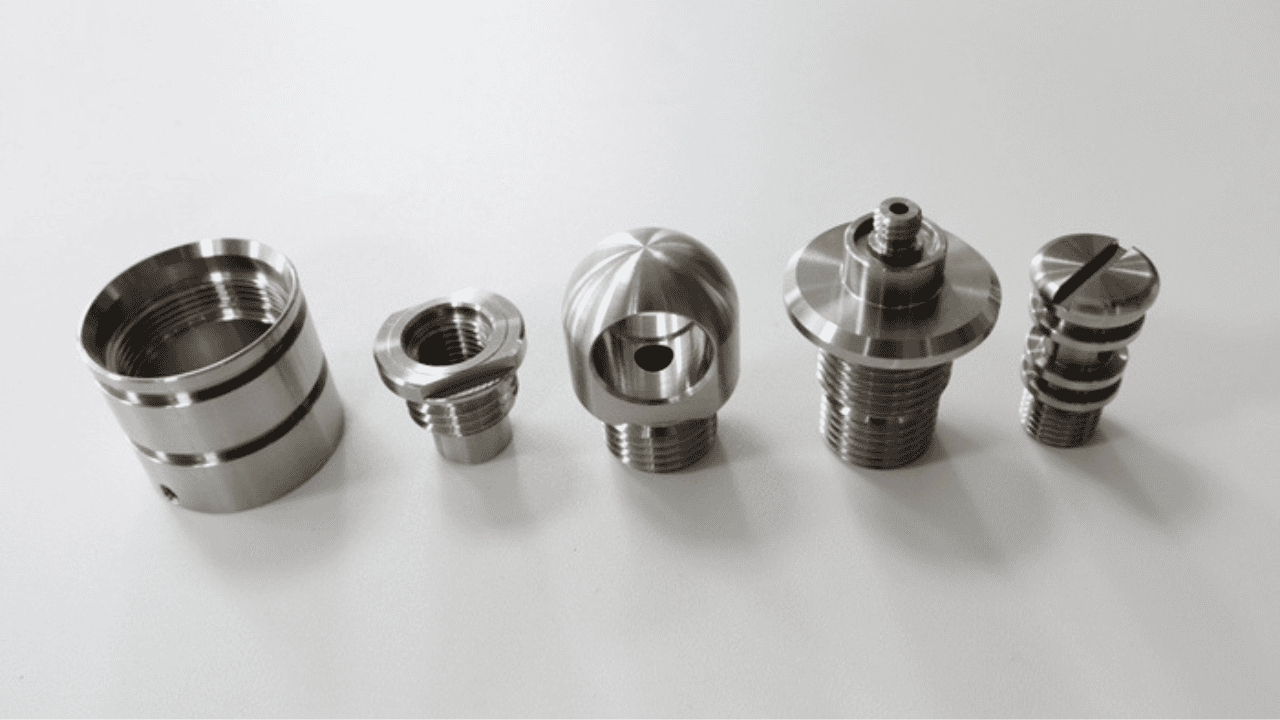

Several machines and equipment need small components to function. Machining these parts is quite difficult, requiring accuracy and precision. This is where micro CNC machining comes in. In this article, we’ll discuss the essentials of this technique and how micro machining companies achieve it. Read on.

What Is Micro CNC Machining?

Micro CNC machining is the use of micro Computer Numerical Control (CNC) machines to manufacture micrometer scaled parts. These parts are so small that you have to view them with a microscope to get the details clearly. Such detailing and precision makes the technique ideal in industries like medical innovations and aerospace.

How Does Micro Machining Work?

We can summarize micro CNC machining process as follows:

- Design and Programming: Micro machining requires computer aided designs. Using any suitable CAD software, you will create the model of the components you want to make and program it into the CNC machine.

- Material Selection: The type of design and the use case of the parts determines the material to use for the fabrication. We covered the common types of materials typically used in micro machining in one of the subsequent sections of this article.

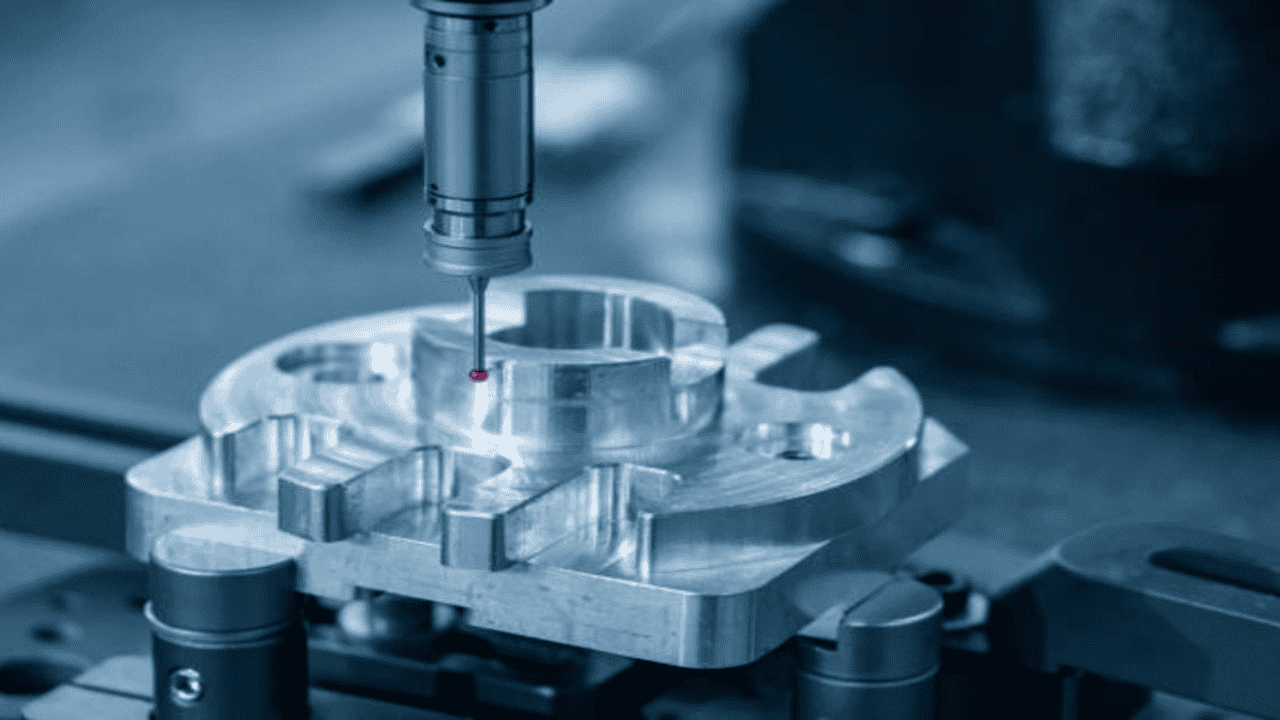

- Ultra-Precision Cutting: In this stage, you will put the material on the machine and start the actual cutting. Parts created through this technique require very low tolerance in micrometers. This is because of their average sizes and the sensitivity of their applications.

Hence, care must be taken to ensure every cut is as precise as it can be with respect to the design’s dimensions. To achieve this, the machines operate at incredibly high speeds and with up to 5 axes.

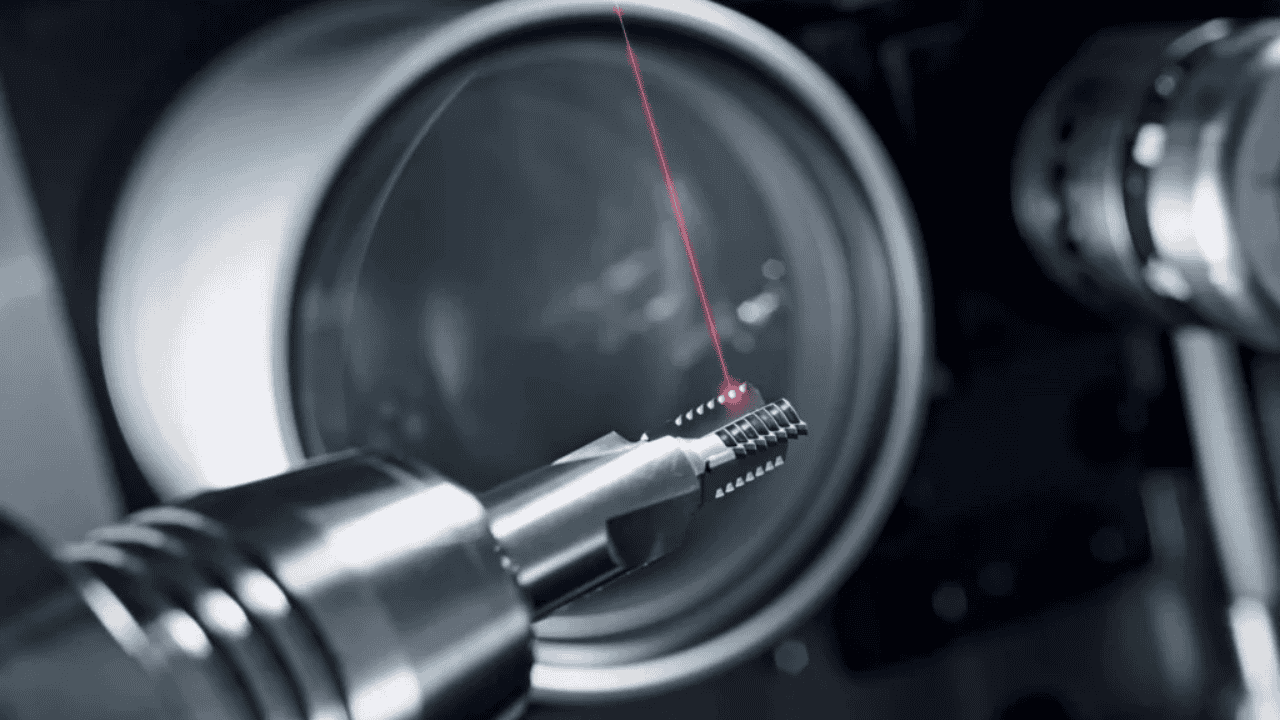

- Real Time Monitoring: As it is with every other CNC machining process, the operator must be on standby to monitor the operations. This will help to foster quality assurance and prevent any potential issues.

- Finishing and Inspection: Once completed, you have to inspect the work thoroughly. Typically, you will use high magnification microscopes to view the part. This will help you see every detail clearly and determine whether you got the intended results. If satisfied, you can go ahead to apply any befitting finishing touches or surface treatment on the component.

Techniques for Micro CNC Machining

These are the three main operations executed under a micro CNC machining process:

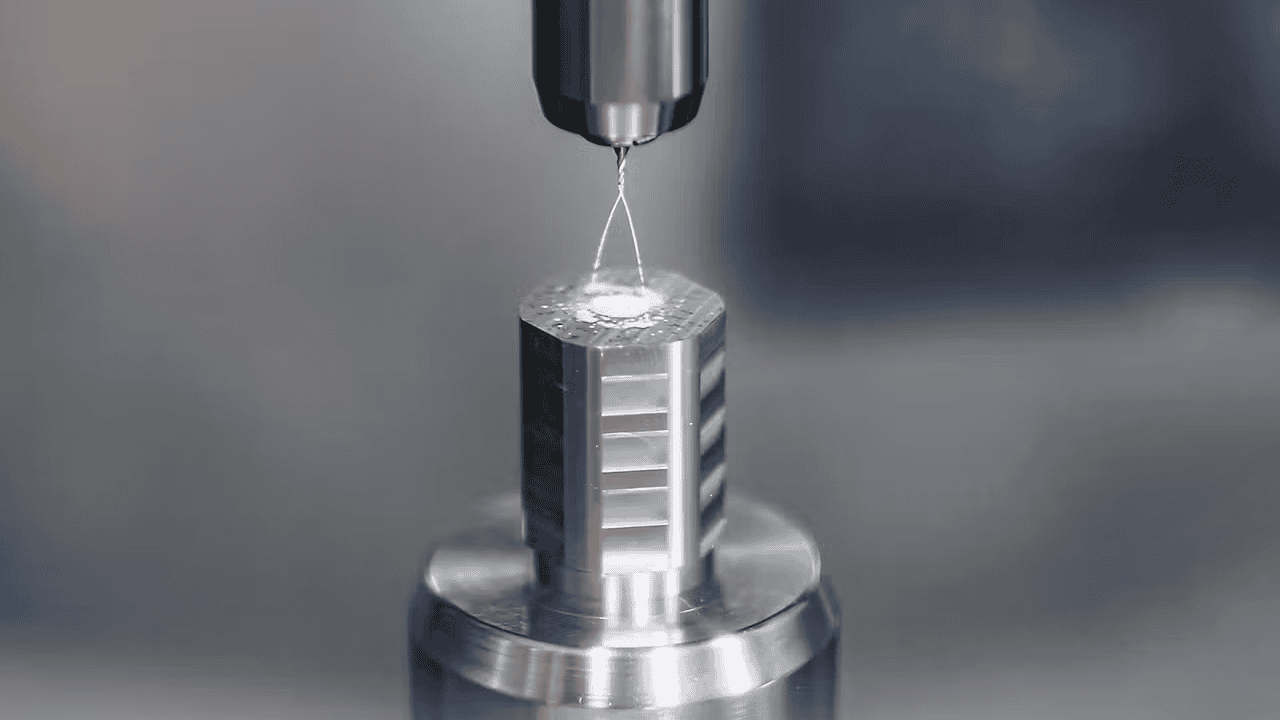

Micro Drilling

CNC micro drilling is used to bore holes of small diameters using micro drills. The drill bits are understandably small with diameters as tiny as 10 – 3,000 microns.

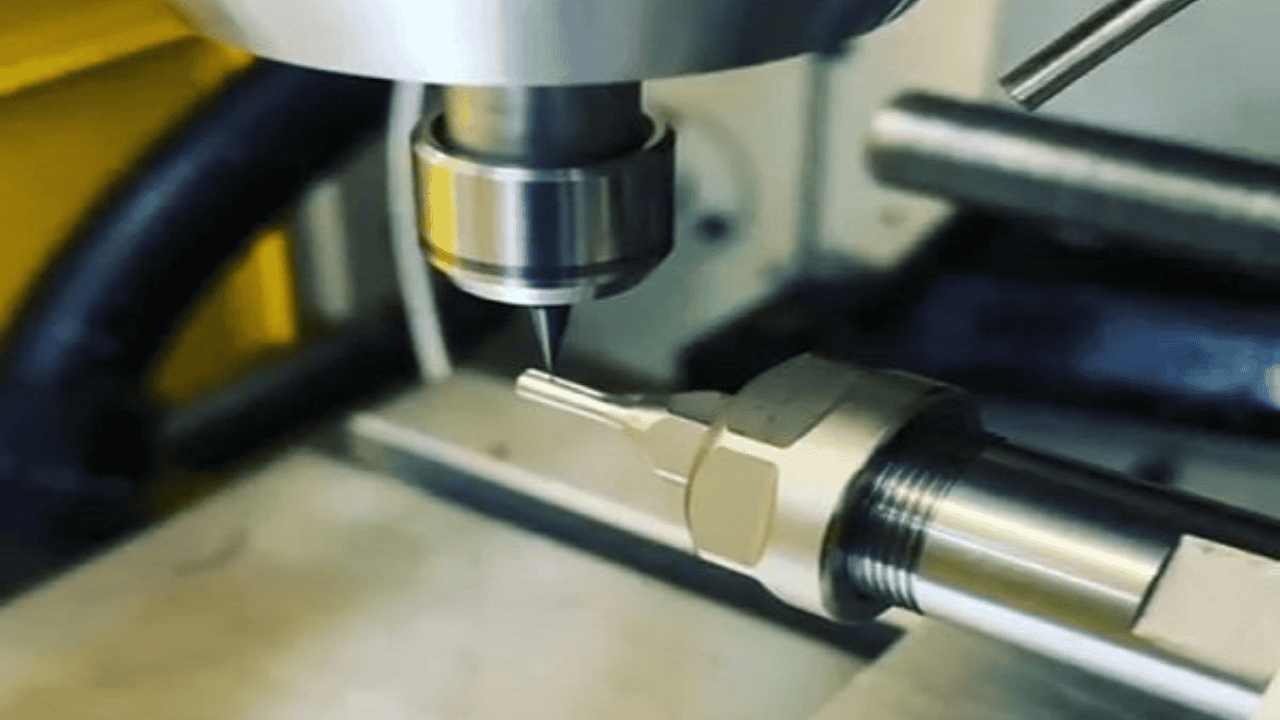

Micro Turning

Micro turning is another micromachining technique where we precisely cut and shape materials on a microscopic scale. The material we wish to shape is placed on a workpiece and moves relative to the cutting tool, which remains stationary to remove excess material, creating our desired design in the process, which is mostly cylindrical-shaped.

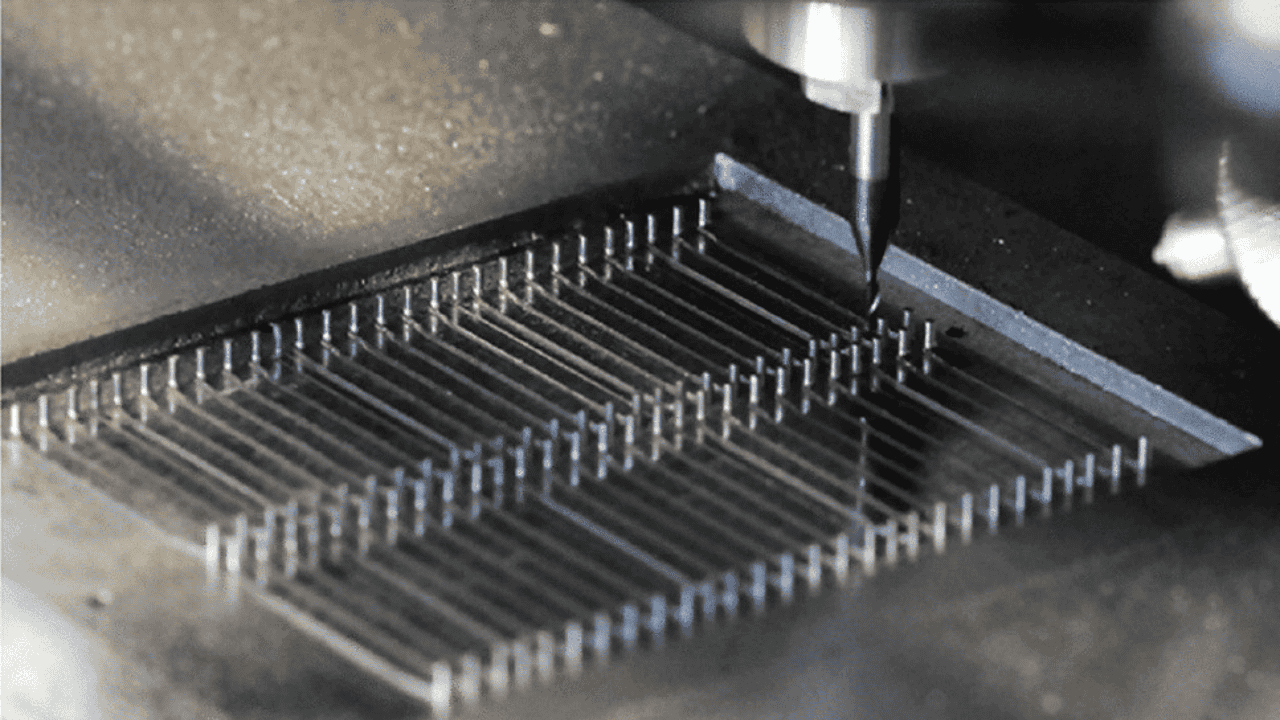

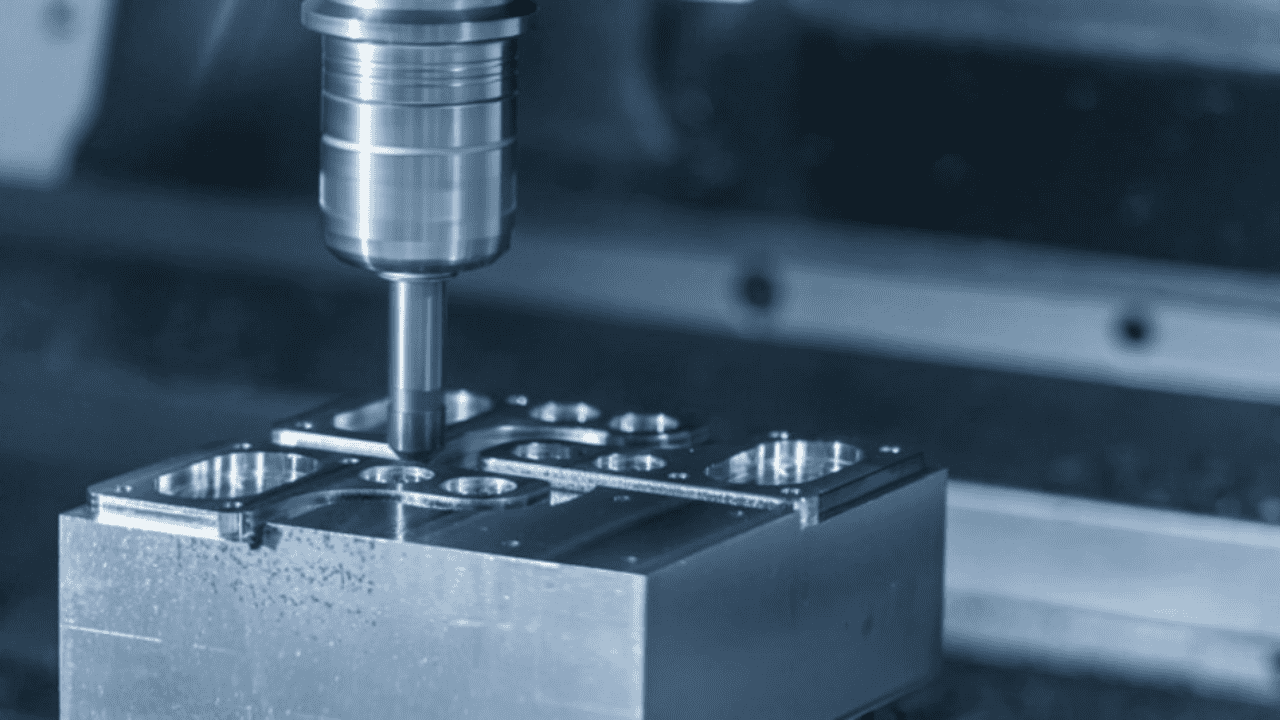

Micro Milling

The distinction between micro turning and micro milling lies in the movements of the cutter with respect to the workpiece. In the latter, the material is placed on a stationary workpiece. Then a rotating cutter removes the excess material. This makes micro milling CNC machines an absolute masterpiece for producing more intricate designs.

Micro Grinding

Micro grinding, just like regular grinding on a micro-scale, is a machining technique used to achieve smooth surface finishes in micro-scale operations. It uses machining tools with rough surfaces to precisely remove excess materials from your workpiece, creating a smooth finish. This technique is extremely beneficial in medical applications like ophthalmology, where very smooth lenses are used.

Materials Compatible with Micro CNC Machining

Plastics

Plastics are an excellent choice of material for carrying out micro CNC machining. This is because of their easy machinability and sought-out mechanical properties, including high tensile strength, resistance to heat, stiffness, etc. Examples of plastics ideal for micro-milling CNC machining are nylon, polycarbonate, ABS, acrylonitrile, etc.

Metals and Alloys

Metals and their alloys remain one of the most popular materials compatible with micro CNC machining for several reasons, including their easy machinability, strength, smooth finish, and strength-to-weight ratio. Leading metals here include Aluminum, stainless steel, brass, and titanium.

Composites

In the world of machining, composites are simply formed from the combination of two or more distinct materials, each with its peculiar properties. This combination is often composed of different fibers in another matrix. Composites are ideal for use in micro CNC machining processes because they can be adjusted to provide specific sought-after properties.

Ceramics

Ceramics are highly compatible with micro CNC machining mostly because of their extreme hardness and easy machinability. They are also resistant to heat, chemicals, and corrosion which are some of the problems commonly seen in other materials.

Advantages of Micro CNC Machining in Precision Manufacturing

Automation

Perhaps the most remarkable advantage of precision CNC machining is automation. You simply run the right set of codes on the machine, directing the entire operation. This makes for minimal human input, and its associated errors, making operations faster and more efficient.

Consistency and Reproducibility

A design model implemented through CNC micro machining can be used to produce batch products of thousands of units. It’s amazing because each unit will be an exact replica of the model. Hence giving run for consistency in results.

Versatility

Micro precision machining is compatible with different materials including metals, plastics, composites, etc. Since the machines typically support 5-axes operations, they can be used for a wide array of applications.

Enhanced Precision

The watchword for manufacturing processes employing micro CNC machining is precision. This technique can deliver higher precision and ultra-lower tolerance parts compared to other forms of CNC machining processes. This makes it ideal for applications where detail is a prerequisite.

Factors to Consider During Micro CNC Machining

Speed and Vibration Control

Regulating the speed and vibration control is of utmost importance to ensure we achieve high precision and accuracy. You can achieve this by adjusting different cutting parameters, especially the speed of the spindle and depth of cut.

Temperature Management

Proper temperature management is necessary in all manufacturing processes, and Micro CNC machining is no exception. Temperature changes are associated with the contraction or expansion of materials, leading to inaccuracies that can prove fatal. Excessive heat also causes wear and tear of the cutting tools over time, adding to the cost of production.

Tools Selection and Maintenance

The appropriate cutting tools should always be used when carrying out micro CNC machining. This is important to ensure you achieve the desired precision. These micro-cutting tools should also be properly maintained to preserve their sharpness and durability.

Software and Programming

Every operation in micro CNC machining requires a computer program. Hence, you must ensure the right software is installed on the machine. Also, your preferred choice of a machinist must be an expert at coding too.

Feed Cutting

Feed cutting refers to the speed and depth with which the cutting tool travels within the material we are shaping. Controlling the feed cutting is important to avoid tool damage during the micro machining process.

Experienced Machinist

An experienced machinist not only inputs the programs needed for the operation but also supervises the entire project ensuring quality control at several stages of production.

Regular Maintenance

Regular maintenance is a must in every manufacturing process. This not only ensures that the tools are in the best condition needed for precision, but it also preserves the lifespan of these materials.

Other Factors

Some other parameters to consider include the feed rate, feed cutting, depth of cut, diameter of the tool, pressure of the coolant, etc. All these have roles to play in determining the final output of the operation.

The Importance of Tight Tolerances in Micro CNC Machining

Tolerance refers to the amount of error or variation that is acceptable during the machining process. Due to the miniature nature of the parts, tolerance is also relatively low. The goal is often to aim for as low as 0.01mm or even lower if possible. This ensures a high degree of precision, while significantly reducing errors.

Applications of Micro CNC Machining

Aerospace Industry

Without a doubt, safety and precision are watchwords in the aviation sector. Hence the aerospace industry is highly dependent on this technique due to the precision it offers. This makes it possible to produce several components to match the intricate designs needed for flying aircraft.

Medical Industry

The list of items in the medical space being produced through this technique is endless. Micro precision machining is also compatible with various bio-friendly materials such as titanium, stainless steel, innate plastics, etc. making it an excellent option for manufacturers in the industry.

Automotive Industry

Micro CNC machining is important in creating various small but essential parts of cars and other automobiles such as parts of the engine, exhaust, sensors, etc. This is because the precision offered by this technique is necessary to ensure the efficiency of the vehicle.

Electronics Industry

The electronic industry relies heavily on micro CNC machining because of the precision to intricate details it offers. This precision is important in manufacturing products like circuit boards, semiconductors, consumer electronics, and even phones.

Photonics Industry

Micro CNC machining is a crucial technique used in the photonics industry for detailed and precise production of complex components used in Photonics devices, such as fiber optic cables and optical mirrors.

Limitations of CNC Micro Machining

Complexity

Micro CNC machining is a complex process requiring automated tools, the correct set of computer programs, and the technical know-how needed to oversee the operation. So while we can all agree this technique is beneficial, it is also very complex and poses a limitation, especially for first-time manufacturers venturing into the world of machining.

Initial Investment

So far, we can agree micro CNC machining requires complex and specialized tools suited for the machining process. These tools are also often customized increasing the cost of production. This initial investment often discourages potential investors serving as a limitation of micro CNC machining.

Lack of Flexibility

The lack of flexibility in this context shows the inability of the CNC machining process to easily adapt to changes whilst in the manufacturing process. This is because these operations are programmed, and so changes must be made to the computer before changes are made. This invariably increases the duration of production since each design requires changes.

Conclusion

Micro CNC Machining continues to stand out as an excellent technique in manufacturing, finding applications in several industries. It is, however, important to source only the best materials for this delicate process, which is why you should trust Hmaking for your micro machining services. Contact us now to get the best micro CNC machined parts.