If you deal in CNC milling components, some of your parts will require high-precision boring machining as a secondary manufacturing process.

This post discusses the boring process, the techniques you can adopt, and the key tools you need. It also highlights the key benefits and limitations of boring machining.

Boring Machining: How Does It Work & The Key Stages

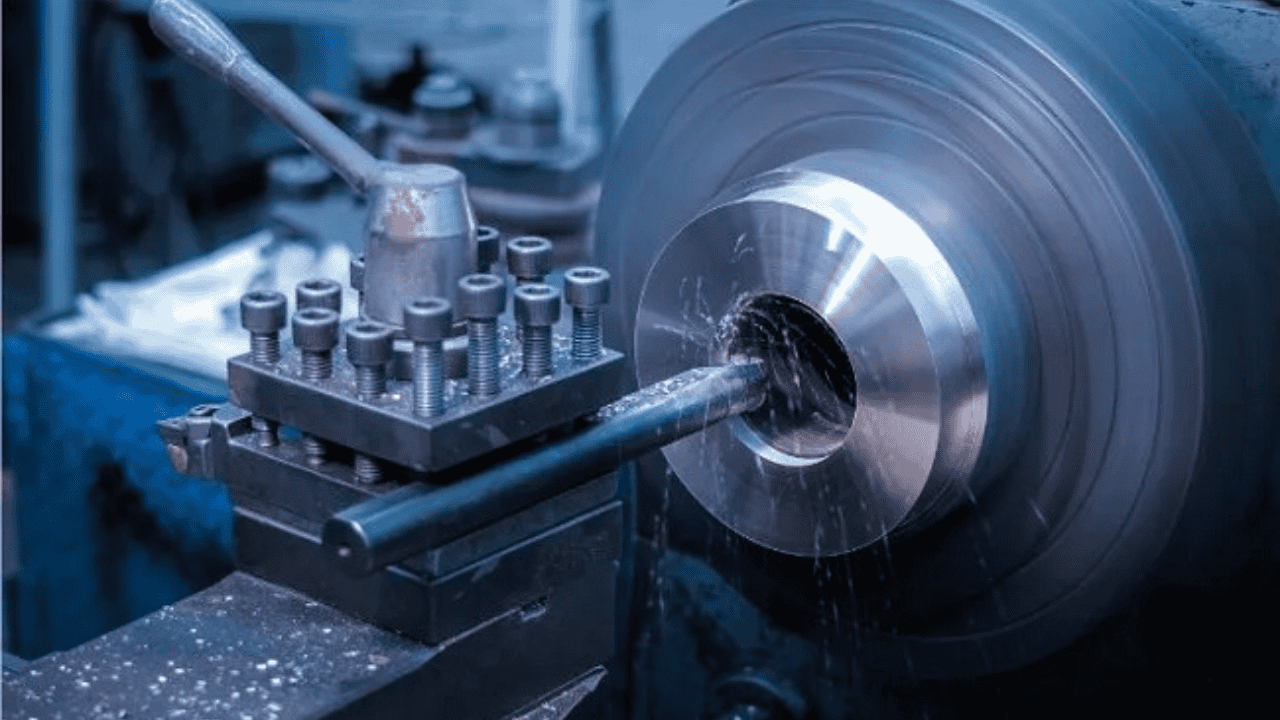

Boring machining, also called “internal turning”, is the process of enlarging a component’s existing hole using a lathe machine or CNC milling machine to achieve the desired dimensional specification.

How The Boring Process Works

The process involves positioning a boring bar into the inner wall of a component’s already prepared hole and setting up the boring parameters.

Before the boring process, the holes can be prepared by drilling or through the casting process.

The boring bar equipped with an insert cutter starts to widen the hole by cutting the inner portions of the workpiece hole. You can achieve this using a lather or CNC boring machine.

If you are using a lathe machine, your cutting insert is stationary while the rotation of your workpiece initiates the machining process.

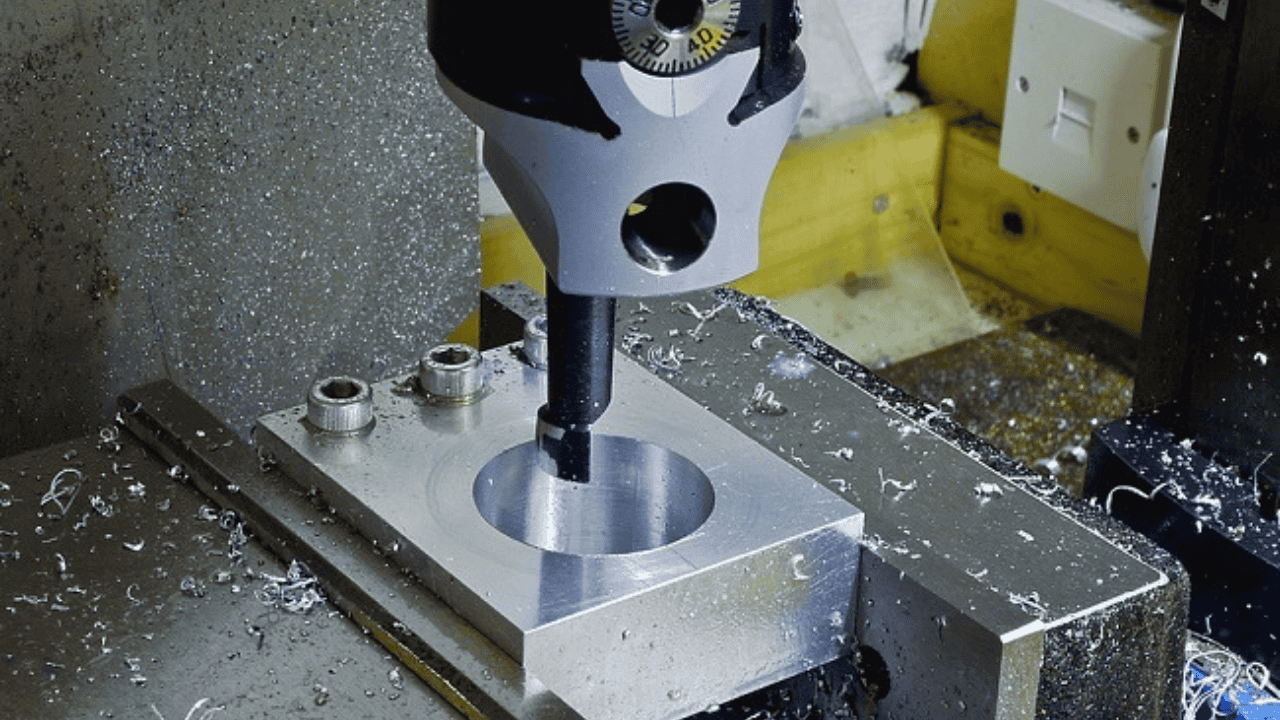

For a CNC mill machine, boring machining is achieved by the cutting tool’s rotation.

For your boring machining process to be successful, some of the main tools or machines you need include a suitable lathe or CNC milling machine, a boring bar, and a cutting insert.

Learn more about different types of boring tools for metal parts here.

Key Stages of Boring Machining

While the working of the boring process may sound simple, it is a technical process that covers the following stages.

Step 1 – Configuration/Setup Stage.

This involves having the most suitable cutting tools for your project and setting up suitable boring machining parameters such as feed rate and rotation speed.

Step 2: Rough Boring Machining

Requires quick removal of excess particles to allow for a high-precision machining stage.

Step 3: Semi-Finishing.

This stage focuses on improving the hole’s surface quality and correcting possible errors.

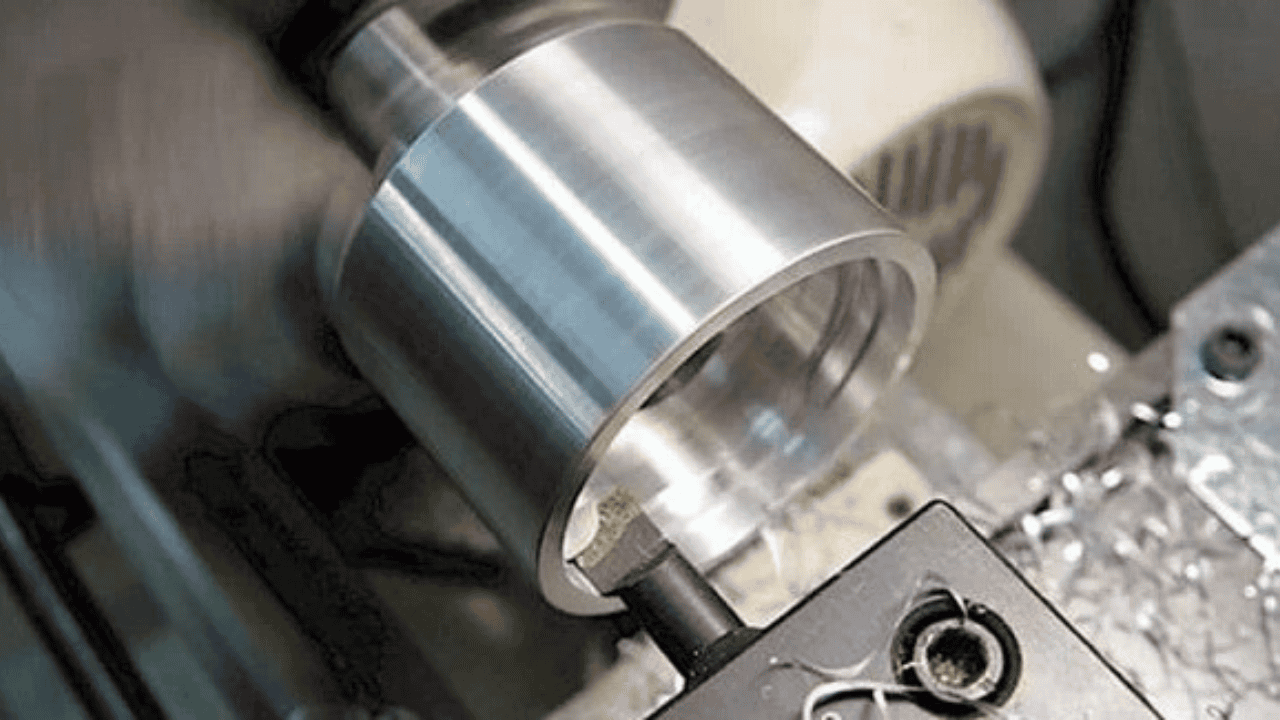

Step 4: High-quality Finishing

At this stage, the focus is to ensure the process achieves the desired hole specifications. This stage demands a careful and high-precision boring machining approach. It is the slowest stage because it focuses on attaining high-level machining accuracy.

Stage 5:Quality Assessment

This is the final stage that assesses if the boring machining provides parts that comply with the set standards or specifications. Any deviations noted are addressed accordingly.

What Are The Main Purposes for Boring Machining?

Below are the three main reasons why you may decide to take your workpiece through the boring process:

- Precise Widening of Drilled Holes: Boring machining helps you enlarge your part’s pre-drilled hole to achieve the desired or specified dimensions.

- Correcting Hole Errors: CNC boring machining enables you to straighten bending pre-drilled holes or to correct casting errors. This is possible because the boring machine tool relies on the hole’s centerline.

- Creating Counter Sinks: You may need to make counter sinks on your component’s drilled holes. This is possible with CNC boring machining with no limitation on the hole size.

- Creating Concentric Holes: CNC boring machining allows you to make high-precision concentric holes on complex machined parts.

Benefits and Limitations of the Bore Milling Process

Boring manufacturing has its advantages and drawbacks that, as a fabricator, you must be fully aware of. Let’s explore them.

Benefits

High Accuracy In Part Holes

Boring machining ensures your component’s holes have a high level of accuracy that you cannot achieve by a standard drilling process.

Smooth Surface Finish

With boring machining, your component’s holes will have a high-quality surface finish for enhanced operational efficiency.

Easy Customization of Parts With Holes

For parts that require unique and high-precision hole sizes, boring machining enables you to customize holes on components to suit different specifications.

This is possible because a single boring tool can be configured to work on different custom hole sizes.

Support Different Materials & Surface Cutting

Boring machining works on metals such as steel, aluminum, stainless steel, titanium, cast iron, brass, copper alloys, etc. It also supports materials such as wood and plastics.

Further, the process is not limited to machining existing holes! You can use boring machining to make groves, counter-sinks, keyways on material, etc.

CNC Boring Enhances Production Efficiency:

CNC boring machining guarantees fast and efficient production of parts. So, you will not be scared of handling bulk orders!

Disadvantages/Limitations/Challenges

Below are some of the bore milling drawbacks that you must take note of:

Only Work On Existing Holes

The boring process only works on an already drilled hole. Therefore, your workpiece or component must first undergo the right drilling process before you can initiate the boring process.

It is Not Suitable for Blind Holes

Typically boring machining only works with straight holes that pass through your workpiece.

So, if your workpiece has blind holes, you must use other specialized tools to avoid machining errors or tool damage from the accumulation of chips.

CNC Boring Machines Are Expensive

If you are in the manufacturing of high-precision or CNC parts, you must invest in a suitable CNC boring or milling machine. The high cost of these machines can be prohibitive.

Deep-Hole Boring’s Effect on Tools & Quality.

If your parts have a deep hole, your boring bar may undergo deflection during the machining process.

Deep hole boring can also subject your cutter to mechanical stress resulting in the production of parts with inaccurate hole diameters or with poor surface finishes.

Machine Configuration Takes Time

Before commencing the boring process, you must configure your CNC machine accordingly.

The setup can take a significant amount of time if you are working on custom CNC parts, which can adversely affect your production rate.

High Maintenance Costs

Boring Machines require regular maintenance to ensure they operate optimally and serve you for longer durations. You may also need to frequently replace cutting tools due to their rapid tear and wear. All these add to high maintenance costs.

Getting An Expert Machinist Is Costly.

Bore milling calls for more skills and experience than standard drilling or reaming.

For your bore milling process to run smoothly without errors or defects on parts, you require the services of a well-trained and experienced machine operator.

Hiring or training such an expert can be costly.

Vibration Challenges

During the bore milling process, the machine ought to be stable. Eliminating vibration is a challenge. This results in machining errors or the production of parts with poor surface finishes.

Demands Large Machining Space

If your manufacturing involves the machining of large parts, you must install large lathe or CNC mills. Finding a suitable large space for such installations can be costly.

Boring Machining Methods

There are different bore milling methods based on the nature of the parts you intend to produce.

You must also remember that the boring machining method you select for your parts determines the type of machine you require.

So, what are the three main bore milling methods or techniques you can consider? Here we go!

Horizontal Boring Machining Method

This is the most common boring method and is highly suitable when working on large and long workpieces.

In this method, you need to secure your workpiece either on a lathe or a suitable horizontal milling or boring machine.

You need to secure your workpiece firmly in a static horizontal position. The boring process is achieved by the boring bar moving on the same horizontal axis as your secured workpiece.

Here are factors you need to consider when buying a horizontal boring machine.

Vertical Workpiece Boring Method

Unlike the horizontal method, this technique requires that your boring machine moves vertically to your workpiece which should be secured at the base or the machining floor.

Therefore, this boring method is ideal if you plan to work on heavy workpieces that require wide holes with high precision and tight tolerances.

To adopt this method, you must invest in a suitable CNC router, a vertical boring machine, or a drill press machine.

Precision Boring Machining Method

Precision bore milling is ideal when working on small parts that cannot be machined by the standard large lathe or CNC boring machines.

This boring method, therefore, requires that you have a small but high-precision machine or lathe suited for your parts.

Conclusion

Production of some components for automotive, medical, or industrial applications requires a high-precision bore milling process.

Investing in the right knowledge, technology, and personnel is critical.

At Hmaking, we have solutions for different CNC machining processes.

For inquiries on drilling operations, and high-precision boring machining on automotive, aerospace, and hardware parts, contact us.