Metal hardness testing standards are one of the most common sources of supplier disputes in CNC machining and die casting.

A drawing says HRC 55, a purchase order says HB 200 max, and the incoming report does not match. Then the same questions repeat: which hardness scale was used, which ASTM standard or ISO standard controlled the test, where exactly the test was performed, and whether anyone used hardness conversion instead of the required method.

This guide is written for B2B buyers, quality engineers, and procurement teams. The goal is simple: make hardness requirements clear, make results repeatable across labs, and build an audit-ready CNC quality control plan that reduces rejects and arguments.

Metal hardness testing meaning for CNC parts

Metal hardness testing measures a material’s resistance to indentation under a defined method. Hardness is not a universal quality score. It is only meaningful when the method, load, indenter type, surface condition, and test location are controlled.

In CNC production, hardness typically affects:

-

tool wear and cutting forces

-

post heat-treatment distortion risk

-

burr behavior and finishing stability

-

assembly fit stability when strength must be consistent

Hardness is a good acceptance requirement when it directly controls performance or process risk, such as:

-

heat-treated steel shafts, gears, and wear components

-

parts that must match a specific temper or condition

-

surface hardening or localized hardening verification, often with Vickers hardness test

If your part risk comes from chemistry, microstructure, or internal defects, hardness alone is not enough. Pair it with the material specification and the right inspection controls.

Hardness callout format for drawings and POs

If you write only a hardness number, you invite disputes. A correct callout should be repeatable and auditable.

Use this format:

Specify method, scale, standard, test location, and readings.

Recommended template:

-

Hardness Rockwell C HRC 55 to 58 per ASTM E18, test on designated pad, three readings, report each value and average.

That one line prevents most supplier disagreements.

Rockwell hardness test standard

The Rockwell hardness test measures indentation depth under load. It is fast and widely used on the shop floor.

Common standards:

-

ASTM E18

-

ISO 6508

A compliant report should include:

-

the scale HRC or HRB

-

the governing standard

-

test location description and number of readings

-

surface condition notes when relevant

HRC for hardened steels

Use HRC for hardened steels and wear-critical components. Hardness is not just a QA number here—just a few points can change tooling life and cycle time, which is why machining plans often link hardness targets to the finishing route you choose, such as hard milling vs grinding for hardened.

HRB for softer conditions

Use HRB for softer steels and appropriate non-hardened conditions. A common failure mode is reporting HRB against an HRC requirement, or converting without approval.

Brinell hardness test standard

The Brinell hardness test uses a ball indenter and measures indentation diameter. The indentation is larger, which helps average local microstructure variation. This is why Brinell is often stable on castings and thicker sections.

Common standards:

-

ASTM E10

-

ISO 6506

A useful Brinell report should include:

-

scale HB

-

governing standard

-

surface condition and test location notes

-

number of readings and how values are handled

HB for castings and thick sections

In die casting and casting supply chains, HB is often used for incoming control and lot stability checks. Brinell is strong for stability, not for small-feature verification. If you need hardness acceptance on thin walls or tiny pads, Brinell is usually the wrong tool.

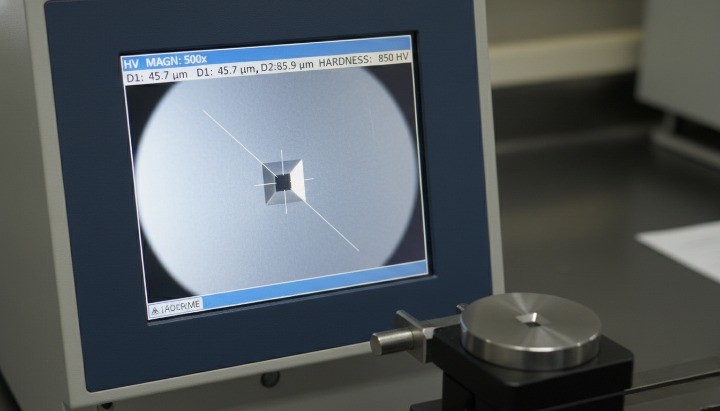

Vickers hardness test standard

The Vickers hardness test uses a diamond pyramid indenter and measures diagonal lengths. Indentation size is controllable, and microhardness is possible. This makes Vickers a practical choice for small features and local verification.

Common standards:

-

ASTM E92

-

ASTM E384

-

ISO 6507

A Vickers report should include:

-

scale HV and the applied load

-

governing standard

-

surface preparation notes

-

test location and spacing notes

HV for small pads and case checks

Use HV when the part has limited flat area, thin walls, or when you need to compare surface and core hardness. Vickers is not “more advanced” by default. It is often simply “more appropriate” for the geometry.

HRC vs HB vs HV selection for CNC quality control

Do not choose a hardness method by habit. Choose it by part conditions.

Decision factors:

-

available flat test area and thickness

-

required indentation size

-

casting microstructure variation

-

whether results must match across labs and suppliers

Quick outcomes:

-

hardened steels for acceptance use HRC

-

castings and thicker sections for stability use HB

-

small pads, thin walls, and local checks use HV

-

no safe test area use a coupon or test tab

If hardness is a CTQ requirement, plan a test pad or tab early. It is cheaper than arguing after shipment.

Hardness testing mistakes

Most hardness disputes come from incomplete specifications and test setup problems.

Hardness requirements should never fight the functional drawing requirements. If a part can pass hardness but still fail fit or function, the issue is usually how tolerances and inspection criteria were written—use this CNC machining tolerance guide as a quick alignment reference.

Common causes:

-

testing too close to an edge or corner

-

testing curved surfaces without proper fixturing

-

testing on rough or oxidized surfaces

-

thin walls allowing opposite-face influence

-

using the wrong scale for the requirement

-

using hardness conversion as acceptance without approval

Prevention checklist:

-

add a test pad, tab, or coupon requirement

-

define surface condition for testing

-

require location notes in the report

-

require individual readings plus average

-

define what happens for borderline readings

Portable hardness tester for incoming inspection

A portable hardness tester can be useful for screening large parts, incoming lots, and field checks. The risk is correlation drift versus bench methods, especially across alloys, finishes, and heat treat conditions.

Best practice:

-

use portable testing for screening and trends

-

confirm with the specified standard method near limits

-

establish correlation baselines by material family and surface condition

If you allow portable results for acceptance, document the correlation rules in writing.

Hardness conversion ASTM E140

ASTM E140 hardness conversion provides approximate relationships between HRC, HB, and HV under defined scopes. A conversion table is not an equivalence guarantee.

If conversion is required:

-

limit conversion to the correct material scope

-

cite ASTM E140

-

treat converted values as estimates

-

avoid converted values as primary acceptance for critical parts

The safest approach is to specify one primary method and test it directly.

CNC quality control plan with hardness testing

Hardness testing works best as one controlled step inside a broader quality plan, not as a standalone pass/fail gate. If you need a simple reference for how we structure documentation, traceability, and inspection checkpoints, see HM quality control.

A stable flow:

-

incoming checks for material identity and lot traceability

-

in-process checks after heat treat when heat treat is in the route

-

final checks only when required and when test locations do not affect function

Mill Test Report MTR checks

A Mill Test Report MTR supports traceability, but it may not represent final part hardness. Hardness can change due to heat treat steps, machining stress history, grinding damage, and near-surface condition changes.

Verify these points:

-

grade and governing specification

-

heat or lot identification

-

stated condition and any hardness values, if provided

When MTR hardness is not enough:

-

when finished-part hardness is required

-

when case depth or surface hardness matters

-

when heat treat occurs after delivery

In those cases, define whether hardness is tested on the part, on a coupon, or on a test tab.

NDT inspection and hardness

Hardness confirms material condition, while dimensional capability is proven by measurement. For critical features, many buyers pair hardness reporting with coordinate measurement, and this overview of CMM inspection for CNC parts shows how that fits into an audit-ready package.

Consider NDT when:

-

parts are safety-critical

-

the material or process has known crack risk

-

failure cost is high or unacceptable

Drawing callouts you can copy

Rockwell callout

Hardness Rockwell C HRC 55 to 58 per ASTM E18, test on designated pad, three readings, report each value and average.

Brinell callout

Hardness Brinell HB 170 to 200 per ASTM E10, test on area A, three readings, report each value and average.

Vickers callout

Hardness Vickers HV per ASTM E384, specify load, test at location B, report each value and average, include surface preparation notes.

These callouts work because they are repeatable across suppliers and labs.

To reduce back-and-forth, include:

-

material grade and governing specification

-

heat treat condition and who performs it

-

hardness scale and hardness testing standard

-

acceptance range and test location

-

required documents such as MTR and hardness report

-

any required NDT inspection scope

Conclusion

For stable, audit-ready metal hardness testing, the goal is repeatability across suppliers and labs, not a one-off number. In most production programs, hardened steels are verified with the Rockwell hardness test using HRC, castings and thicker sections are better controlled with the Brinell hardness test using HB, and small pads or localized checks are best handled with the Vickers hardness test using HV. The fastest way to prevent disputes is to specify method, scale, standard, test location, and number of readings on the drawing or PO, then require the report to list individual values plus the average.

If you want a quick check on your hardness callout wording or need practical suggestions for test pads, coupons, or tabs based on your part geometry, you can share your drawing and RFQ notes via Request a Quote.

FAQ

Can I specify HRC without a standard?

You can, but you should not. Without ASTM E18 or ISO 6508 and a defined test location, cross-lab alignment becomes difficult.

Can I convert HB to HRC for acceptance?

Only approximately and only within the correct scope. Do not use conversion as acceptance unless both parties approve it in writing and cite ASTM E140 hardness conversion.

Should hardness be tested before or after finishing?

Test after the step that changes the hardness you care about. For final hardness requirements, define a pad or tab and test after finishing.

How many readings should be reported?

Define it on the PO or inspection plan. Require individual readings plus average, and define how outliers are handled.

Can hardness be tested on curved surfaces?

Avoid it when possible. If unavoidable, agree on fixturing and treat results as higher uncertainty.

Do portable hardness testers count for acceptance?

Portable tools are useful for screening. Acceptance should follow the specified standard method unless correlation and approval rules are documented.

What if hardness is slightly out of spec?

Re-test at the agreed location with the agreed surface condition, verify lot traceability, and review heat treat and surface condition before rejecting.