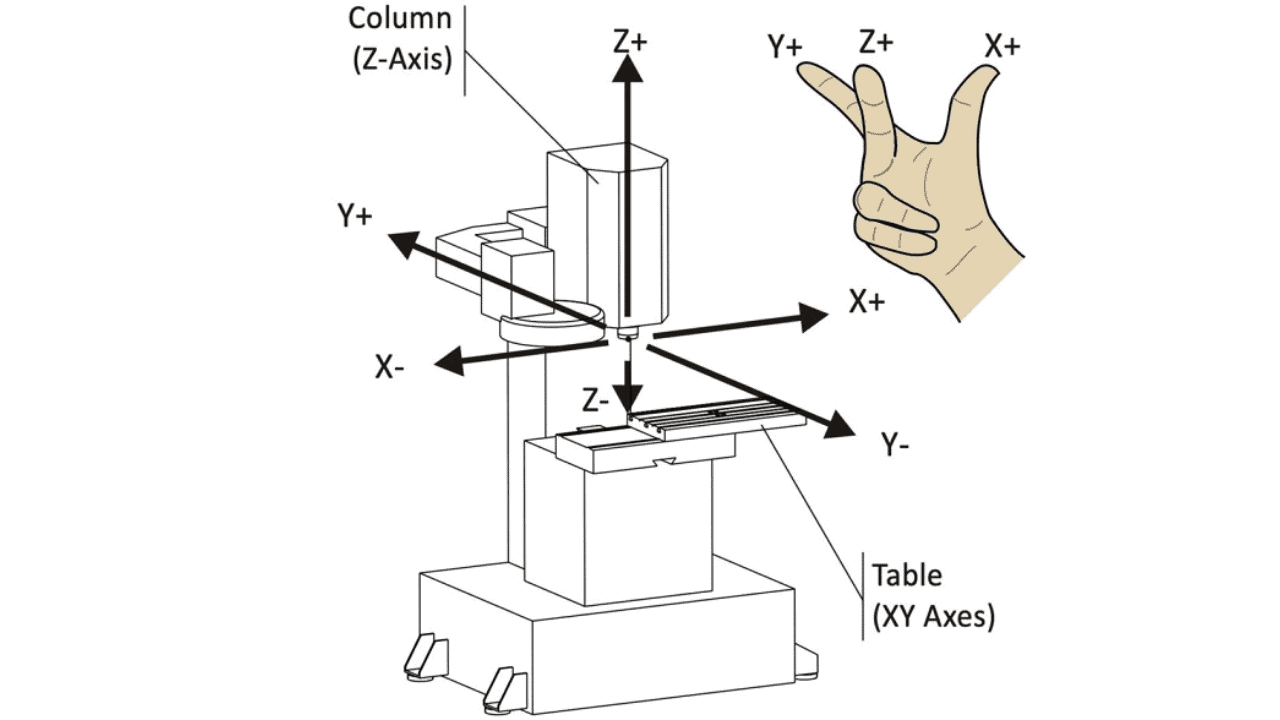

As the name denotes, 3-axis CNC machining is a computer-controlled or production process that uses a high-tech CNC machine with cutting tools that can operate in 3 linear axes to create components. The three cutting tool movements are:

- Left-Right Horizontal or X-axis Movement: Your machining tool can move horizontally in either right, or left directions. This allows for easy cutting of your workpiece’s lateral dimensions.

- Front to Back Horizontal or Y-axis Movement: The machining tool can easily move to cut your workpiece from front to back or vice versa.

- Vertical or Z-axis Movement: The machine’s ability to achieve vertical or upward and downward cutting where necessary during parts milling or drilling operations.

Key Advantages of 3-Axis CNC Machines

Some of the general advantages or benefits of 3-axis CNC machining include:

- Automation capabilities: Because CNC machines are programmable, you can automate your production process. Therefore, it allows you to produce more parts.

- 3-axis machines do not consume much energy leading to low production costs.

- Versatility: The production supports different machining processes. You can also use different materials to produce components or parts.

- High machining accuracy: You can achieve higher parts accuracy than basic machining options.

- Compact Design with High Production Capacity: 3-axis CNC routers are more compact in design and have a higher production capacity than 2-axis CNC machines.

- Low Material Wastage: 3-Axis CNC machining relies on software that ensures high-level cutting precision. This reduces material wastage or rejects resulting from production errors.

Drawbacks of 3-Axis CNC Machining

Cost Limitations: Purchasing, operating, and maintaining 3-axis machines can be prohibitive because of the high costs involved.

Machine Setting Is Time-Consuming: Setting up your 3-axis cutting tools for parts machining is time-consuming. Therefore, your production rate will be lower compared to other superior options.

Limitation on Complex Parts Production: The machine may not produce parts with complex 3D designs or shapes because its movements are limited to the three axes.

Which 3-Axis CNC Machines Types Can You Consider?

If you are into CNC manufacturing, such as aluminum CNC parts production, and you intend to embrace 3-axis CNC machining, you must be aware of the various types of 3-axis machines. This is to help you choose the most suitable solution for your machining or fabrication project.

You must be aware that each type of 3-axis machine has its benefits and limitations.

Below are six common types of 3-axis CNC machines you can choose from depending on your manufacturing requirement:

3-Axis CNC Machining Lathes

The 3-axis CNC lathe machine is an advanced version of the standard 2-axis lathe machine that allows you to achieve the front and back or Y-axis machining on your workpiece.

With the right type of lathe-cutting tools, this machine enables you to produce more complex components in comparison to traditional 2-axis machines.

It allows you to undertake both milling and turning processes to suit your manufacturing needs. The machine guarantees quality machining, and a perfect option when working on cylindrical components.

Limitation: The machine does not allow for the machining of large components

3-Axis CNC Milling Machines

If you are searching for a versatile machine for your parts’ precision CNC machining, the 3-axis CNC milling machine is your ideal choice. You can use the machine with metals, wood, and plastics workpieces.

The machine is easy to set up and allows you to produce parts with tight tolerances that a CNC lathe machine cannot achieve.

The machine will suit your needs especially where you plan on producing parts with flat surfaces with slots.

The 3-Axis machine is also less expensive when you compare its cost to the more advanced solutions like 4-axis and 5-axis CNC machines.

Limitation: The machine cannot cut curved surfaces unless a rotary table is incorporated.

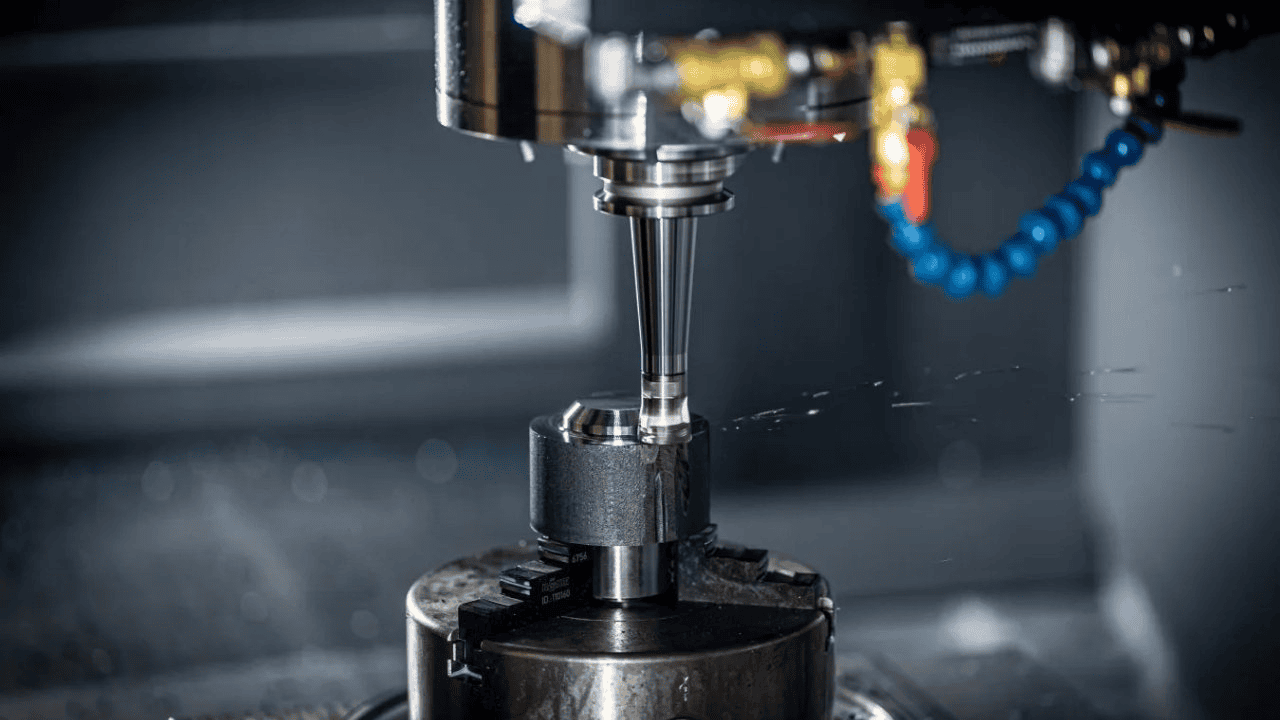

3-Axis CNC Machining Center

If your manufacturing project demands high-capacity production of complex parts with high precision, the 3-axis CNC machining center is your ultimate solution.

The machine boasts the capacity to mill, drill, and tap, making it flexible for your various production requirements.

Its Automatic Tool Changer (ATC) technology and the capacity to perform multiple machining processes allow you to achieve a higher and more efficient production rate.

Limitations:

- The technology costs more compared to other 3-axis machining options.

- Controlling your parts’ machining routes is not as easy as other machining machines.

- The machine’s operation and maintenance require highly skilled machine operators.

3-Axis CNC Engraving Machines

If you are into CNC engraving and need a machining solution to create complex signs or decorative parts such as jewelry designs, a 3 a-xis CNC engraving machine is what you should go for.

The machine’s compact design and ability to work on different materials, such as metal, plastic, and wood, make it ideal for a true professional engraver!

Limitations:

- Some engraving solutions such as 3-axis rotary CNC engraving machines are expensive.

- The operation of the machine requires a highly skilled and experienced machine operator.

- Some plastic materials produce harmful fumes during the engraving process. This may require a special fumes extraction system which is an additional cost.

3-Axis CNC Machining Routers

3-Axis CNC router is an easy-to-use milling machine that is suitable when you work on wooden or plastic components for easy cutting, shaping, or creating decorative patterns.

It also works well on other materials such as foam, making it a vital machine if you are in the furniture production industry.

When equipped with suitable cutting tools, you can also use the machine on softer metals such as copper, brass, or aluminum.

Limitations/Drawbacks:

- The machine is only suitable for wooden materials. Using it in softer metals may not produce the high-quality results you would achieve with suitable CNC milling machines.

- The workpiece is only held at fixed angles, making it hard to create complex 3D shapes.

3-Axis CNC Plasma Cutter

For your large-scale production of parts through 3-axis CNC machining, you require an efficient cutting solution that can work on different conductive metal materials. The 3-axis CNC plasma cutter machine fits the bill!

It is designed with an effective heat control capability ensuring your workpieces or parts are free from heat-related distortions.

Limitation.

- The cutting process produces hazardous fumes that can affect your health conditions.

- Produces flashes that can be damaging to your exposed eyes

- The cutting process is noisy and therefore, you must have proper ear protection.

Application Areas of 3-Axis CNC Machining

You can embrace 3-axis CNC machining to produce a wide range of custom parts for different industry applications.

Below are some of the industries and how they benefit from the 3-axis CNC manufacturing technology:

Automotive Industry Applications

3-Axis CNC fabrication helps in producing auto parts for different car models. Such components may include classic car components, transmission casing, car brake rotors, etc.

Aerospace Industry Applications.

The 3-axis CNC machining is used to produce aerospace parts such as clamps, bushings, and hinges.

Medical/ Health Sector Applications

The 3-axis CNC manufacturing technology allows for the easy production of high-accuracy medical parts such as dental prosthetics, medical instruments such as cutters, orthopedic implants, and surgical instruments.

Electronics & Consumer Sector Applications.

Specialized 3-axis CNC machining is also adopted in the manufacture of electric components such as motherboards, heat sinks, and machined electrical enclosures.

Rapid Prototyping/ Product Development Industry

3-axis CNC machining is used by rapid prototyping firms to produce prototypes to facilitate the rapid development of new products.

Construction & Hardware Manufacturing Industry

The construction industry is yet another sector that relies on the 3-axis technology to produce several hardware parts. These include but are not limited to, threaded rods, welding tabs, fasteners, engine gears, and hydraulic components.

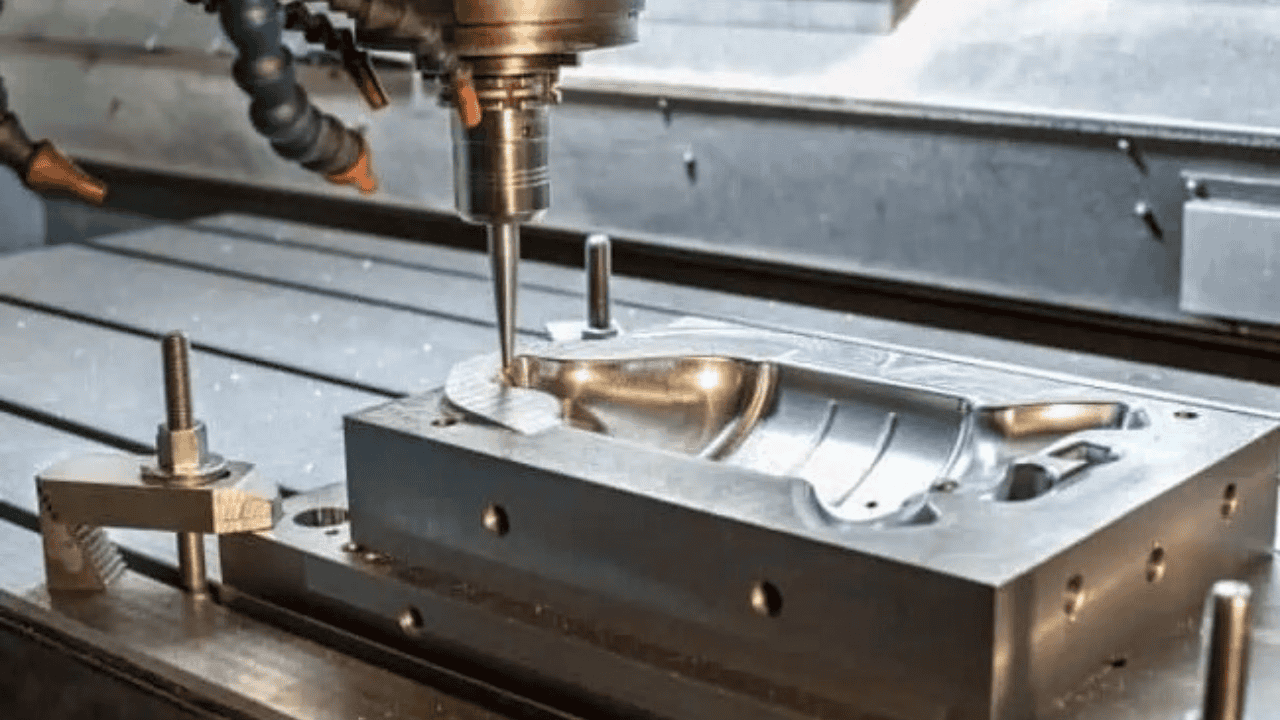

Mold & Die-Machining Industry

The easy and cost-effective production of some components is by molding or custom die-casting. With the 3-axis CNC machines you can produce molds or flat dies which are used in the production of different parts or hardware components.

Jewelry Manufacturing Industry

Advanced jewelry manufacturers use small 3-axis CNC machines to manufacture rings or pendants. The machine aids in precision-cutting and engraving processes.

Furniture/Woodworking Industry.

If you are in the woodworking or furniture-making industry, you require 3-axis CNC machining as well! You can use the technology to cut, shape, or create decorative patterns or shapes on your wooden pieces.

Conclusion

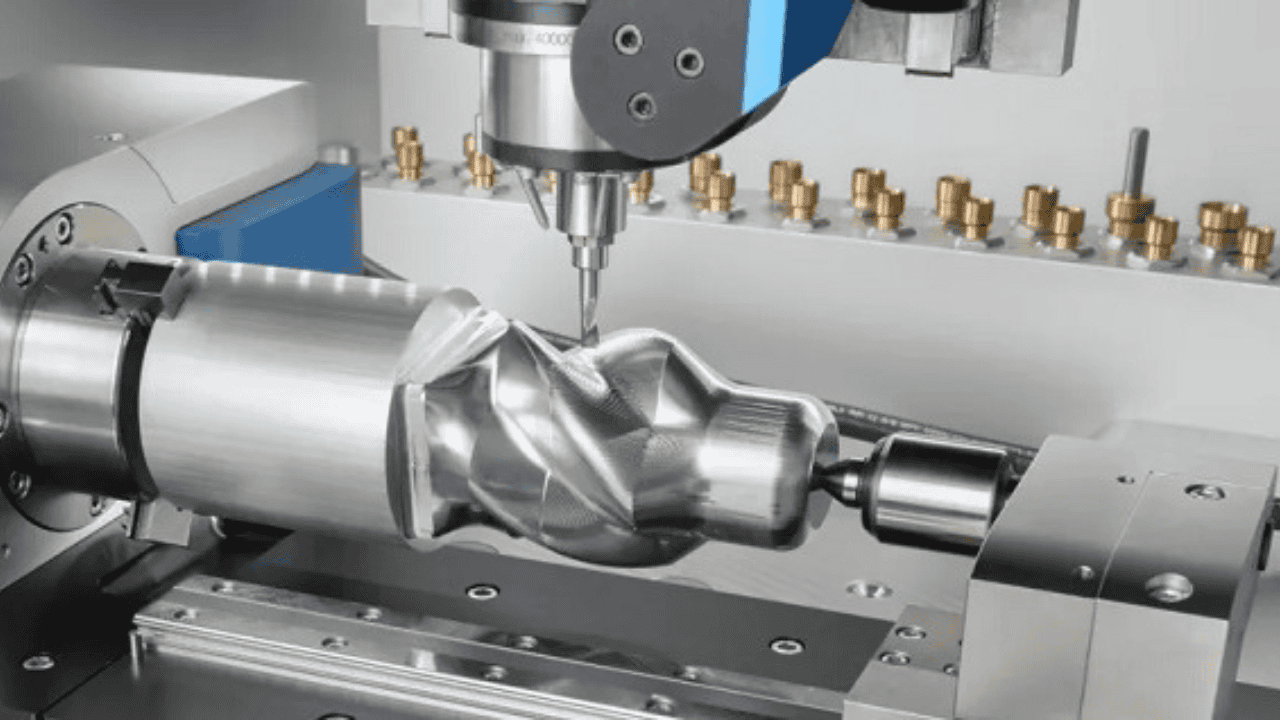

3-axis CNC Machining is an ideal manufacturing technology for efficient and cost-effective production of simple but high-precision parts.

However, if your project requires the machining of parts with complex geometrical designs, you should consider investing in more advanced machining solutions such as 4-axis or 5-axis CNC machining.

With different types of 3-axis machines to choose from, acquiring the right machine for your project requires you to seek the guidance of a machining expert.

HM has been a world leader in CNC manufacturing for over 20 years.

For inquiries on how we can help you deliver on your CNC machining projects, contact us.

Links to Relevant Resources:

- An In-Depth Guide To The Different Types Of CNC Machine Tools

- CNC Grinding Machine Buyers’ Guide

- Difference Between 3-axis, 4-axis, and 5-axis Milling

- Essential CNC Router Parts: Top Accessories for Maintenance

- How to Choose The Right 3-Axis Machine

- Top 10 CNC Machining Centers Factory in China

- What Are the Features of Top-Rated CNC Cutting Machines?

- What Is CNC Turning? A Beginner’s Guide