Die casting, sand casting, and investment casting can all produce strong metal parts. The wrong choice usually shows up later as unstable quality, slow iterations, or a unit cost that never comes down.

Volume drives the economics and the risk. A process that works for 5 parts can be a poor fit for 5,000 parts, even if the geometry looks similar.

This guide compares the three processes in plain terms. You will learn a volume-first way to choose, what each process does well, and what to include in an RFQ so your supplier can quote accurately.

Pick the process by volume first

If you only remember one rule, use this: choose the casting process by volume first, then refine the choice by tolerance, surface, and complexity.

A simple volume-first rule of thumb

-

Prototype / very low volume (one-offs to small batches): sand casting, CNC machining, or additive often win because they avoid heavy tooling commitments.

-

Low to medium volume:

-

High volume (often 1,000+ parts/year): die casting often becomes the practical choice because it scales repeatably and drives unit cost down when you amortize tooling.

You still need to validate material requirements, cosmetic needs, and machining allowances. But volume gives you the shortest path to a correct shortlist.

Why volume flips the cost equation?

Casting processes differ in how they “spend” cost:

-

Some processes have higher upfront tooling but lower unit cost and faster cycle times.

-

Others keep tooling lighter but carry higher unit cost because the process is slower and more labor-intensive.

That is why a process that looks expensive on a prototype can become the cheapest option over a production program.

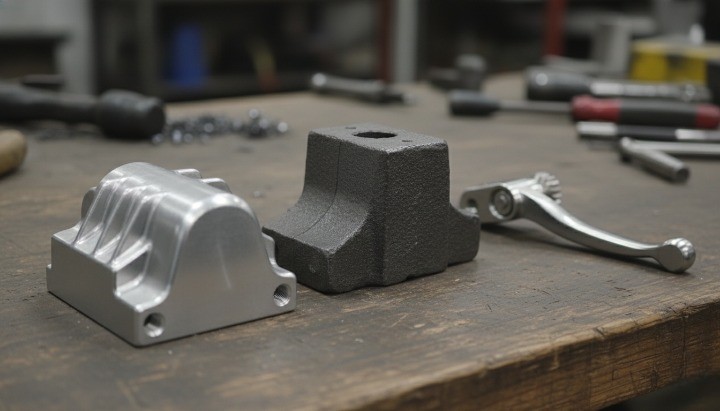

What each casting process really does?

Die casting for aluminum and zinc parts

Die casting injects molten metal into a steel die under pressure, then ejects the solidified part. It supports high repeatability and high throughput. Suppliers often combine die casting with CNC machining, finishing, and assembly to hit functional and cosmetic requirements.

Advantages:

-

Scales well for stable, repeatable production

-

Fast cycle times for many part types

-

Consistent geometry once the tool and process stabilize

Disadvantages:

-

Higher upfront tooling commitment

-

Design changes can become expensive after tooling

-

Feature decisions (parting line, draft, ejection, slides) constrain the design

Sand casting

Sand casting forms a mold from sand, then pours molten metal into the cavity. It works well for low volumes, large parts, and a wide range of alloys. The tradeoff is higher variability in surface and dimensions, and more secondary machining to hit tight features.

Advantages:

-

Lower tooling barrier for early-stage programs

-

Wide alloy compatibility and large part potential

-

Easier to modify early geometry in many cases

Disadvantages:

-

More variability in surface and dimensions

-

More machining and inspection burden for tight features

-

Slower throughput for many production programs

Investment casting, also called lost wax casting

Investment casting builds a ceramic mold around a wax pattern, then melts the wax out and pours metal into the ceramic shell. It often produces better surface finish and more detailed geometry than sand casting, with less need for heavy steel tooling than die casting. It can be a good bridge between prototypes and high-volume die casting.

Advantages:

-

Good detail and complex geometry potential

-

Often better as-cast surface than sand casting

-

Can reduce machining in some near-net designs

Disadvantages:

-

Unit cost can stay higher than die casting at scale

-

Still commonly needs machining for CTQ features

-

Process limits depend heavily on part geometry and alloy

Side-by-side comparison buyers actually use

The right comparison is not “which is best.” It is “which fits my program constraints.”

Upfront tooling and cost structure

-

Die casting: higher upfront investment in the steel die and related tooling. Once built, it can support consistent production.

-

Sand casting: lower tooling barrier in many cases, especially for simple patterns, but more manual steps can raise per-part costs.

-

Investment casting: typically needs pattern tooling, but the tooling and process choices vary widely by part and material.

If your design will change often, prioritize processes that reduce the pain of engineering changes.

Unit cost and scalability

At scale, unit cost often tracks cycle time and labor content:

-

Die casting usually scales best when the part fits the process window and you plan stable production.

-

Sand casting and investment casting can scale, but they often carry more process steps and less cycle-time advantage.

If you expect 1,000+ parts per year, you should at least evaluate die casting, even if you start elsewhere for prototyping.

Lead time and design iteration

-

Die casting needs time for die design, build, and trials. It rewards stable designs.

-

Sand casting can move quickly for early iterations, depending on the pattern approach.

-

Investment casting sits between them. You often get better near-net geometry than sand casting while keeping tooling lighter than die casting.

If you anticipate frequent ECOs, plan a prototype path first, then lock the geometry before you commit to a production die.

Tolerance expectations and repeatability

No casting process is a substitute for good casting tolerance standards and inspection planning. If you want a quick refresher on how tolerance intent should be communicated, review how to read CNC machining drawings and GD&T basics. That said:

Die casting can provide strong repeatability for features that the die controls well.

Sand casting usually needs larger machining allowances and tighter control on “critical” features through machining.

Investment casting can reduce machining in some designs, but you still need to machine sealing surfaces, tight bores, and threaded features in many cases.

Treat tight tolerance as a system decision: casting + machining + fixturing + inspection.

Surface finish and cosmetic consistency

-

Sand casting tends to show the most variation in surface texture.

Investment casting often achieves a finer as-cast surface and better detail.

Die casting can produce consistent surfaces, but parting lines, gate marks, and ejector pin locations still matter. If you have strict appearance targets, review typical die casting surface finish outcomes early so the tool, gating, and post-finish plan match your A-surface expectations.

If your part has an “A-surface,” define it clearly in the drawing and discuss finishing early.

Material options and common alloy considerations

Material choice can narrow your options:

-

Sand casting supports a wide range of alloys.

-

Investment casting supports many alloys, including some that are difficult in other processes.

-

Die casting commonly focuses on aluminum and zinc alloys for many industrial and consumer applications.

Do not choose a process first if the alloy requirement is non-negotiable. Confirm process compatibility with your supplier.

Secondary machining and assembly impact

Most functional parts need some machining. Plan for it:

-

Use casting for the overall shape and non-critical geometry.

-

Use machining for critical bores, threads, sealing faces, and datums.

-

Define datum strategy and inspection early so you do not “discover” stack-up issues after tooling.

Volume based decision guide from prototype to 1,000 plus

Use this section as a decision tree. Start with volume. Then validate with design and quality needs.

Prototypes and very low volume: what usually wins

If you only need a handful of parts, you usually want flexibility:

-

Sand casting can work for larger geometries or alloys where machining would be wasteful.

-

CNC machining can be faster and more predictable when geometry fits subtractive manufacturing.

-

Investment casting can be a good prototype path if your final program likely stays in investment casting.

Avoid committing to a production die when the design is still moving. You can spend money fast and still end up redesigning the tool.

Low to medium volume: where investment casting often fits

Investment casting often makes sense when you need:

-

More geometric detail than sand casting can reliably hold as-cast

-

Better surface quality without heavy finishing

-

A near-net shape that reduces machining on complex forms

However, you still need to plan machining for critical features and define acceptance criteria for surface and internal quality.

High volume production: when die casting often makes sense?

If your program is stable and demand is consistent, die casting often becomes the most controllable path:

-

It supports repeatable output once the die and process stabilize.

-

It can reduce unit cost because the process is fast and scalable.

-

It pairs well with secondary machining for critical features.

This is where aluminum and zinc die casting suppliers can add value: tooling design, DFM review, process control, machining, finishing, and assembly under one quality plan.

When to mix processes: cast near net shapes and machine critical features

A mixed strategy is common and often optimal:

-

Cast the near-net body to reduce material waste and cycle time.

-

Machine datums, bores, threads, and sealing interfaces to ensure function.

If you do this, specify which surfaces must be machined and which can remain as-cast. Also define how you will inspect each category.

DFM constraints that frequently decide the process

DFM issues decide cost and yield. They also decide how “painful” the tool will be.

Parting line, draft, and ejection basics for each process

Die casting needs a clear ejection plan. That often means:

-

You plan the parting line early.

-

You add draft where the die pulls.

-

You place ejector pins where they will not damage cosmetic surfaces.

Sand and investment casting have different mold constraints, but they still benefit from sensible draft and clear datum strategy.

Undercuts, side actions, and internal features

Undercuts can force complexity:

-

In die casting, you may need side actions (slides) or redesign the feature.

-

In sand casting, cores can create internal geometry but can increase variability and risk.

-

In investment casting, you can achieve complex forms, but you still need to think about shell strength and post-processing.

If a feature forces tool complexity, ask whether machining that feature is cheaper and safer.

Thin walls, ribs, and distortion risk

Thin walls and long, flat sections raise distortion risk in any casting process. Manage it by:

-

Adding ribs or curvature where function allows

-

Avoiding abrupt thickness transitions

-

Defining realistic flatness/straightness expectations and machining only where needed

Holes, threads, and sealing surfaces: what to cast and what to machine?

In most production programs:

-

Machine sealing faces and critical bores.

-

Machine threads when strength and repeatability matter.

-

Use cast holes only when tolerance is loose and function allows.

For leak-tight parts, align early on how you will verify integrity (for example, pressure testing) and where you will machine to control sealing.

DFM cheat sheet table for drawing reviews

Use this as a practical checklist when you review a drawing with your supplier.

| Design topic | Die casting | Sand casting | Investment casting | Practical recommendation |

|---|---|---|---|---|

| Volume fit | Best at higher volume | Best at low volume / large parts | Often fits low–mid volume | Start with your annual volume plan. |

| Tooling commitment | Higher | Lower | Medium (varies) | Prototype first if design is still changing. |

| Repeatability | Strong once stabilized | More variable | Often better than sand | Machine CTQ features regardless of process. |

| Surface finish | Consistent but shows tool marks | Rougher as-cast | Often finer detail | Define cosmetic surfaces and finishing early. |

| Undercuts | May need slides | Cores possible | Complex shapes possible | Ask: “cast it” vs “machine it” per feature. |

| Thin sections | Needs careful gating and design | Risk of misruns/variation | Better detail but still risk | Avoid sharp transitions; add ribs where possible. |

| Threads/bores | Usually machined for CTQ | Usually machined | Often machined | Mark machined surfaces explicitly on the drawing. |

RFQ checklist: what to send your casting supplier

A clean RFQ reduces re-quotes, delays, and quality surprises.

Drawing and tolerance info that prevents re-quotes

Send:

-

2D drawing with GD&T for critical features

-

3D model (STEP preferred)

-

Clear datum scheme

-

Notes identifying: as-cast surfaces vs. machined surfaces vs. cosmetic surfaces

If you only send a model without tolerance intent, suppliers will assume, and assumptions are expensive.

Volume plan and delivery schedule

Include:

-

Expected annual volume (and how it may ramp)

-

Order size / delivery frequency

-

Target lead time and buffer requirements

This information directly affects tool strategy and unit pricing.

Cosmetic requirements and “A-surface” definition

Define:

-

Which faces are customer-visible

-

Allowed marks (parting line, ejector pins, gate vestige)

-

Finishing requirements (coating, plating, texture)

If you do not define cosmetics, you will likely pay for rework later.

Inspection, documentation, and quality expectations

Specify:

-

Which dimensions are CTQ (critical to quality)

-

Preferred inspection method for CTQ features (gage, CMM, functional gage)

-

First article requirements and sampling expectations

-

Any documentation needs (material certs, inspection reports)

Do not ask for every report “just in case.” Ask for what you will actually use to accept the lot.

Common pitfalls and how to avoid them

Choosing sand casting for a program that will scale

Sand casting can be the right start, but it can become costly when you scale because:

-

More variability drives more inspection and more machining

-

Cosmetic consistency can require more finishing effort

If you forecast scale, ask early: “What changes when we move to 1,000+ per year?” That question protects you from a mid-program process switch.

Choosing die casting without a stable design

Die casting rewards stability. If you expect many changes:

-

Prototype with machining or a lower-commitment process

-

Lock key geometry first (especially mating interfaces and cosmetic faces)

-

Only then invest in a production die strategy

The fastest way to waste tooling money is to tool a moving target.

Choosing investment casting without clarifying post-machining needs

Investment casting can reduce machining, but it rarely eliminates it. If you do not define machining intent, you can end up with:

-

Unexpected machining cost for critical features

-

Misaligned datums and functional stack-up issues

Align your datum strategy and CTQ features before you finalize the casting design.

FAQs

Is die casting always cheaper at high volume?

Not always. Die casting often reduces unit cost at scale, but only when the part fits the process window and the design stays stable long enough to amortize tooling. If your design changes frequently, the effective cost can rise quickly.

Can I prototype a die cast part without paying for a full production tool?

In many programs, yes. You can prototype geometry using CNC machining, or you can use alternative tooling approaches depending on risk and timeline. The best approach depends on what you need to validate (fit, strength, cosmetics, leak performance) and how soon you plan to ramp.

How do I decide what to machine vs. cast?

Machine features that drive function and acceptance:

-

Sealing surfaces

-

Precision bores and bearing fits

-

Threads with strength or alignment requirements

-

Datums that control assembly stack-up

Cast features that do not need tight control and mainly define shape.

What should I specify for inspection and acceptance?

Start with CTQ features. Define:

-

How you will measure them

-

How many parts you will sample

-

What documentation you need for acceptance

If you want support (FAI, capability studies, or a control plan), discuss it during quoting so the supplier can build it into the process.

Conclusion

If you are choosing between sand casting, investment casting, and die casting, start with volume and then confirm design and quality requirements. For stable programs at 1,000+ parts per year, die casting often becomes the most repeatable and scalable option.

If you want a fast, practical answer for your part, send a drawing and your annual volume plan. At HM, we can review DFM, recommend the best process path (including machining and finishing), and quote aluminum or zinc die casting for production.